Laser technology is revolutionizing the woodworking industry, giving woodworkers access to a range of incredible new tools and capabilities. In this article, we’ll explore just one such tool – laser cutters – and discuss how they are unlocking new opportunities and potential in the woodworking sector. From increased speed and accuracy to lower energy costs and better finish quality, laser cutters offer unique advantages that are transforming the industry. By looking at the benefits of incorporating laser technology into how products are made, it becomes clear just how much power these tools hold for the industry’s future.

Benefits of Laser Cutters

Accuracy and precision

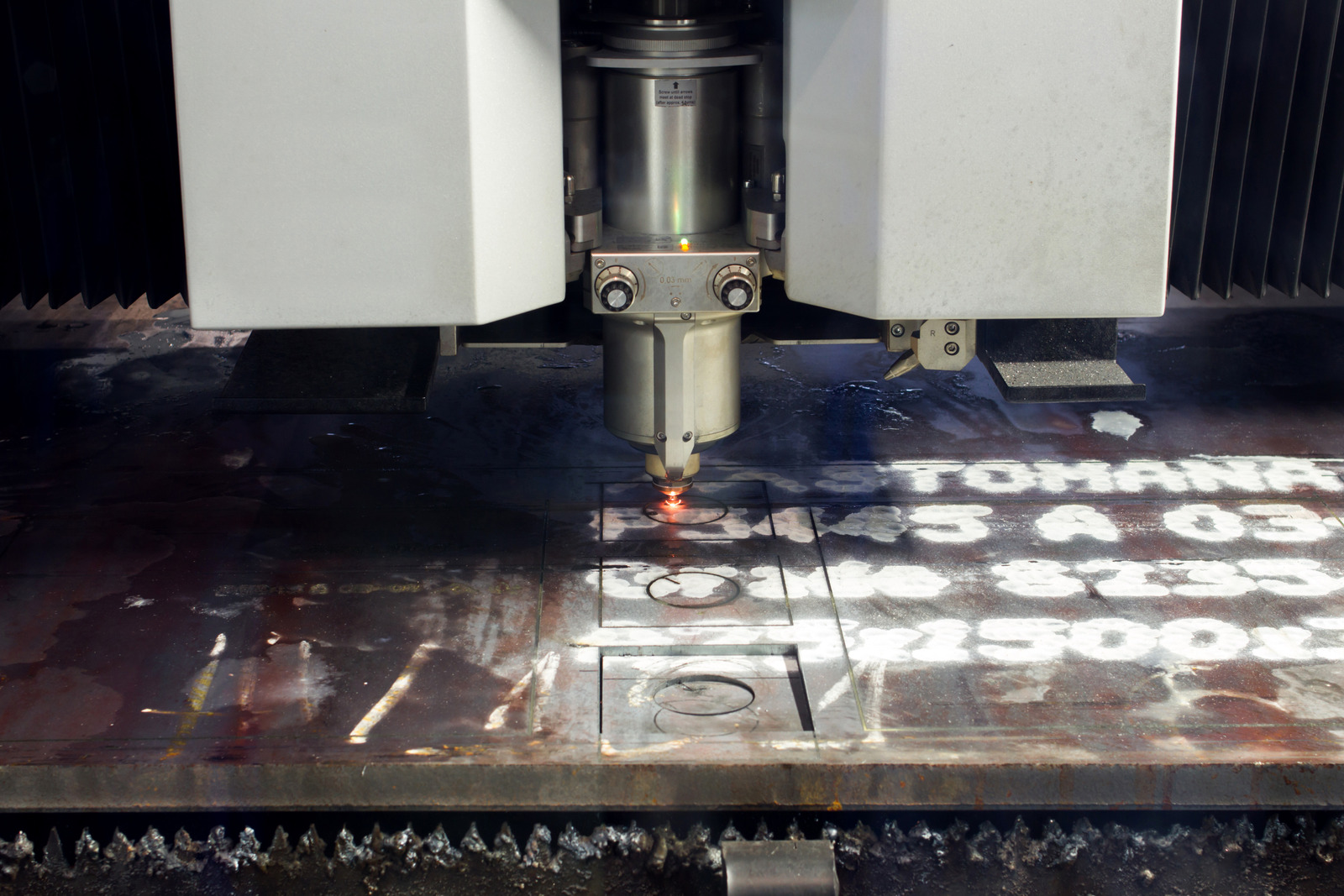

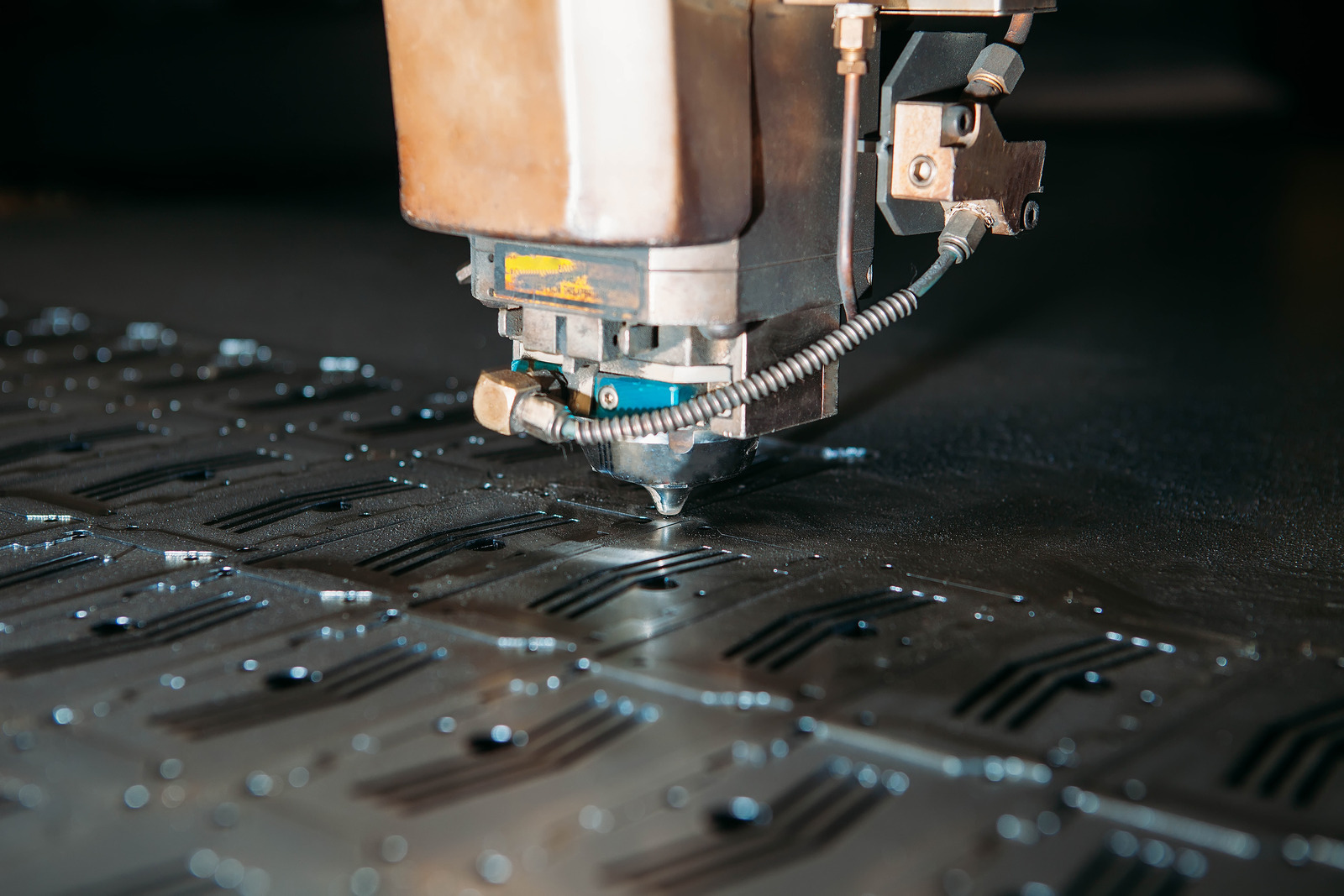

When it comes to precision and accuracy, laser cutters are in a league of their own. Laser cutters are specialized machines that use focused lasers to produce precise cuts on flat materials. Whether it’s wood, metal, plastic, or fabric, laser cutters can make intricate and detailed cutting patterns with ease.

In the woodworking industry, laser cutters are being used to rapidly and accuratly cut intricate designs into wood products. Thanks to the super accurate cutting capabilities of laser technology, woodworkers are able to create complex furniture, decor, and architectural pieces. Companies across the globe are utilizing the versatility of laser cutters to develop new and innovative products.

Increased productivity

When it comes to cutting materials with precision, laser cutters are a game-changer in the woodworking industry. Laser cutters use a powerful laser beam to precisely cut and engrave flat materials with minute accuracy. With laser cutters, woodworkers have an incredibly powerful tool at their disposal that can cut intricate details out of wood at a fraction of the time and cost required by traditional manufacturing processes.

Furthermore, by using laser cutters, woodworkers can cut multiple pieces of material at once; this greatly increases productivity and reduces cost.

Reduced wastage

One of the greatest benefits of using laser cutters to produce products in the woodworking industry is their ability to make precise cuts on flat materials. Thanks to the highly focused nature of the laser beam, manufacturers are able to make exceedingly exact cuts with a fraction of the level of wasted material. Whereas in the past, cutters would either have to leave excess material beyond the cutting line or resort to extremely slow, manual cutting methods, laser cutters can accurately mark and cut a wide variety of materials with laser cut precession–sometimes even less than 0.1 millimeters of material wastage.

This precision also helps reduce the amount of time required to complete projects.

Ability to produce intricate designs

When it comes to producing intricate designs with precision cuts on flat materials, laser cutters are revolutionizing the woodworking industry. Laser cutters make it easy to produce incredibly intricate designs with accuracy that is unmatched by hand craftsmanship. By using a laser cut process, manufacturers can precisely cut and engrave materials in a fraction of the time it normally takes.

Laser cutters are mainly used in woodworking to prepare materials for manufacturing. Laser cutters are capable of cutting through many different materials including wood, plastics, acrylics, textiles, and foam.

How Laser Cutters are Changing the Woodworking Industry

Increased capabilities of woodworkers

Laser cutters have revolutionized the woodworking industry, allowing woodworkers to unlock the potential of laser technology. By directing the beam of a laser onto a material, laser cutters are able to make precise, accurate cuts on flat materials. This means that the traditional limitations of woodworking processes have been eliminated, allowing for much greater precision in manufacturing processes than ever before.

Laser cutters have allowed woodworkers to create complex designs with intricately detailed cuts, engravings, logos, font styles and other graphics. This level of detail is unmatched by any other manufacturing process, and it allows woodworkers to take their projects to the next level and truly unlock the potential of their products.

Improved cutting methods

The potential of laser technology has been increasingly recognized in recent years, with its potential to improve cutting accuracy and speed in the woodworking industry – and that’s incredible news for woodworkers! Laser cutters offer woodworkers a great tool to work with the most delicate materials. Not only can laser cutters produce highly precise cuts on flat materials, but the precision and speed of their cutting is second-to-none.

This can give a new level of accuracy and detail to any woodworking project! One of the best aspects of the laser cutters is the variety of materials they can cut and engrave.

Increased access to high-level electronics

Laser cutting has allowed woodworking professionals to access the exact and precise cuts needed for their projects in ways previously unimaginable. Laser cutters can precisely cut out flat materials such as wood, metal, and even acrylic. This technology is quickly revolutionizing the woodworking industry by giving professionals the opportunity to turn out high-level electronics quickly and with greater accuracy.

One of the many benefits of using laser cutters is that it eliminates the need to manually measure and cut materials.

Increased range of materials

Laser cutters have been revolutionizing the woodworking industry due to their ability to make precise cuts on flat materials with high accuracy. Before laser cutters, woodworkers relied on manual cutting techniques, but these techniques are not as accurate as laser cutters and often consume more time, resources, and labor. With the help of laser technology, laser cutters are able to increase the range of materials that woodworkers can work with.

Softwoods, hardwoods, MDF, formica, and many other materials can be cut with ease, allowing woodworkers to create luxurious designs with intricate details.

Challenges of Laser Cutters

Highly specialized machines

It’s no secret that laser cutters are a highly specialized machine that offers precise cuts on flat materials, ranging from hardwoods to metal and plastic. As advances in technology continue to further automate and advance the manufacturing process, laser cutters have grown in popularity and become the go to option for cutting and engraving materials. One of the biggest advantages of utilizing laser cutters is their versatility.

Complexity of operation

The complexity of operating laser cutters can make them a difficult choice for many woodworking operations, but with the right training, they can be very effective. Laser cutters use a beam of high-power light to precisely cut through flat materials, including wood, plastic, and metal. This can lead to superior results compared to traditional woodworking techniques, as it allows for precise cuts on even complicated shapes.

When compared to other traditional manufacturing processes, laser cutters are capable of cutting and engraving materials quickly and with high precision. With the right equipment, they can be programmed to accurately cut shapes or engrave designs into surfaces, eliminating the need for human labor.

Cost of energy consumption

With traditional woodworking methods, precise cuts on flat materials can be difficult to achieve. This is why laser cutters are becoming an increasingly popular option for manufacturers. Laser cutters use a focused light beam to quickly, accurately, and precisely cut or engrave materials like wood and metal.

Unlike traditional woodworking tools, which require a lot of physical effort, laser cutters are much faster and more convenient. However, one of the biggest challenges of using laser cutters is the cost of energy consumption. Running a laser beams constantly draws significant power, so laser cutter operators have to be mindful of the electrical cost associated with their projects.

Safety concerns

When it comes to laser cutters, safety is top of mind. After all, laser cutters use a powerful beam of light to create precise cuts on flat materials. While this makes laser cutters extremely effective and efficient tools for cutting and engraving, it also calls for paying close attention to safety protocols.

The most important safety concern is avoiding direct contact with the beam.

How does a laser cutter work on wood?

A laser cutter is a tool used for cutting and engraving certain materials with a high degree of precision. For the woodworking industry specifically, laser cutters are used for making precise cuts on flat materials, such as veneers, plywood, solid wood and other medium density fiberboard. Laser cutters use a laser beam to cut through materials, leaving clean and precise edge cuts compared to traditional cutting methods.

The laser cutter works by focusing a highly concentrated beam of light onto the material.

How is a laser cutter used in industry?

Laser cutters are highly precise tools used in industry to quickly and accurately cut and engrave flat materials like wood, plastic, and metal. Using a beam of light to direct its cuts, a laser cutter is capable of making smooth, exact cuts on any number of different materials. The laser cutter has brought a level of precision previously unseen in the woodworking industry, with products having intricate, precise shapes and designs easily achievable in minutes, with no fuss.

In terms of woodworking, laser cutters can make all manner of precise cuts with ease.

Conclusion

Summary of the impact of laser cutters on the woodworking industry

In short, laser cutters have had a dramatic impact on the woodworking industry. Laser cutters are precise cutting tools that use a laser beam to cut flat materials in a variety of shapes and sizes. This technology has massively advanced the manufacturing processes of woodworking, allowing for precise cuts on all sorts of materials.

This has not only revolutionized production techniques, but also opened up countless possibilities for artisans, allowing them more scope for creativity in their projects.

Future trends in the woodworking industry

Conclusion As laser cutters continue to evolve, the potential of the technology is becoming increasingly obvious. We are only scratching the surface of what can be done with this amazing tool, and only time will tell the true breadth of its capabilities. The woodworking industry is already feeling the effects of the use of laser cutters, as they are able to produce precise cuts on flat materials that would otherwise be difficult to achieve with traditional woodworking techniques.

Additionally, laser cutters allow for faster and more efficient manufacturing processes to cut and engrave materials.

Final thoughts on the potential of leveraging laser technology

Finally, it’s worth mentioning the potential of leveraging laser technology for today’s modern woodworking industry. Laser cutters offer some of the most precise cuts on flat materials when compared to other cutting tools currently in the market. Whether these laser cutters are used for manufacturing processes to cut and engrave materials or simply to execute something as intricate as a simple woodworking project, it’s clear that they are changing the way we work.