If you’re looking to learn how to troubleshoot common problems when using a laser cutter, you’ve come to the right place! Laser cutting is an incredible tool for crafting and fabrication, but of course, it can sometimes have issues. Knowing how to quickly diagnose and solve any problems you experience while using a laser cutter can save you time, money, and headaches. In this guide, we’ll go over some common problems and solutions when using a laser cutter.

How to make sure the machine is functioning properly

Explain the importance of testing speed and power settings

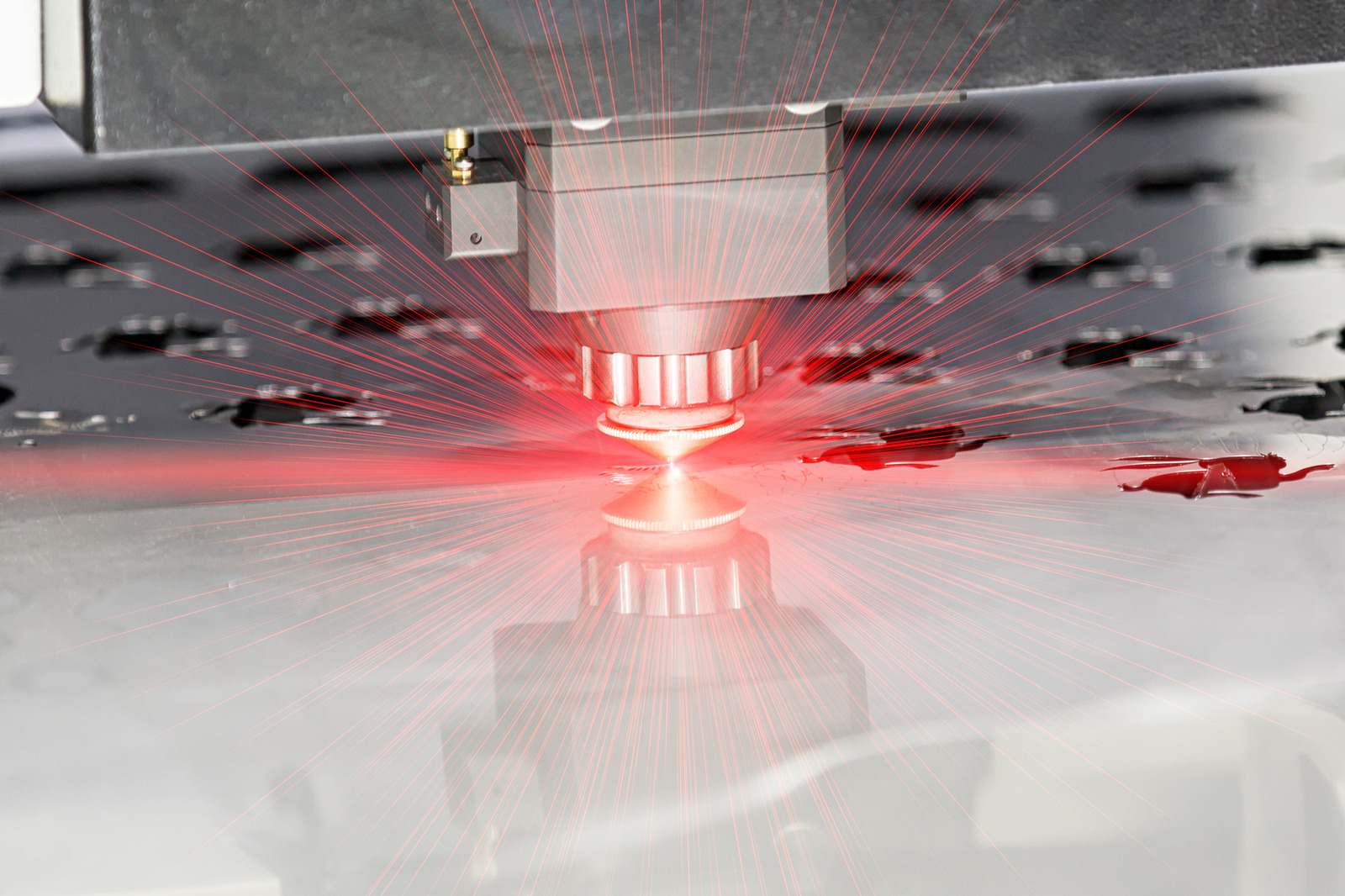

a scrap piece of material The key to successful laser cutting is properly setting the speed and power of the machine. When these settings are off, it can lead to poor results, or even damage to the material being cut. That’s why it’s important to understand and test these settings first before attempting a full cut.

The best way to test speed and power settings is to cut through a scrap piece of material.

Provide instructions for calibrating the laser cutter

a calibrated material to check it is focussed properly When it comes to calibrating your laser cutter, the best way to make sure things are functioning properly is to perform a test cut. This involves getting a sheet of material that is specifically designed to be used for calibrating a laser cutter and placing it into the machine. Your laser cutter will have a test specific button.

You should select this and the machine will then read the pre-programmed settings that has been set for the material you have placed in the laser cutter. It is important to make sure you have picked the correct material setting to ensure that the machine will make accurate and precise cuts.

What material is best suited for laser cutting?

How should materials be prepared for optimal results?

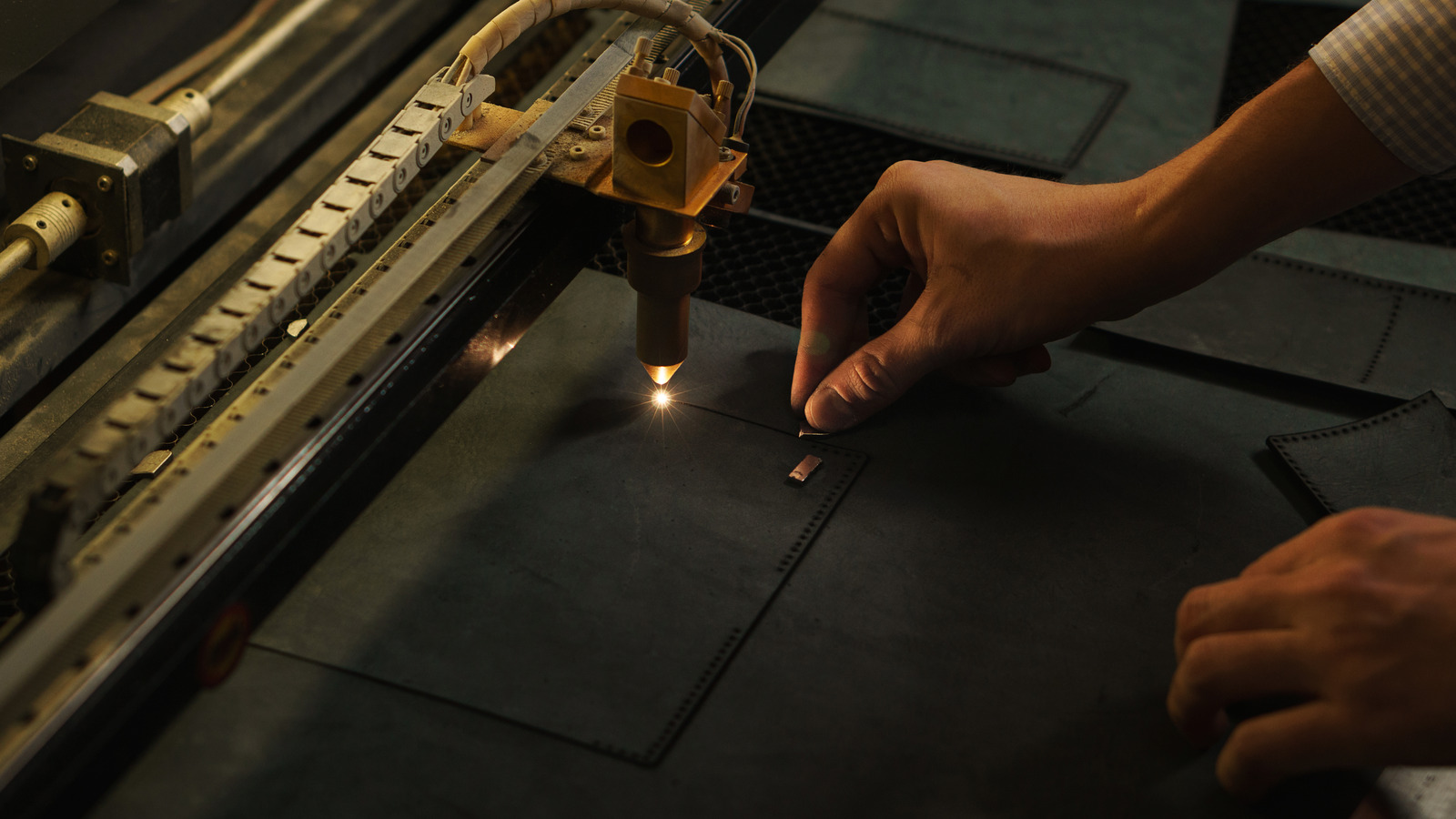

, When preparing materials for laser cutting, it is important to make sure that the material is as flat and smooth as possible. This will help ensure that the laser cutter is able to cut through the material cleanly and efficiently. If the material is not flat and smooth, the laser may jump or skip over portions of the material, resulting in an uneven edge or surface on the cut item.

Tips for using different types of materials (wood, metal, fabric, etc.)

the noise When laser cutting, the type of material you’re cutting will significantly affect the outcome — and depending on the type of material, there are a few different tips and tricks to keep in mind when troubleshooting common problems. Wood: Wood can be a tricky material to laser cut as it can badly char or even catch fire. To prevent this, make sure that you’re using a low power setting, and keep the speed setting low as well.

How to load the materialshints on how to position the materials

Why is it important to create a safe and tidy working environment?

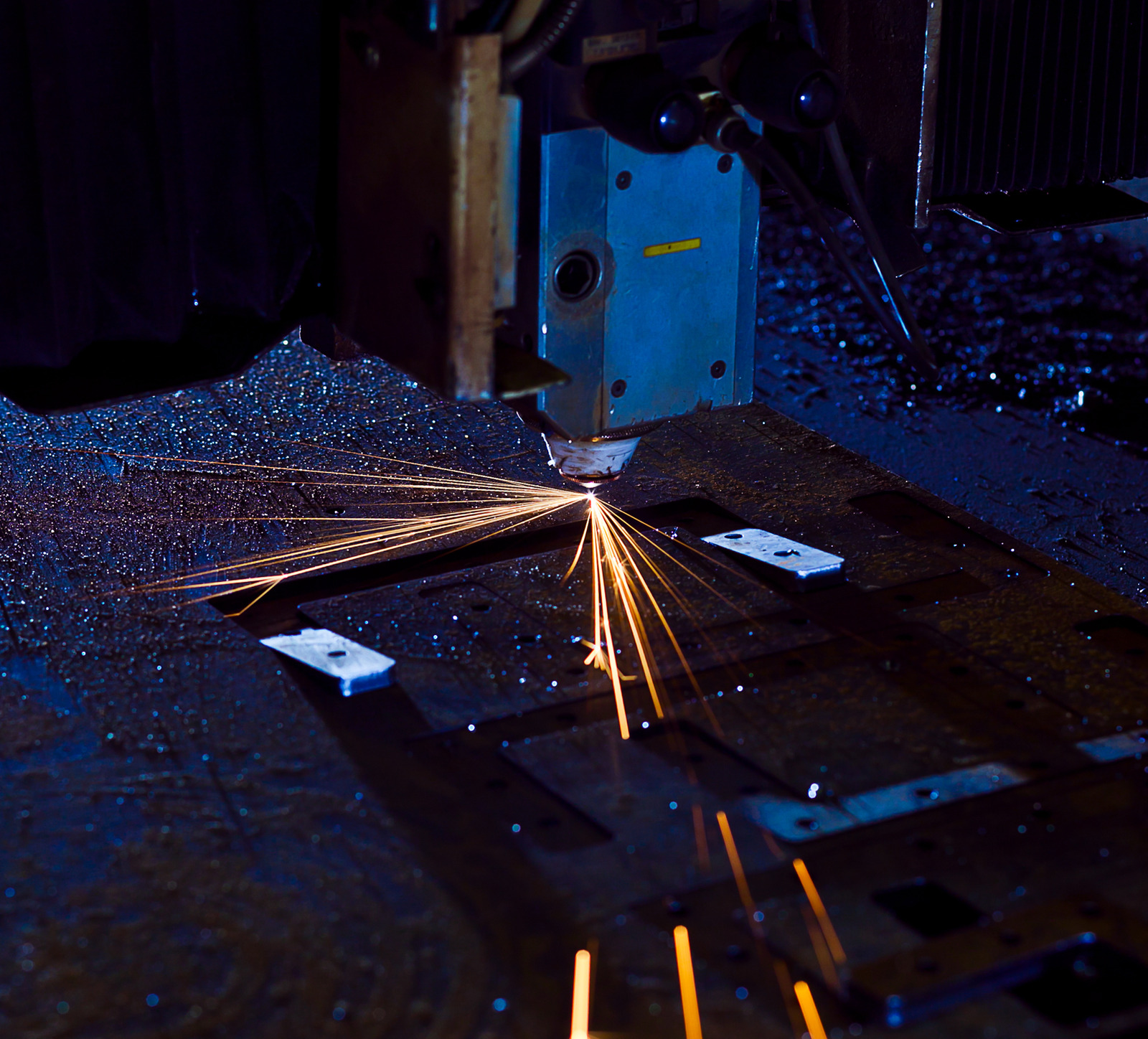

Creating a safe and tidy working environment when using a laser cutter is of utmost importance. Not only do you need to make sure that the area is free of any debris, but also that all of the materials you are cutting with are properly positioned and secured. Without taking the proper safety steps and ensuring that your workspace is clean and organized, you can run the risk of creating a hazardous situation and damaging the laser itself, or even yourself.

When cutting with a laser cutter, you can cut with either marked or unmarked materials.

Give an overview of the general safety rules for using a laser cutter

When using a laser cutter, the first step is loading the materials correctly. Materials should be secured onto the laser cutter bed and supported when possible with bracing materials. Avoid using liquid glue or adhesive tapes as they can cause smoke and fire hazards.

- Wear protective eyewear while operating the laser cutter.

- Make sure the material is positioned correctly to ensure accurate and safe cuts.

- Check the laser cutter’s settings to ensure the laser beam is the right power level and material type.

- Be sure to keep the area around the laser cutter clear of any objects that might be hazardous.

- Ensure that the exhaust fan and air filtration system are working properly in order to avoid smoke or fumes from any materials being cut.

Summarize the key points of troubleshooting a laser cutter

Provide additional resources for people looking for more information

Troubleshooting common problems when using a Laser Cutter is necessary to ensure the machine is working properly and safely. The first key point for troubleshooting is to read through the owner’s manual, as it will have detailed instructions for maintenance and troubleshooting. Common problems that can be fixed include debris buildup in laser optics, file problems, low laser power, air assist problems, and lack of focus.

- Read the instruction manual for your laser cutter thoroughly and understand the safety warnings associated with it.

- Make sure you have the correct type and size of air filter installed that is compatible with the laser cutter’s filter requirements.

- Ensure you are using the right material settings to process and avoid feeding damaged or warped materials into the machine.

- Always check the measurements and adjust them as necessary, as well as keeping an eye on the air flow and alignment of the beam.

- Use a combination of materials, lenses, mirrors, and optics to ensure proper operation of the machine.

- Additional Resources: Laser Cutter Tutorials by Epilog Laser Laser Cutting Basics by Inventables Troubleshooting Prevents Downtime by Trotec Laser Laser Safety for Users by Laser Safety Industries Tips for Trouble-Free Laser Cutting by Additive Manufacturing

Conclusion

a variety of materials with a laser cutter In conclusion, the laser cutter is an incredibly useful tool for cutting through a variety of materials. It’s a great way to make intricate and complex projects quickly, and with accuracy. However, like any tool, laser cutters can experience problems from time to time.