When you think about permanent markings on materials, you might picture the pecking of dot peen machines or the endless smudges of inkjet printers. But let’s take a step up into the world of laser marking—a shiny, high-tech process that leaves its mark (pun intended) efficiently, precisely, and permanently. But what is laser marking, and why should you care? Strap in as we unravel the mystery behind this innovative marking technique.

What Is Laser Marking?

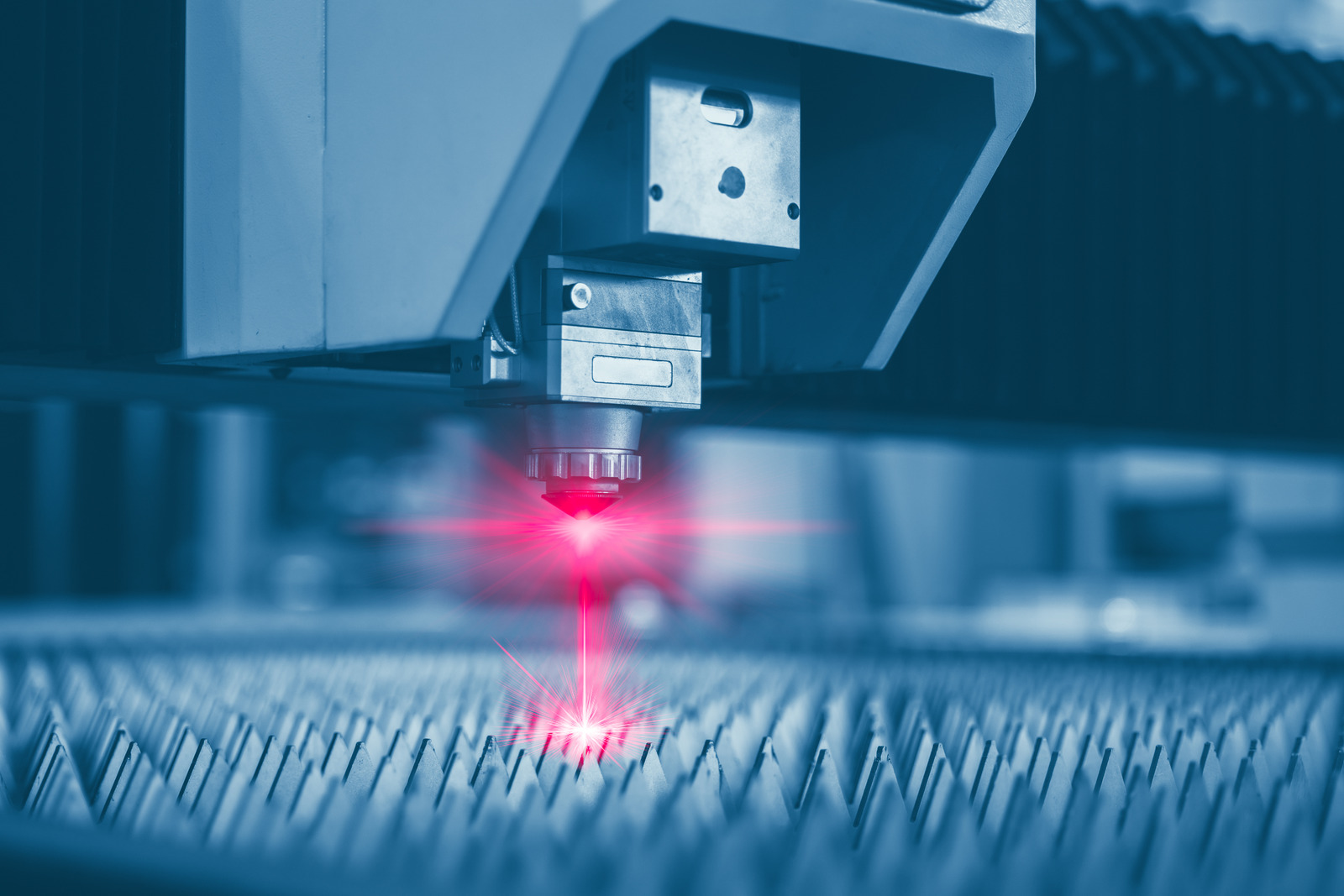

In essence, laser marking is a process that utilizes a focused beam of light to etch, engrave, or modify surfaces on various materials. It creates permanent marks through several methods like engraving, etching, and annealing. Imagine a lightsaber, assuming it wasn’t just a sci-fi fantasy tool, but a functional weapon for marking parts with high precision—now we’re in the right realm!

Laser marking might sound like some mystical art form, but it’s actually a highly controlled technique that produces various effects depending on the process and material used.

How It Works

The magic happens when a laser beam interacts with the target material. Here’s a breakdown of the common methods:

– Engraving: Removing material to create depth.

– Etching: Using heat to change the surface characteristics.

– Annealing: Altering the material properties without significant removal.

– Foaming and Discoloration: Changing the appearance without much alteration.

Each method has its own set of applications, depending on the required outcome.

Types of Lasers

Now, not all lasers are created equal. Different kinds cater to different needs:

– Fiber Lasers: Best for metals, offering precision and speed.

– CO2 Lasers: Perfect for organic materials like wood and plastics, making them the go-to for everyday crafting projects.

– Green and UV Lasers: Right for heat-sensitive and delicate surfaces, ideal for intricate designs.

– Pulsed Lasers: Deliver high energy density for faster and deeper marking, providing a quick solution for marking high volumes.

Tools like Trotec laser machines stand out for their speed and high productivity, capable of marking delicate materials while still invoking the power of the force—or at least that’s how they feel.

Benefits of Laser Marking

One of the key advantages of laser marking is its permanence. Unlike traditional methods, which can wear out over time or smudge, laser markings resist abrasion, heat, and chemicals. Here are a few nifty benefits to consider:

– Speed: This process is much faster compared to older techniques, making it suitable for high-paced production lines.

– Precision: You can achieve very detailed markings, ensuring that even the tiniest logos or serial numbers remain legible.

– Sustainability: It’s eco-friendly, with no need for inks or chemicals, cutting down on waste and operational costs.

– Traceability: Playing a pivotal role in industries where part identification is crucial, such as automotive manufacturing.

As researchers have noted, laser marking is incredibly advantageous for its minimal maintenance and environmentally friendly approach, making it a smart choice for many companies. On top of that, it reduces operational costs due to the elimination of consumables like inks or tags, making it an efficient solution.

Applications Across Industries

Laser marking isn’t just a fancy tool for the tech-savvy; it’s a versatile solution found across various sectors. Here are some key areas where you might see it:

– Automotive: Marking parts with 2D barcodes and serial numbers ensures proper identification and traceability even after post-treatments.

– Aerospace and Medical: Sealing the deal on precision, safety, and regulatory compliance, critical in ensuring the success of complex assemblies.

– Product Branding: Creating logos on goods sans the messy labels (goodbye fading stickers!).

– Consumer Goods: From electronics to furniture, laser marking is employed to provide consistent and durable branding.

Choosing the Right Laser System

Selecting an appropriate laser marking system is no walk in the park because it hinges on a variety of factors, including the materials being used, the required marking characteristics, and the operational environment. For instance:

– Material Composition: Metals may require fiber lasers, while plastics may be best suited for CO2 lasers.

– Desired Mark Quality: What type of marking do you need? Deep engravings or surface modifications?

– Production Speed: Are you racing against time in a high-output situation?

Understanding these aspects is crucial for getting the most out of your investment in laser technology.

Key Considerations for Safety

While we’re all fans of high-tech wizardry, it’s crucial to prioritize safety when operating laser markers. Following proper guidelines can ensure you don’t turn your laser from a marking hero into a cautionary tale.

Laser accidents, while rare, can lead to serious injuries, so it’s essential to use protective gear and follow operational protocols. For instance, always wear safety goggles specifically designed to filter laser light and ensure the work area is well-ventilated to prevent the inhalation of any hazardous fumes.

Enhanced Operational Efficiency

In addition to its practical uses, laser marking significantly boosts operational efficiency. As industries continue to prioritize automation and precision, laser marking provides an ideal balance of speed and quality. This not only saves time but also reduces waste, aligning with modern sustainability initiatives. Moreover, laser marking can integrate seamlessly into automated production lines, allowing for uninterrupted workflows and minimal downtime.

Conclusion

In a nutshell, laser marking is an advanced, efficient way to achieve permanent, high-quality marks on a variety of materials. Its numerous advantages over traditional methods make it invaluable across diverse industries, enhancing speed, precision, and sustainability while also ensuring compliance with necessary regulations. From automotive components to branding products, this method serves as a powerful tool in the modern manufacturing toolbox. So, if you’re looking to get into this cutting-edge world, roll up your sleeves and dive into the laser marking revolution!