Welcome to this introduction on understanding laser cutting machines and their capabilities. You may be wondering what these machines are and what they can do. In this introduction, we will explain the basics of laser cutting technology, its wide array of uses, and the benefits that come with using such machines. We will also discuss the different laser cutting machines available on the market and their various capabilities. Finally, we’ll discuss the safety issues that go with using laser cutting machinery. By the end of this introduction, you will have a better understanding of laser cutting machines and their capabilities.

Basic Overview

Types of laser cutters

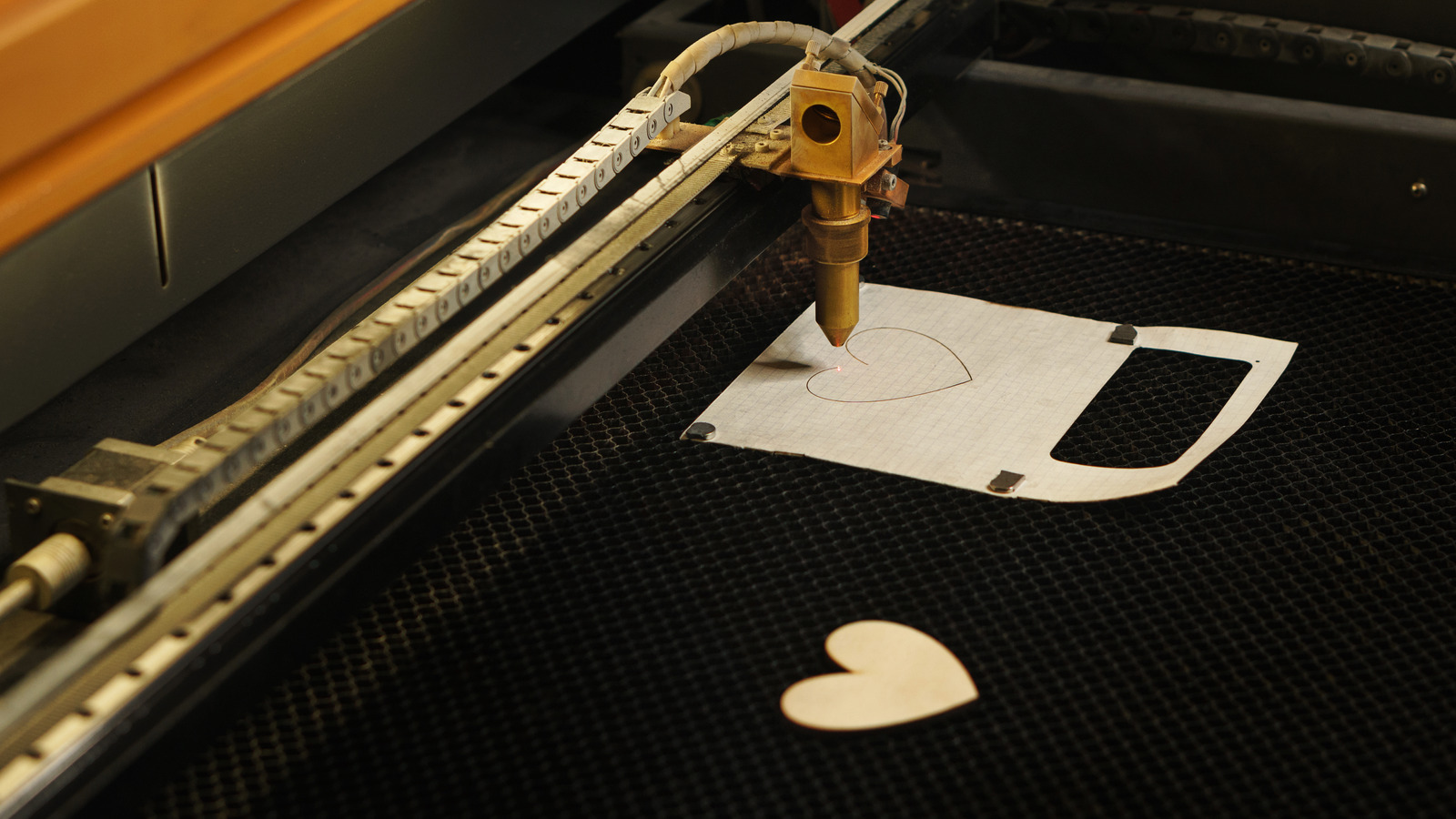

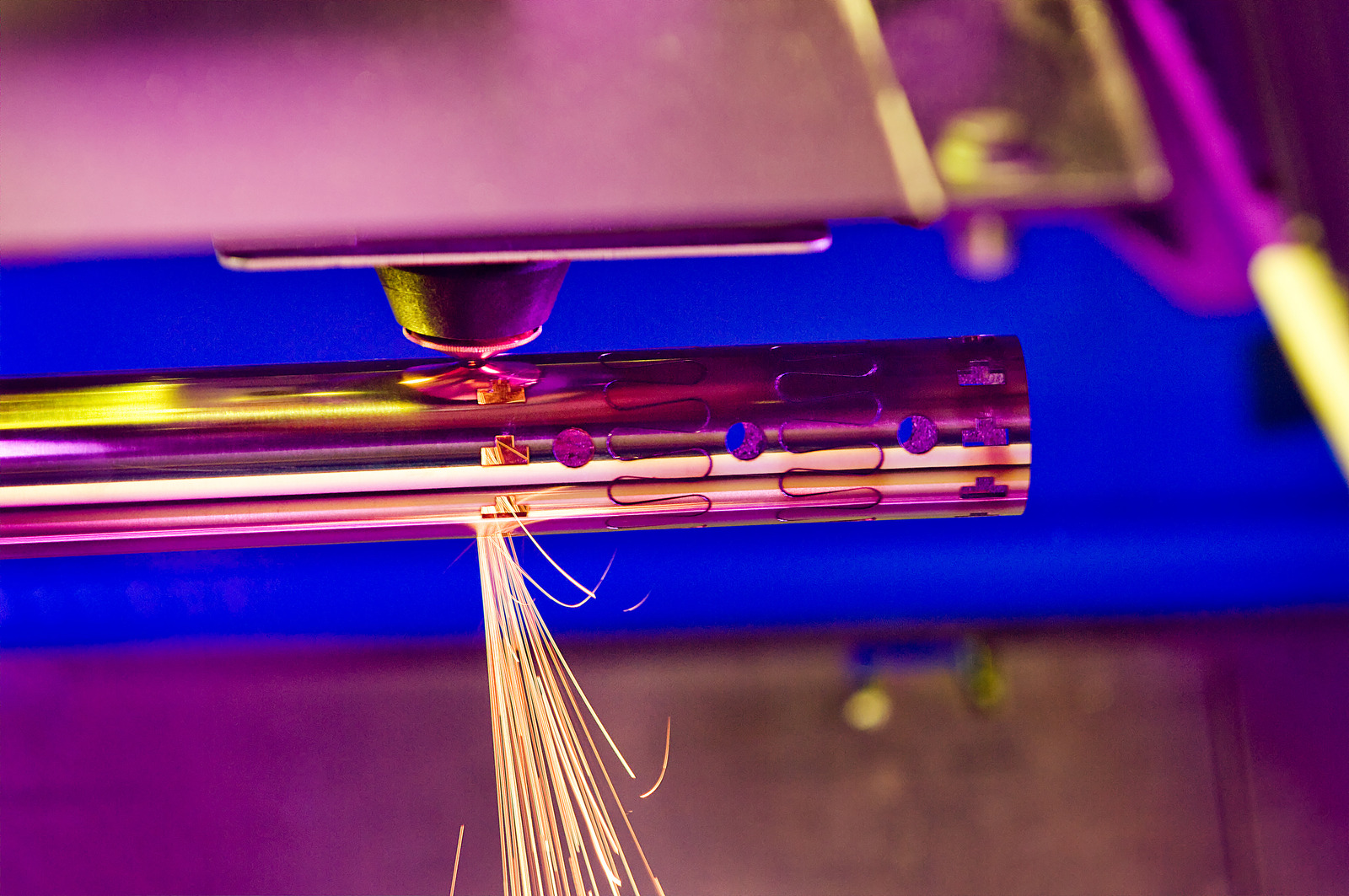

When it comes to laser cutting machines, there are several different types that can be used to create different designs and patterns. These machines use a laser to vaporize materials and are capable of creating extremely precise cuts without any human intervention, resulting in a cut edge that is very precise. Depending on the size and complexity of the material to be cut, the type of machine used will determine the accuracy and speed with which the cuts are made.

The most popular type of laser cutting machine is called a CNC (computer numerically controlled) laser cutter.

Advantages of laser cutting

One of the most advantageous aspects of laser cutting machines is the precision and accuracy with which they can make cuts. Using technology that utilizes a laser beam to vaporize materials, laser machines are able to make cuts exactly the way your design goes with excellent accuracy and precision. This allows creators to more easily get the results they are looking for, with the cutter ensuring a consistent and clean cut every time.

Another advantage of laser machines is that they can create intricate patterns and designs using their cutting power.

Disadvantages of laser cutting

Laser cutting machines are a popular technology that uses a laser to vaporize materials and cut them exactly the way your design goes. Laser cutters create patterns and designs by cutting into various materials, resulting in a cut edge. Although laser cutting machines can be great for quickly and accurately cutting materials, there are several disadvantages with this technology that should be considered.

The cost of laser cutting machines can be high, making them out of reach for hobbyists and smaller businesses.

Materials Used for Laser Cutting

Types of materials that can be used

When it comes to understanding laser cutting machines and their capabilities and the materials they can cut, there is a lot to go over. Laser machines use a laser beam to vaporize materials in order to cut intricate and precise shapes. Laser cutters are amazing pieces of technology that can cut out parts and shapes with the utmost accuracy, exactly the way your design goes.

Advantages of specific materials

When it comes to understanding laser cutting machines and their capabilities, it’s important to understand the advantages of certain materials when it comes to creating patterns and designs by cutting into them. Using technology that uses a laser to vaporize materials, laser machines cut materials exactly the way your design goes, allowing high accuracy and precision that may not be achievable with other cutting methods. The materials most often used for laser cutting include wood, acrylic, plastic, and metal, although different machines may be able to achieve different levels of accuracy and precision with each of them.

Depending on the material being used, laser cutting machines can create intricate and complex shapes as well as text and symbols with a high degree of precision.

Tips for finding the best material for a project

Finding the right material for your project is one of the most important steps in utilizing a laser cutting machine. Laser cutting machines are a type of technology that uses a laser to vaporize materials in order to create patterns and designs. A laser cutter creates highly precise cuts and is capable of cutting many different materials, though some materials may require more powerful laser machines while other materials may require a lower power setting.

Before you purchase a material or begin a project with a laser cutter, you should determine what type of design or cut you want to produce.

Laser Cutting Process

Step-by-step guide to the laser cutting process

A detailed and casual explanation of the laser cutting process involves gaining an understanding of laser cutting machines and their capabilities. Laser cutting is a technology that uses a laser to vaporize materials like wood, plastic, glass and paper, and it can create extremely precise patterns and designs by cutting into the material exactly the way your design goes. The precision of laser cutters also allow for complicated or highly detailed designs, depending on the desired outcome.

Common components and setup of a laser cutter

A laser cutting machine is a unique type of technology that uses a laser to vaporize materials, making precision cuts that have an exact level of detail. The laser machine cuts materials exactly the way your design goes, and allows for change in the cutting path mid-process if need be. Laser cutters create patterns and designs by cutting into materials, and predictably shape the items with great accuracy and detail.

Safety measures to take when operating a laser cutter

When operating a laser cutting machine, safety should always be the top priority. There are numerous safety measures to take when operating a laser cutter, such as protective glasses and other PPE, proper ventilation, and correctly following operational procedure. Technology that uses a laser to vaporize materials is typically very precise and reliable when used correctly.

All laser machines cut materials exactly the way your design goes, resulting in a cut edge that is precise and accurate. All CNC laser cutter users should always wear safety glasses and other protective clothing when the machine is in operation. The laser beam can be harmful to both the operator and bystanders if proper protection is not worn.

Software Used for Laser Cutting

Different types of software

Understanding Laser Cutting Machines and their Capabilities, Software Used for Laser Cutting When it comes to creating intricate patterns and designs on material, laser cutting machines are the way to go. These machines use a laser beam to accurately vaporize materials and cut them exactly the way your design goes – all with the help of powerful and dedicated software. Here, we discuss the different types of software and their capabilities in helping laser cutting machines do their job.

The first type of software used for laser cutting machines is CNC software.

Advantages of specific software

When it comes to laser cutting machines and their capabilities, one of the main advantages of using specific software is that you get a much more precise cut than you would without. With laser cutters, you can design your cut and the machine will cut it exactly the way you’ve designed it, resulting in a much more accurate and exact cut. With the software, you have the ability to customize everything from the size and shape of the cut to the type of material you’re cutting.

This makes it easier to create intricate patterns and designs by cutting into various kinds of materials.

Tips for finding the best software for a project

Finding the best software for a project involving a laser cutting machine is essential for ensuring successful end results. Laser machines cut materials exactly the way your design goes, with precision that cannot be achieved with other cutting methods. It is important to understand the capabilities of laser cutting machines and the software used in order for them to perform most efficiently.

The type of software used with a laser cutting machine will depend on the project you are undertaking, as the requirements will differ. It is important to use software that can be easily integrated with the laser machine and provide users with the freedom to adjust settings, as needed, to get the best results.

Finishing Touches

Tips for achieving the best results

Achieving the best results with laser cutting machines requires a few tips and tricks. First, the right technology needs to be chosen. Laser cutting machines use a laser to vaporize materials, making it essential to choose a machine that is powerful enough to cut through the material type being worked with.

Laser machines are precise and cut materials exactly the way your design goes, resulting in a cut edge that is highly accurate. Second, ensure the material being cut is properly secured. To ensure accuracy, it is important that the material does not move during the cutting process.

Post-processing techniques

Post-processing techniques are used after a piece has been cut by a laser cutting machine. Depending on the material being cut and the desired output, several post-processing techniques may be used. These techniques can also be used to further refine the cut edge resulting from the laser cutting.

The most common post-processing techniques used with laser cutting machines include sanding and smoothing, annealing, cutting to size, tumbling, deburring, and polishing. Each of these techniques provide intricate detailing and finishes to the laser cut piece and can make the material surface more aesthetically pleasing.

How many types of laser cutting machines are there?

There are many types of laser cutting machines available on the market today, each designed to perform different tasks. They can come in a variety of sizes, from machines that can be used for a home DIY enthusiast to huge industrial models. These machines are generally categorized by the type of laser technology that they use, but the majority of them can cut materials exactly the way you design them to.

What can a laser cutting machine do?

A laser cutting machine is a technology that uses a laser beam to vaporize materials and cut into them, providing perfect accuracy and precision in the cutting process. It can create highly detailed designs and patterns by cutting into many different materials with a CNC (Computer Numerical Control) laser cutter. The laser works by using a light source to heat the material, resulting in a cut edge that is clean, precise, and free from burrs or smearing.

The capabilities of a laser cutting machine are only limited by the material being used, the type of laser, and the software on the machine itself.

Conclusion

Conclusion: In conclusion, laser cutting machines are incredibly useful and powerful tools that allow us to create intricate and precise designs with minimal difficulty. The technology behind them uses a laser to vaporize materials and cut them precisely the way your design goes, resulting in complex patterns and designs by cutting into materials and creating a perfect, smooth edge. CNC laser cutters allow us to apply this technology to a variety of materials, subject to certain limitations.

With laser cutting machines, you get the satisfaction of seeing a design come alive with the precise cuts that the machine provides. With the right knowledge and skill, these tools can be used to make stunning and complex projects that will last for years to come.