Welcome to a discussion on the benefits of laser-cutting your own vinyl records! Whether you’re an avid fan of vinyl records, a budding record producer, or music enthusiast looking to create an extraordinary piece of art, laser-cutting is an efficient and cost-effective way to create custom records. In this article, we’ll explore the advantages of laser-cutting vinyl records, discuss the different types of technology required, and cover a few of the challenges that may arise. So, let’s get started and dive into the world of laser-cutting vinyl records!

The History of Vinyl Record Cutting

Advancements in technology

The vinyl record is an artistic medium that holds a special place in many people’s hearts. From Alanis Morissette to Ray Charles, countless audiophiles and music enthusiasts have fallen in love with the its rich sound – and with the ability to cut one’s own vinyl records using a laser cutter, that appreciation for vinyl can be taken to a much deeper level. Advances in technology have made it possible to get laser cut vinyl records with unprecedented precision and detail that was never before possible.

How this technology has been traditionally used

The idea of laser cutting vinyl records to produce audio recordings has been around since the late 1950s, though the actual practice wasn’t commonplace until the mid-1980s. Laser cutting was first explored as a means to produce extremely accurate and high quality audio recordings after conventional cutting techniques had reached their limits in terms of sound quality and fidelity. Since then, laser cutting technology has been greatly refined, and nowadays it’s widely used when making vinyl records, from the home hobbyist to the professional mastering engineer.

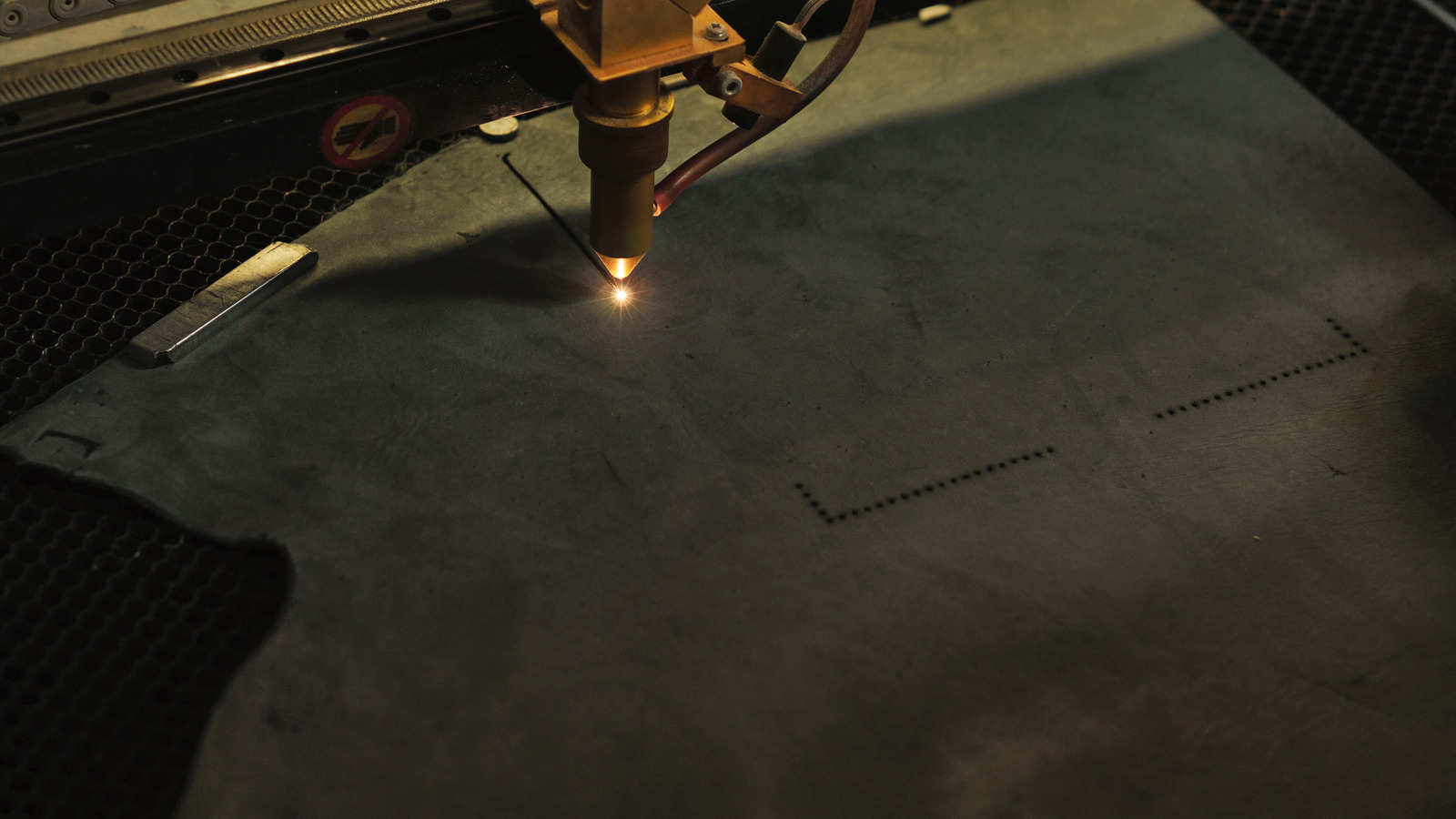

At its core, laser cutting of vinyl records relies on a focused laser beam to cut a master record out of a blank vinyl disc.

Laser Cutting for Vinyl Records

Benefits of Laser Cutting

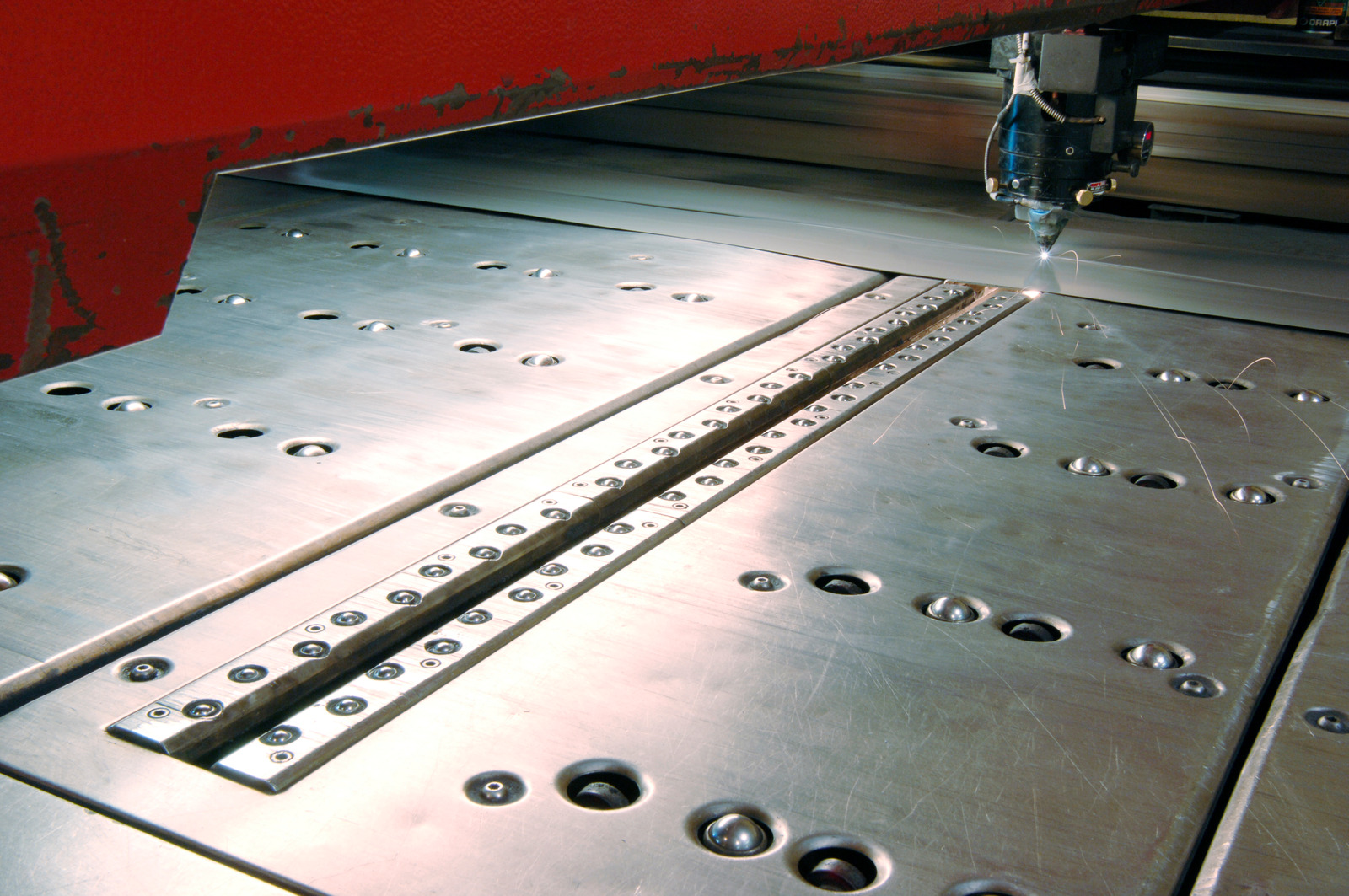

The benefits of laser cutting your own vinyl records are numerous and varied. For starters, laser cutting allows for precise and accurate cutting of vinyl discs to create customized one-of-a-kind records that can be cherished for life. Unlike traditional methods of cutting vinyls, such as using die cutting and a point-and-press system, laser cutting offers a unique, narrow-footed pattern that delivers precise cutting along the edges of the vinyl, leaving no room for error or warping within the disc as it is cut.

Cost savings

The cost savings related to laser cutting your own vinyl records are immense. Laser cutting machines are relatively inexpensive, compared to traditional vinyl cutting machines– a medium-sized vinyl laser cutter can be purchased for $3,000 or less. Additionally, the process of laser cutting is incredibly efficient, since it only requires a single operator and the laser can be used to cut both sides of the vinyl record at the same time.

Ability to customize

One of the main benefits of using a laser cutter to create your own vinyl records is the ability to customize the design. With a laser cutter, you can etch intricate details that you can’t get with traditional cutting methods. This allows you to make the perfect design for your project.

You can also use a laser engraver to add text and symbols to your records. This means you can customize your records to suit your needs.

Increased sound quality

Using a laser to cut records has become increasingly popular in modern music production. In this process, a laser beam is used to cut a groove on the surface of the record. This process offers many advantages including increased sound quality.

The laser cutter ensures accuracy in recording, so the initial recorded signal remains in its purest form when it is transferred to the actual vinyl record.

Tools Needed

Creating your own laser-cut vinyl records may seem intimidating at first, but it’s a project that you can easily do with a few specialized tools. For this project, you’ll need a laser cutter, vinyl records, a cutter bed, and vinyl masking tape. The most important piece of equipment you’ll need is a laser cutter.

Materials Needed for Laser-Cut Records

Types of vinyl

When it comes to laser cutting your own vinyl records, understanding the different types of vinyl is key. Vinyl, short for polyvinyl chloride (PVC), is a type of plastic that comes in two main forms: flexible and rigid. The flexibility of the vinyl you choose will depend on the application and the type of design you are laser cutting.

Flexible vinyl is often used in audio-recorded applications, such as records, due to its ability to vibrate when a sound is applied to it.

Mastering equipment

When it comes to making your own vinyl records, mastering equipment is a necessity for producing high-quality results. Without the right equipment, the process can be very time consuming and costly, as well as prone to errors. This is why many vinyl enthusiasts opt to use a laser cutter to quickly and accurately cut their records.

The basic equipment needed for laser-cutting vinyl records consists of a laser engraving machine, a record pressing machine, and a cutting vector file.

Software needed

In order to make a laser-cut vinyl LP, the software needed is relatively simple, but specific. A laser cutter is able to cut up materials such as paper, foam, wood, plastics or vinyl. To make a vinyl record, you will need a vector graphic program, such as Adobe Illustrator or Corel Draw, to design your artwork and prepare the data for the laser cutter.

This artwork will be the template for the cuts that the laser cutter will make on the vinyl disc.

The Process of Laser Cutting Your Own Vinyl Records

Preparation and setup

When it comes to creating your own vinyl records, preparation and setup are key. Before you even think about cutting vinyl with a laser cutter, you need to make sure that you have all of the necessary supplies and materials on hand. You will need a laser cutter capable of cutting vinyl, such as the Trovan Laser 350, as well as a vinyl cutting software program, a good quality vinyl record, and a device to hold the record while it is being cut.

Tips for successful laser cutting

Laser cutting your own vinyl records can be a great way to add a personal touch to your music, as well as expand your creative expression. The process of laser cutting a record allows for cutting intricate patterns, grooving and texturing that can produce one-of-a-kind designs or shapes to customize your music.

- Ensure that the record is completely flat before beginning the cutting process – this will help the laser to evenly and accurately cut the grooves.

- Wear protective eyewear and gloves when handling the vinyl as the laser cutting process produces small debris.

- Start with a low power setting and gradually increase the power until you have the desired cutting effect.

- Make sure you are using the correct cutting speech for the material you are cutting – some materials require higher power settings.

- After the laser is finished, clean the record surface of any remaining debris before playing the vinyl.

Can you cut vinyl records with a laser cutter?

Yes, you can cut vinyl records with a laser cutter and the results can be quite impressive. Laser cutting is able to provide precise, accurate, and high-quality cuts for your vinyl LPs. With the right software, you can transform a standard vinyl record into whatever you want – a one-of-a-kind piece of art.

There are a few key benefits of laser cutting records. First, it is convenient, as the entire process can be handled within the laser cutter itself.

Conclusion

Summary of the benefits of laser-cutting your own vinyl records

In conclusion, laser cutting your own vinyl records can be a great way to get your music heard. This beneficial technique offers excellent sound quality, an aesthetically pleasing surface, as well as an affordable price. Laser cut records are made from an existing finished record, making them incredibly easy and cheap to produce.

Vinyl LPs created using laser cutting give each record a unique look, allowing them to be seen as works of art. Furthermore, laser engraving can be used to add additional features and layer depth, increasing the value and collectibility of each piece.

Final thoughts on the process

If you’re an avid vinyl collector, you have probably heard about the growing trend of using laser cutters to make your own vinyl records. From producing custom labels and designs to playing that one-of-a-kind artwork on your record player, the possibilities that come with laser cutting your own vinyl records are endless. The process of laser cutting records consists of a few simple steps.

First, you must create or find digital artwork that you want to cut onto the record. Once you have your digital artwork, you will need a laser cutter that is capable of cutting the vinyl material. Once you have the laser cutter and the artwork, you can then start cutting the records.