With the ever-evolving world of interior design, there’s always something new and exciting coming on the market. One of the latest trends in high-end design is the use of laser-cut railings to create sculpturesque embellishments to any home or workspace. Laser cutting railings allow for intricate patterns and shapes to be crafted, and can be used in combination with other unique finishes to create striking architectural designs that really stand out. In this article, we’ll explore the potential of using laser cutting railings to take elevated design to a whole new level.

Laser Cutting Basics:

Overview of Process

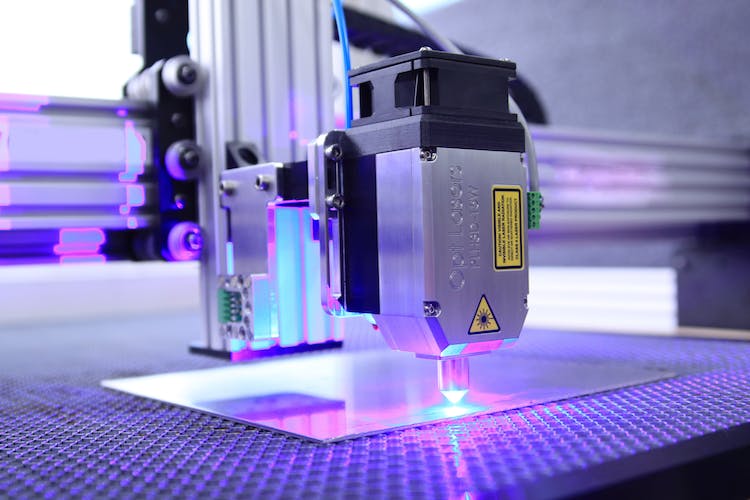

Taking Elevated Design to New Levels with Laser Cutting Railings, Laser Cutting Basics: Overview of Process Laser cutting is a precise and incredibly versatile technique for cutting metal, wood, and other materials. By using a high energy beam of focused light, this method of cutting can create intricate shapes and designs at high speeds. Laser cutting is also precise enough to achieve a very precise level of accuracy.

When it comes to taking elevating design to a new level, laser cut railings offer lots of possibilities.

Advantages of Laser Cutting

Laser cutting is a process that uses a powerful laser to create intricate and precise cuts with incredible accuracy. But did you know it can also be used to take your designs to a whole new level? With laser cutting railings and laser cutting basics, you can create unique and innovative designs that stand out.

Laser cutting brings about a number of advantages for projects involving railings, walls, and other intricate parts or designs. Perhaps the biggest advantage of laser cutting is the amazing level of accuracy it achieves. The laser beam is incredibly precise, giving you the opportunity to create incredibly detailed designs with little effort.

Taking Elevated Design to New Levels with Laser Cutting Railings:

Customizations Available

When it comes to taking elevated design to the next level with laser cutting railings, there are many customizations available for homeowners to choose from. One of the most popular customization options is laser level railings. This custom railing system allows for precise measurements and angles.

The laser cutting process provides accurate results, and the positioning of the rails can be adjusted from any angle to achieve the perfect look. Additionally, the laser cut railings can be customized for any size and shape, allowing for greater design flexibility. For an even more precise cut and an even more unique finished product, homeowners can opt for laser cut railings.

Examples of Laser-Cut Railings

Laser cutting is quickly becoming a preferred method for creating custom railings. Laser cutting is the process of using a laser beam to cut through metal, wood, and other materials. The laser level is used to ensure the precise and accurate cutting of the metal, creating a professional and clean finish.

From intricate designs to elegant straight lines, laser-cut railings can add a unique and eye-catching touch to any space. Laser cutting allows for highly precise designs that are impossible to achieve with traditional metal cutting methods. The result is an exceptionally clean and precise finish that looks great and lasts for years.

Benefits of Laser Cutting:

Accurate Finishes

When it comes to achieving precise, attractive finishes in your design projects, turning to laser cutting can make all the difference. Laser cutting is an incredibly accurate method of cutting and shaping materials such as steel, aluminum, and plastic, allowing you to take your design to a new level. By using a laser level, the laser produces a line of accurate cut in the material, meaning that your railings can be cut with precision, leaving no room for errors.

Most laser cutters will also be programmed to provide a variety of finishing options.

Faster Turnaround

When it comes to creating elevated designs, laser cutting railings is a rapidly growing technology that can make this possible with incredible accuracy, allowing projects to be completed in shorter turnaround times. With laser cutting, the railing can achieve curves, angles, and intricate details that have never before been possible with traditional tools. This not only allows for more creative and detailed design work, but also results in faster turnaround times due to the speed and accuracy of the laser.

Cost-Efficient Laser Cutting Solutions:

Cost Considerations

Taking Elevated Design to New Levels with Laser Cutting Railings, Cost-Efficient Laser Cutting Solutions Cost Considerations Using a laser level to create laser-cut railings is a cost-effective way to achieve a unique and visually pleasing look. When using a laser-level cutter, the costs savings are tremendous. The precision and accuracy of the cuts do not need to be matched to traditional cutting methods, reducing labor costs.

Cost Savings when Using Laser Cutting

When it comes to design, laser cutting is one of the most innovative and cost-efficient ways of taking any project to the next level. Laser cutting railings is a great example of where this technology can provide added value. With laser level technology, it is possible to precisely cut even complex designs with greater accuracy, eliminate sawing and hand-tooling time and reduce costs associated with traditional methods of production.

Conclusion:

Recap of Benefits of Laser Cutting

Taking Elevated Design to New Levels with Laser Cutting Railings, Conclusion: Recap of Benefits of Laser Cutting Laser cutting railings is an increasingly popular design choice that can help elevate the look of any space. Laser cutting gives railings that have a smooth, intricate finish that can’t be achieved with traditional methods. Laser cutting can create complex shapes and patterns, giving any railing the perfect customized look.

Aside from the aesthetic appeal, laser cutting offers a host of other benefits.

Summary of Taking Elevated Design to New Levels with Laser Cutting Railings

In the conclusion of our exploration of the concept of taking elevated design to new levels with laser cutting railings, we discussed the importance of precise measurements and quality materials. Using laser levels to ensure that the measurements are exact and that the materials are of the highest standard, can help ensure that the resulting railings will be durable, aesthetically pleasing, and compliant with safety codes. Laser cut railings are also more cost-efficient than handcut railings while maintaining accuracy in their craftsmanship.

Conclusion

In conclusion, laser cutting railings is an exciting way to take design to new levels. This process has the potential to unlock innovative designs, like those with intricate details and designs you wouldn’t find used in everyday railing construction. And, with a laser level’s pinpoint accuracy, you can create a railing that’s stylish and sturdy enough to last for years to come.

Laser cutting railings gives designers the creative freedom to customize staircases, balconies, and patios without sacrificing quality.