Summary

Materials Compatible with Laser Engraving

Date: January 30, 2025

Author: Max

When it comes to laser engraving, selecting the right materials is akin to finding the perfect match on a dating app — you need to consider compatibility, characteristics, and sometimes even a touch of chemistry. Whether you’re wielding a CO2 laser or a fiber laser, the right material can make or break your engraving game. Let’s dive into the intricacies of choosing materials that will help you achieve that flawless engraving you’ve been dreaming of.

Understanding Material Compatibility

Laser Types Matter

Compatibility depends on the laser type you’re using. CO2 lasers, fiber lasers, UV lasers, and blue lasers each have unique advantages and limitations with various materials. Choosing a material that matches your laser type is essential; otherwise, you might be left with a subpar engraving that looks more like a science experiment gone wrong than a work of art. As outlined, here are the types of lasers:

– CO2 Lasers: Good for organic materials like wood and leather.

– Fiber Lasers: Work well with metals and plastics.

– UV and Blue Lasers: These are versatile and can handle a wider variety of materials, including glass and some specialized plastics.

Material Properties to Consider

Reflectivity, Thermal Conductivity, and Hardness

Each material comes with its own set of characteristics that can affect the engraving quality. Factors like reflectivity (which can cause damage to your laser), thermal conductivity (which can influence how the material absorbs heat), and hardness (which determines how easily the material will engrave) are crucial. For instance, metals generally require different settings than wood to achieve that desired precision. You’ll want to read the engraving manual like it’s the latest blockbuster novel.

Safety First

Safety should never be an afterthought. Some materials can release toxic fumes when burned, or they might even be flammable. Materials such as PVC and polycarbonate are big no-nos; those can create nasty smoke that can not only ruin your project but also pose serious health hazards. Always prioritize materials that ensure your safety while still delivering beautiful results.

Commonly Used Materials

Now that we have the nitty-gritty out of the way, let’s talk about the star players in the world of laser engraving:

– Wood: Highly versatile and easy to work with. Different types (like plywood or MDF) offer varied results.

– Plastic: Comes in various grades; make sure to choose laserable acrylic or specific plastics to avoid disaster.

– Metal: Generally requires a fiber or UV laser for best results.

– Leather: Great for personalized items, but keep thickness in mind.

– Fabric and Textiles: Easy to engrave, commonly used in fashion and home décor.

– Glass: Beautiful results can be achieved, but requires careful handling and the right laser type.

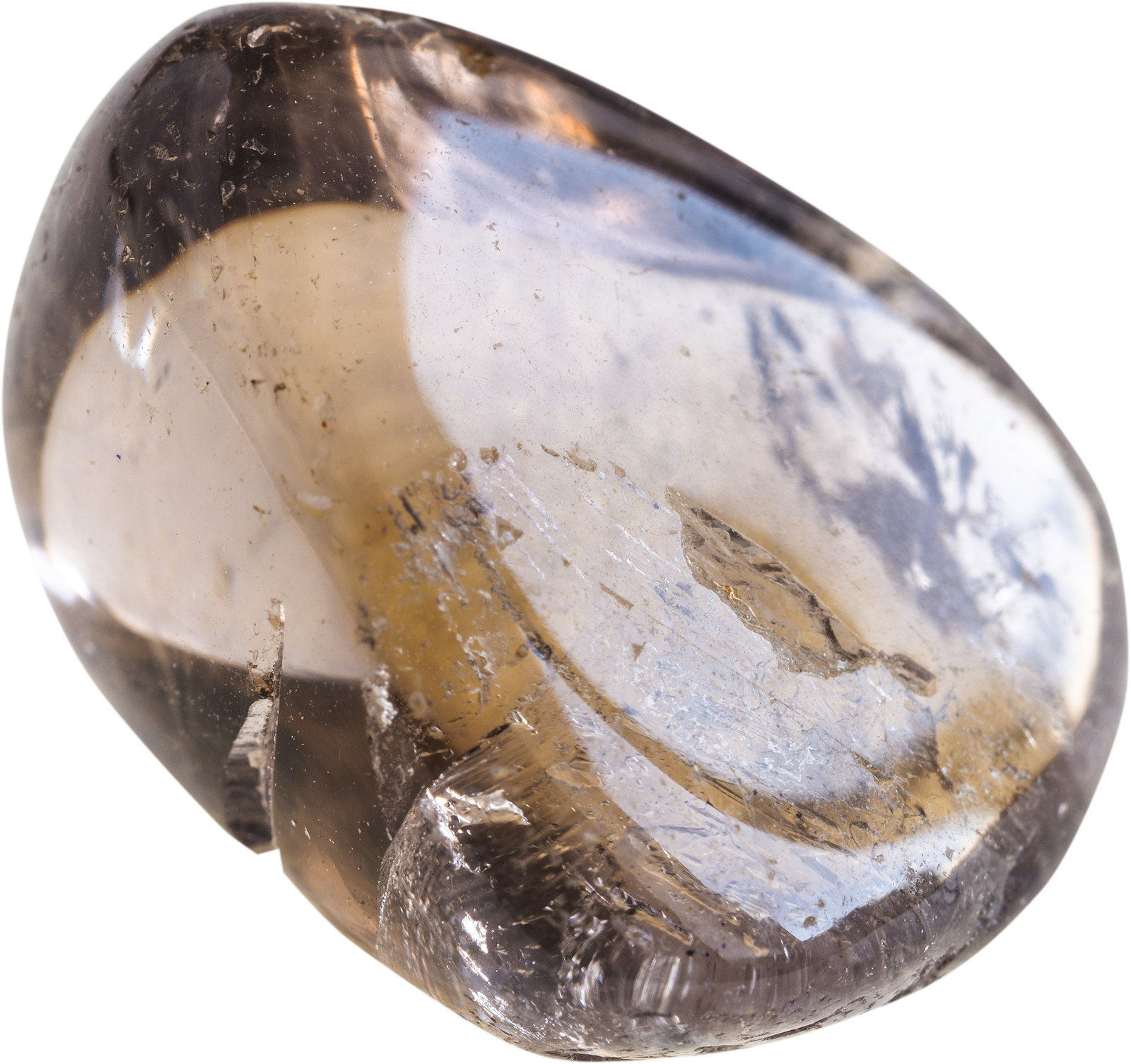

– Stone: Offers stunning finishes, especially for awards or decor pieces, but suits specific laser settings.

Choosing the appropriate thickness, color, and quality of these materials is a must. The thickness often affects engraving depth and clarity. In many cases, opting for high-quality materials yields dramatically better outcomes — think of it as investing in that designer jacket rather than a knock-off.

Equipment Highlights

Exploring Various Laser Machines

To complement your material choices, let’s look at the machines that can make magic happen.

– Epilog Laser Machines: Known for their laserable material compatibility, Epilog provides a comprehensive guide on materials tested with their FiberMark Laser©. If you want reliable data, check this out! Their material compatibility guide ensures you won’t end up with a surprise middle school science project.

– xTool Laser Machines: These machines shine when cutting and engraving on materials like wood, acrylic, and even metals with fiber lasers. Their P2 55W CO2 laser cutter can take your material ambitions to new heights by delivering precision with every cut. However, avoid naughty materials like PVC that can ruin the party. Detailed guides on suitable and unsuitable materials can save you from an enchanting disaster.

– Trotec Laser Machines: These bad boys can handle everything from plastics to textiles and rubber. Their Flexx laser, which combines CO2 and fiber lasers, maximizes your processing options, so you can engrave just about anything — from your friend’s face to a motivational quote (or both). Plus, their material testing services can play matchmaker for you and your material of choice.

DIY and Supply Options

If you’re on a quest for versatility, then consider kits like the Csyidio 175 PCS Engraving Material Box. It has everything from wood to acrylic and comes with handy instructions, making it suitable for users at any skill level. Plus, easy returns are part of the package if you find it’s not your material soulmate.

Cost and Availability

While material selection is critical, let’s not overlook the elephant in the room: cost and availability. When you’re on a budget (who isn’t?), it’s wise to do a little research to find suppliers that offer quality materials without charging an arm and a leg. Websites like ACMER Laser provide a wide range of materials and color options at competitive prices, allowing you to stock up without breaking the bank. And let’s face it; the thrill of a good deal is just as satisfying as a perfectly engraved piece.

Best Practices for Handling Materials

When dealing with various materials, especially those that are tougher or more hazardous, implementing best practices can be the difference between success and disaster. Always ensure you:

– Use appropriate safety gear: Gloves, goggles, and masks are non-negotiable.

– Work in a well-ventilated area: This reduces the risk of inhaling toxic fumes.

– Store materials properly: Flammable materials should be kept away from heat sources and out of direct sunlight to avoid spontaneous combustion.

– Maintain your equipment: Regular maintenance will extend the life of your machine and improve engraving quality.

Ensuring Safety Standards

Adhering to safety standards can’t be overstated. It’s essential to understand the specific hazards associated with each material and the proper precautions to mitigate risks. For instance, using laser safety glasses and ensuring your workspace is adequately ventilated are crucial steps. Following the regulations established by OSHA and other safety organizations helps maintain a safe environment for all. Laser safety should never be optional; our eyes and lungs depend on it!

Understanding Laser Safety Regulations

To dive even deeper into the world of safety, it’s essential to familiarize yourself with laser safety regulations. OSHA standards cover general workplace practices that help reduce exposure to hazards associated with lasers, including personal protective equipment (PPE) requirements and the importance of a Laser Safety Officer (LSO). Having someone watching your back while you play with high-powered equipment is always a smart move. You’ll want to ensure your materials and processes are within guidelines to avoid involuntary visits from safety inspectors.

The Bottom Line

Choosing the right materials for laser engraving isn’t just a technical decision; it’s an art form in itself. With the right knowledge about material compatibility, properties, safety, and machine capabilities, you can create stunning engravings that leave a lasting impression. Understanding the unique properties of various materials will also allow you to experiment, innovate, and perhaps even stumble upon a new technique that revolutionizes your engraving style. So gear up, make informed choices, and let those lasers burn their way into your projects with flair and precision!

Key Takeaways

- Material Compatibility: Align your material with the laser type for optimal results.

- Safety is Paramount: Know the hazards associated with materials and adhere to safety standards diligently.

- Experiment & Innovate: Use high-quality materials and the correct laser settings to maximize your engraving quality.

- Cost-Effectiveness: Keep your budget in check by sourcing from reliable suppliers who offer variety without exorbitant prices.

- Don’t Fear the Manual: Read user manuals and machine guidelines; they’re your best friend in this engraving journey.