Rubber sheets are often used in laser cutting processes due to their malleable nature and their ability to absorb heat better than other materials. Preparing these rubber sheets for the laser cutting process is important to ensure the accuracy and quality of the cut. In this article, we will provide an overview of the steps that need to be taken to properly prepare rubber sheets for laser cutting processes. We will cover a few key areas, including the appropriate surface finish and the type of laser required for best results.

Steps to Prepare Rubber Sheets for Laser Cutting

Cleaning and Inspection

Before you start any laser cutting processes on your rubber sheets, it’s important to complete a thorough cleaning and inspection to make sure they’re ready for the job at hand. The first step is to make sure the surface is completely clean and that there is no dirt, dust, or other materials. You can do this by using brushes or other appropriate cleaning methods to make sure everything is free from contaminants.

Once it is washed and dried, it’s time to inspect the rubber sheet for any flaws or issues that can affect the cutting results.

Marking Guidelines

Marking guidelines is an important step in the process of preparing rubber sheets for laser cutting. It is essential to ensure that the laser cuts the rubber sheets precisely and accurately. To mark proper guidelines, the first thing you should do is to measure the thickness of the rubber sheet with a measuring tape or caliper.

Then, make sure to use the correct marking tool, such as a laser pointer or a cutter, to mark out the cutting line.

Selecting the Proper Resin and Double-Sided Tape

When preparing rubber sheets for laser cutting, one of the key steps is to select the proper resin and double-sided tape. Resin can provide protection from heat that is generated from laser cutting processes, and make sure the rubber sheet is held in place securely. Double-sided tape is important to use when preparing rubber sheets for laser cutting since it helps keep the sheet securely in place during the process.

Additionally, it helps create a precise and clean cut with no excess material.

Pre-Cutting Tests

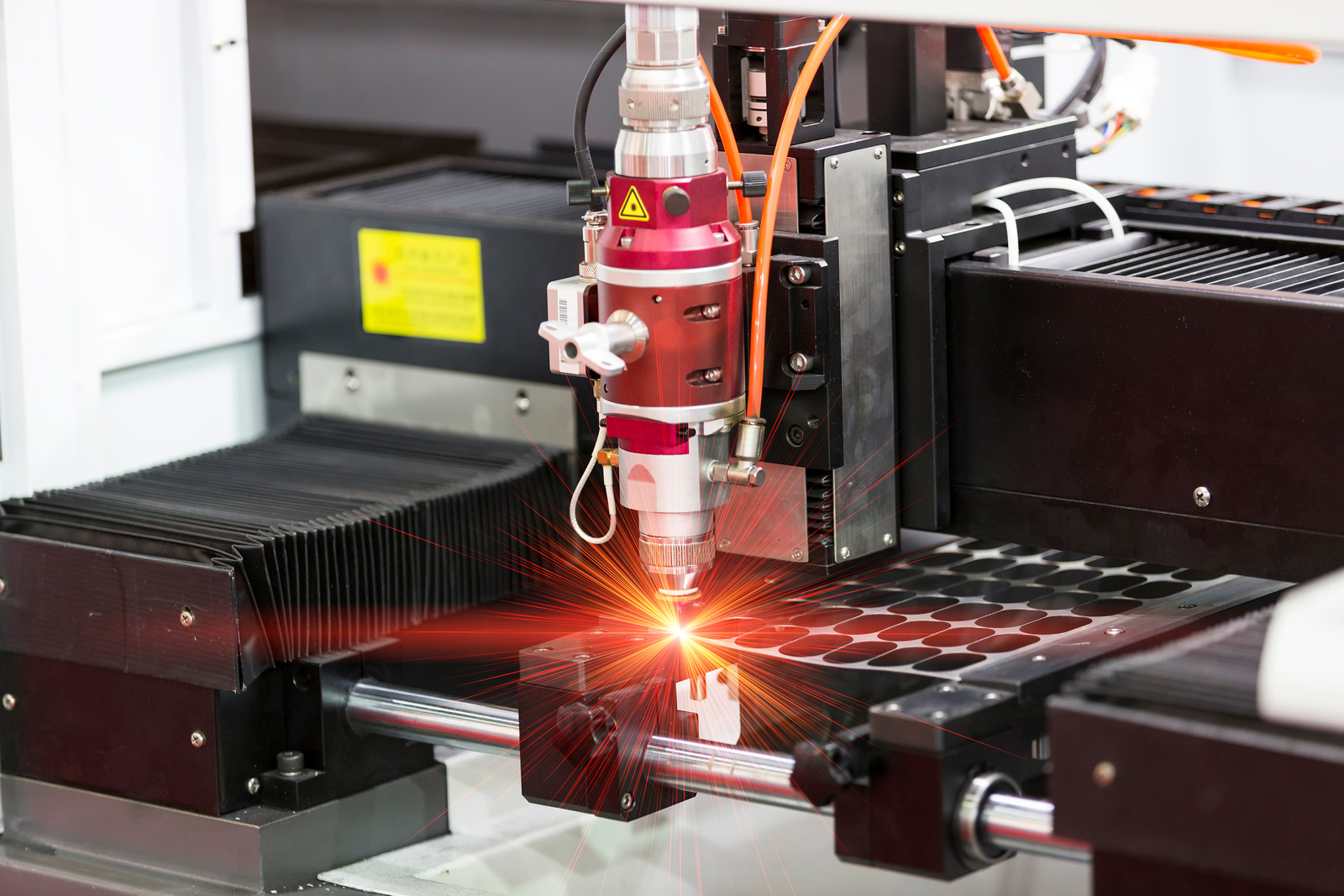

Pre-Cutting Tests Before you begin the laser cutting process for rubber sheets, it is important to make sure you are prepared for the task at hand. Pre-cutting tests can help ensure that your laser cutting process runs smoothly and efficiently. One important test is to check the laser for any damages to the laser cutting head and mirrors.

This is important to ensure that the laser is of good quality and working properly and will be able to accurately cut the rubber sheets. Another test is to ensure that the rubber sheets and laser are set up properly on the cutting bed. This helps in ensuring that the laser is properly aligned with the material, which will help in delivering clean and precise cuts.

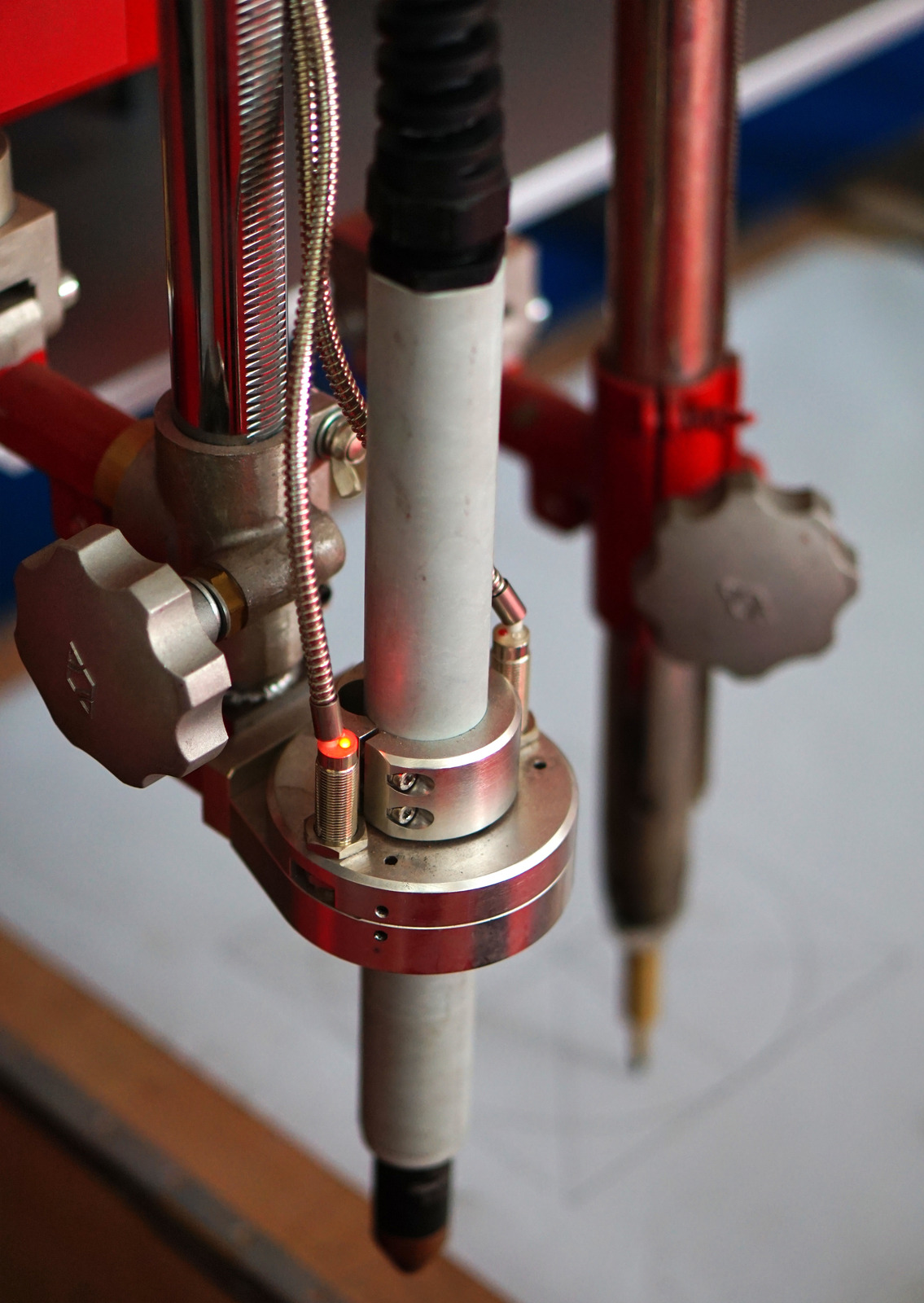

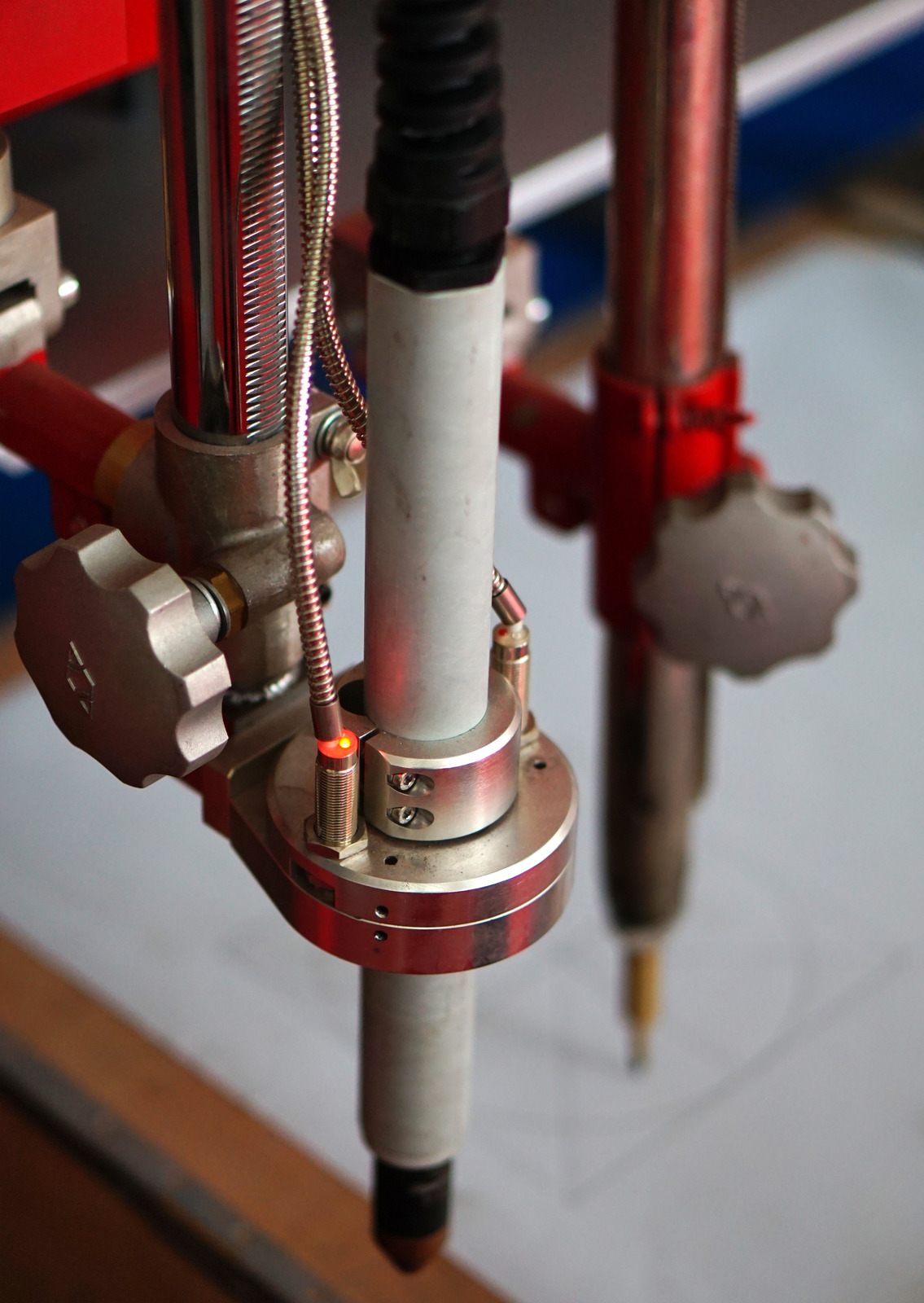

Setting Up Laser Machines

Choosing the Correct Settings

Choosing the correct settings when preparing your rubber sheets for laser cutting processes and setting up laser machines is a crucial step in ensuring a successful outcome. It is important to understand the type of material you are working with to determine the correct speed, power, and frequency settings. Additionally, the thickness of the material will determine the type of focus lens to use, as well as the size of the beam.

It is essential to set the correct speed, power, and frequency settings to ensure an even cut. Additionally, the beam size should be large enough to penetrate the entire sheet for clean, uniform cuts.

Safety Precautions

Safety is always a priority when working with lasers, especially when it comes to cutting rubber sheets. It’s important to take the time to set up your cutting area properly. Make sure you follow the user guide of your laser machine for exact safety protocols and wear safety glasses.

When setting up the laser machine, be sure to adjust it to the correct distance from the rubber sheets and correct cutting speed. It’s also important to keep your work area well-ventilated to prevent fumes from the rubber sheets. Also, make sure there are no flammable materials in the vicinity of the laser machine – if there is, move it to a safer distance away.

Programming and Calibration

Before you begin the laser cutting process for rubber sheets, you need to set up your laser machine for the job. To do this, you will need to program the machine with the ideal settings that will provide the best cut quality. The programming and calibration of your laser machine is a very important step in maximizing the potential of this technology.

First, you need to set up the cutting parameters for the rubber. You should decide on the power level and the speed of the laser beam. Choosing a higher power level will allow the laser to cut through the rubber faster, however, it may also result in a rougher cut quality.

Laser Cutting Processes for Rubber Sheets

Choosing the Right Cut Type

When it comes to laser cutting processes for rubber sheets, it is important to choose the right cut type for your project. Generally speaking, rubber is cut using a laser cut or a die cut. A laser cut uses a laser beam to create a precise and smooth line between two edges, while a die cut uses a metal die to punch a precise shape into the rubber sheet.

Laser cutting is the most accurate type of cut, and is also the most precise.

Utilizing Advanced Cut Techniques

When it comes to using advanced cut techniques for laser cutting processes on rubber sheets, it is important to prepare your rubber sheets correctly. The initial step is to ensure that both the laser and the rubber sheet are clean. If there is any dust or dirt on either, it can affect the cutting process.

Once the rubber sheet and laser are clean, the sheet must be secured onto the cutting bed. Laser cutting requires the sheet to remain secure during the cutting process, as the pressure needs to be consistent throughout the cut.

Post-Cutting Refinements

Post-Cutting Refinements Once a laser cutter has finished its job, there are usually still some post-cutting refinements that need to be done prior to the finished product being ready for shipment to customers. One example is a process called skiving. This technique is used to smooth the surface of the rubber sheet that has been cut, which can help to reduce drag resistance of the sheet and make it easier to install.

Can I laser etch rubber?

Yes, you can laser etch rubber! Laser cut rubber is a great way to create precise shapes and designs in the material. Laser cutting is a process in which a laser beam is used to cut through rubber sheets with high degrees of accuracy and precision.

It is particularly advantageous when you need to make intricate or very small cuts in the material. When laser cutting rubber, it is important to make sure that you are using the right type of material.

How do you clean laser cut rubber?

Cleaning laser cut rubber is a crucial step in the laser cutting process as it helps to prolong the life of the rubber, keep cuts clean and precise, and makes it easier to work with. The cleaning process helps to remove dust, debris, oils, and other debris that has built up on the rubber. The best way to clean laser cut rubber is to use a mild detergent solution, such as a mixture of 1 part mild dish soap and 10 parts water.

Simply use a soft cloth or brush to apply the detergent to the rubber surface and then rinse with clean water. This process should be repeated as often as necessary to ensure a clean, consistent cut.

Conclusion

Summary of What We Learned

In this blog, we discussed the importance of properly preparing your rubber sheets for laser cutting processes. First, we discussed the best rubber sheets to use based on the thickness, stiffness, and absorption of laser power. We then went over the various laser cutting parameters that need to be considered when it comes to rubber sheets, such as the laser power, speed, focus, and distance.

Benefits of Laser Cutting on Rubber Sheets

tting The benefits of using a laser to cut rubber sheets are hard to ignore. Laser cutting on rubber sheets is a precise, accurate and reliable way to cut, shape and form rubber into any desired shape, contour or size. Laser cutting can also be used to create intricate detailing and uniformity not usually possible with conventional methods.

Additionally, with the use of a laser beam, heat generated from the cutting process is significantly reduced, resulting in less oxidation, distortion and shrinkage of the rubber material during the cutting process.