The laser cutting of zinc coated steel is an ever-evolving technology that has become increasingly important to the metalworking industry. As the demand for precision and accuracy increases, so does the need for expertly engineered laser cutting machines capable of consistently delivering exceptional results. In this article, we’ll look at the latest technologies used in laser cutting zinc coated steel and provide insight into how these advances can help your business achieve the highest standards and consistent quality.

The Latest Technologies

Advantages of using CO2 for traditional laser cutting zinc coated steel

The use of CO2 lasers for cutting zinc coated steel has been growing in popularity in recent years. This is due to the fact that the CO2 laser is able to cut through thicker materials and offers advantages over other traditional methods. The advantages of using CO2 for traditional laser cutting zinc coated steel include: 1) Faster Cutting Speed – The CO2 laser is able to cut through coated steel at a much faster speed than other cutting methods.

Advantages of using Nd:YAG for precision laser cutting zinc coated steel

Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers are the latest technology used in precision laser cutting of zinc coated steel. This type of laser cutting has a number of advantages over traditional methods such as plasma, oxyfuel and waterjet cutting, particularly when large areas of zinc coated steel need to be cut accurately and quickly.

Advantages of using sealed CO2 lasers for fine laser cutting zinc coated steel

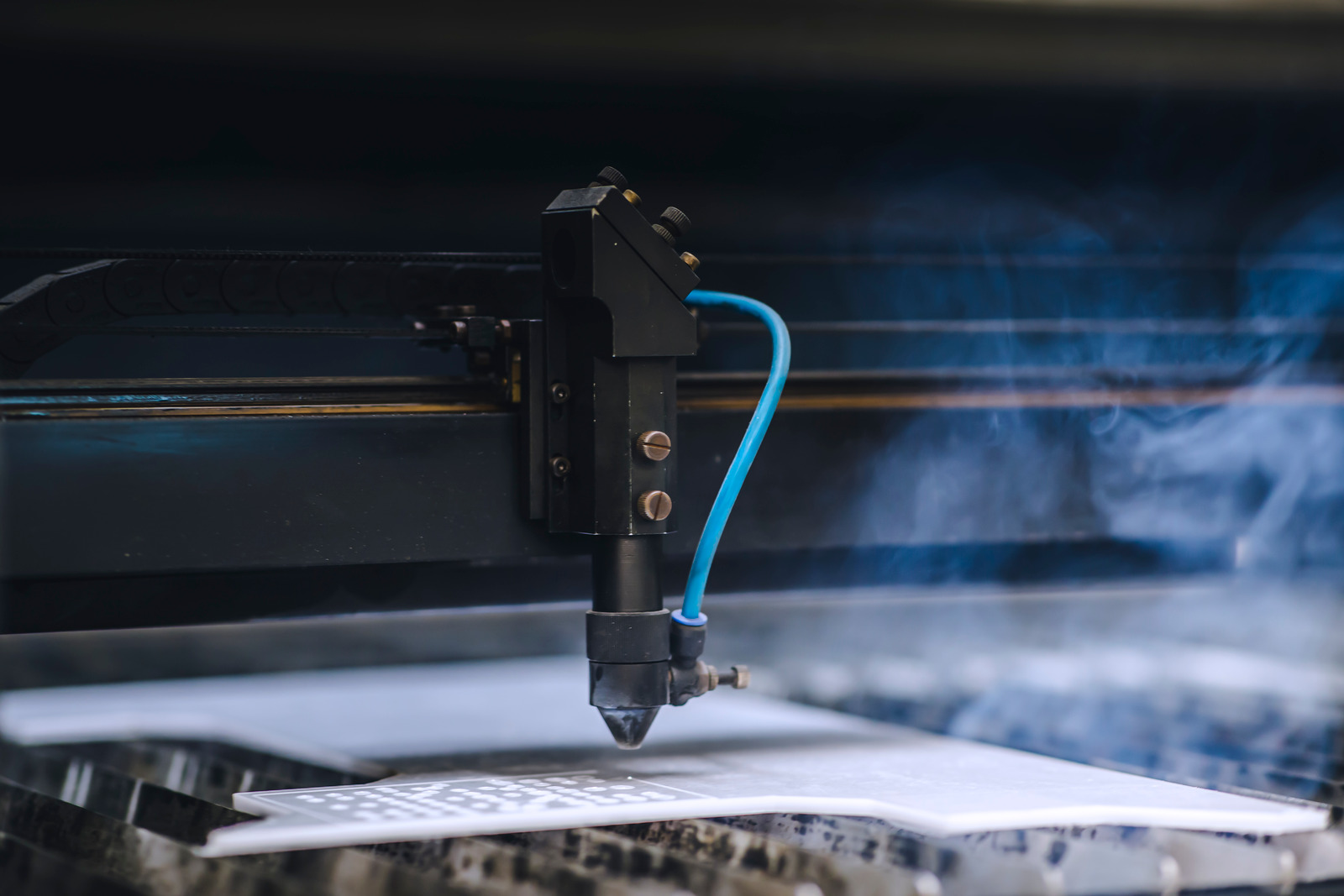

Laser cutting zinc coated steel has become increasingly popular as the technology has improved. With a sealed CO2 laser, precise and accurate laser cuts can be made with minimal damage to the zinc coating. The advantages of using this type of laser are many, primarily due to the highly precise cutting of the zinc-coated steel.

First, sealed CO2 lasers are far more precise than traditional cutting methods such as plasma or flame cutting. This allows for precise cutting of the zinc coating, minimizing any damage or deformation of the underlying steel.

Advantages of using fiber lasers for high speed laser cutting zinc coated steel

laser cut Laser cutting zinc coated steel is one of the most popular applications of modern laser cutting technology. This is due to the combination of the ability to process various thicknesses, complex shapes and nearly any component shape. By using laser cutting, numerous advantages are offered when cutting zinc coated steel, such as improved quality and speed, cost efficiency and environmental friendliness.

One of the main advantages of using fiber lasers for high-speed laser cutting zinc coated steel is their capability of a smooth and fast cut. This is due to the lower power required, meaning that cuts can be made faster, while ensuring high quality.

Applications in Industry

Automobile production

The automobile industry has long relied on zinc coated steels to create high-quality, corrosion-resistant parts. As technology has advanced and new methods of forming and manufacturing metals have become available, the automobile industry has come to rely on laser cutting for some of its metal components. Using laser cutting to process zinc coated steels for automobile production allows for precise and highly detailed parts.

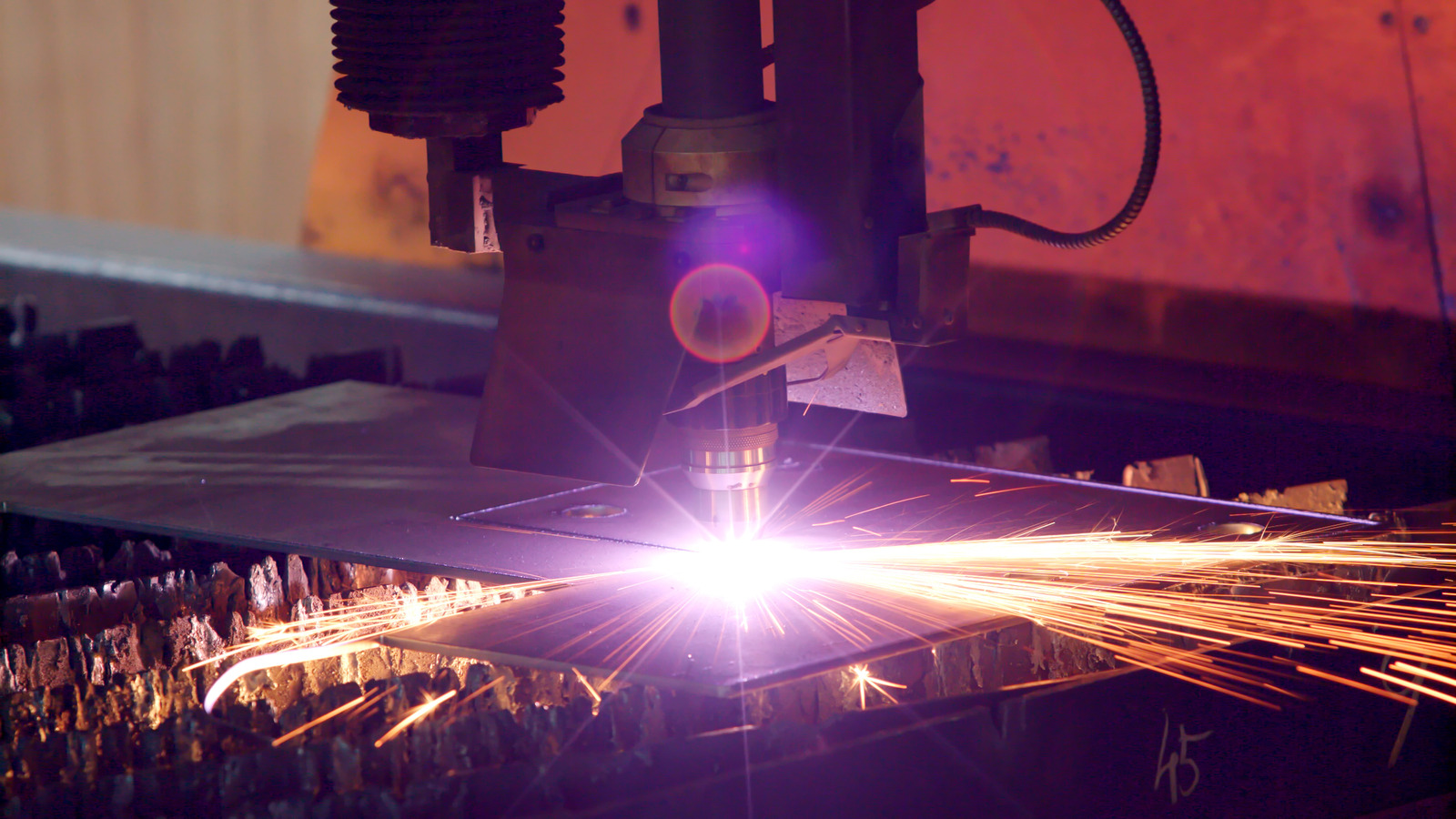

The laser cutting process uses a focused beam of light to cut through the steel.

Aerospace manufacturing

The aerospace industry is increasingly turning to the latest laser cutting technologies to cut through sheets of zinc coated steel. Laser cutting is a process that uses a beam of light to quickly cut through metal into shapes and patterns. To cut through zinc coated steel, a high power laser system is used because the zinc coating adds additional thickness that must be penetrated.

This type of cutting technology is used to create intricate and precise parts used in the manufacturing of aircrafts. The laser cutters used to cut zinc coated steel deliver more precise cutting than traditional cutting tools. The accuracy of the cuts, sharpness of the edges, and the quick turnaround times make the laser cutting process ideal for manufacturing in the aerospace industry.

Construction

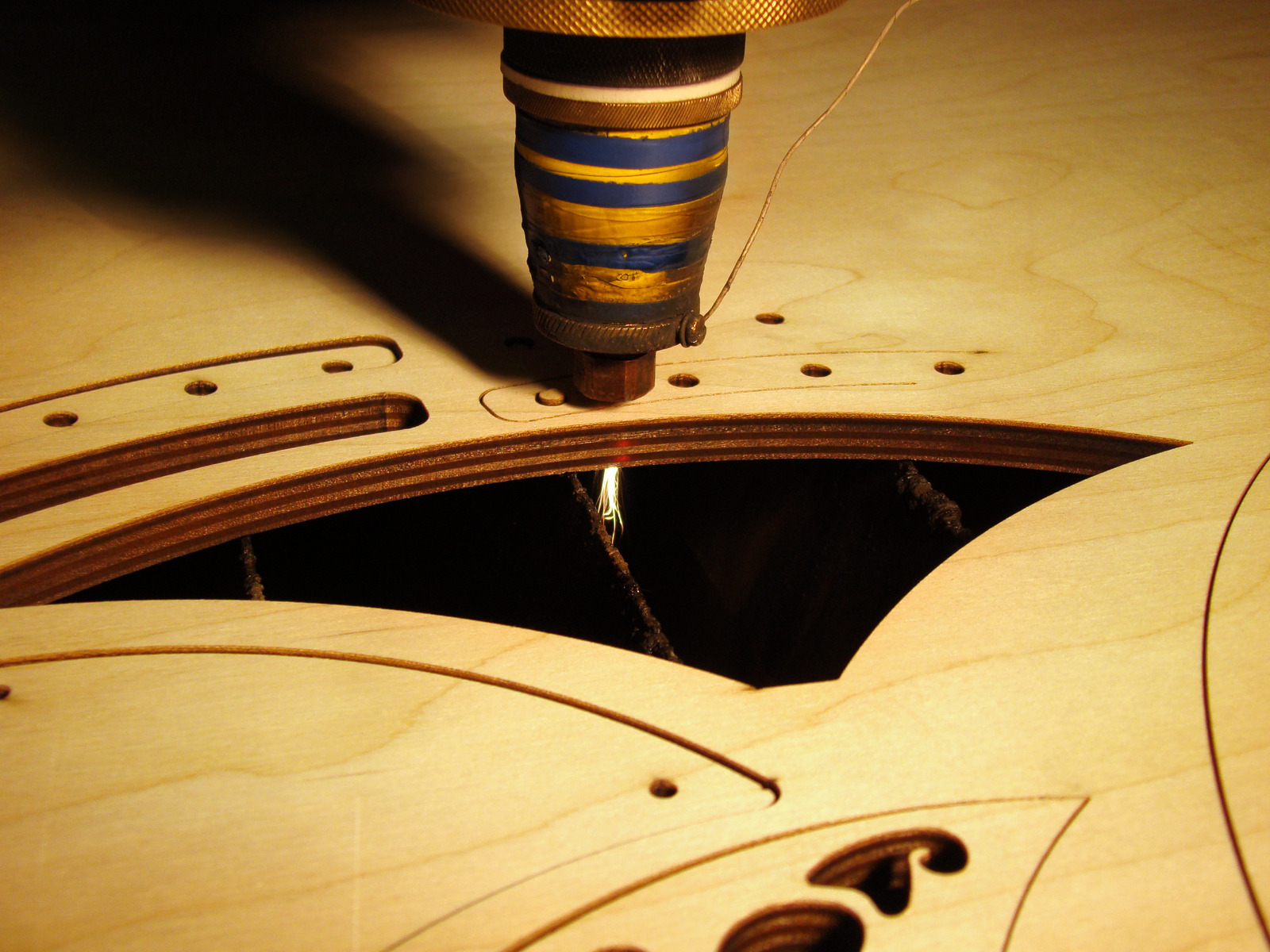

uses Laser cutting of zinc coated steel is gaining more traction in the construction industry. This advancement has enabled a fast and accurate method of cutting zinc coated steel in a wide range of applications. The process of cutting zinc coated steel with a laser is quite simple and efficient.

First, a pass is made over the steel with the laser to burn away the zinc coating, followed by a second pass to cut through the steel material. This process produces a much cleaner cut with no need for secondary operations such as masking, grinding, or sanding. Laser cutting of zinc coated steel has many advantages for the construction industry.

Can Galvanized Steel be laser cut?

Yes, galvanized steel can be laser cut, and the latest technologies have made it even easier and faster to do so. The process of laser cutting zinc coated steel involves a laser beam melting away a desired part of the material layer. This process is usually performed on thin gauge steel sheets and plates, but can produce different thicknesses depending on the type of laser used.

Zinc coated steel is a popular material of choice when it comes to laser cutting.

Can you laser cut Zintec?

Yes, you can use laser cutting to cut Zintec, which is a type of zinc coated steel. Zinc is a metal with unique properties that makes it an ideal choice for coating steel. It is corrosion-resistant, offers excellent wear-resistance and powder adherence, and has a shiny finish.

The process of laser cutting zinc coated steel makes use of the latest technologies available to provide a more accurate and precise result than traditional methods. The laser cutting process enables both thin and thick sections of steel to be cut with a very high degree of accuracy. This accuracy is achieved by using a high-powered laser beam to precisely trace and cut along predetermined lines.

Conclusion

Benefits of using laser cutting zinc coated steel

Using laser cutting technology to cut zinc coated steel has some major benefits compared to other methods. It’s fast, precise, and more cost effective than other cutting methods. The laser cutting procedure does not require any additional tooling, thus drastically reducing the costs associated with machining.

Additionally, the laser can cut complex shapes and provides the most precise cut possible. Its high speed capabilities also reduce the overall time it takes to finish the job and thus helps to increase the productivity. Zinc coated steel is an ideal material to use in laser cutting because it has great corrosion resistance and can withstand high temperatures.

Future of laser cutting zinc coated steel

The future of laser cutting zinc coated steel looks bright indeed. As laser cutting technology continues to advance, more companies are incorporating the use of zinc coating into their steel parts. This allows them to produce stronger, longer lasting and more corrosion resistant parts.

As before, the process itself still involves using a mixture of high intensity light beams or fibers in order to vaporize the actual steel material. In addition, the use of zinc coated steel improves the accuracy of cuts, as well as reduces downtime by increasing the speed at which cuts can be completed.