Welcome! Whether you are new to the world of laser cutting and engraving machines or you have been using them for a while, you may have encountered issues along with the way. This guide is designed to help you troubleshoot common issues when it comes to these laser machines, allowing you to use them efficiently and for longer periods of time. Let’s get started!

Identifying and Understanding the Problem –

Diagnosing and Troubleshooting Techniques

Diagnosing and troubleshooting techniques for laser cutting and engraving machines can be a complicated process. Having an understanding of the most common problems and their causes makes the task much easier. While each individual machine type or model may have its own particular issues, there are some common problems of laser engraving machines that cause the majority of service calls.

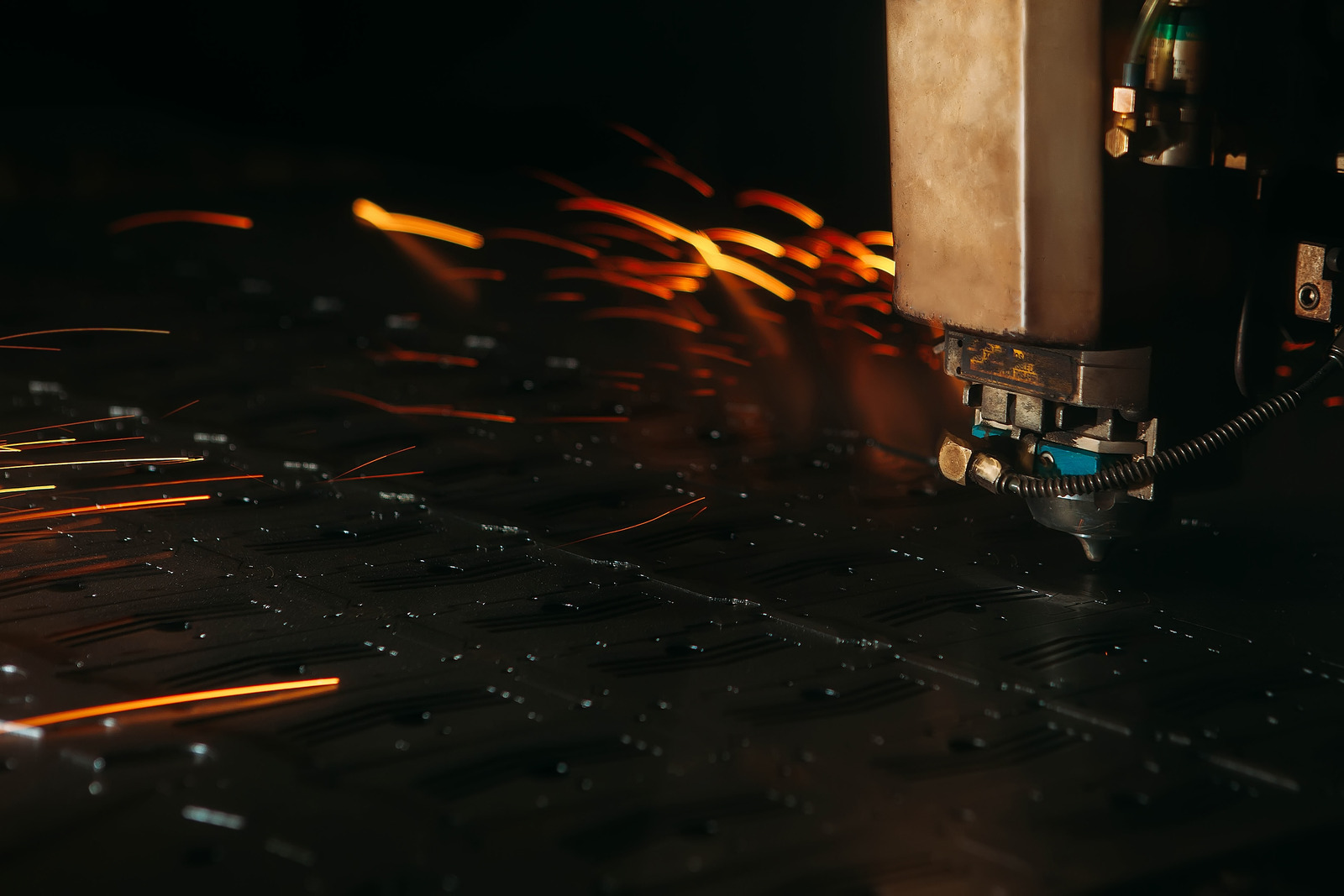

One of the first common issues is related to the cutting/engraving head.

Start with the Basics

The first step to troubleshooting common issues with laser cutting and engraving machines is to start with the basics. Before attempting to identify and understand the problem, it is important to ensure that all basic operations are functioning correctly. Things to check include the overall power supply, the power switch is on, and the ventilation system is working.

If there is an issue with any of these, this must be addressed before moving on with fixing any of the other issues. Next, it is essential to inspect the machine itself.

Analyze the Source of the Problem

When troubleshooting common issues with laser cutting and engraving machines, it is important to identify the source of the problem in order to effectively resolve it. In most cases, the problem is caused by an inexact calibration, incorrect settings, machine malfunctions, or a combination of these issues. The most common problems experienced with a laser engraving machine are generally related to the machines calibration, settings, or internal hardware malfunctions.

Calibration: The laser head, material holder, and spindle must be correctly aligned.

Common Issues and Their Solutions –

Power Problems

Power problems are some of the most common issues you’ll encounter when troubleshooting a laser cutting and engraving machine. In most cases, there is an issue with the power source or the settings of the machine, so there are numerous things you should check before ruling out a power problem. The first thing to check is the type of power supply.

Heat Problems

Heat Problems are one of the most common issues experienced when working with laser cutting and engraving machines. Heat problems can affect the engraving and cutting capabilities of a machine and can be caused by a number of different factors. One of the most common causes of heat problems is the machine being overworked.

If a machine works continuously for long periods of time, it can generate a lot of heat. This can cause issues such as the bed and frame heating up, the material getting hot and deforming, and the mirrors and lens becoming distorted due to the excess heat. Another cause of heat problems is poor ventilation in the area surrounding the machine.

Software Problems

Software issues with laser cutting and engraving machines can be one of the most challenging to diagnose and troubleshoot. Common software issues can be solved by ensuring the machine is properly calibrated and the laser focusing lens is set correctly. Additionally, if using a computer for the machine, make sure all program software and drivers are updated to the latest versions.

- Make sure the correct software program is being used to control the machine. Most laser cutting and engraving machines have specific software, so it is important to make sure that it is compatible and up to date.

- Ensure a stable and reliable internet connection. Many machines communicate with the software over the internet, so it is important to make sure there are no interruptions in the connection.

- Verify that all settings and parameters are correct. This includes checking the origin point, laser power, speed, frequency, and more.

- Check for any loose data cables or connections. It is important to make sure that all connections are secure and no data is being lost due to a faulty connection.

- Make sure the software is properly configured. Make sure the software is set up the way it should be, as incorrect configurations can cause errors.

Laser Beam Issues

When it comes to laser cutting and engraving machines, there are a few common issues that occur that can hamper the efficacy of your machine. Although some issues can be complex and require professional assistance to diagnose and resolve, there are some common problems that can be troubleshooted by yourself with relative ease. The first of these common issues involves the laser beam, which is the primary mechanism by which a laser cutting or engraving machine works.

Special Considerations –

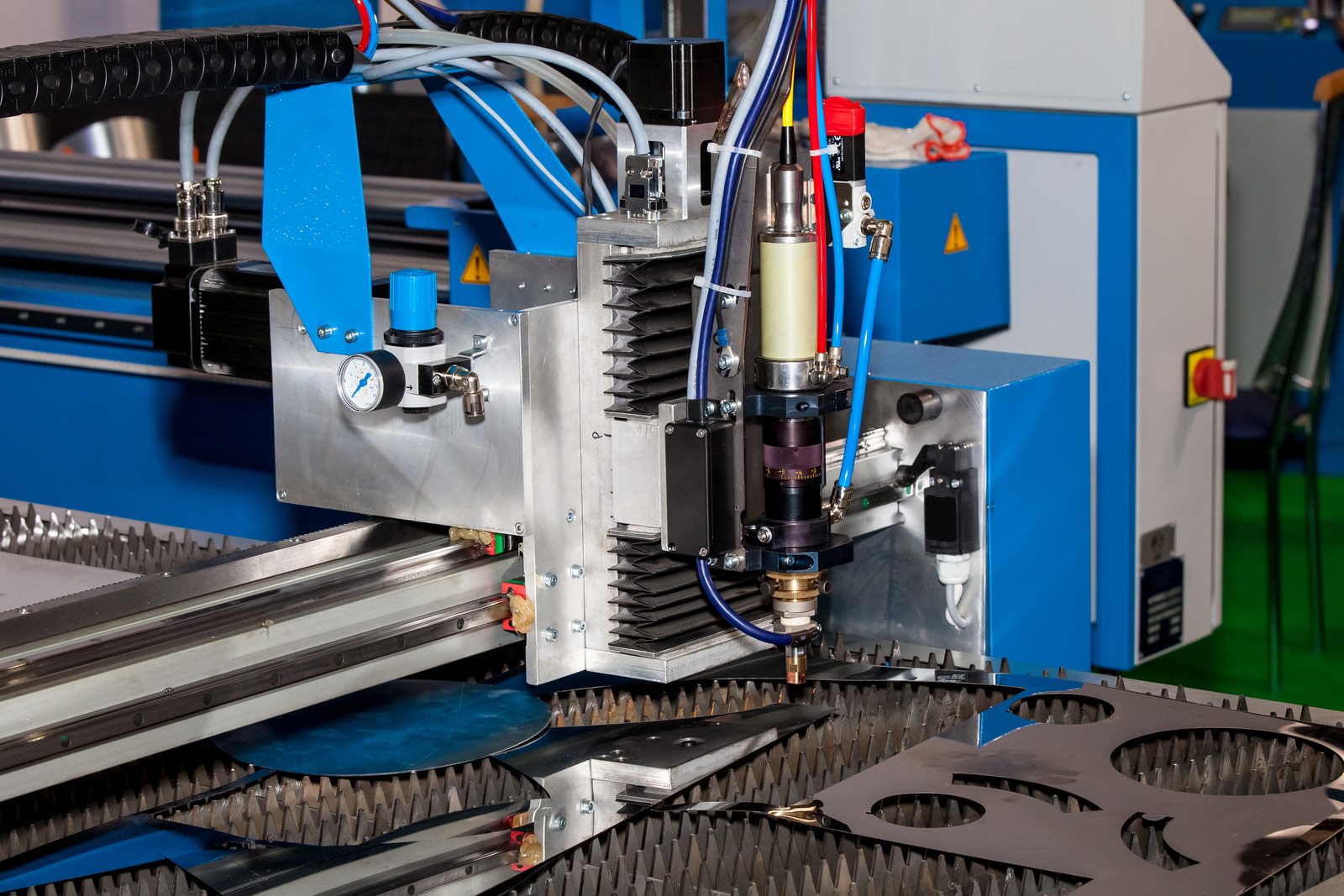

Types of Machines

When it comes to troubleshooting common issues with laser engraving and cutting machines, it is important to understand the different types of machines and their inherent capabilities. Depending on the specific needs of the project, different types of laser engraving and cutting machines may be better suited than others. While there are a wide range of laser engraving and cutting machines available on the market, there are a few key categories that all machines fall into.

Safety

When it comes to laser cutting and engraving machines, safety should be your top priority. Laser engraving machines use powerful lasers, which can cause severe injury or even death if not operated correctly. Before using one of these machines, it is important to understand the risks and take all necessary safety precautions.

One of the most common problems associated with laser engraving machines is the potential for burns. Although the beam of light is not very powerful, it still has the potential to cause serious damage to exposed skin and eyes. Therefore, it is important to wear protective eyewear and gloves when operating any laser engraving machine.

Conclusion –

Summarizing Common Issues With Laser Cutting and Engraving Machines

At the end of this blog section, it is important to sum up the common issues experienced by users of laser cutting and engraving machines. The most commonly reported issues with laser cutting and engraving machines are that the laser lines are not uniform, the engraving speed is too slow, and that the laser power output is not adequate. Additionally, users may also experience technical difficulties due to improper setup and maintenance, as well as mechanical problems caused by worn out or defective parts.

To properly troubleshoot these issues, it is important to first test the machine’s settings and calibrate its laser power.

Pros and Cons of Using Machines

Concluding our blog topic of troubleshooting common issues with laser cutting and engraving machines, we’re going to look at the pros and cons of using machines for laser engraving. Laser engraving machines offer a wide range of advantages for users, including speed and accuracy. They are capable of engraving or cutting any material or shape, have minimal material waste, and require minimal setup and training.

At the same time, using laser engraving machines has its pitfalls.

Why is my laser engraver skipping?

When using a laser engraving machine, it’s important to remember that any minor problem can have a major impact. One of the most common issues with these machines is skipping. It can be caused by a number of different possible factors, which can range from the mild to the serious.

The first step in troubleshooting any problem with a laser engraving machine is to double-check the equipment and make sure that it is in good working order. This includes checking for any signs of wear or damage, and making sure that all the parts are functioning properly.

Conclusion

Conclusion: Troubleshooting common issues with laser cutting and engraving machines can be a difficult and time-consuming process. However, with a better understanding of the underlying mechanisms of these machines, it is possible to identify and correct the most common issues. In this article, we have explored some common problems encountered with laser engraving machines, including defects in cutting, engraving and design, power supply issues, and safety considerations.