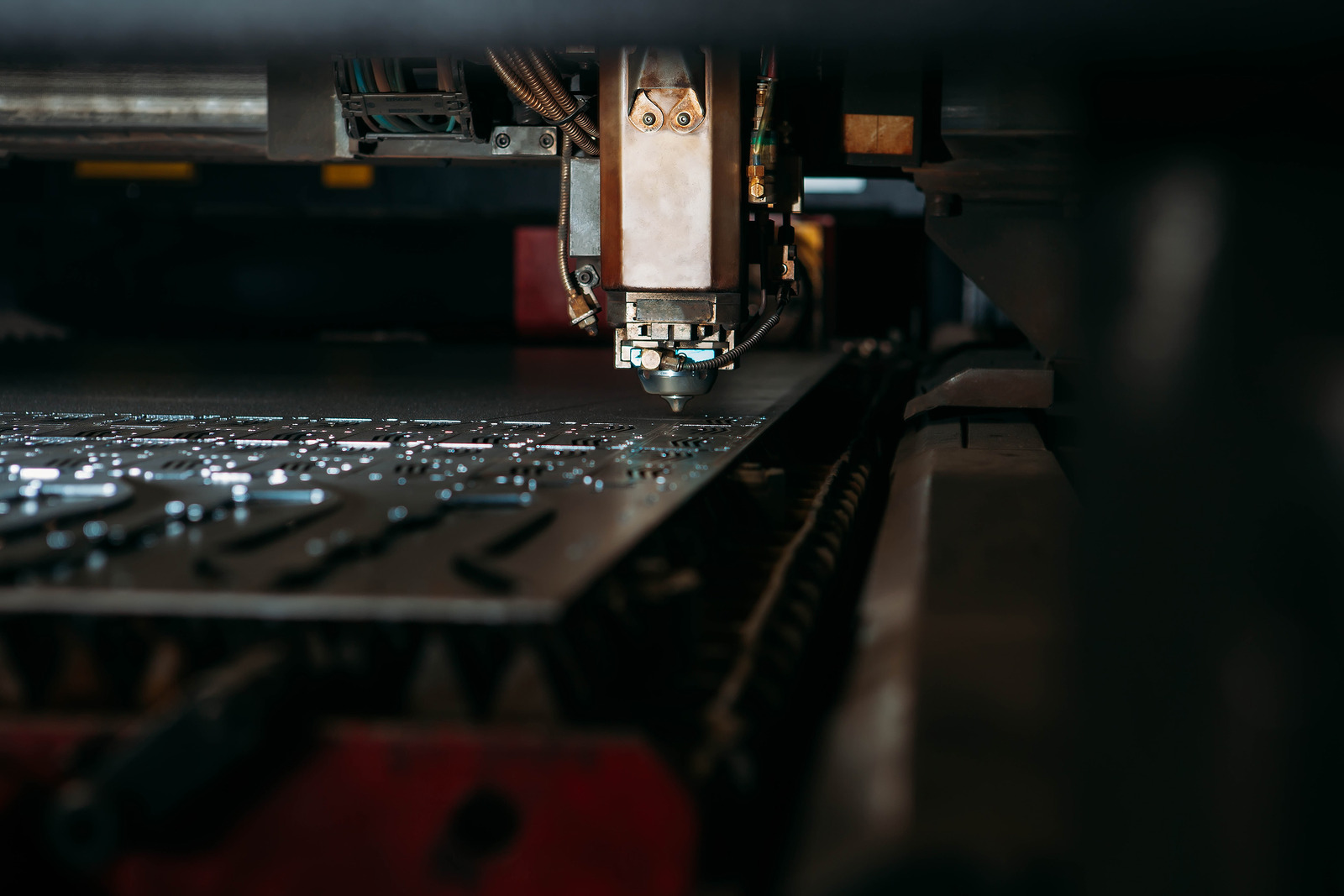

In recent years, creative and innovative laser cutting techniques for Zinc-Coated Steel have become increasingly popular as a method of improving production efficiency. One of these methods is utilization of Heat Treatments to enhance the laser cutting process of Zinc-Coated Steel. In this guide, you will learn the principles of Heat Treatments and the benefits they provide in laser cutting Zinc-Coated Steel.

Utilizing Heat Treatments for Laser Cutting Zinc Coated Steel

What is Zinc Coated Steel?

Zinc coated steel is a type of steel that is coated with a layer of zinc. This zinc layer helps improve the steel’s durability and protect the metal from corrosion and rust. Commonly referred to as galvanized steel, this coating is most often used in applications that are exposed to weather or moisture, such as roofing and outdoor furniture.

Zinc coated steel can also be used in laser cutting and welding processes as a way to reduce the amount of heat and energy needed to complete tasks. When using zinc coated steel for laser cutting, the steel must go through a process of heat treatments to ensure the correct cut and reduce the risk of further damaging the material.

Difference Between Zinc Coated and Other Steel

When utilizing laser heat treatments for laser cutting zinc coated steel, it is important to be aware of the difference between zinc coated and other types of steel. Zinc coated steel is a type of metal that has been coated with a protective layer of zinc. This layer helps protect the metal from corrosion, rust, and other harmful effects of exposure to the elements.

The layer also provides the material with a superior degree of strength and durability, making it suitable for use in high-stress applications. In comparison to other types of steel, zinc coated steel is more resistant to heat and wear due to its anti-corrosive properties.

Advantages of Laser Cutting Zinc Coated Steel

When it comes to laser cutting, zinc coated steel provides many advantages over other materials. It offers superior accuracy and precision in cutting, along with faster cutting speeds and lower costs. Furthermore, there are various heat treatments available that can further improve the performance and quality of the cut.

By using a heat treatment during the laser cutting process of galvanized steel, the sharpness and accuracy of the cut can be enhanced.

Heat Treatments When Laser Cutting Zinc Coated Steel

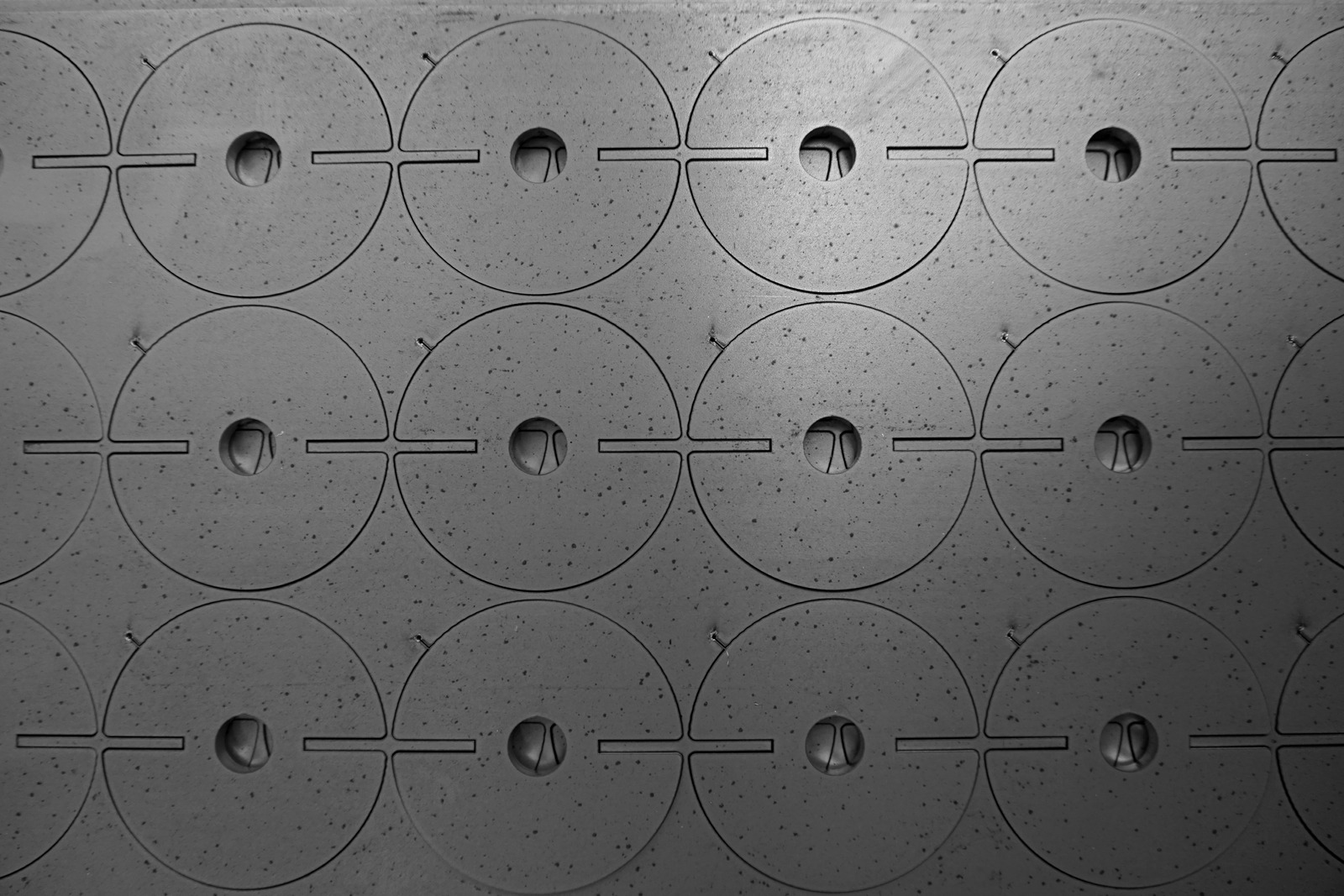

Laser heat treatments are used when laser cutting zinc coated steel to create a high-quality edge cut. The heat treatment removes superficial layers of zinc from the edge and helps to prevent the formation of burrs and slivers. The process works by utilizing a timed sequence of laser pulses that gradually raise the temperature of the edge to a point where the zinc coating is melted.

Identifying Heat Treatments

Common Heat Treatment Methods

Heat treating is an important yet complicated process when it comes to laser cutting zinc coated steel. This is because the high temperature of the laser beam burns away the zinc coating, which can lead to issues with adhesion and corrosion. To prevent this, many heat treatment methods have been developed to protect the zinc coating and improve cutting results.

Benefits of Heat Treatments for Laser Cutting Zinc Coated Steel

Heat treatments are extremely beneficial when it comes to laser cutting zinc coated steel. Heat treatments can dramatically improve the cutting quality by changing the mechanical and physical properties of the steel. Heat treatments can be used to reduce the hardness, strength and residual stress of the steel so that it is easier to cut and less likely to break.

This can lead to faster, cleaner, and more precise cuts. Heat treatments can also protect the steel from thermal shock and reduce the burrs that can form when cutting thin materials.

Challenges of Laser Cutting Zinc Coated Steel

One of the main challenges when it comes to laser cutting zinc coated steel is that the coatings can cause the laser beam to refract, which can lead to a distorted final product. Additionally, the heat generated during the process can cause the coatings to oxidize and discolor, resulting in a poor finish. It is also difficult to cut galvanized steels, as the zinc coating on the steel can block part of the laser beam and cause it to miss parts of the cutting area.

Safety Tips for Heat Treatments

General Safety for Heat Treatments

When utilizing heat treatments for laser cutting zinc coated steel, it is important to be aware of the general safety protocols for the process. Heat treatments involve extremely high temperatures, meaning the process must be managed with careful caution. For any process that is heat-related, a fire extinguisher should not be far away should an emergency arise.

Some processes require heat resistant gloves to prevent direct contact with any hot components, as well as safety goggles to protect eyes from potential sparks or further heat effects. Heat treatments also require an extensive ventilation system to reduce the amount of smoke in the air and increase the amount of oxygen. When it comes to specifically working with galvanized steel, some additional safety measures are necessary.

Minimizing Risks of Heat Treatment

Heat treatments are an integral part of laser cutting zinc coated steel since they are responsible for reforming the material and improving the cutting process. Unfortunately, given the high temperatures involved, there is potential for safety risks if safety precautions are not taken. Minimizing these risks starts with procuring the correct PPE for the workers.

- Always wear protective equipment such as face masks, gloves, and heatproof garments when dealing with laser cutting and heat treatments.

- Make sure the area has enough ventilation when working with laser cutting and heat-treating, since they can produce toxic fumes and vapors.

- Check the temperature of the heat treatment area frequently to make sure it is not overheating.

- Be mindful of static buildup as a result of the laser cutting and heat treatments. Proper grounding techniques should be used to prevent any unexpected electric shocks.

- Always remember to read through the manufacturer’s safety guidelines and document any procedures related to your project, so that if any questions arise, you can refer to the documentation.

Preventing Accidents and Injury

Cutting galvanized and other types of coated steel with a laser can be a risky venture when not handled correctly. Heat treating laser cutting machines requires a great deal of caution and attention – with the wrong moves, serious accidents, fires and even explosions can happen. It is important to take the proper steps before and during heat treatment to ensure that these risks can be avoided.

The first step in preventing accidents and injury during laser heat treatment is understanding the potential consequences of a careless misstep. Most laser machines are powered by high voltage electricity and can produce sparks which can quickly ignite flammable materials.

Can you cut galvanized steel on a laser?

Yes, you can definitely use a laser to cut galvanized steel. The key is to use a heat treatment, which helps to prevent the laser from damaging the zinc coating. Heat treatment involves using pressure and heat to treat the steel so that the zinc resists the laser’s beam, making the cut more precise and accurate.

It also helps to increase the life of the laser, as the heat treatment reduces the effects of the beam melting the zinc coating. Heat treatments also offer longer cuts, which can be beneficial when laser cutting large pieces of galvanized steel. When choosing a heat treatment for laser cutting galvanized steel, it’s important to consider the thickness and the size of the coated steel.

Does laser cutting harden steel?

When it comes to laser cutting galvanized steel, one of the most common questions is whether or not laser cutting can harden the steel. The answer is yes–but only in certain circumstances. Laser cutting itself does not always produce the desired hardness, but with the right heat treatments, laser cutting can effectively harden steel.

Heat treatment is the process of rapidly heating and cooling a metal in order to develop certain physical and mechanical properties within the steel. For laser-cut steels, the goal of heat treatment is to achieve a desired hardness and strength. For galvanized steel, this means maintaining the zinc coating while still producing a strong, hard part.

Which laser is used for cutting steel and other metals?

When it comes to cutting steel and other metals, lasers are the go-to choice for many fabricators and engineers. But when it comes to cutting galvanized or coated steels, it’s important to know the best laser power and wavelength for the specific coating and desired effect. Heat treatments for laser cutting galvanized steel are an important part of the process.

A heat treatment is the application of additional heat to a metal in order to change its properties. When cutting galvanized steel, the heat treatment helps to break down and melt the zinc coating more quickly and effectively.

Does laser cutting harden stainless steel?

No, laser cutting does not generally harden stainless steel. It may be possible to harden stainless steel through a heat treatment process called laser heat treatment, though it is not typically used for laser cutting galvanized steel. Laser heat treatments work by using a laser beam to impart energy into the material’s surface.

This energy is absorbed into the steel, causing it to become more hardened or less brittle. For example, this energy can be used to reduce the risk of cold cracking, which can occur after laser cutting due to the high temperatures used in the process.

Conclusion

Summary

In summary, utilizing heat treatments for laser cutting zinc coated steel can provide many benefits. It can reduce the amount of burr that forms on the cut surface and also reduce the amount of stress on the material. This can help to improve the quality of the laser cut item.

Heat treatments can also improve the overall speed of the laser cutting process. This is because the heat generated by the laser accelerates the cutting process allowing for quicker and more consistent cuts. Heat treatment also helps to extend the life of the laser cutting tool as it prevents wear and tear.

However, due to the high temperatures involved, it is important to use extra caution when working with galvanized steels.

Benefits of Utilizing Heat Treatments for Laser Cutting Zinc Coated Steel

Using a heat treatment technique when laser cutting zinc coated steel, or galvanized steel, provides many advantages. First of all, the process creates a cleaner cut as the heat from the laser causes the surface of the steel to melt, thus limiting the splatter and debris found in standard laser cutting. Another benefit is that the edges of the cut are smoother and more refined, which allows for a better fit and increased strength in the finished product.

Tips for a Successful Laser Cutting Process

When it comes to laser cutting zinc coated steel, utilizing heat treatments can be a crucial part of the process. Heat treatments such as annealing and quenching can be used to improve the properties of the steel, making it more suitable for laser cutting.

- Ensure that laser cutting output is adjusted to allow for the zinc coating. This can be done by increasing the power output of the laser, slowing the cutting speed, or narrowing the beam size.

- Make sure that the laser beam is aligned correctly relative to the steel material to ensure consistent results.

- Use the right type of assist gas to remove fumes and debris that can clog the nozzle.

- Minimize heat buildup by employing preheating and cooling techniques. This will ensure that the zinc coating does not become charred.

- Monitor the process regularly to make sure that the laser cutting machine is working correctly. Problems such as misalignment should be quickly addressed.