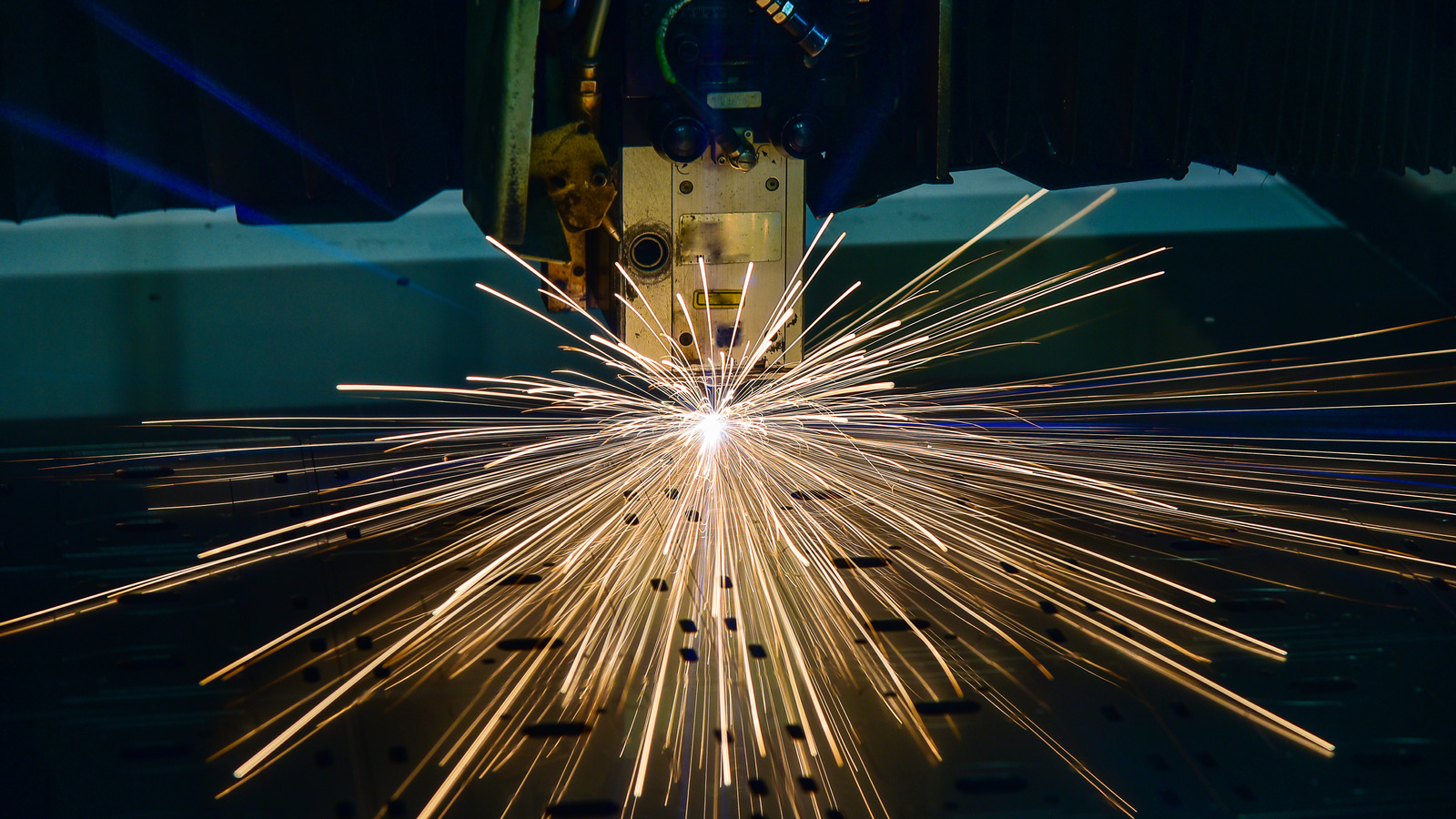

Lasers are becoming increasingly popular for their versatility and precision in creating detailed cutting designs. Lasers have so many potential applications, including being used to cut quartz. Quartz is a particularly hard material that can be difficult to work with using traditional cutting methods, making lasers the ideal choice for many quartz cutting projects. In this article, we will explore the top uses for lasers to cut quartz and how this process can improve your project.

Types of Lasers Used to Cut Quartz

Overview of different laser types

quartz When it comes to laser cutting quartz, there are several different types of lasers that can be used. Each type has its own advantages and limitations, depending on a variety of factors like the size, thickness, and type of quartz. The most common types of laser used for cutting quartz include CO2 (carbon dioxide), Nd:YAG/Nd:YVO4 (neodymium-doped yttrium aluminum garnet/neodymium-doped yttrium vanadate), and excimer.

Comparison of laser properties and efficacy

quartz When it comes to cutting quartz, one of the most accurate and precise methods is laser cutting. The process can be used to create intricate designs, smooth cuts and complicated shapes with ease. There are several different types of lasers that can be used for quartz cutting, each with their own unique characteristics and requirements.

CO2 lasers are one of the most popular and widely used lasers for cutting quartz.

Benefits of Using Lasers to Cut Quartz

Accuracy and precision

quartz When it comes to accuracy and precision, lasers are a great choice to use when it comes to cutting quartz. When quartz is cut, precision is essential and lasers provide this accuracy. Lasers use a focused beam of light that is extremely precise, meaning that you can get extremely accurate cutting of quartz without damaging the material or leaving any rough or jagged edges.

This process is much faster and more efficient than traditional methods of cutting quartz, such as sawing or grinding.

Low impact on environment

quartz When it comes to cutting quartz with lasers, one of the main advantages is that it is low impact on the environment. Traditional methods of cutting quartz use hazardous acids and other toxic substances, making them unsafe to both use and dispose of. Lasers offer a much cleaner alternative, without any negative impact on the environment.

With a laser cutter, no harsh chemicals or materials need to be released into the environment, meaning it is an eco-friendly process. Additionally, lasers do not generate heat, so no dangerous materials are released into the air during the cutting process, unlike with traditional methods. The laser process is also quite efficient in terms of energy consumption, making it a cost-effective solution.

Low risk of damaging the quartz

quartz Using a laser to cut quartz has a number of advantages and one of the most important is that it has a much lower risk of damaging the quartz compared to other methods. Conventional methods, such as sawing and drilling, often cause fracturing and chipping due to the intense forces involved. Even manual cutting with a diamond blade has its risks, as the quartz material tends to chip and shatter easily when handled improperly.

Top Uses for Laser-Cut Quartz

Jewelry making

quartz Lasers have revolutionized how quartz is used for jewelry making. Laser cutting quartz has many uses, including the creation of intricate details for unique designs and cabochons for detailed designer pieces. One of the most common applications of laser-cut quartz is in the formation of highly precise bezel settings.

Lasers can accurately create the intricate shapes needed to provide a secure fit for semi-precious and precious gems. Laser cutting quartz is also commonly used to create earring posts and studs, as well as creating curved shapes to fit the contours of rings and bracelets.

Tools manufacturing

quartz Laser cutting is an advanced technology used to cut and shape many materials, including quartz. It relies on a powerful beam of light to heat up and harden the material, which allows for precise and accurate cuts. The great benefit of using lasers for cutting quartz is that it provides a clean and uniform cut with minimal waste.

This makes it a perfect tool for engineering and manufacturing industries. Tools manufacturing industries are particularly well-suited to benefit from laser cutting quartz. Using this method, intricate and precise parts can be rapidly produced, depending on the requirements of the product.

Artwork production

quartz Artwork production is one of the top uses for lasers to cut quartz. Quartz is a unique material that can be formed into virtually any shape and size, making it an ideal material for creating intricate designs and patterns. Its hardness and ability to withstand high temperatures also make it especially suitable for laser cutting.

A laser cutting machine operates by focusing a high-powered light beam, usually at the wavelength of an infrared ray, onto the quartz material. The material is then vaporized, cutting it with incredible precision and accuracy. This can create intricate artwork on quartz, with the laser being able to cut perfectly straight lines or delicate curves or shapes.

Where to Find Laser-Cut Quartz

Overview of laser-cut quartz suppliers

quartz Laser cutting is a powerful and precise fabrication process that uses a highly concentrated beam of light to cut Quartz. Laser cutting quartz makes it possible to create intricate patterns and cut pieces with perfect accuracy. It’s a popular choice of technology for creating intricate shapes and cutting pieces of quartz into exact size and shape specifications.

There are a few different types of lasers used in laser-cutting technology.

Tips for selecting the best supplier

Lasers are a great tool to use for cutting quartz, allowing for precise and accurate cuts with minimal material waste. One of the top uses for laser-cutting quartz could be the construction of quartz watches and jewelry, which require precision in their parts and components.

- Consider the types of laser cutting technology used – make sure the supplier you are choosing is familiar with the type of quartz you will be using.

- Check customer reviews for the supplier’s products and customer service – this will help you get a better understanding of quality, responsiveness, and dependability.

- Ask the supplier for samples of their laser cut quartz before committing to a purchase – this is a good way to decide if the quality is what you want.

- Consider the cost of the service provided – this includes the price per cut, the turn around time, and any additional fees.

- Make sure the supplier offers laser cutting services suitable for the commercial, industrial or medical uses you have in mind – Additionally, confirm that the supplier adheres to all safety regulations necessary for working with quartz.

Conclusion

Summary of the uses for laser-cut quartz

quartz In conclusion, lasers are a powerful tool for cutting quartz. They are precise, accurate and capable of creating intricate designs. Depending on the project, quartz can be cut with different types of lasers.

CO2 lasers are best for cutting thicker quartz such as those used for architectural projects and higher-end jewelry production. Nd:YAG lasers are ideal for cutting finer pieces of quartz, such as those used in medical and scientific applications. Laser etching is also an effective way to customize quartz pieces with unique designs and symbols.

While there are many other uses for lasers to cut quartz, these are some of the most commonly-used applications.

Summary of the benefits of using lasers to cut quartz

quartz Conclusion Using lasers to cut quartz has a range of advantages. Laser cutting offers fast, precise cuts with less debris buildup and lower thermal impact. The process itself is highly automated, allowing complex cuts to be made with minimal effort.

Furthermore, laser cutting is a cost effective method, saving money on traditional machining and cutting processes. Lasers are also relatively easy to maintain and require little input energy, meaning that operations can continue for extended periods of time without interruption. Overall, laser cutting offers an efficient and cost-effective solution for quartz processing.