Creating really cool crafts and DIY projects can be made so much easier by using a laser cutter. The precision and speed of laser cutting gives you the ability to take any type of material and make amazing things with it. In this article, we’re going to cover some great tips for laser cutting foam for DIY crafts. Learn how to get the perfect cut in any type of foam and how to make sure your project comes together quickly and perfectly.

Safety

Safety Precautions

When laser cutting foam, safety should be your top priority. Even though laser cutting might seem like a straightforward and simple process, there are a few safety precautions to keep in mind. To protect yourself and your craft projects, follow these important tips.

First, always wear protective gear. Laser cutting foam produces a lot of smoke and other particulate material, which can be hazardous if inhaled. Goggles, a full face shield, and gloves should be worn when operating the laser cutter.

Proper Protective Gear

DIY crafts When you’re laser cutting foam for DIY crafts, it’s important to take safety precautions to protect yourself. One of the most important items you need to wear are safety goggles and a protective face shield. The bright light from the laser can be extremely harmful to your eyes, so these should always be worn while you’re operating the laser cutter.

Techniques

Design Creation

Design Creation when it comes to laser cutting foam for DIY crafts can be a tricky process – but with the right tools, tips, and techniques you can create beautiful, intricate designs. The first thing you’ll need to do is decide on your design. This could be a logo, a pattern, a saying, or anything else you can come up with.

It’s important to keep the design simple, so that the laser cutter can easily understand and create your masterpiece. Once you’ve established the design, you can think about making some tweaks so that it comes out perfectly.

Setting the Correct Power and Speed Settings

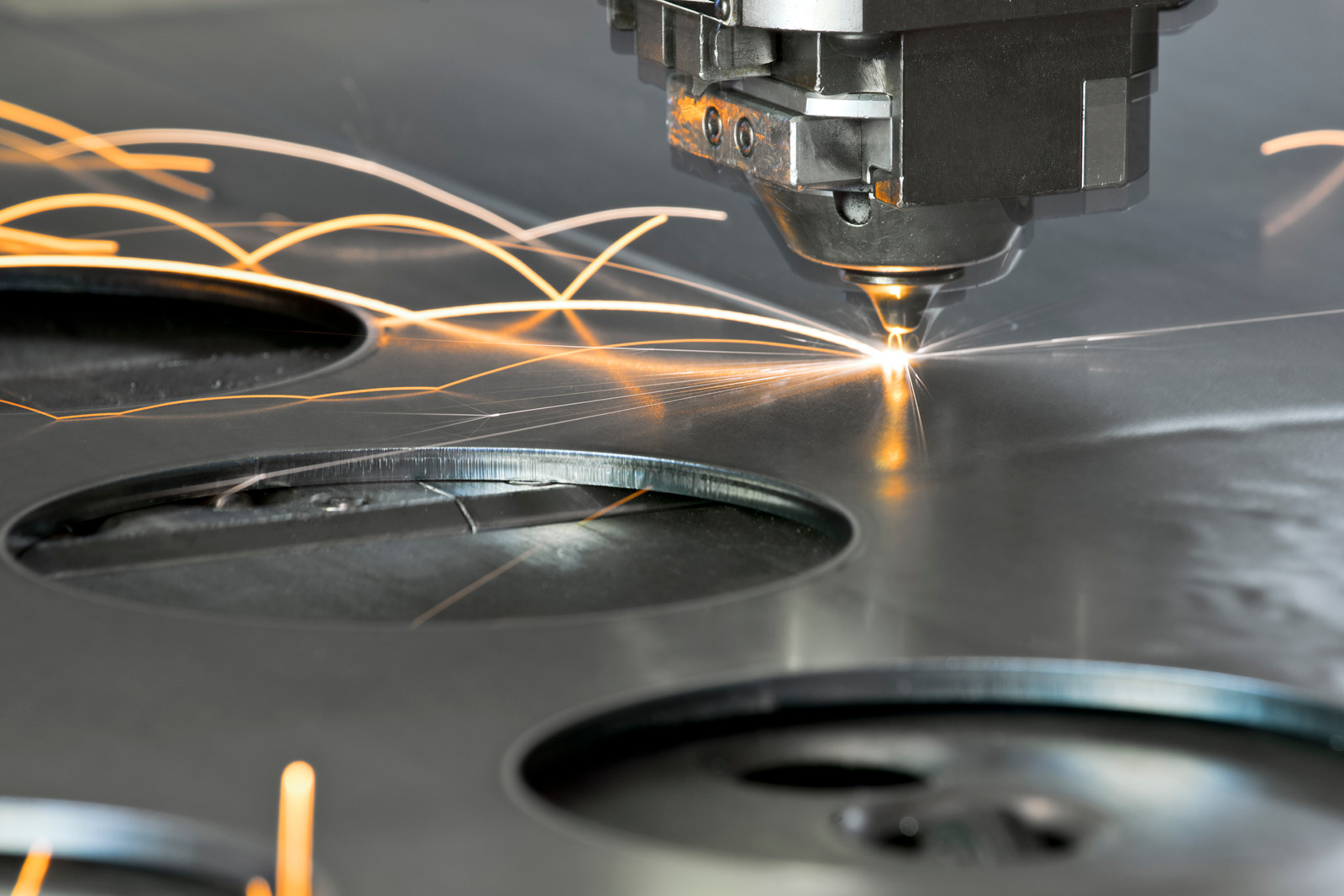

When laser cutting foam for DIY crafts, it is essential to get the right power and speed settings. The best way to achieve optimal results is to experiment on scraps before cutting your finished piece. When selecting the power and speed settings, the starting point is to adjust the power according to the size and durability of the foam material.

If the material is thin and soft, start at a low power setting between 20%-50%.

Equipment

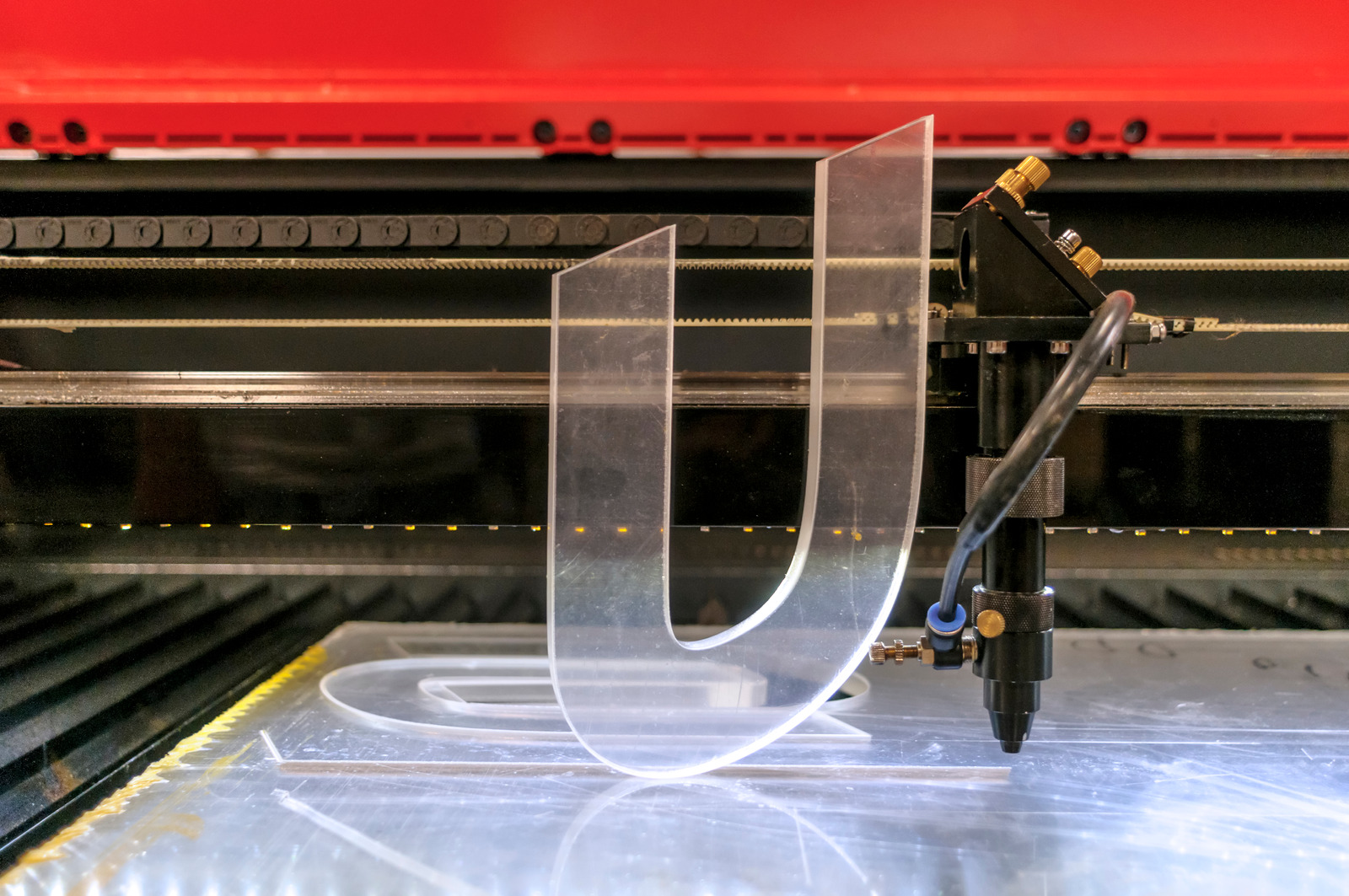

Selecting the Right Laser Cutter for Foam

When it comes to selecting the right laser cutter for foam, there are several things to consider. First, the type of foam you’re working with will determine the wattage requirements of your laser cutter. For example, if you’re working with a soft foam, like a craft foam or packaging foam, a 1000-2000 watt laser cutter should be sufficient.

For harder foams, such as rigid urethane, you will need a laser cutter with 4000+ watts of power.

Maintaining a Clean Work Area

craft When it comes to laser cutting foam for DIY crafts and equipment, maintaining a clean work area is a must. There are a few important tips to keep in mind when working with this material. First, be sure to always wear safety goggles and, if possible, a full face shield while operating the laser cutter.

You should also pay attention to the layout of your workspace and ensure there is enough clearance between any potential obstructions and your laser cutter. Additionally, make sure to use a dust vacuum or fume extractor to keep your area clean and breathable. Lastly, it’s important to store your materials in a safe place, as some foam materials can be sensitive to temperature and humidity.

Finishing Tips

Adding Texture and Color

DIY crafts When it comes to adding texture and color to laser cut foam for DIY crafts, the possibilities are virtually endless! There are a variety of options that can be used to texturize, dye, or paint your foam pieces. One popular method for texturizing your foam is to sand the edges with a variety of sandpapers ranging from coarse to fine.

A coarse paper will leave a more prominent, noticed texture, while a finer one will provide more subtle and precise details. You can also use metallic markers to give your pieces extra highlights. Dying or painting your foam is also an option.

Sealing the Foam

Sealing the Foam When it comes to finishing your laser cut foam, one of the most important steps is sealing it. Sealing the foam will not only help protect it from the elements, but it will also give your project a nice, finished look. There are a few different ways to seal foam, but one of the most popular methods is to use a spray-on foam sealant.

The sealant will provide a thin, protective layer over the foam, helping to prevent it from warping due to moisture or heat.

Can you laser cut craft foam?

Yes, you can laser cut craft foam for DIY projects. This is a great way to add detail to your crafts, as laser cutting offers many more design possibilities than traditional cutting techniques. Laser cutting foam can also create intricate and intricate shapes that would be difficult or impossible to achieve with hand cutting tools.

The process of laser cutting foam is relatively simple. You need to start with the right foam material. Most foam sheets used for crafts are lightweight and relatively easy to cut, though other more dense types may be laser cut as well.

What kind of foam can you cut with a laser?

Cutting foam with a laser cutter is a great way to get a precise and professional looking result for your DIY crafts. But not all foams will cut the same on a laser cutter–so it’s important to choose the right one for your project. The type of foam that can be cut with a laser typically includes EVA foam, Styrofoam, and similar materials.

EVA foam is a type of synthetic rubber foam–it’s often used in sports and martial arts padding, and provide a nice, cushy feel with a little bit of give and bounce.

How do you cut foam for crafts?

Using a laser cutter to cut foam is a great way to make intricate craft projects with precision and accuracy. Whether you’re looking to make a 3D model or create a custom cushion, laser cutting gives you the flexibility to create a wide variety of shapes, designs, and patterns. To laser cut foam, you’ll need a laser cutting machine, the right type of foam, and the right laser settings.

Depending on the size and complexity of your project, you may also need a workbench and a few other tools.

Conclusion

Closing Remarks

In this blog, we’ve explored the ins and outs of laser cutting foam for DIY crafts. We discussed the best types of foam to use, tips for prepping the foam and equipment setup, and considerations to ensure a successful project. In closing, here are a few tips to remember when laser cutting foam: * To avoid smoke and a ragged cut, use a smooth, clean foam with no impurities.

* Whenever possible, do some test cuts on scrap foam so you can adjust the settings accordingly. * Make sure your equipment is properly set up and maintained, and that your laser is properly calibrated for foam cutting.

End of Post Questions for Readers

At the end of this blog post, we’d love to hear your thoughts and opinions on using laser cut foam for DIY crafts.