Laser cutting is a versatile and efficient manufacturing technique used for cutting aluminum alloy products. It has a variety of applications, from automotive components to architectural components. Traditionally, aluminium alloys have been the preferred material choice for laser cutting jobs due to their strength, durability and ability to retain shape. Choosing the right type of aluminium alloy for laser cutting is critical for quality and cost-effectiveness. In this article, we will discuss the different types of aluminium alloys and which are best suited for laser cutting.

Advantages of Laser Cutting

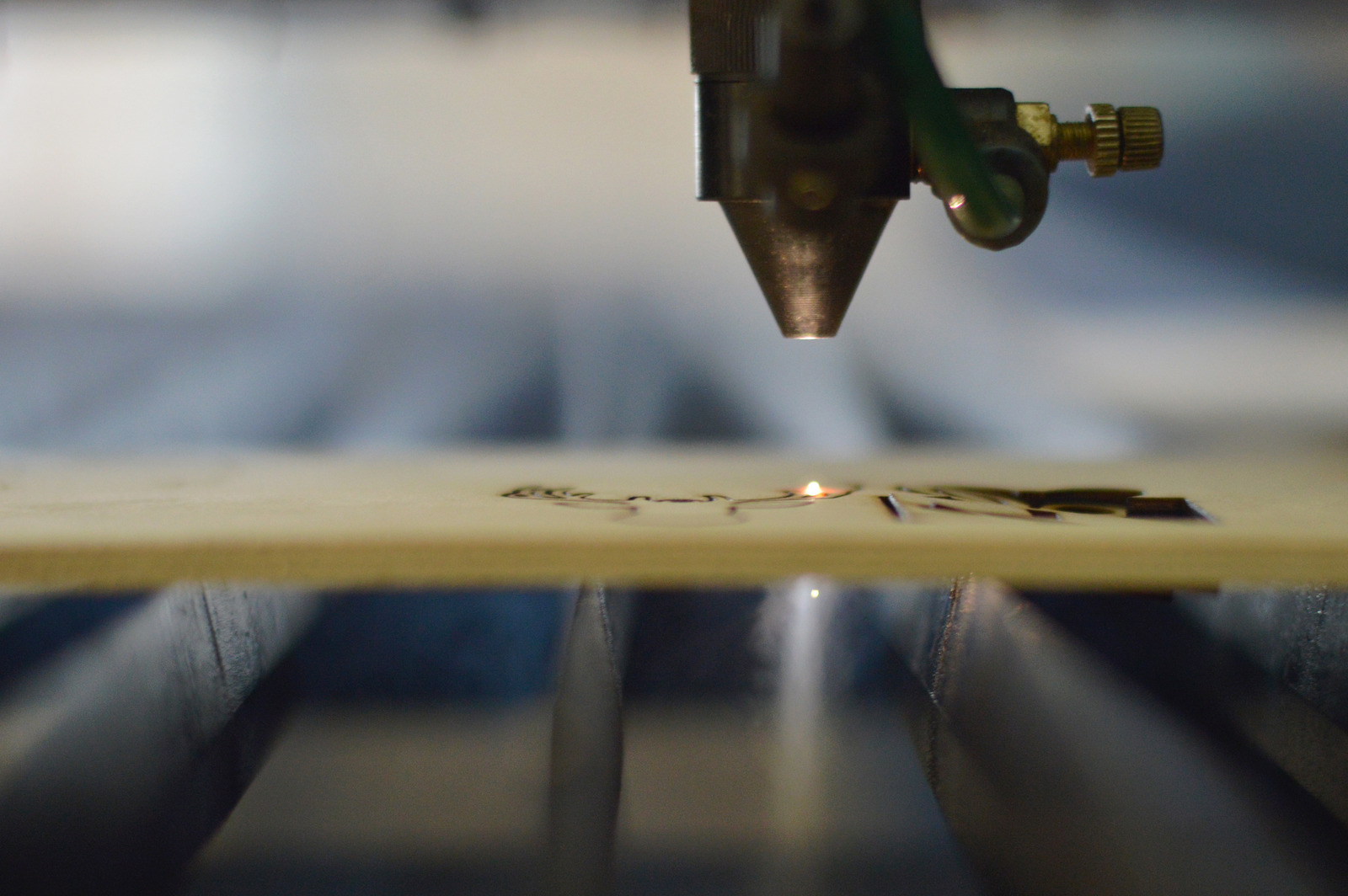

Photochemical machining

Photochemical machining is one of the best methods for laser cutting aluminium. It is a process where aluminium is vaporised and a beam of energy is used to cut out a desired shape. This technique is an efficient and cost-effective way to laser cut aluminium.

The technique is more suitable for thin aluminium as it allows more accurate cuts than other techniques. It also produces less wasted material than other techniques. Photochemical machining is used when a good laser cut aluminium is required.

The technique melts the aluminium alloy and produces a smooth, round cut.

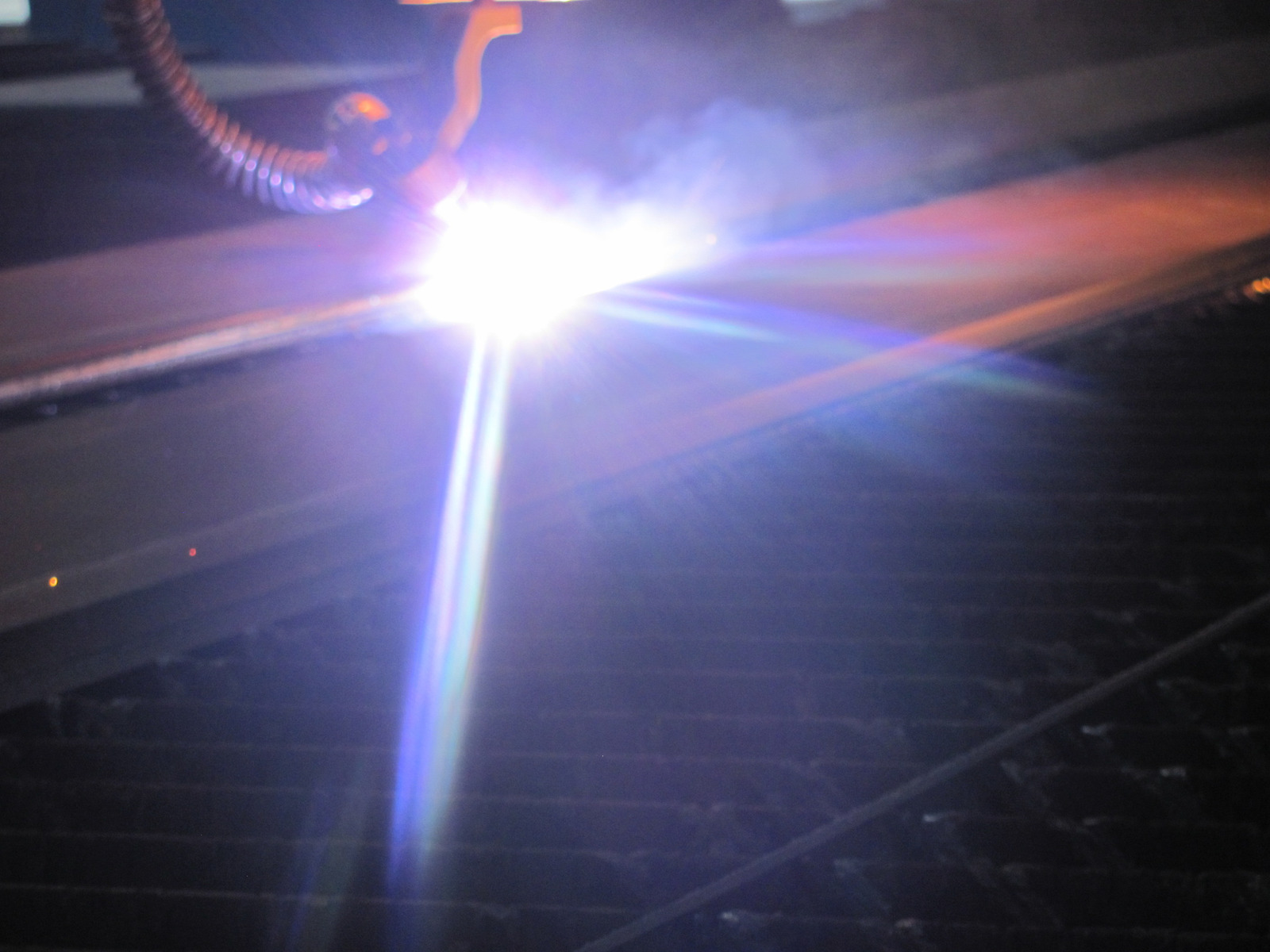

Ability to cut a variety of metals

Laser cutting is a great tool for cutting a variety of metals, including aluminium alloys. This is because a laser beam is able to precisely cut through material with minimal wastage. Because of its ability to precisely control the accuracy and speed of the cutting process, laser cutting can efficiently and effectively cut even complex shapes quickly and accurately.

Aluminium alloys are often more suitable for laser cutting operations than other metals due to their ability to be more easily shaped. It is also lighter and more malleable than other materials, making it easier to work with. Its malleability also allows for more intricate designs with unique cuts and shapes.

High speed and precision

advantage Finding the best aluminum alloy for laser cutting may seem like a daunting task, but it doesn’t have to be! Knowing the advantages of laser cutting will help you narrow down which aluminum alloy would be more suitable for your project. One of the major benefits of laser cutting is its tremendous speed, a laser can quickly and accurately move through material in a fraction of the time it would take to use traditional cutting tools.

Additionally, precision is key when it comes to laser cutting aluminum alloys. A laser will be able to achieve much tighter tolerances than other cutting tools and the tight tolerances create a smooth, burr-free cut edge.

Uses of Laser Cutting

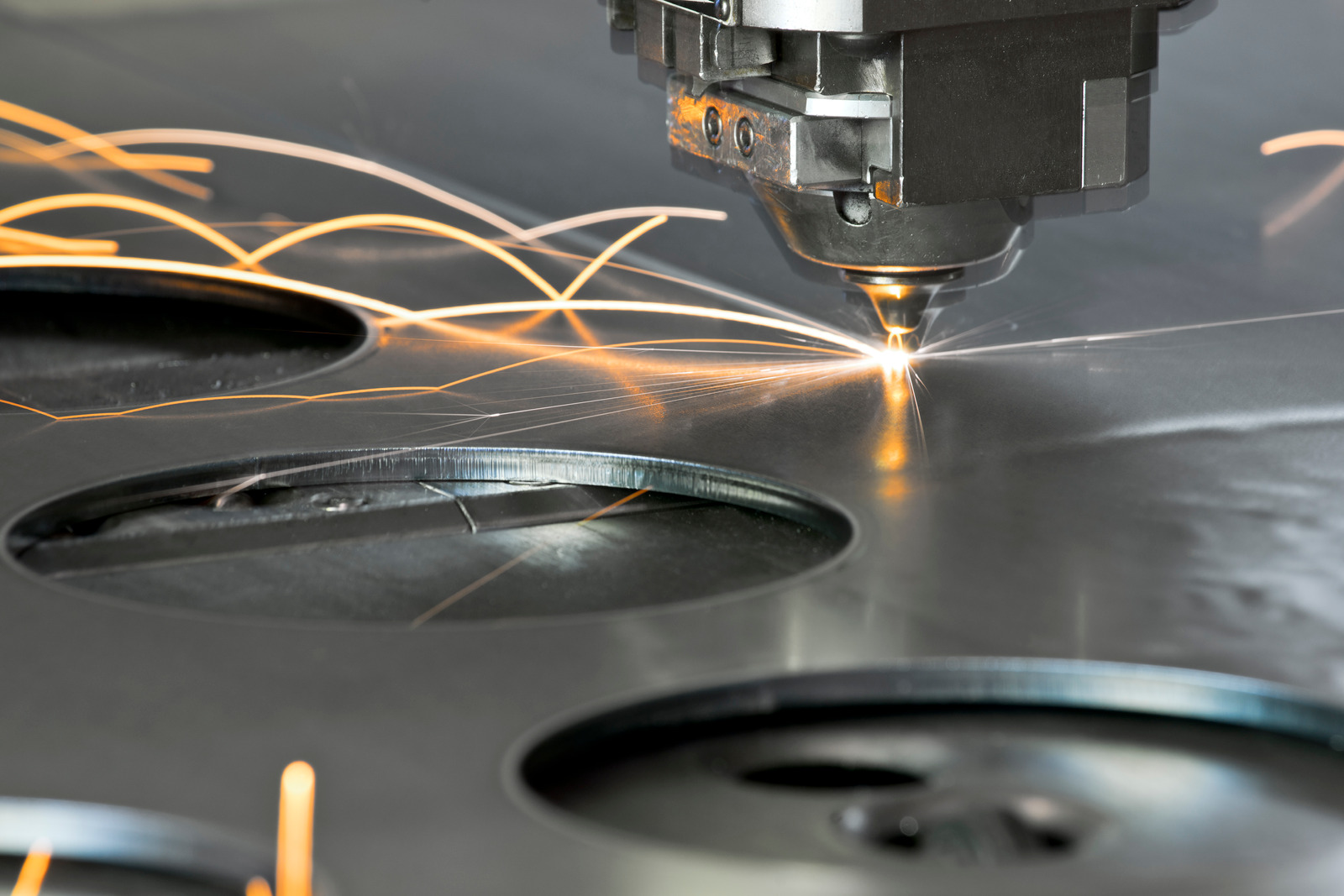

Automotive

The automotive industry often needs to cut aluminium in order to create components and parts, so it’s important to know which aluminium alloys are best suited for laser cutting. Laser cutting enables precise and precise cutting, which ensures superior quality in the end product. This, in turn, means less wastage and lower costs for automotive manufacturers.

When choosing which aluminium alloy to use for laser cutting, the main considerations include the type of alloy and its ability to withstand heat generated from laser cutting. The two main categories are high-alloy series and non-high-alloy series.

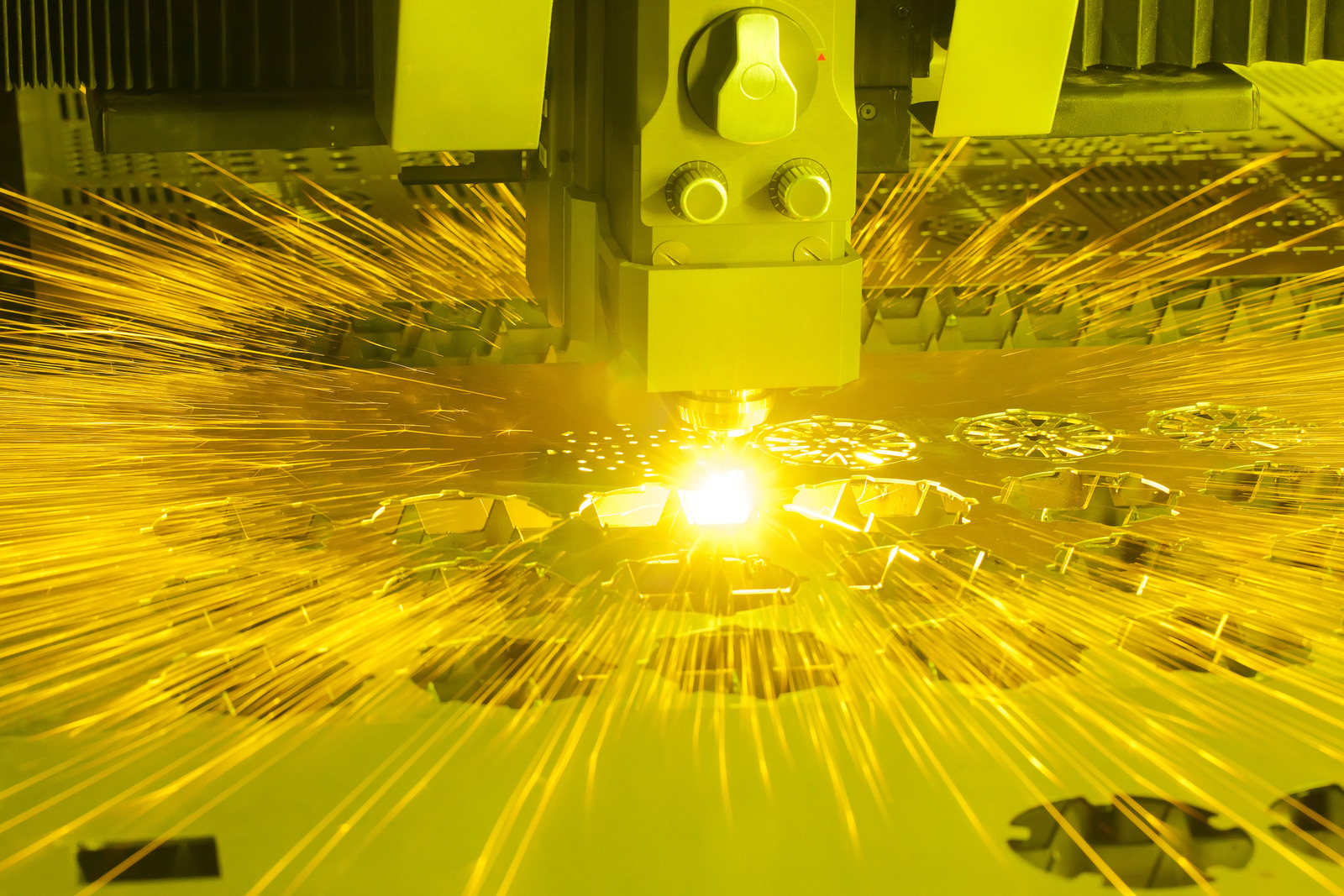

Machinery

When looking for a good material to use in laser cutting, aluminum alloys are often a great choice. There have been many advances in laser cutting technology in recent years, and it’s now possible to cut aluminum with high precision using lasers. This makes aluminum alloys a more suitable material for laser cutting than many other metals.

Aluminium is a popular choice for laser cutting due to its wide range of advantages. It doesn’t require pre-treatment, the cuts are cleaner and neater, and the thinness of the metal allows for an even cutting surface.

Fabrication

Fabrication with aluminum alloys is an incredibly common activity. It involves cutting, bending, welding, and forming metals into parts and components for a variety of applications. Using a laser for these operations is an efficient and cost-effective process.

But which aluminum alloys are best suited for laser cutting? Aluminum alloys come in various forms, each with its own set of properties. In order to accurately cut an alloy with a laser to the desired shape and size, a specific alloy is often best suited.

Types of Aluminium Alloys for Laser Cutting

6XXX Series Alloys

The 6XXX series of aluminium alloys are a good option for laser cutting due to its unique qualities. These alloys are more suitable for laser cutting because they are more easily machined and often less expensive than other types of aluminium alloys. 6XXX series aluminium alloys can be easily formed and machined, allowing for complex shapes and intricate details without sacrificing its strength and integrity.

7XXX Series Alloys

process The 7XXX series of aluminium alloys is a good option for laser cutting. It is an extremely popular series – one of the most widely used Aluminium alloys – due to its excellent weldability and strength. This series contains some of the strongest aluminium alloys, as well as it’s easy to machine.

As a result, these alloys are suited for fabrications which need to be formed into complex shapes. This series is also more suitable for laser cutting compared to other aluminium alloys, as the melting point of aluminium alloys in the 7XXX series is lower than the rest.

8XXX Series Alloys

The 8XXX series of aluminium alloys are some of the most suitable options for laser cutting. These alloys contain a high percentage of magnesium and silicon, which makes them much more weldable than other alloys. They also have excellent hot-forming characteristics, which further enhance their suitability.

This makes them a great choice for laser cutting applications, as they can be quickly and easily handled with no need for additional post-welding processing.

Pros and Cons of Different Aluminium Alloys

6XXX Series Alloys

aluminum Aluminium alloys of the 6XXX series are among the best suited for laser cutting. This includes 6016, 6022, 6063, 6082 and 6105 – but 6105 is considered the most suitable alloy due to its mechanical properties and favorable machinability. The 6XXX series of aluminums contain relatively high amounts of manganese and silicon, which gives these alloys higher strength than some of the other aluminium alloys.

Pros

Aluminium alloys can be a good choice for laser cutting because they offer excellent strength, durability, and controllability. The alloys are more suitable for laser cutting than other materials, as they provide a high surface finish and require less energy to cut. Additionally, they are lightweight and can be easily machined or shaped.

Aluminium has a relatively high melting point, which makes it less likely to warp or lose its shape when being cut. This means that the parts will be more consistent and of a higher quality once they are cut. As a result, aluminium alloys are typically the preferred choice for laser cutting.

Cons

When looking for the best aluminium alloys for laser cutting, it is important to consider the cons associated with each type. One key con of using aluminium alloys for laser cutting is the fact that some alloys are more susceptible to heat damage than others. Not all alloys are created equal and some are much more susceptible to warping, discoloration, and other signs of heat damage when undergoing the laser cutting process.

In addition, some of the more brittle aluminium alloys can be difficult to cut and require higher focal lengths to ensure a good quality cut.

7XXX Series Alloys

In terms of laser cutting, the 7XXX series of aluminum alloys is one of the more suitable options. This series includes a range of aluminum alloys that are heat treatable, meaning they can be strengthened through certain heat treatments while still being relatively lightweight and malleable. The 7000 series aluminum alloys also have excellent corrosion resistance, making them an especially good choice for projects that will be used outdoors or in wet environments.

These alloys also feature good welding characteristics and hold a decent level of tolerance when being cut.

Pros

aluminium A good aluminum alloy is essential for successful laser cutting of aluminium. A variety of aluminium alloys offer both benefits and drawbacks that can impact the success of your laser cutting project. One major benefit to utilizing aluminium alloys is that they are generally easier to cut.

Alloys are created by blending one or more metals together, which creates a stronger and more versatile material.

Cons

aluminium Aluminium alloys have some drawbacks when it comes to laser cutting. The most notable of these is that some alloys have higher surface roughness, which can impair the integrity of the metal. Additionally, some aluminium alloys are more difficult to cut than others, requiring a higher power output laser to penetrate the metal and create a clean cut.

8XXX Series Alloys

The 8XXX series alloys are a good option when it comes to laser cutting aluminium. These alloys are particularly strong and versatile, giving them a wide range of potential applications. They also have good weldability and formability, which makes them suitable for a variety of complex and intricate shapes.

They are also easy to machine, making them more suitable for laser cutting compared to other aluminium alloys. When it comes to laser cutting aluminium, the 8XXX series alloys offer several advantages. These alloys can withstand extremely high temperatures which make them ideal for the laser cutting process.

They also have excellent strength and ductility, making them less prone to cracking during the cutting process.

Pros

One of the advantages of using aluminium alloys for laser cutting is their high strength and durability. Aluminium alloys are incredibly tough and can withstand higher levels of heat and pressure than many other materials. This makes them more suitable for use in laser cutting machines than mild steel, for example.

Additionally, aluminium alloys can be cut quickly, easily and accurately with a laser, making them a good option for many different projects.

Cons

aluminium When it comes to choosing laser cut aluminium, there are some cons that should be considered. Firstly, aluminium is relatively soft and ductile, meaning that it can cause thermal damage during the process. If the laser is too powerful, it can deform and burn the edges of the aluminium, leaving a poor finish.

Additionally, depending on the specific alloy that the aluminium is made of, it can be more difficult to laser cut than other metals.

Can 6061 aluminum be laser cut?

aluminium Yes, 6061 aluminum can be laser cut. This aluminum alloy is made up of magnesium and silicon, and it is highly resistant to corrosion and environmental damage. It is very malleable and can in turn be easily laser cut into a variety of shapes.

This alloy is also cost effective and very lightweight, making it a great option for use in a variety of industrial applications. However, while 6061 aluminum is a very suitable alloy for laser cutting, there are some other aluminum alloys that may be more suitable depending on the application.

Can a laser cutter cut aluminium?

Yes, a laser cutter can definitely cut aluminium! Laser cutting uses a high-power laser beam to cut through the material, and aluminium is no exception. In fact, many metals, including aluminium alloys, can be cut with a laser cutter.

Before deciding to laser cut aluminium, however, it’s important to think about what specific alloy might be best suited for laser cutting.

What aluminum for laser cutting?

aluminium When it comes to creating parts using laser cutting, the choice of aluminium alloys used is critical to achieving the desired result. Different alloys are more suitable for laser cutting than others, so it is important to choose the right material. When it comes to laser cut aluminium, the two most common alloys used are the 5XXX and 6XXX series.

The 5XXX series is aluminium-magnesium-silicon, while the 6XXX series is aluminium-magnesium-silicon-copper. Both alloys are relatively easy to cut, and they both provide an excellent finish.

Conclusion

aluminum In conclusion, when it comes to what aluminium alloys are best suited for laser cutting, it really depends on the needs of the project. For projects that need thicker parts, 2024 and 5052 alloys are both a good option. These thicker parts will require more energy to be cut and both 2024 and 5052 can withstand higher temperatures with minimal deformation.

For the thinnest parts needed, the best alternatives are 6061 and 7075 alloys. These are more suitable for laser cutting because they require less energy and are less likely to deform during the process.