If you’ve ever considered laser cutting leather for a project, there are certainly some things you need to consider beforehand. From the type of leather you should use to the safety protocols you need to follow, learning the basics ahead of time can help save you time and resources in the long run. In this article, we will go over what to consider before laser cutting leather.

Types of Leather & Properties:

When it comes to laser cutting leather, there are several types of leather and their properties to consider. Different types of leather vary in their thickness, texture and dyeing attributes, all of which will affect how they react to laser cutting. Vegetable-tanned leather, for example, is made by tanning animal hides with vegetable matter such as tree bark and can have a special glossy finish.

How different types of leather vary

When you’re planning to laser cut leather, it’s important to consider the different types of leather and how they vary. Different types of leather can have drastically different effects when exposed to laser cutting, so understanding the materials you’re working with is essential for a successful outcome.

Which types of leather are best for laser cutting

When it comes to laser cutting leather, it’s important to consider which type of leather you are using and how it will respond to the heat. Leather is a material made from animal hide, and is available in a variety of grades and types, ranging from soft and supple to stiff and sturdy. Different grades of leather react differently to the laser cutting process, so it’s important to understand the characteristics of the material you are working with.

Pre-Cutting Techniques:

Making sure the leather is properly prepared before the cutting

Before you begin laser cutting leather, it’s important to make sure the leather is properly prepared for the process. There are several factors to consider in order to achieve the highest quality results and ensure the material is not damaged. One of the most important factors is to make sure that the leather has been cut to the correct size and shape before the laser cutting process can begin.

It’s important to use a sharp knife or leather cutting machine to make sure the edges are smooth and uniform.

Suggested tools and techniques to achieve clean cutting

Before you start laser cutting leather, it is important to consider a few factors to make sure you achieve a clean cut. One of the most important considerations is what type of tools and techniques you should use. Generally, if you’re using a laser cutter, you’ll need a minimum of two tools: a cutting head and etching head.

The cutting head is used to apply heat to the leather, while the etching head is used to apply controlled pressure in order to shape the leather.

Post-Cutting Care:

Tips to care for the leather once it has been cut

When it comes to post-cutting care for leather that has been laser cut, there are several factors to consider. First and foremost, you should use a leather-safe finish to protect your leather from discoloration, cracking, and other damage. This can include specialized leather finishes, or you can use a sealant to give it an extra layer of protection.

When you’re done cutting and finishing your leather, it’s important to store it in an area with low humidity to avoid any warping or stretching.

Ensuring the longevity of the leather

When considering laser cutting leather, it’s important to take into account both pre-cutting and post-cutting factors to ensure the longevity of the leather. Pre-Cutting Factors: Knowing the type of leather you’re working with is essential before laser cutting. Generally, leather will range in thickness from 1mm to 5mm, and different types of leather may require different laser settings for optimal results.

It’s also recommended to test out different settings on scrap leather before cutting anything important. During the cutting process, factors like laser power, speed, and focal point all play a role in the quality of the cut.

A summary of the importance of considering the different elements of laser cutting leather

It’s important to consider the different elements of laser cutting leather in order to achieve the desired results when working with this material. By understanding the type of leather and its properties, how the leather will respond to the laser cutter, the power of the laser and its settings, the artwork or pattern that will be used, and other elements, one can ensure that the project is successful. When laser cutting leather, the first thing to consider is the type of leather being used, as different types may be more or less suitable for the project.

Various factors such as thickness, texture, and color all contribute to the ideal leather choice.

The advantages of using this cutting method for leatherworking projects

One of the advantages of using laser cutting for leatherworking projects is its precision. Lasers are capable of producing precise, detailed cuts with exacting dimensions, making them ideal for intricate leatherworking that requires templates or contours that other cutting methods can’t easily produce. Laser cutting also offers faster production speeds compared to traditional cutting methods and can be used with a variety of craft materials, such as paper, acrylic, plastics, wood, and of course, leather.

Using a laser cutter for leatherworking has other advantages, too. You can create intricate details without the worry of making a mistake or having to manually cut pieces of leather.

Is leather safe to laser cut?

Laser cutting leather is one of the more popular applications for laser cutters. It can produce stunning intricate designs that are difficult to create any other way. But when it comes to using a laser to cut leather, there are several factors to consider.

First, you’ll want to make sure that the leather is safe to laser cut. To ensure this, it’s best to only use vegetable-tanned leather, as this has been treated with tanning oils that won’t produce any toxic fumes or gases when exposed to the laser’s heat.

How do you prevent burn marks when laser cutting leather?

When laser cutting leather, it is important to consider several factors in order to prevent burn marks. First, it is important to choose the right laser cutting setting based on the type of leather being used. Different types of leather require different laser cutting settings. Second, it is important to use the correct size and number of passes to make sure that the leather is cut evenly and the right depth.

- Take into account the overall thickness of the leather. The thicker the leather, the harder it is to avoid burn marks.

- Avoid prolonged exposure of the laser on the leather. Excessive heat will lead to the burning of the leather.

- Make sure the laser is properly set up for the correct intensity. Depending on the machine, heat intensities can be controlled differently.

- If possible, use a laser cutting template as a guide to avoid uneven edges.

- Ensure the laser is properly cleaned and lubricated if necessary. This will help maintain the quality of the cut and prevent damage to the leather.

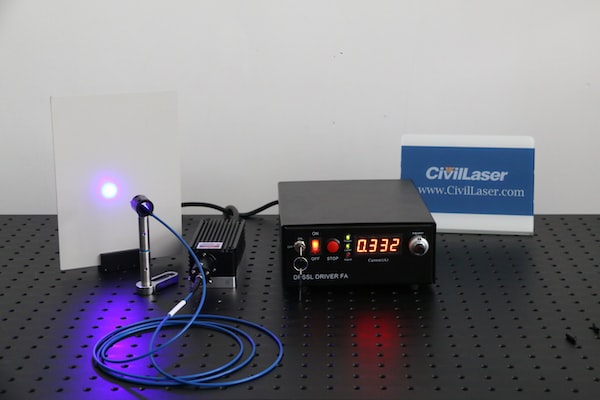

How strong a laser to cut leather?

If you’re considering laser cutting leather, then one of the most important factors to consider is how strong a laser you’ll need to be able to successfully cut the material. Leather is a relatively tough material and so will require a laser with specific power and energy levels to be able to work properly. When choosing a laser cutter for leather, the most important factor is the wattage output.

Leather requires a higher wattage laser to be able to cut it properly, usually in the range of 40 watts to 280 watts of power.

Conclusion

Conclusion In conclusion, laser cutting leather requires a lot of consideration. You need to think about the type of laser cutter you’ll use, the size of the leather piece you want to cut, the preferred thickness of the leather, and the desired result you want to achieve. You also need to consider the type of leather and the effects that power, speed, and frequency will have on the leather.