With the rapid evolution of technology, it is more important than ever for businesses to keep up to date with the latest trends in order to stay relevant. One such trend is 3D printing, which has become increasingly popular in recent years. If your business currently involves laser cutting, then you may want to consider exploring the potential benefits of incorporating this technology into your business model. In this article, we’ll discuss how introducing 3D printing to your laser cutting business can help you stay ahead of the competition and increase customer satisfaction.

What You Need to Introduce 3D Printing to Your Laser Cutting Business

Evaluating the Benefits of 3D Printing for Your Business

Evaluating the Benefits of 3D Printing for Your Business With the advent of 3D printing technology, companies everywhere are exploring the potential of this highly versatile technology to improve their business output. 3D printing has the power to revolutionize a wide range of industries, including laser cutting. One of the major benefits of introducing 3D printing to your laser cutting business is the improved production efficiency and speed.

3D printing processes can be completed much faster than traditional methods because they do not require any tooling or jigs that may otherwise slow down the work process.

Supplies and Materials Needed for 3D Printing

When it comes to introducing 3D printing to your laser cutting business, there are a few supplies and materials you’ll need to get started. First off, you’ll need a 3D Printer. There are tons of options out there from desktop to industrial grade, so it’s important to research and select one that is suitable for your business needs.

Next, you’ll need filament for your 3D printer.

Costs Involved in Setting Up a 3D Printing Facility

Introducing 3D Printing to Your Laser Cutting Business can be a great way to expand your services and provide more value to your customers. However, like any new business venture, there are costs involved in setting up a 3D printing facility. Depending on the type of 3D printer you choose and how capable you want it to be, these cost can range from a few hundred dollars for an entry-level FDM machine to tens-of-thousands for top-of-the-line SLA options.

Training Your Staff

Theoretical and Technical Training

Introducing 3D Printing to Your Laser Cutting Business, Training Your Staff – Theoretical and Technical Training When transitioning to a 3D printing business, your laser cutting staff will need to be properly trained on the theoretical and technical aspects of the technology. They will need to understand the concept of a 3D printed object, how different materials are used in the process, and how to ensure optimal performance when using the 3D printer. To start, it’s important to familiarize your staff with different aspects of 3D printing.

Safety Training

to a laser cutter When it comes to introducing 3D printing to your laser cutting business and training your staff, safety should always be a top priority. 3D printing and laser cutting involve powerful machines and the potential for danger. Therefore, providing your staff with the right safety training is essential when it comes to the successful adoption of this technology.

Setting Up the 3D Printing Facility

Finding Space for the Facility

If you are considering introducing 3D printing to your laser cutting business, one of the first steps is to find the space for the facility. Depending on the size of your business, this could mean leasing or buying additional space, or finding a spot in an existing building to house the equipment. It’s important to take into account the size of the 3D printer, as well as other equipment and supplies, you will need to properly run the facility.

You’ll also need to consider electricity and air ventilation when deciding on a suitable place. Another factor to consider when finding space for the facility is accessibility.

Ensuring Optimal Ventilation and Particulate Control

When introducing 3D printing to a laser cutting business, ensuring optimal ventilation and particulate control is essential to the safety and quality of the production facility. 3D Printing produces small particles of plastic or resin that are released into the air, which can accumulate in the workspace and cause problems for workers, machinery, and other components in the production facility.

Calibration and Initial Set Up of the Machines

When introducing 3D printing to a business that currently utilizes laser cutting, there are important steps to take in order to ensure the calibration and successful initial set up of the machines. Before beginning anything, make sure that your 3D printer and laser cutter are compatible. Make sure the 3D printer is certified to be used with laser cutting technology and that all necessary safety preparations have been taken.

Once the hardware is sorted, proceed with double-checking the software setup to make sure both the 3D Printing and Laser Cutting programs are up-to-date and properly installed. Doing frequent software updates and scans can help ensure smooth operations of both the 3D Printer and laser cutter.

Making Your First 3D Print

Selecting the 3D Model

Selecting the 3D Model When it comes to introducing 3D printing to your laser cutting business, the first step is selecting a 3D model. This is especially true if you are new to 3D printing. You need to find a 3D model that is suitable for printing with your 3D printer and compatible with your laser cutter.

There are many websites that offer 3D models that can be downloaded, such as Thingiverse.

Slicing the 3D Model and Generating the G-Code

One of the most important steps of introducing 3D printing to your laser cutting business is the slicing of the 3D model and generating of the G-Code. Slicing is a process where the 3D model is divided into multiple, thinner layers. These slices are used to generate the G-Code, which contains all information the computer needs to interpret and control the 3D printer.

Preparing the Materials for the Print

Preparing the materials for your first 3D print can be both daunting and exhilarating! Whether you’re introducing 3D printing to your laser cutting business, or simply embarking on a personal 3D printing project, there are a few key steps that you’ll need to take before processing your first 3D print. The first step is to identify the right 3D printing material.

Promoting Your New 3D Printing Capabilities

Leveraging Social Media and Online Platforms

Introducing 3D printing to a laser cutting business is a great way to stay ahead of the competition and offer customers something unique. Promoting your new 3D printing capabilities can be done through traditional and digital marketing outlets, but one of the most effective ways to quickly spread the word is by leveraging social media and online platforms.

- Leverage relevant social media platforms to increase your reach: Create profile pages for your business on leading social media platforms such as Facebook, Twitter, LinkedIn, and Instagram. Use frequent, informative posts to showcase the new 3D printing capabilities your business has to offer.

- Run targeted digital advertisements: Take advantage of well-established platforms such as Google Ads, Facebook Ads, and Instagram Ads to create highly targeted campaigns that spread the word of your 3D printing capabilities and reach new leads.

- Leverage existing networks: Tap into your existing networks of contacts such as customers or vendors to let them know of your new capabilities and generate interest.

- Have a clear Call to Action: When promoting your 3D printing capabilities, make sure to include a clear call to action in your posts and messages. Encourage users to contact you for more information or for a free quote.

- Invest in a website/blog: Creating a blog or website to showcase your 3D printing capabilities is a great way to draw attention to your business and provide customers with more in-depth information about your offering.

Working with Local Suppliers for Advertising

When introducing 3D printing to your laser cutting business, working with local suppliers to promote your new capabilities is a must. Local suppliers can provide you with a variety of resources, such as materials, samples, and marketing advice. Consider networking with local print shops, laser cutting businesses, and 3D printing companies, who can help you understand the local market’s needs and connect you to potential customers.

How 3D printing can help your business?

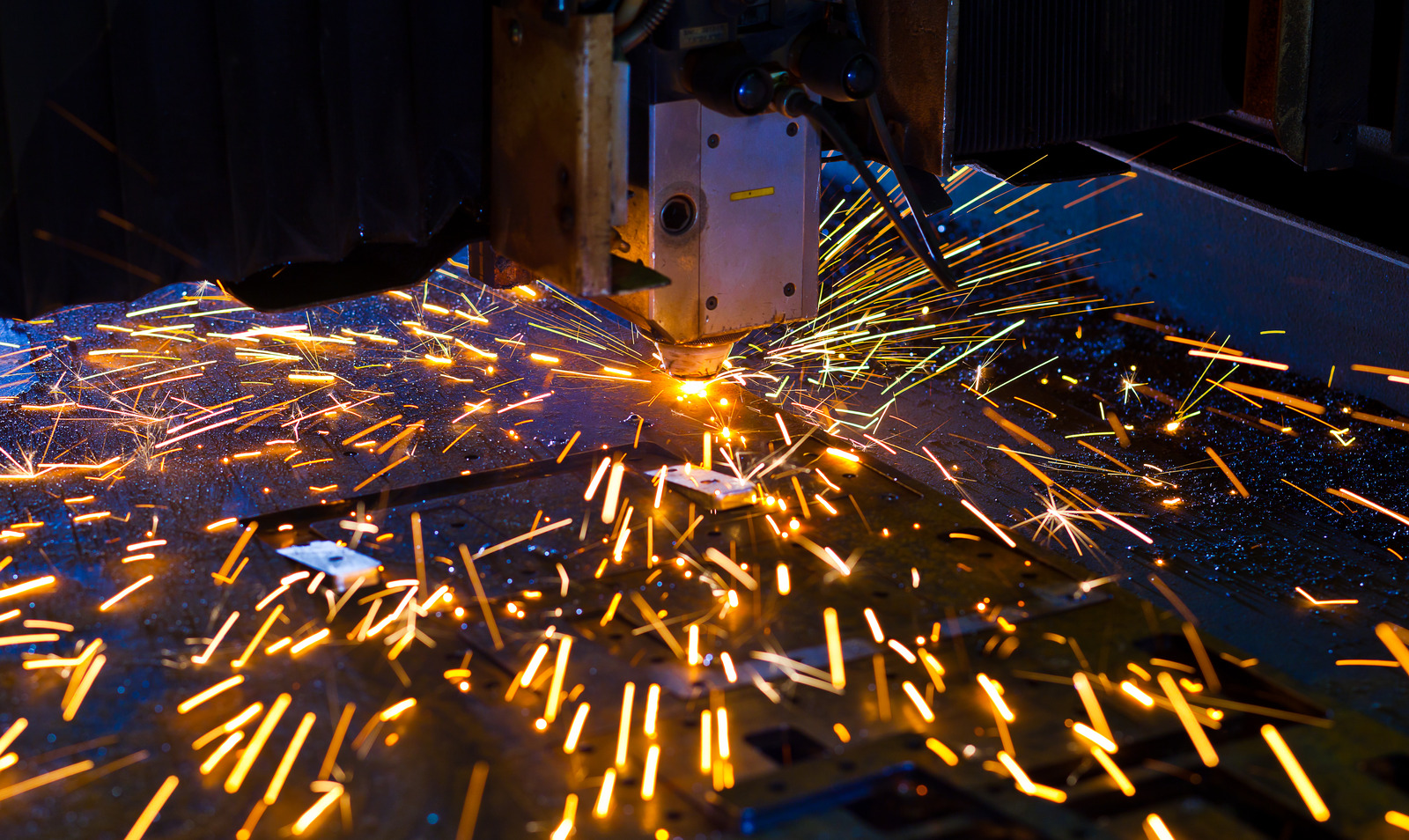

Introducing 3D printing to your laser cutting business can open up new possibilities and opportunities. Combining both processes can give you the opportunity to create more intricate designs as well as expand your product range. Laser cutting services can provide precise, sharp edges and details, while 3D printing can fill in the middle and add complexity.

Is it profitable a 3D printing business?

The short answer to the question of whether introducing 3D printing to your laser cutting business is profitable is, yes. 3D printing is a rapidly growing sector of manufacturing that can help your business get ahead of the competition, open up new lines of products, and make your customers more satisfied. With 3D printing, you can expand your product lines in a much shorter timeframe than traditional manufacturing methods.

Moreover, instead of the expensive tooling that is often required for the manufacture of custom parts, 3D printed parts come off your printer almost ready-to-use. This cuts down on costs associated with manufacturing parts and can add to overall profitability of your business.

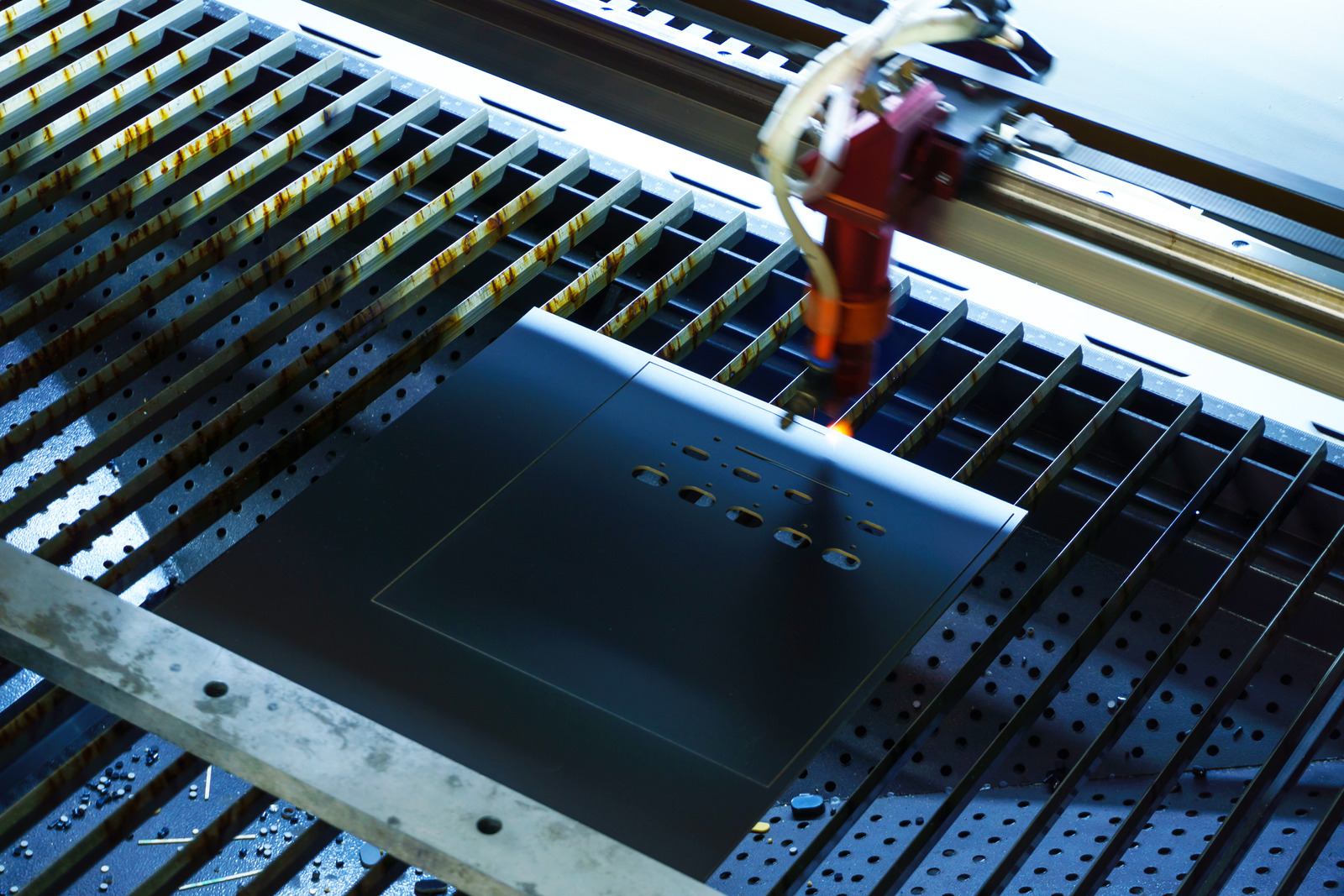

What is 3D printing and laser cutting?

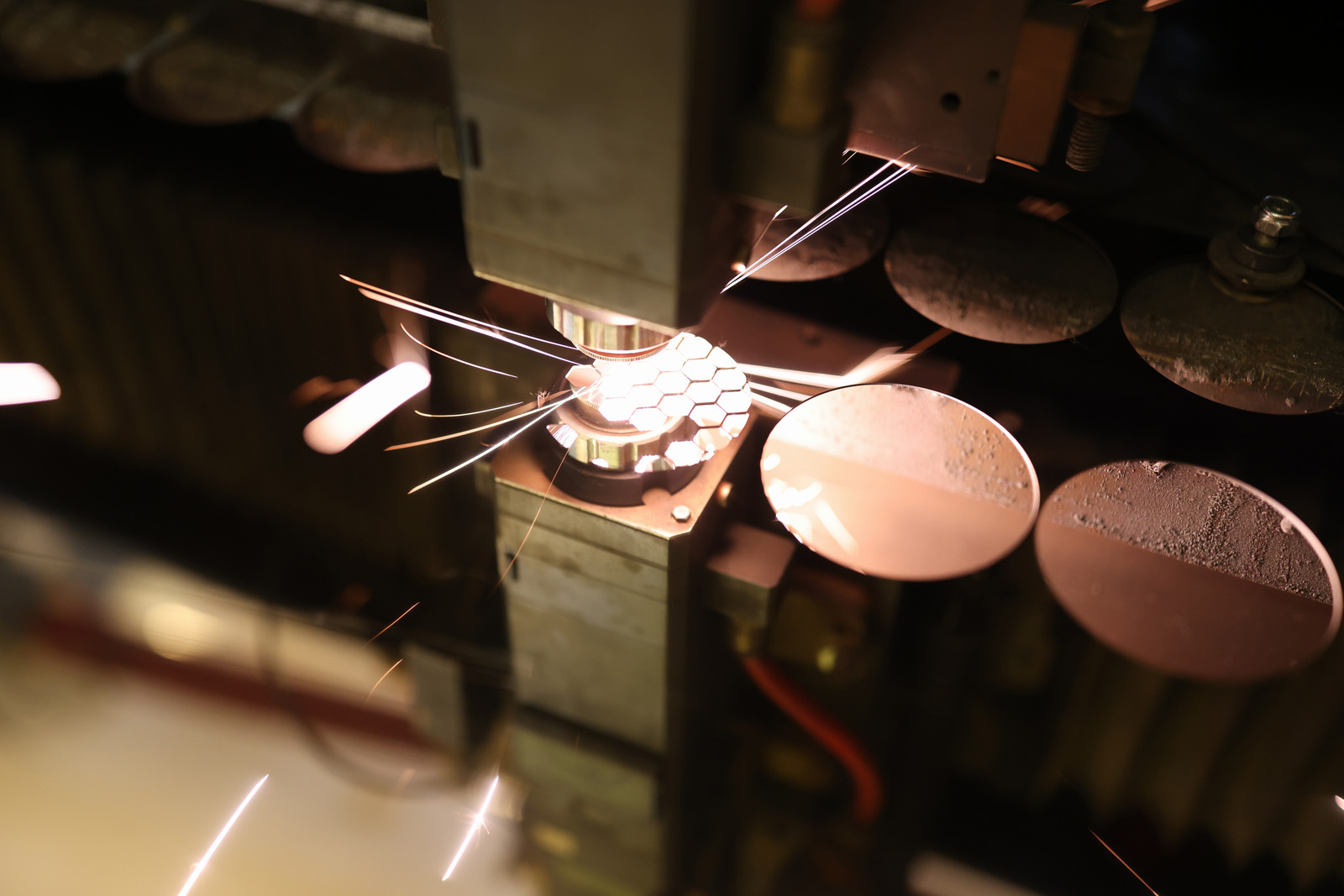

3D printing, sometimes referred to as additive manufacturing, is a process whereby a three-dimensional object is created from a digital file. Digital files made from specific software programs are sent to the printer, which reads the data and translates it into three-dimensional objects. During the printing process, the printer deposits layers of a material, such as plastic, resin, or metal powder, until the desired product is formed.

Can you use a 3D printer as a laser cutter?

No, you cannot use a 3d printer as a laser cutter. While some 3D printers are capable of cutting materials using a laser, this is not the same process as laser cutting. Laser cutting is a specific method that uses a powerful laser beam to cut through materials like plastics, metals, and paper.

The laser’s heat melts the material and vaporizes it, quickly and accurately cutting a desired shape. 3D printing, on the other hand, works by adding layers of material in a specific pattern to create a 3D object.

Conclusion

Conclusion Integrating 3D printing into your laser cutting business can be a great way to add value, increase efficiency, and save costs. It also opens up new possibilities with difficult materials and complex shapes. Although 3D printing has been around for decades, there are still many new techniques and materials that can be explored.

With advances in technology, 3D printing is becoming more accessible to businesses of all sizes, so it’s an ideal time to introduce it to your laser cutting business.