Cutting foam with a laser can be a great way to make precision cuts while getting a high quality finish. It’s a popular choice among makers, DIYers, and professionals alike due to its speed and accuracy. In this article, we’ll explore why using a laser for cutting foam can be used to your advantage and how it can make your projects faster, easier and more successful.

Advantages of Laser Cutting

Increased precision

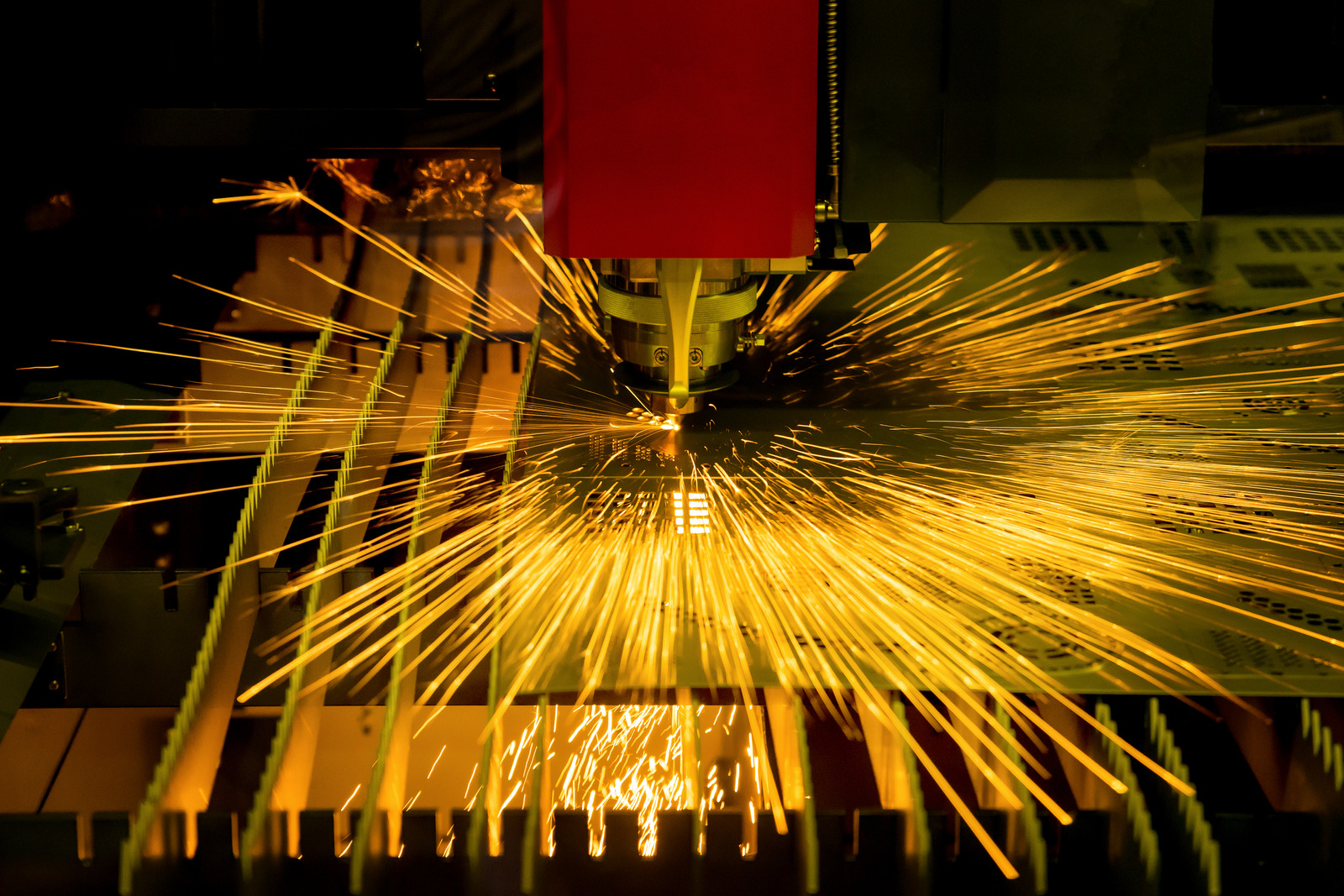

of laser cutting Using a laser cutter to cut foam provides a level of precision that is not possible with traditional cutting methods. This is due to several advantages of using lasers over other cutting tools. The beam of light produced by a laser is incredibly thin and precise, making it possible to create intricate designs with little deviation from the original template.

The laser beam also eliminates the need for specially designed cutting tools, since it melts and vaporizes whatever material it is pointed at with ease. Additionally, the laser cutter’s lack of physical contact with the material allows for fast and even cutting without causing any damage or distortion.

Highly repeatable cuts

of using a laser for cutting foam When it comes to the advantages of using a laser cutter to cut foam, one of the primary benefits lies in the precision and repeatability of cuts. A laser cutter works by focusing a beam of light onto a specific point on the material, slowly burning away the surface or cutting through it with extreme accuracy, resulting in consistent and precise cuts. Depending on the size of the laser cutter and the size of the material to be cut, it can be used to create small intricate patterns and finely detailed objects.

Reduced tool wear

of using a laser for foam When laser cutting foam, one of the biggest advantages is that the tool wear is reduced greatly. Typically, when cutting foam with a saw blade or other traditional cutting tool, the material of that tool incurs a lot of wear and tear, which can decrease its lifespan and cause more frequent repairs and replacements.

Minimal material waste

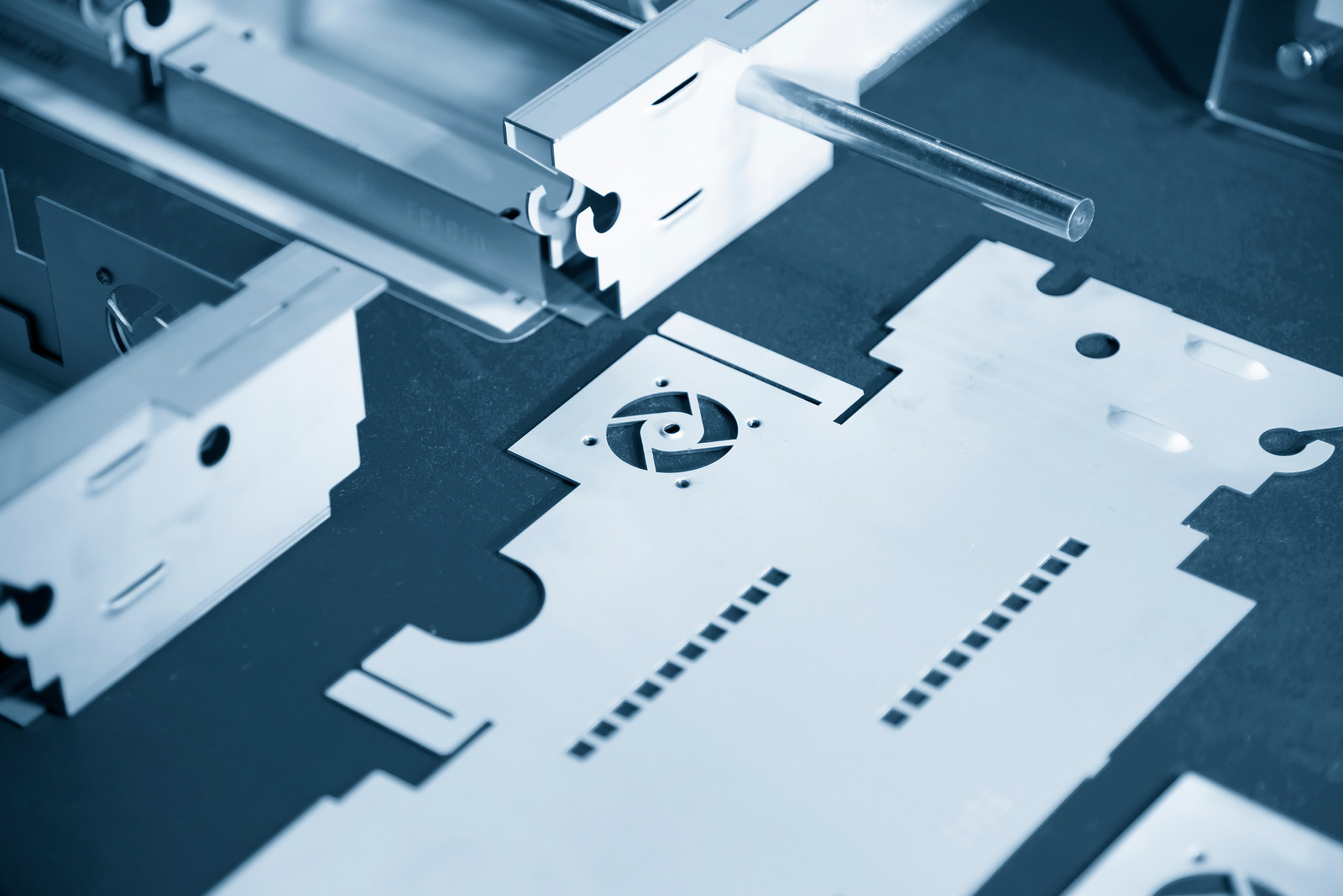

of laser cutting One of the biggest advantages of using a laser cutter to process foam is that it helps minimize material waste. Traditional cutting or machining methods can increase production costs due to their tendency to create a large amount of material scrap or offcuts. Laser cutters, on the other hand, cut the material with a focused beam of light and can be programmed to accurately target cuts, allowing them to produce the desired end product with precision and minimal waste.

Types of Foam Suitable for Laser Cutting

Polyurethane foams

of laser cutting foam The advantages of using a laser for cutting foam are numerous. Lasers have the accuracy and precision needed to make intricate and complex shapes. They offer a cleaner cut edge with minimal heat distortion.

In addition, they are fast and efficient, making them an ideal choice for high-volume production runs. Polyurethane foams are among the most suitable materials for laser cutting. Their open cell structure means that the laser beam is able to penetrate throughout the foam and cut it easily.

The result is a clean, smooth cut edge with minimal heat damage. Lasers can easily handle the complexity of intricate shapes and transitions, allowing for rapid prototyping or fast production of parts.

Polyethylene foams

of laser cutting foam Polyethylene foams such as Expanded Polyethylene foam (EPE foam) and Crosslinked Polyethylene foam (XLPE foam) are suitable for laser cutting. Both foams can easily be cut by laser energy, making them ideal for manufacturing precise parts and components with any desired shape. Laser cutting of polyethylene foams ensures high-precision cuts, with minimal thermal damage and almost no distortion of the material.

This allows for a precise, smooth finish, no additional finishing work and fast prototyping.

Styrofoam

of laser cutting When it comes to cutting foam for a variety of applications, laser cutting offers a number of benefits. For example, laser cutting can produce a precise, high quality finish with minimal waste. Additionally, laser cutting can be conducted faster than manual cutting, resulting in overall cost-savings.

One of the most common forms of foam that can be cut with a laser cutter is styrofoam. Styrofoam is a lightweight, white foam that is used for a variety of applications such as thermal insulation, packaging, and more.

Specialty foams

of using a laser When it comes to laser cutting specialty foams, the advantages of employing such technology are pretty incredible. Specialty foams, such as polyurethane, PVC and polyethylene, are generally soft and can be easily deformed, but with a laser cutter, you can make precise cuts that won’t tear or distort the material. This means that you get a smooth cut with uniform laser-produced edges – perfect for foam crafting applications and for product prototyping.

Laser Cutting Techniques for Foam

Vector cutting

of laser cutting foam Vector cutting with a laser cutter is an effective way to cut foam material. Laser cutting techniques for foam use a focused laser beam to cut and shape shapes in the material. This type of cutting technique has the advantage of creating intricate detail, making it ideal for projects that require precision.

When cutting foam with a laser cutter, the intense heat of the laser beam melts the material in the same way that a hot knife would cut butter.

Scanning cutting

of laser cutting Scanning cutting is a technique used in laser cutting that allows for the precise and accurate cutting of various materials, including foam. This technique involves the organized scanning of the material while the laser beam moves across it, essentially “sculpting” the shape of the object into the material. This technique enables the laser cutter to achieve precise, intricate shapes and designs with a very high level of accuracy and detail.

The advantages of scanning cutting with a laser cutter when cutting foam are numerous. For one, it’s fast and efficient, allowing for virtually any shape to be quickly and accurately cut.

Engraving

of laser cutting foam Engraving foam with a laser cutter is one of the most advanced and precise types of laser cutting and is a popular method for creating intricate details. Engraving foam with a laser makes it possible to achieve precision and detailed designs with very intricate shapes. Laser engraved foam is commonly used for signs, fixtures, packaging, furniture, and architectural models.

How powerful of a laser to cut foam?

of laser cutting When working with foam materials, one of the biggest advantages of using a laser cutter is the power it provides when it comes to cutting foam. It is important to consider how powerful of a laser is needed when determining which laser cutter to use when working with foam. A laser cutter that is too powerful can end up burning the material and resulting in a low quality cut.

The power of the laser cutter affects the speed in which it can cut through foam, as well as its accuracy. If you have a powerful laser cutter, it can cut through foam quickly and accurately.

Is it safe to cut foam board on a laser cutter?

of laser cutting One of the key benefits of using a laser cutter to cut foam is that it is much safer than using other methods. Compared to manual cutting or using a power tool, laser cutters are far less likely to cause any damage to your foam board or to yourself. With the right precautions, a laser cutter can be a safe and precise tool for cutting foam.

The biggest advantage of using a laser cutter is the precision and accuracy it provides.

Conclusion

Summarizing the Benefits of Using a Laser for Cutting Foam

In conclusion, laser cutting foam offers many advantages when compared to traditional techniques. Not only is a laser cutter more precise, but it is also more efficient, enabling you to cut more intricate pieces in a shorter amount of time. A laser cutter also eliminates the need for additional tools such as jigsaws, die cut machines, saws, and scalpels.

This makes laser cutting the preferred method for various tasks, such as prototyping, manufacturing, or crafting. Furthermore, since a laser cutter is clean and relatively quiet, it does not create a mess or require much ventilation like conventional cutting methods.

Inviting further dialogue

of a laser The conclusion of the blog on the benefits of using a laser for cutting foam can be summarized as laser cutters provide precise, fast, and accurate results with smooth edges, saving time and reducing costs. Additionally, laser cutting foam is ideal for lightweight materials and other intricate designs. We hope this article has provided valuable insight into the advantages of using a laser cutter to cut foam.