Welcome to The Ultimate Guide to Using a Laser Cutting Key Machine. In this guide, we will help you understand how to use a laser cutting key machine in order to produce accurate and reliable results. We will explain the different types of machines, their features, and how to operate and maintain the machines properly. We will also explain the benefits of using laser cutting key machines and how to choose the right machine for your needs. This guide will provide you with everything you need to know about laser cutting key machines. So let’s get started!

Getting Started

Types of laser cutting key machines

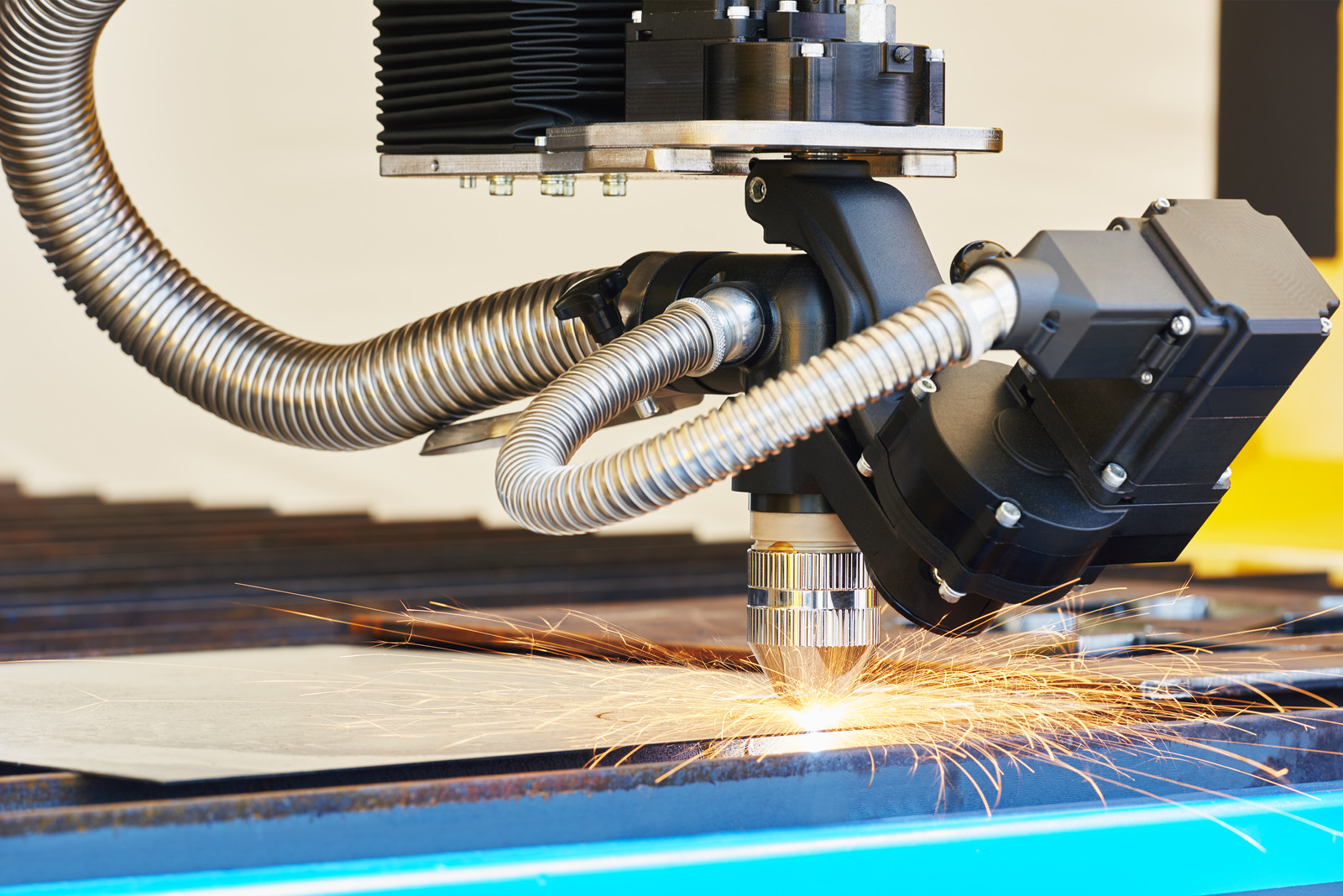

The ultimate guide to using a laser cutting key machine begins with understanding the different types of machines available. Laser cutters are the most common type of machine used for key duplication. They employ a high intensity laser beam to cut or engrave material.

Laser cutting machines come in a range of sizes, from small desktop units to large full-scale industrial machines. The cutting process is driven by a computer-controlled software, with the user controlling the overall design and cutting process via a user interface.

Necessary tools and materials

When it comes to using a laser cutting key machine for your key making projects, one of the most important things you will need is the right tools and materials. To make sure that you get the best results when working with a laser cutter, make sure to have the following on hand: Firstly, you’ll need a laser cutting machine. Laser cutters come in a variety of types and sizes, so it’s important to find the one that is best suited to the project you’re working on.

Next, you’ll need the appropriate material for your project.

Key Machine Set-Up

Equipment assembly

setup When it comes to assembling a laser cutting key machine, it can be intimidating and overwhelming trying to figure out the ropes. However, with the right instructions, the right tools, and the right settings, anyone can be a master of their key machine set-up in no time. The great thing about laser cutting key machines is that they’re both versatile and precise.

With a laser cutting key machine, you can cut a wide variety of different materials with just a few clicks of a button.

Proper alignment of machine

setup When you’re setting up a laser cutting key machine, it’s essential to ensure proper alignment. Aligning your machine correctly ensures that the laser performs accurate cuts and that the cutouts are perfectly shaped. For this reason, proper alignment is very important when working with a laser cutter.

The first step in alignment is making sure that all four of the machine’s axes– x, y, z, and the spindle– are level. This usually requires an adjustable stand or a spirit level.

Expert Tips

Speed and accuracy of cut

machines Using a laser cutting key machine comes with many benefits–it’s accurate, fast and reliable, which makes it an ideal tool for a variety of cutting and engraving tasks. When it comes to speed and accuracy of cut, laser cutters are the go-to solution for many professionals like locksmiths, makers, and hobbyists alike. If you’re ready to invest in the ultimate guide to using a laser cutting key machine, you’re probably wondering what makes it so fast and accurate.

Different styles of cutting

When it comes to using a laser cutting key machine, there are several different styles of cutting available. Each style offers different benefits and drawbacks, and knowing which one is best suited to your needs is important. The most common type of laser cutting is called CO2 laser cutting.

A laser beam is fired into an oxygen-rich environment, which heats the material to be cut, allowing it to be melted through with an extreme degree of precision. This method is best suited to smaller material, such as key blanks, as it can cut through curves with ease.

Key Cutting Techniques

Pre-cutting key preparation

Pre-cutting key preparation is one of the most important steps when using a laser cutting key machine. This step sets the foundation for successful key cutting and the final product. When using a laser machine there are several items that need to be taken into account before beginning the cutting process.

First and foremost, the key blanks should be trimmed to the correct size based on the specifications of the particular machine. Key blanks that are too small could cause problems during cutting and will give a poor finish. The next step is to ensure that all cutting surfaces are clean and free of debris.

Step-by-step instructions for cutting duplicate keys

Cutting duplicate keys with a laser cutter is surprisingly easy and invites a number of advantages over traditional methods. This ultimate guide to laser cutting key machines and key cutting techniques will provide step-by-step instructions for getting the job done. To begin, you will need to decide on the type of key cutting machine and accompanying software that you would like to use.

This decision should be based on your budget, cutting needs and variations of keys you will be cutting.

Troubleshooting and Maintenance

Common machine issues

maintenance The modern workplace is increasingly reliant on the use of laser cutting machines, and keeping them in good working order is essential for the best results. Unfortunately, unexpected issues can arise when it comes to your laser cutters- and it’s important to know how to troubleshoot them.

Best practices for maintaining key machine

maintenance Maintaining a laser cutting key machine is an important task for any locksmith. With proper maintenance, you can ensure that your machine is working in optimal condition and ready to handle the day’s work. By following the best practices outlined below, you can maximize the lifespan of your machine and keep your business running smoothly.

First, keep your machine clean and dust-free by regularly wiping it down with a dry cloth. This will help to prevent dirt from entering the inner workings of the machine, which can be damaging.

Conclusion

Summary of key points

machine In this ultimate guide to using a laser cutting key machine, we’ve discussed the advantages, disadvantages, and common applications for laser cutters. The advantages of a laser cutter machine include a high level of precision, the ability to cut complex shapes, and the versatility to cut a variety of materials. On the other hand, laser machines can be expensive and require more care to protect them from environmental factors.

Reflection on value of owning a laser cutting key machine

While a laser cutting key machine may not be on the top of many people’s must-have list, these tools are incredibly helpful for any locksmiths or security professionals. For anyone who regularly works on locks and keys, laser cutting key machines can save hours of effort in comparison to manual methods. They can cut keys faster and more precisely than ever before and can be used for a range of other tasks, including creating customized key cards, making duplicate keys, and programming transponder keys.

The benefits of laser cutting key machines are undeniable: they are faster, more precise, and can save time and money. The drawback is the cost of purchasing a machine, and the maintenance that comes with it.