When it comes to cutting materials, laser cutting is one of the most effective and efficient processes available. With its wide range of uses, laser cutting opens up an array of possibilities for a variety of applications. But, like any technology, it also comes with some disadvantages. In this article, we’ll discuss the pros and cons of laser cutting so you can decide if it’s the right choice for you.

Pros of Laser Cutting

Accuracy

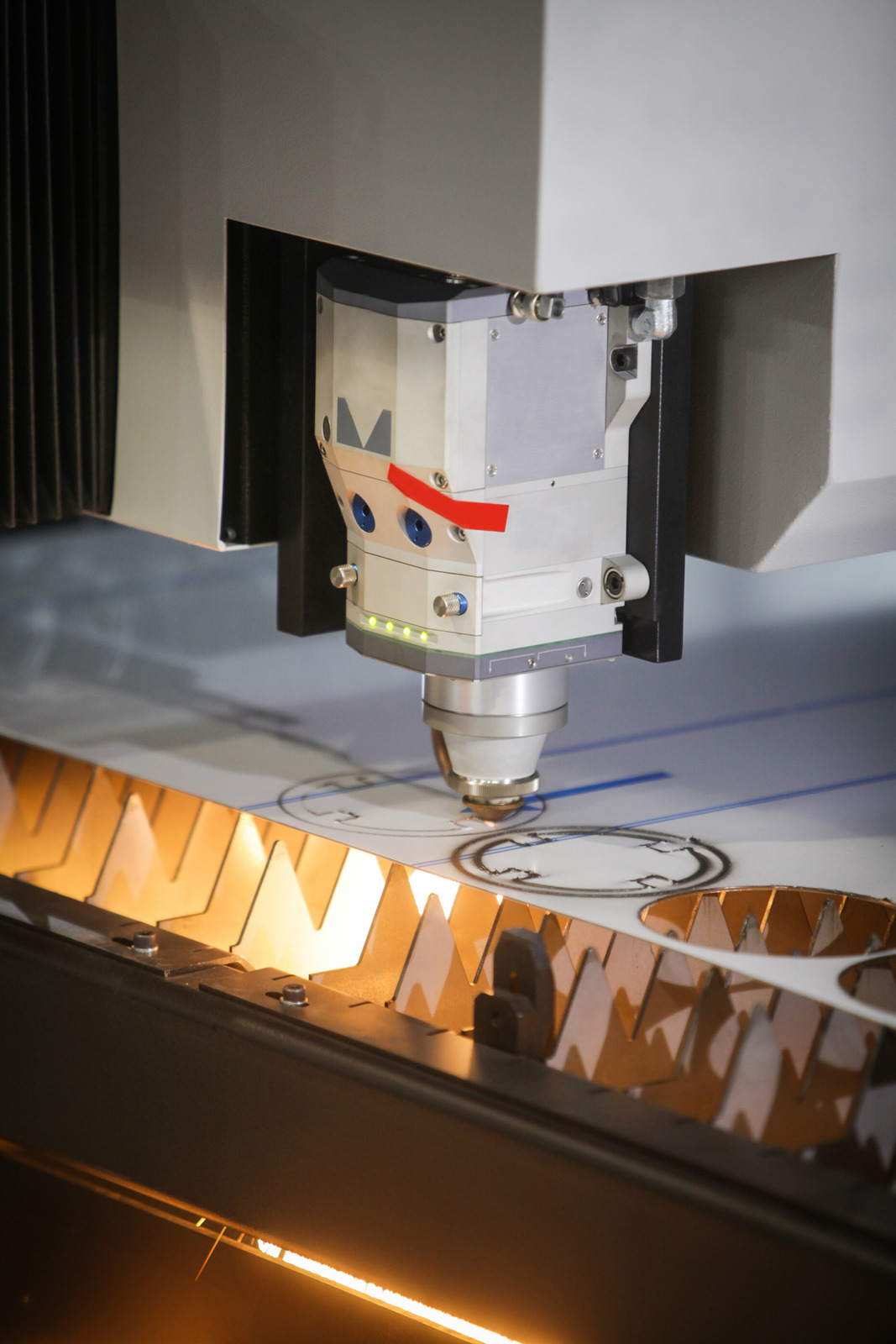

One of the biggest advantages of laser cutting is its accuracy. Laser cutting is incredibly precise, with the lasers able to accurately cut to 0.1 mm, or even thinner in some cases. As a result, you can expect extremely precise results in whatever project you are doing with laser cutting, making it an ideal solution for complex parts that require exact specifications.

Laser cutting doesn’t have any problems with misalignments and errors, making it easier to create quality products that match the desired specifications exactly.

Versatility

One disadvantage of laser cutting is that it can be quite expensive to maintain. The machines are costly to purchase, and they require regular servicing and maintenance in order to operate at peak efficiency. Additionally, laser cutting can be somewhat limited in terms of size and the materials that can be cut.

Laser cutting usually works best on thin and flat materials such as acrylic, wood, and some metals. The type of material being cut may require special tools and setup that can increase the cost and time associated with the process. As with any industrial process, laser cutting produces hazardous waste that must be disposed of safely.

Time and Cost Efficiency

One of the biggest advantages of laser cutting is its time and cost efficiency. For example, lasers are able to cut material in a faster, more precise manner than traditional cutting tools such as saw blades, which can take considerably longer due to the amount of material being removed. Laser cutting also requires less human labor compared to other methods, allowing for a lower cost of production.

Cons of Laser Cutting

Health and Safety Risks

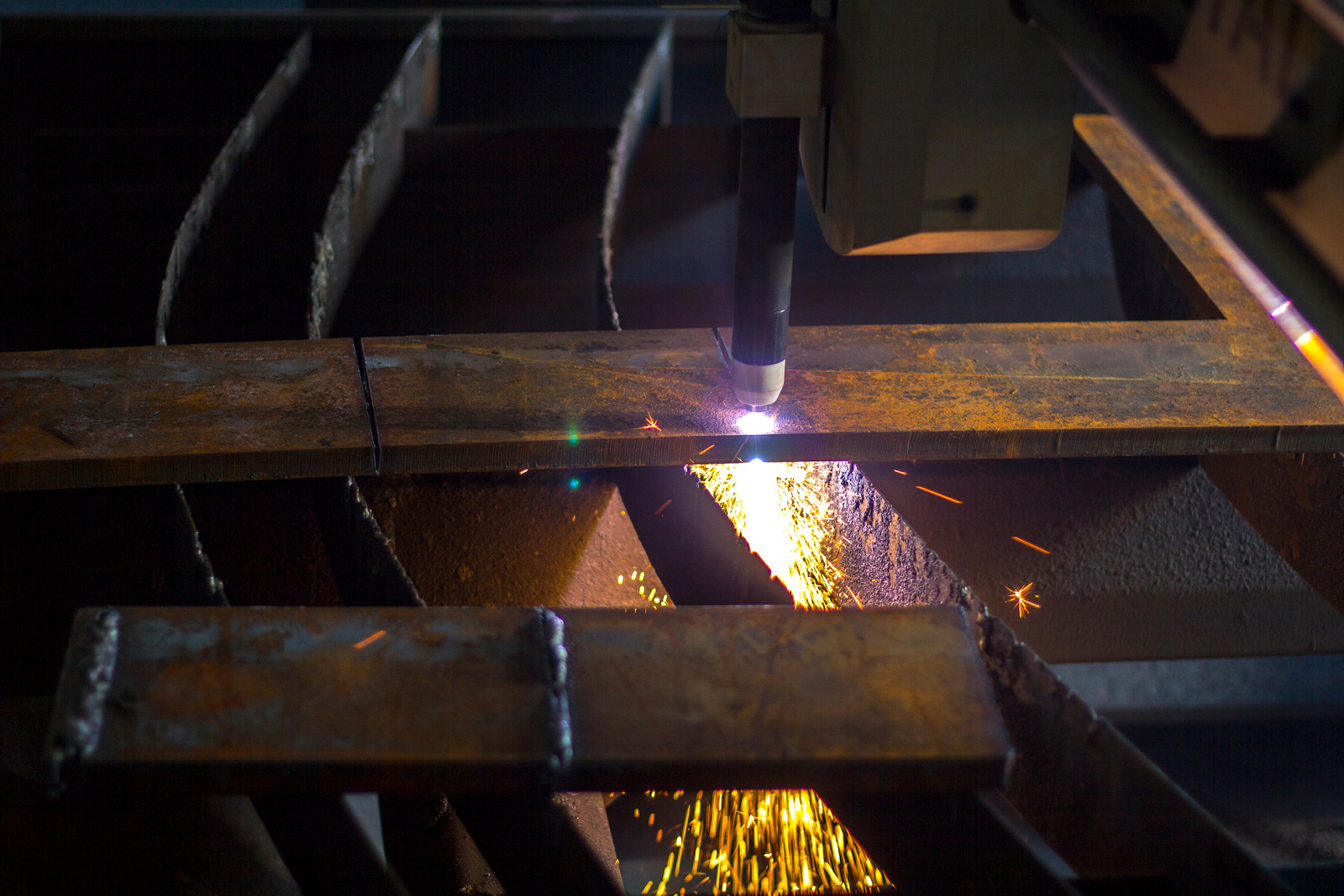

When considering laser cutting, one of the main disadvantages to consider is the potential health and safety risks associated with it. Laser cutting generates a powerful, concentrated beam of light that can be dangerous if not used with caution. The risks of not properly using the laser cutting technology can range from minor skin irritation to more significant injuries such as permanent eye damage and even death.

If a person is not adequately trained or informed about the use of laser cutting, it can be risky and lead to serious safety concerns. Protective eyewear and other safety measures should always be taken when laser cutting.

Specialized Training

One disadvantage of laser cutting is the fact that it requires specialized training. While some basic elements of the technology may be familiar to those who run standard machine tools, the specifics of laser technology require a deeper level of expertise to operate and manage the machines. This means that someone usually has to be hired with the appropriate training and experience before the machines can be used in production.

This can be a costly investment in both labor and money and cause delays in getting the laser cutting process up and running.

Necessary Infrastructure

When looking to determine the pros and cons of laser cutting, it is important to consider the necessary infrastructure needed to use the technology. In order to implement laser cutting, you need access to a stable power supply, laser cutting system, and highly trained personnel to operate the machine. The power supply is a large overhead cost for companies looking to use laser cutting technology.

It is necessary to have an available power supply that is capable of providing the intense levels of energy necessary for laser cutting. This additional cost may limit the number of businesses that can use laser cutting, since not all businesses are able to afford it.

What are the disadvantages of a laser cutter?

The laser cutting process involves using a laser beam to cut and shape materials like metals, wood, paper and plastic. The process is precise, creates smooth, clean cuts and can be used for a variety of projects, from electronics to jewelry. But like any method of cutting and shaping, there are a few disadvantages associated with laser cutting.

One disadvantage of laser cutting is the cost associated with the process.

What are the dangers of laser cutting?

When it comes to the disadvantages of laser cutting, safety is a major concern. Laser cutters use high-powered lasers and the intense beam of light can cause serious burns and even permanent vision loss if it’s not operated properly. In addition, laser cutters create a substantial amount of heat and smoke, which can be harmful if inhaled.

Finally, the high operating temperatures, energy outputs, and contact with flammable materials, can cause fires and further safety risks.

Conclusion

Summary of Pros and Cons

Conclusion: When deciding whether or not to use laser cutting for your project, it’s important to consider the pros and cons associated with it. On the one hand, laser cutting has incredibly precise results, can utilize many materials, and is relatively efficient, making it ideal for intricate or complex work. On the other hand, laser cutting is expensive and time consuming and may not be suitable for large projects or those that require deep trenches or intricate designs.

Recommendations on Utilizing Laser Cutting

Conclusion: When it comes to utilizing laser cutting, there are both pros and cons to consider. It is important to weigh these thoroughly when determining if laser cutting is the right choice for your project. Advantages include cost efficiency, higher accuracy, superior speed and quality, repeatability and versatility.

On the downside, laser cutting does require a high-level of safety, precision, and a protective environment, making it difficult to be done in a residential environment. It also requires experienced operators, making initial costs higher than other cutting methods.