Laser cutting tables are a highly innovative invention that has opened up a range of new possibilities for a variety of applications. In recent years, laser technology has been utilized in different cutting processes – from sheet metal to 3D designs. It provides a high level of precision and accuracy, making it extremely beneficial for a multitude of tasks. In this article, we will discuss the different uses of laser cutting tables and how they can revolutionize your projects.

Materials Used and Cut

Metals

When it comes to laser cutting tables, metals are some of the most commonly used materials. This is because they possess high stiffness, strength, hardness, durability and wear-resistance. They also stand up well to extreme temperatures, corrosion, and other environmental conditions.

Depending on the type of laser cutter, different metals can be used in a variety of cutting projects. Common metals for laser cutter projects include aluminum, stainless steel, copper, titanium, brass, and more. Aluminum is one of the most popular metals used in laser cutter projects.

Plastics

Plastics are one of the most common materials used in laser cutting tables, due to their low cost, ease of fabrication, and range of properties. These properties can make plastics ideal for a variety of applications. Laser Cutting Tables can make precise cuts into plastics, like acrylic and polycarbonate sheets, with minimal waste.

Each plastic has different characteristics, so it’s important to select the right laser cutter, laser settings, and material type specifically for the job. Laser cutting machines generate high power beams that can cut through thin materials with precision.

Wood and Paper

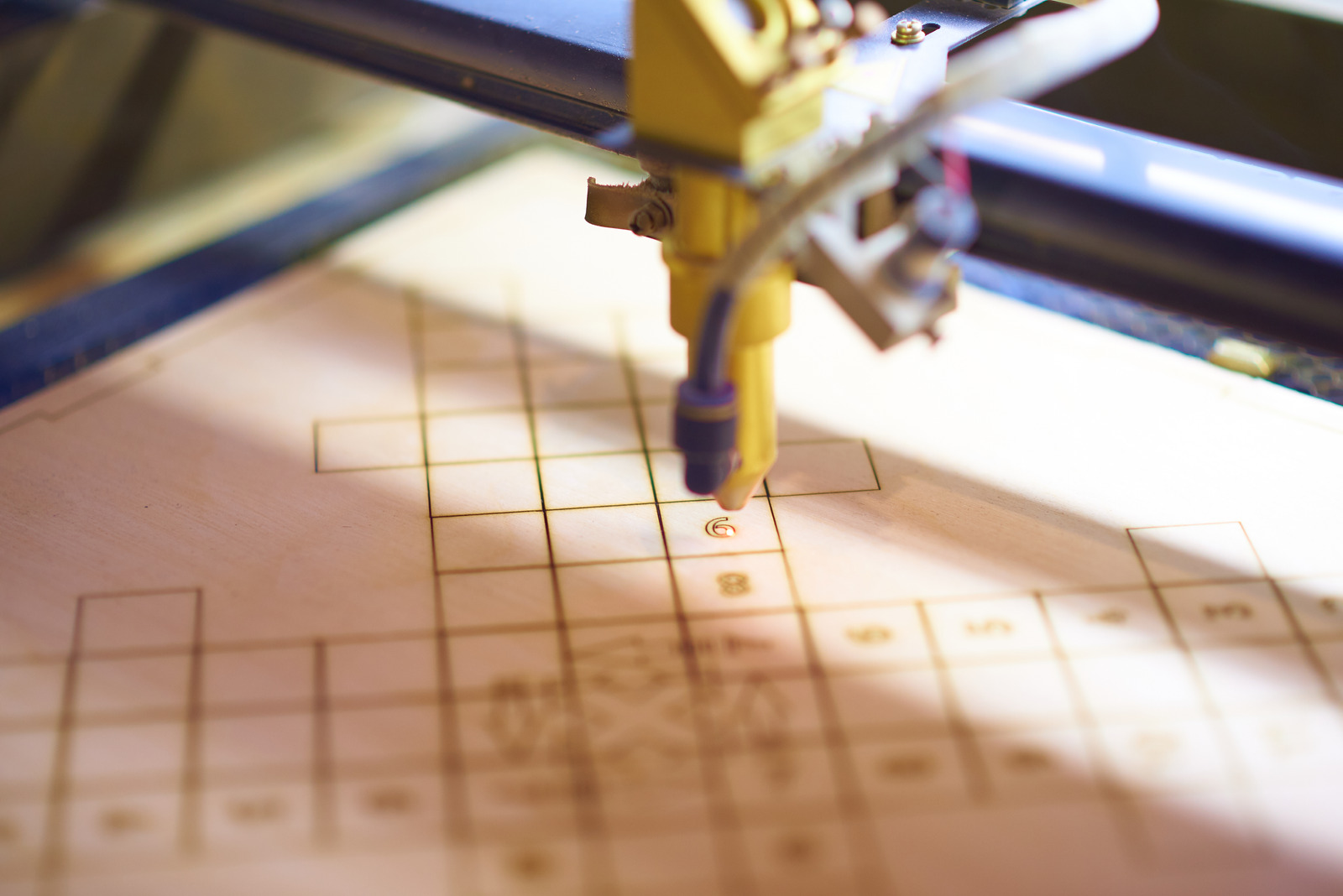

Materials Laser cutting machines are versatile tools used for a variety of different purposes in both industrial and non-industrial settings. Laser cutting tables can be used to cut materials like wood and paper. When working with wood and paper, laser cutters are a great choice.

Laser cutting tables have the ability to cut intricate designs with a perfect finish and stability, making them ideal for delicate cuts.

Textiles

ters and materials Laser cutting is an incredibly useful tool for a wide variety of applications. It is especially useful in the textiles industry due to its high-precision cutting ability. Laser cutters can be used to cut textiles into complex shapes and designs with precision, accuracy, and speed.

By using the heat of a laser, it can cut it through a range of materials including fabric, wool, leather, denim, and spandex.

Applications of Laser Cutting Table

Computer-aided design (CAD)

ters Computer-aided design (CAD) is an essential tool for operating laser cutting machines, as it provides the data needed to program and cut intricate parts. With computer-aided design, a laser cutting table can follow intricate shapes and create a wide range of features inside the material. CAD also helps to streamline the process, as the complexity of a design can easily be changed by updating the CAD files and the laser cutter parameters.

Mechanical engineering

ters Laser cutters are a type of machine that uses a laser to cut through a variety of materials, including metal, plastic and wood. They are used in a wide range of industries, including the manufacturing of cars, computer components, furniture, and household goods. In the field of mechanical engineering, laser cutters can be used to shape, trim and carve components of machines and engines, as well as to make molds for casting and pressing.

The two common types of laser cutters for mechanical engineering applications are CO2 and fiber laser cutters.

CNC machining

ters CNC machining is a process where a computer controls a machine to precisely cut, shape, engrave and mark a material for a specific purpose. A common example of this is laser cutting tables, which use a variety of laser cutters to complete tasks from just cutting sheet materials to intricate CAD drawings. Laser cutters are the most common type of CNC machine used in manufacturing and fabrication projects, as they have the capability to cut through a wide range of materials with speed and accuracy.

Types of Laser Cutting Tables

Laser Marking Tool

ters A laser cutting machine, commonly referred to as a laser cutter, is a tool used to cut and engrave a variety of materials. Laser cutting tables are available in a variety of sizes, power and design, making them suitable for a range of uses. Commonly produced materials include metals, wood, acrylic, fabrics and paper.

The laser marking tool is a type of laser cutting tables that focuses its beam on the surface of a material, and uses different levels of power to mark it.

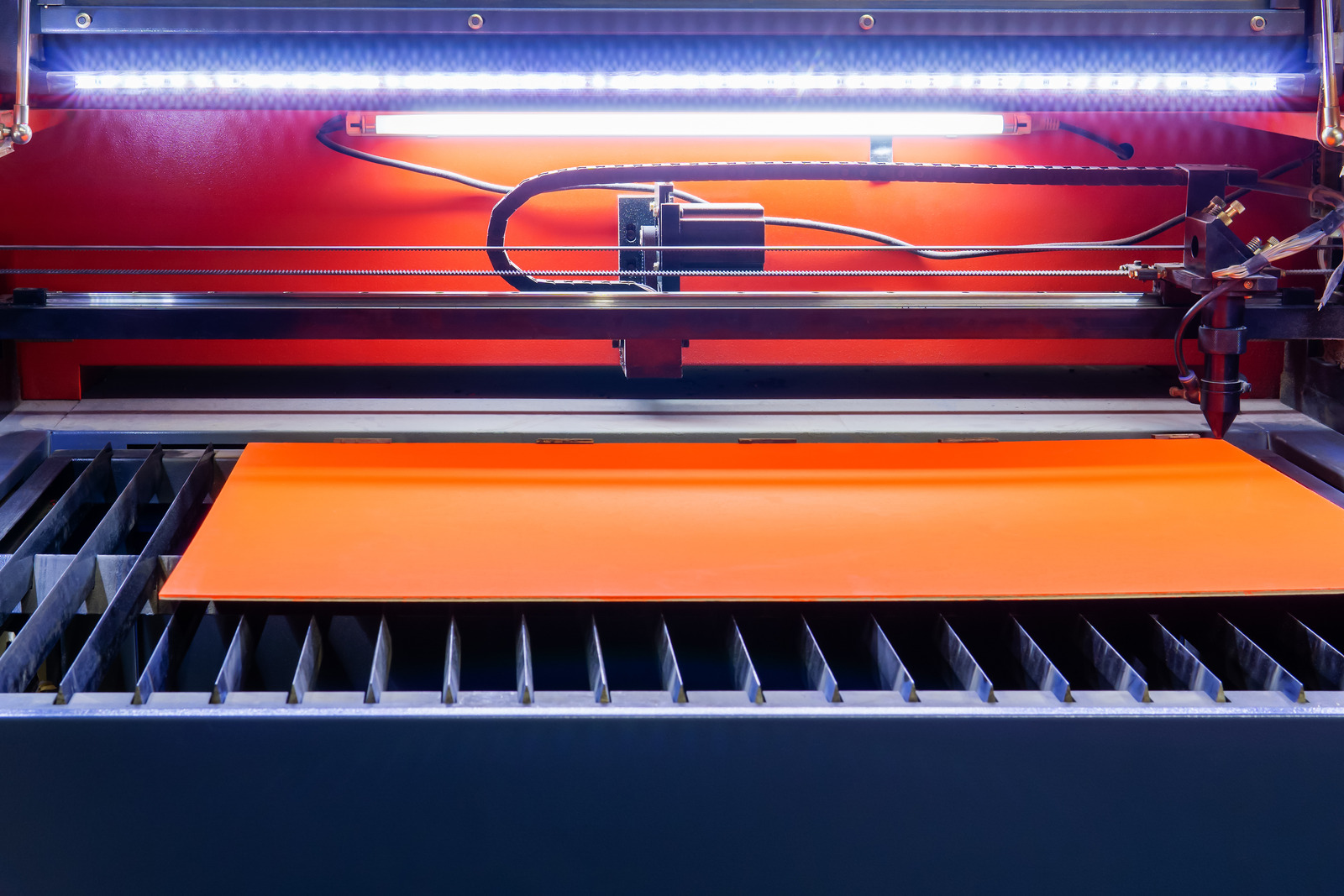

Fiber & CO2 Laser System

Laser cutting machines, also known as laser cutters, are a type of machinery used for engineering and manufacturing industries. They are used to cut, shape, and engrave materials to a precise specification. These machines employ powerful lasers as their cutting heads.

The most commonly used lasers are Fiber and CO2 models. Fiber lasers are more efficient, cutting at higher speeds and with increased accuracy. Most industries use them to complete medium-to-high-volume projects with precision, speed, and efficiency.

CO2 laser cutters use a beam of light to cut through materials.

3D Printer

ters Laser cutting tables, more commonly referred to as laser cutters, have become increasingly popular amongst industry and hobbyists alike in recent years due to their accuracy and versatility. Laser cutters are highly precise machines capable of cutting various kinds of materials with a beam of highly focused light. Additionally, they offer a wide range of applications, from routine cutting and engraving jobs, to 3D printer applications.

Considerations when Purchasing Laser Cutting Tables

Budget

ters When it comes to budgeting for a laser cutting machine, the first thing to consider is the type of laser cutting you want to do. There are several different types of laser cutters, each of which offer unique advantages and come with different price points. CO2 laser cutters are the most commonly used type; they’re versatile and can be used on many materials like acrylic, cardboard, and even metals and ceramics.

They can also be used on intricate designs, allowing you to make intricate, detailed items with precision.

Cutting material thickness

Keyword: Laser engraving When it comes to laser cutters, cutting material thickness is one of the most important factors to consider when buying a machine. This is because most laser cutters can only cut certain thicknesses of material, which vary depending on the type of cutter and laser power. To ensure a clean, accurate cut, it is important to use the right laser cutter for your particular project.

Type of laser cutting

ters Laser cutting is a widely popular and widely used manufacturing process where a high-powered focused laser beam is used to cut through and engrave various materials. Laser cutting machines are used in manufacturing, industrial and commercial projects, ranging in size and complexity. Depending on the type of laser cutting machine you purchase, you can use laser cutters to process wood, plastics, foam, textiles, glass, and even metal.

Automation and safety

Automation and safety are major considerations when looking at the different uses of laser cutting tables. Laser cutting machines are typically known for their high level of accuracy and precision when cutting materials for various components and products. However, having comprehensive safety and automation features built into the laser cutting table can provide users with extra reassurance that their laser cutters are being operated safely and efficiently.

What are lasers used for cutting materials?

Laser cutting is a type of computer-programmed machine that has enormous industrial value. It uses a laser beam to cut different kinds of materials into specific shapes and sizes. Laser cutting machines are used in many industries due to their accuracy, speed, and affordability.

Laser cutting is used for many purposes in industrial settings, from cutting through thicker materials like metal to precision-cutting on thinner materials like paper.

Conclusion

Recap on different types of laser cutting tables

ters In this blog, we’ve discussed the different types of laser cutting tables and their various uses. Laser cutter tables use lasers to cut through material including wood, metal, leather, and paper. The types range from CNC laser cutting machines, to plasma cutting machines, to water jet cutting machines.

CNC laser cutting machines use a combination of numerical control technology, high powered laser beams, and software programming to cut through materials with precision. Numerical control technology allows a variety of shapes, patterns, and curves to be created by the machine.

Overview of various applications for laser cutting tables

ters A laser cutting table, or laser cutter, is a type of machine used in a variety of industrial and commercial applications. Laser cutting tables have the ability to cut through a range of materials with extreme accuracy, including wood, metal, plastic, paper and cardboard. They are an invaluable tool used in a wide variety of industries.

One of the most common uses of laser cutting tables is to cut patterns into plastic to create custom parts for a variety of applications.

Summary of factors to consider when selecting laser cutting table

ters Choosing the right laser cutting table can be a tricky process, but it’s important to make sure you get the right one for your needs. There are a few key factors to consider when selecting a laser cutting table, such as the type of cutting, the size of the laser cutting area, the table design, the speed, and the cost. When it comes to the type of cutting that needs to be done, there are two main types of laser cutters: CO2 and Fiber.