Are you interested in taking your leathercrafting to the next level with laser cutting? Laser cutting leather can seem intimidating, but don’t let that stop you – with the right materials, some practice, and a few easy tips, you can become a pro at laser cutting leather quickly! In this article, we’ll provide you with the knowledge you need to get started with laser cutting leather.

Prepare the Leather

Explain the importance of properly prepping the leather before cutting

leather When it comes to laser cutting leather, properly prepping the material is vital for a successful cut. If the leather is not properly prepared, laser engraving can be uneven and may even cause damage to the leather. Preparing the leather before laser cutting creates the perfect surface for a neat and even cut.

One of the most important steps in prepping leather before laser cutting is to clean the surface.

Discuss the different tools that can be used to mark the leather

leather When it comes to laser cutting leather, there are a few different tools that can be used to mark the leather. A few of the most commonly used tools are a mechanical or electric rotary engraver, a laser engraver, and a CNC (computer numerical control) router. Mechanical or electric engravers are the oldest type of leather-engraving tools and are still used today.

Give advice on how to properly size the leather before cutting

leather When it comes to laser cutting leather, it’s important to properly size the leather before you begin cutting. To size the leather, first measure your leather piece by cutting a square or rectangle that is slightly larger than the size of your laser cutting project. You can also mark any desired cutouts or patterns that you would like to create on the leather.

Once you have your measurements and marks set, double check them to make sure they are accurate and make any necessary adjustments.

Setting Up Your Laser Cutter

Discuss the components of a laser cutter

Getting started with laser cutting leather can be a daunting task, so it’s important to understand the different components of the laser cutter before getting started. Generally, most laser cutters come with three essential components: the laser head, the bed, and the controller. The laser head is the most critical portion of the laser cutter, as it’s responsible for cutting or engraving the leather.

Describe the different types of laser cutters available

When it comes to cutting leather, there are a variety of laser cutters that can be used, depending on what your needs are. Generally, laser cutters are broken down into three main types: CO2 laser cutters, Nd:YAG laser cutters, and Fiber lasers. CO2 laser cutters are the most common type and use infrared laser beams to cut through materials.

They are often used for engraving and cutting various materials, including wood, plastic, acrylic, and fabric.

Explain how to properly set up the laser cutter and adjust the settings for leather

Setting up a laser cutter and adjusting the settings for cutting leather requires special knowledge and attention to detail. If done properly, it can produce stunningly intricate and detailed results. Firstly, you need to choose the right type of laser cutter for the job.

Most laser cutters are designed for use with thin materials such as fabric or thin wood, but for thicker materials such as leather you’ll want to use a laser cutter with a higher power output. bear in mind that laser cutters can be dangerous to operate and should never be used without the correct safety equipment.

Cut the Leather

Explain the process of laser cutting leather

When it comes to tackling a new and exciting project, laser cutting leather can be a great way to add intricate details to the design of your project. With a laser engraver, you can cut and pattern the leather in whatever manner you choose for a beautiful results. The first step to laser cutting leather is to prepare the materials.

You will need leather that is at least 2 mm thick, as well as a cutting surface, such as a cutting mat or fabric. It is important to make sure the material is clean and free from dust or dirt before cutting.

Give detailed instructions for the actual cutting process

Cutting leather with a laser is a great way to create intricate designs and patterns with precision and accuracy. It’s faster than traditional methods and provides great results. Before getting started, it’s important to prepare the leather by cleaning and conditioning it.

This ensures that the leather will cut cleanly and that the cuts are even. Once the leather is prepared, the laser cutting process can begin. First, the design of the leather should be determined.

A template or vector design can be used, or a more intricate design can be created in a vector graphics editor like Adobe Illustrator.

Suggest tips for getting the best results and avoiding mistakes

When getting started laser cutting leather, it is important to be well prepared before beginning. Start with a good quality leather, and make sure it is properly conditioned and sealed with a protective product to prevent it from burning during laser cutting.

- Start by creating templates on paper. This will help you create a plan of action and make sure everything fits together properly. You can also experiment with different shapes and designs to find what works best.

- Choose your leather carefully. You should buy the best quality leather you can find. Also, make sure to accurately measure the leather you need to cut so that the design fits together properly.

- Make sure to use the right laser settings for cutting leather. The settings will depend on the type of leather you are cutting.

- Don’t forget to use a specialized leather cutting blade for the laser. This will ensure that the leather cuts correctly and precisely.

- Take the time to practice cutting leather on scraps first before trying to cut the final product. This will give you a better idea of what can be achieved and the best settings to use. It can also help you avoid mistakes when cutting the final product.

Summarize the main points of the article

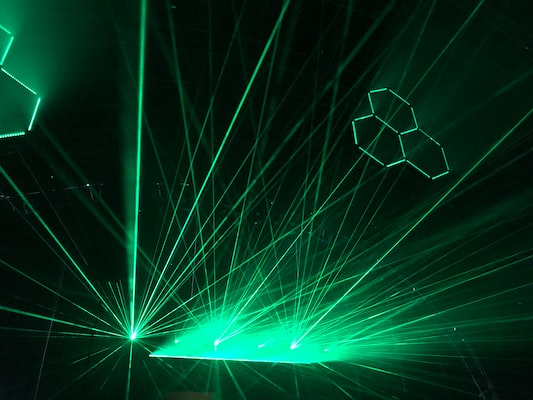

The article “Tips for Getting Started with Laser Cutting Leather” provides a concise overview of the process of laser cutting leather. The article provides an overview of the various tools and equipment available for laser cutting leather as well as tips on getting started. It explains that the process typically consists of first designing a pattern with a computer-aided design (CAD) program, then selecting the right type of leather and materials, and finally executing the laser cutting process itself.

It also emphasizes the importance of safety by recommending the use of protective eyewear.

Encourage the reader to explore different

When you’re ready to get started with laser-cutting leather, it’s important to explore different options and techniques before jumping in. The key is to understand the basics and implications of laser-cutting leather before investing resources into the project. First, it’s important to consider the type of leather you’d like to use for the project.

Can you use a laser cutter on leather?

Yes, you can use a laser cutter on leather! Laser cutting is a popular option for working with leather because of its precision and cleanliness. It is a very precise way of working with leather because the laser can be exquisitely directed towards the exact location where cuts need to be made, giving you the ability to make intricate cuts with ease.

Laser cutting is also a great way to add interesting details and textures to leather, such as decorative holes, patterns, and other etchings. It is important to note that laser engraving a different process than cutting, although it is used on leather just as often as cutting.

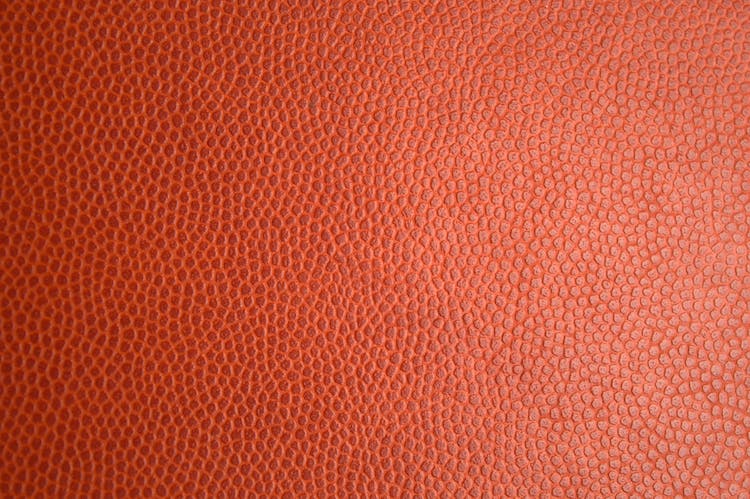

What type of leather is best for laser engraving?

When it comes to laser cutting leather, the type of leather you use will make all the difference. The fiber content, thickness, and grain of the leather can all impact the outcomes of your laser engraving project. Firstly, look for leather that is made from a natural fiber like cowhide, bison, or deer hides.

Many synthetic leathers can be too thin and contain plastic polymers that won’t engrave as easily, or quickly, as natural fibers. You should also consider the grain of the leather.

Should you wet leather before laser engraving?

When it comes to laser cutting leather, there is debate around whether or not you should wet the leather before laser engraving it. Some people believe that wetting the leather beforehand helps ensure a crisper, cleaner cut, while others think it can cause a lot of damage to the leather or even cause the laser to burn it too much.

Conclusion

The conclusion to getting started with laser cutting leather is to practice and do some research. It’s important to remember that laser cutting leather is an incredibly delicate process and it can take some time to perfect. There are many tricks and techniques you can learn, such as ensuring the leather is properly “tanned” or conditioned before cutting, to get the best results.

It’s also recommended to make a few sample cuts to test out the settings before starting a bigger project.