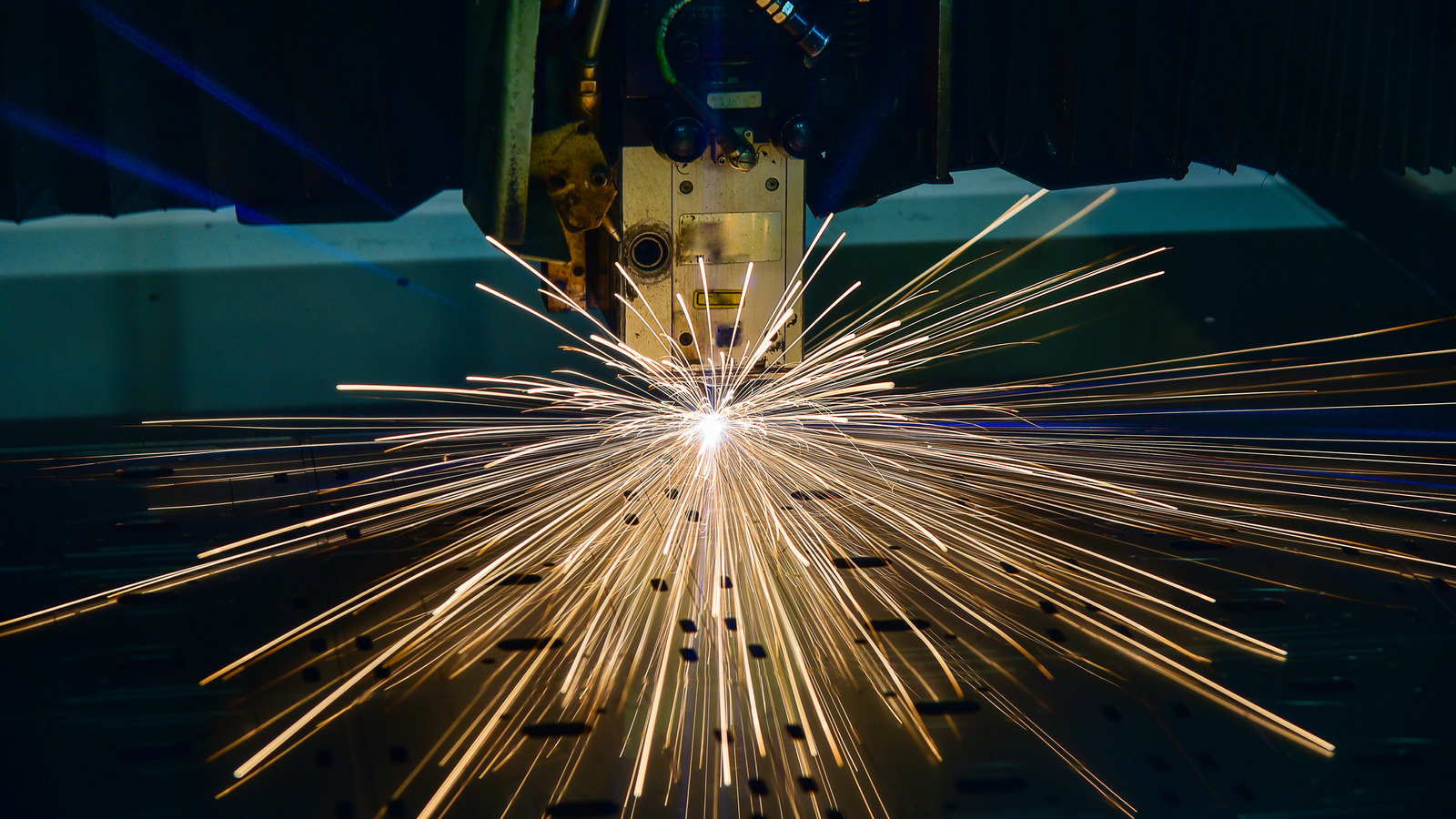

Are you an experienced laser cutter dealing with challenging foam issues? If so, this guide will be extremely helpful in providing you with essential troubleshooting tips to fix common laser cutting foam issues. By reading through and implementing the tips discussed in this article, you will be able to identify and resolve any difficulties you may have with your laser cutting foam projects. Let’s get started!

Common Issues with Laser Cutting Foam

Melting Foam

foam When it comes to laser cutting foam, problems with melting can be a significant source of frustration. It’s an issue often caused by the wrong type of laser cutting software settings. In particular, burning and melting that’s occurring at a depth beneath the surface is most common when using a CO2 laser cutter.

It’s important to note that laser cutting into soft materials can cause two different types of burning. The first is known as charring, which leaves a charred, dark residue on the surface. The second is a burning that results in a molten state, where the surface appears to be melted.

Charring Foam

foam issues When laser cutting foam, charring can be an issue, leading to poor quality results. Charring occurs when too much heat is applied to the material, resulting in a burn and discoloration of the surface. When laser cutting foam, the power of the laser should be set just enough to vaporize the material without causing additional damage.

To adjust the power output, test cuts should be made ahead of time to determine what optimal settings would be. Sometimes charring can occur even when the power output is adjusted correctly.

Improperly Cut Foam Pieces

foam When troubleshooting improperly cut foam pieces resulting from laser cutting, there are a few common sources of issues. One possible problem is that the laser may not be cutting at the correct power setting. This may be caused by a mismatch in the laser’s power setting for the type of foam being cut, or the laser may be set to a lower power setting than necessary.

Ideally, the power setting for the laser should match the type of foam you are cutting.

Tips for Troubleshooting Laser Cutting Foam

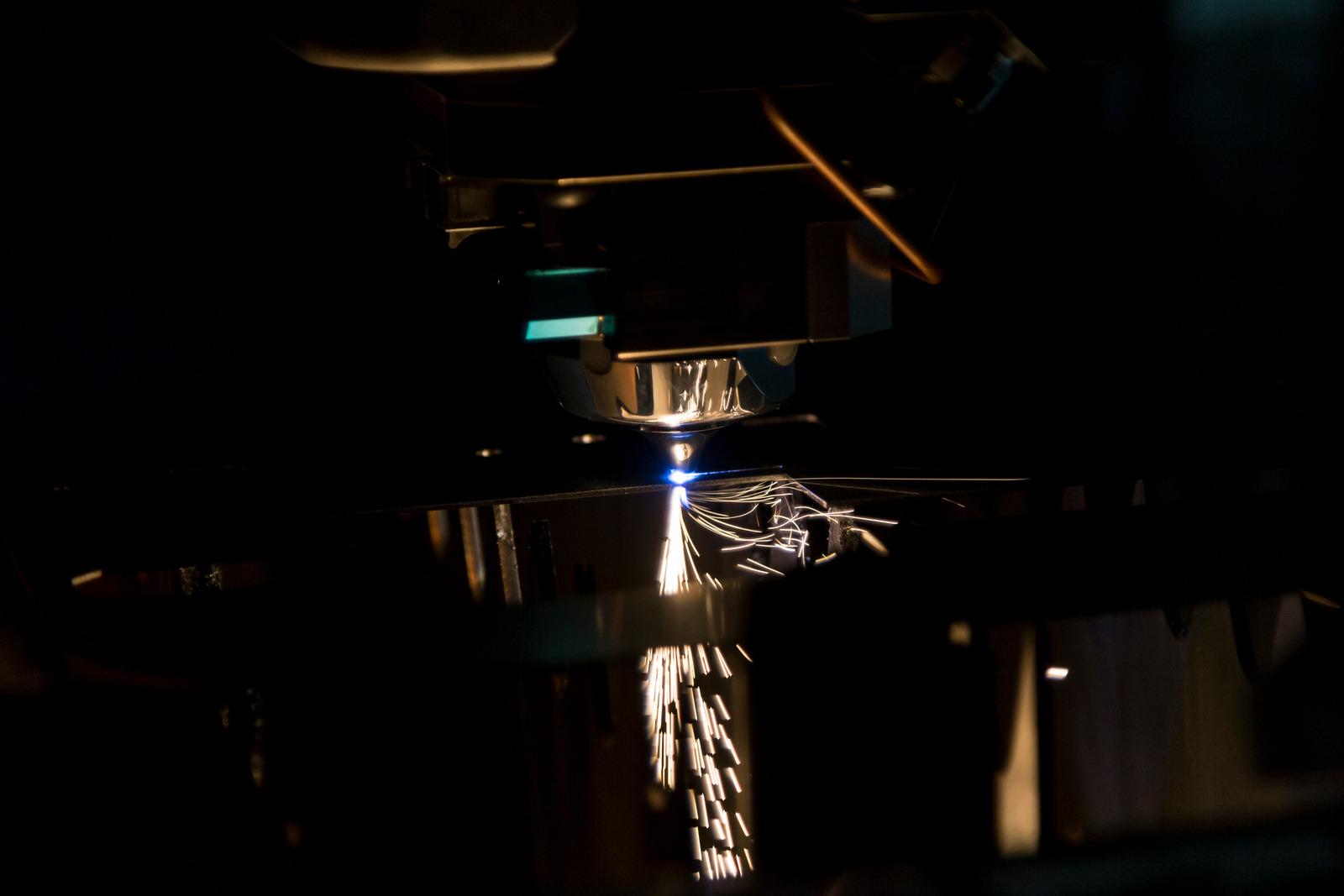

Check the Laser Beam Power

foam When troubleshooting any issues with your laser cutting foam, one of the first steps is to check the laser beam power. The power rating of the laser beam is a key factor in the successful laser cutting of foam materials as it determines the depth that the beam can penetrate the material. To check the power of the laser beam, you will need to use a device with a power meter that measures the power of the beam.

Check the Foam Material Specifications

foam When troubleshooting issues related to laser cutting foam, the first step is always to check the foam material specifications. Different types of foam have different properties that can affect the accuracy and success of your laser cutting project. For instance, some foams are more absorbent than others and will require more power to cut and higher speeds to avoid burning.

Similarly, some have higher melting temperatures, which will require slower speed settings and more time in the laser.

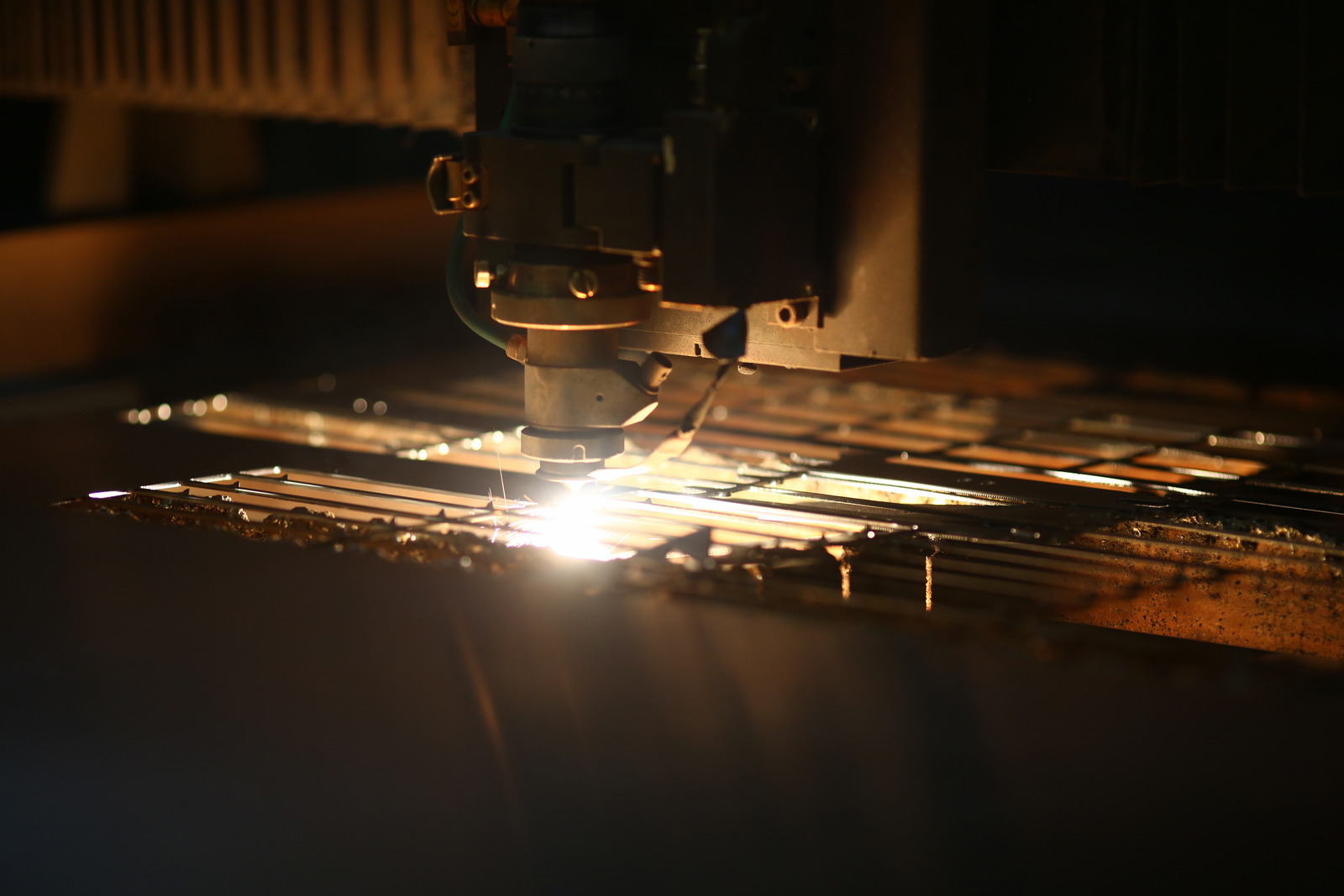

Adjust the Settings on the Machine

foam Adjusting the settings on the machine is an essential part of troubleshooting any issues when it comes to laser cutting foam. Depending on the type of foam being cut, different laser power and frequency settings may need to be adjusted to achieve the desired cut quality. When starting out, it’s important to understand the basics of laser cutting and the working nature of each parameter.

Power settings will affect the speed, accuracy, and overall cut quality.

Summary

Laser Cutting Foam is a Complex Process

foam Laser cutting foam is a complex process that requires careful attention and precision to achieve the desired outcome. The foam needs to be cut in a way so as to achieve a smooth and even cut, while minimizing undesirable effects such as slag, warping, and discolouration. Additionally, the laser cutting process needs to be monitored constantly in order to avoid potential scrap pieces and over exposure to the laser.

When cutting foam, it is important to understand the differences between polyethylene, polyurethane, and polystyrene foam. Each of these types of foam has various features which must be considered when choosing the best laser cutting settings for your application.

Troubleshooting Tips Allow You to Properly Cut Foam Pieces

foam When it comes to laser cutting foam, it can be a tricky process. Even with the right settings and a well-calibrated machine, small details can cause the foam pieces to come out wrong or not fit the intended shape. Troubleshooting tips can help you identify the causes of foam cutting issues and get the correct results.

The first step in troubleshooting is to check the incident energy emitted by the laser beam. The energy of the laser beam must be lower for foam than for other materials, and the best energy setting for cutting foam depends on its density and thickness.

Can you cut PolyStyrene foam with a laser?

foam Cutting Polystyrene foam with a laser is possible, but it can be a tricky material to work with. Polystyrene foam does not absorb much energy from the laser and it can melt instead of cutting, leading to poor results. It is best to use a low-power laser with a wide beam to cut the foam.

A bee-shaped laser beam works best because the wider tip provides more power to the foam and helps prevent excessive melting. The laser settings will depend on the thickness of the foam and the power of the laser being used.

Can you cut EVA foam with a diode laser?

foam When it comes to laser cutting foam, it can be a tricky process due to certain materials not responding well to the laser. It’s important to understand the basics of how your laser will react to the foams so you can handle any issues that may arise. In the case of EVA foam, the answer is yes.

You can cut it with a diode laser, but you will need to adjust the settings accordingly. The laser output power should be decreased since the foam is more likely to deform when exposed to a higher output.

Why is my laser not cutting evenly?

foam troubleshooting When laser cutting foam, it’s essential that the cuts are even and precise. However, sometimes the laser may not cut evenly, and there are a few possible causes for this. Let’s take a look at some troubleshooting tips to fix laser cutting foam issues.

The first step is to check the power settings. Depending on what type of material you are cutting, you may need to adjust the power setting to a higher or lower level.

Conclusion

foam Conclusion When troubleshooting laser cutting foam issues, it is important to remember that the most common issue is usually related to the cutting path or the laser’s settings. Many issues can also be related to the type of foam used, the power of the laser and the speed of the cutting process. This can all contribute to an unsuccessful laser cut and should be taken into consideration when making adjustments.

Keep in mind that if the issue persists, the best solution may be to seek assistance from a qualified technician or to purchase a different type of foam that may yield better results.