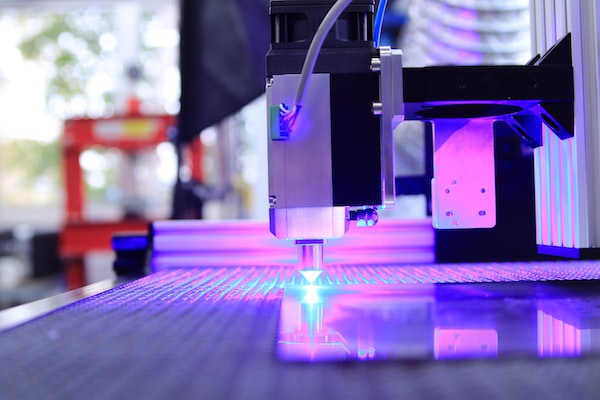

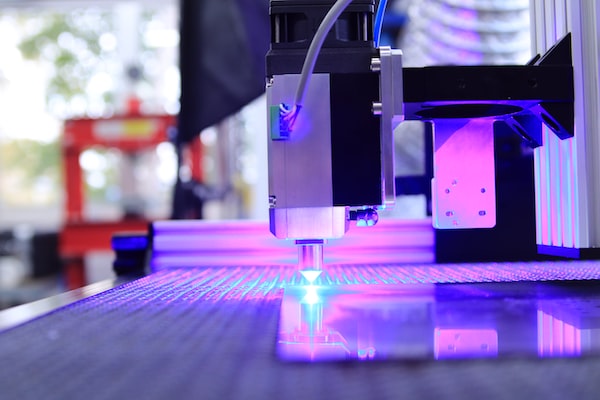

Welcome to this tutorial about keeping your laser cutter in the best shape for your woodworking projects! We’ll discuss the different ways you can maintain your laser cutter properly and why it’s important to take the necessary steps to keep it running smoothly. This includes regularly cleaning and lubricating key components as well as troubleshooting common issues. Read on to learn more about how to keep your laser cutter in tip-top shape!

Materials Needed

Cleaning Clothes

Cleaning clothes are one of the most important tools in the arsenal of anyone who uses a laser cutter or laser engraver. Cleaning clothes are used to both protect the laser cutter from dust and debris, as well as remove any material, dust, or residue that has been created while using the laser cutter. The material on the cleaning cloth should be lint-free, so as to not leave any unwanted residue on the material you are cutting/etching.

When using a laser cutter, you should clean the laser cutter off with a lint-free cloth before starting each cut or engraving job.

WD-40

For woodworking and other projects with a laser cutter or laser engraver, it’s important to keep your machine in tip-top shape. One of the best things you can do is protect the moving parts with a product such as WD-40(r). WD-40 is a multi-purpose lubricant that can be used on a variety of machines such as your laser cutter or laser engraver to help them run optimally.

The active ingredient in WD-40, Xylene, works to break down and remove any built-up dirt and debris on the machine, helping to keep it running smoothly and efficiently.

Cotton Swabs

Cotton swabs are an important and in many cases irreplaceable part of keeping a laser cutter and/or laser engraver in tip-top shape while woodworking or doing other projects or crafts. There are some materials that are particularly sensitive to heat, such as some of the thinner and more delicate woods, and using a laser cutter can cause some of this buildup. In order to protect the more delicate materials, cotton swabs can be used to clean and remove any buildup that may occur after using a laser cutter.

This can help prevent any damage to your materials, as well as your equipment, as it will prevent dirt, debris, and buildup from accumulating on the laser cutter’s parts.

Basic Maintenance

Clean Moving Parts

When it comes to woodworking, maintaining a laser cutter is key for producing high-quality results. As laser cutters rely on a laser beam to cut and engrave materials, the moving parts of a laser cutter must be kept in working order to ensure accuracy and safety. Cleaning the moving parts of your laser cutter is the best way to protect the longevity of your machine and guarantee you the best results.

There are a few steps you must take when cleaning your laser cutter. Firstly, make sure you shut the machine down and unplug it before working on it. You’ll also want to wear protective glasses when handling the components.

Start by checking the laser beam’s path.

Check Calibrations

ters When it comes to getting the most out of your laser cutter when making woodworking projects, it is important to make sure it is in tip-top shape. One key element of maintenance to consider is checking calibrations on your laser cutter or laser engraver. This includes regularly checking the power settings and refocusing the laser head when necessary.

When checking the power settings on your laser cutter, make sure that the laser is not burning too deeply into the wood.

Check for Obstructions

Keeping your laser cutter in top-shape isn’t difficult if you remember to check for obstructions regularly. Whether you’re using a laser cutter for basic maintenance or for woodworking, it’s important to make sure there’s nothing blocking the beam that could damage the laser cutter or your project. Even the tiniest speck of dust can be incredibly harmful, so you should inspect your laser cutter on a regular basis for potential blockages.

If you’re using a laser cutter for woodworking, it’s especially important to be aware of potential blockages like sawdust and wood particles that could cause damage to the machine.

Advanced Maintenance

Greasing of Motors

ters Greasing of Motors is an important part of the maintenance of a laser cutter and engraver to keep them running optimally. All the moving parts that make up the mechanisms of a laser cutter need to be properly greased to protect the metal parts from wear and tear as well as to provide protection from heat generated by the device. The most important areas to grease on your laser cutter include the stepper motors, lead screws, pulley bearings, and drive shafts.

Each part needs to be lubricated in order to keep it working properly and functioning efficiently.

Replacing Wear Parts

Replacing Wear Parts on your Laser Cutter for Woodworking and Advanced Maintenance When you’re working with a laser cutter for woodworking and other advanced materials, it’s important to protect the quality of the machine in order to keep it in tip-top shape. A laser cutter can be an expensive investment, but proper maintenance and upkeep can ensure that it lasts for many years to come.

Checking Focus Distance

ters When it comes to keeping your laser cutter in top shape for woodworking or other advanced maintenance, one of the first things to do is to check focus distance. If you have a laser engraver, you probably already know about focus distance and how to adjust it when setting up. But if you’re new to laser cutting, understanding how to properly set your focus distance can help protect the integrity of your cutter and create the best possible results in your projects.

How do you align a laser head?

Aligning a laser head on a laser cutter is an important step in making sure your laser cutter is in tip-top shape for woodworking. Aligning a laser head ensures that the beam of light emitted from the laser is accurately aligned with the top surface of the laser bed. This is important because it helps protect the surfaces being cut and ensures a high-quality final product.

In general, most laser cutters come with instructions on how to align the laser head, although some machines may differ.

Why are my laser cut edges not straight?

When dealing with laser cutters, one of the most common frustrations is that the edges of the cut may not be as straight as desired. This issue can be caused by a variety of different factors, but the most common reasons typically include an incorrect cutting speed, incorrect machine settings, and/or not calibrating the machine correctly. Incorrect cutting speed means that too many pulses of air are used to cut the material, resulting in ragged edges.

How do you set the origin of a laser machine?

Setting the origin on a laser cutter can be a helpful step towards more accurate woodworking projects. Additionally, it helps protect the machine and ensures that your work is precise. Setting the origin of your laser cutter is a relatively straightforward process, and while it can vary based on the specific model of laser, the basic steps are typically the same.

First, find the touch-point (also called the origin point) on your laser cutter.

Conclusion

Summary of Tips

Conclusion: Keeping your laser cutter in tip-top shape for woodworking projects is essential for achieving the best results. Following the steps outlined in this guide will not only help you protect and maintain your laser cutter, but also keep it running efficiently, cleanly, and safely. In summary, the most important tips are to clean the laser cutter on a regular basis, use the right accessories and materials, protect the laser cutter from dust and other particles, keep the power source stable, and use the right settings for your project.

Benefits of Regular Maintenance

One of the primary benefits of regular maintenance for laser cutters is that it helps to protect the machine from wear and tear. Many materials used in woodworking create smoke and debris, and without proper upkeep of your laser cutter, these contaminants can take a toll on your machine. Regularly inspecting and cleaning your laser cutter will ensure that it runs smoothly and captures even the finest details while cutting.

Additionally, regular maintenance can help extend the lifespan of your laser cutter. Cleaning is also beneficial for precision and accuracy when laser cutting.