If you’ve ever had to cut materials for a project with a laser cutter, you know that selecting the right foam for your application can be tricky. Foam is often used for cutting delicate materials, for insulation, and for intricate curves and shapes. With so many different types and grades of foam available, it can be hard to choose the best fit for your needs. That’s why we’ve compiled this guide to help you select the best foam for your laser cutting job. Read on to learn more about what to look for in the perfect foam for the job.

Understanding Different Types of Foam

Common Types of Laser Cuttable Foam

When it comes to selecting the best foam for your laser cutting job, it’s important to understand the different types of foam that can be safely cut using a laser cutter. There are a variety of different materials, each with its own specific application, so it’s important to select the right one for the job. The most popular types of foam for laser cutting include polyurethane foam, polyethylene foam, and acrylic foam.

Each has its own unique properties, some of which may be more suitable for a given application than others.

Why Use Laser Cuttable Foam?

cutter When it comes to choosing the right material for your laser cutting job, foam is an ideal option. Laser cutting foam allows for precise and clean cuts on shapes of nearly any complexity and the material is incredibly durable. With laser cut foam, you can easily create intricate designs with a high degree of accuracy and detail, making it the perfect choice for a wide range of applications.

Factors to Consider When Choosing Laser Cuttable Foam

Shape and Size of the Project

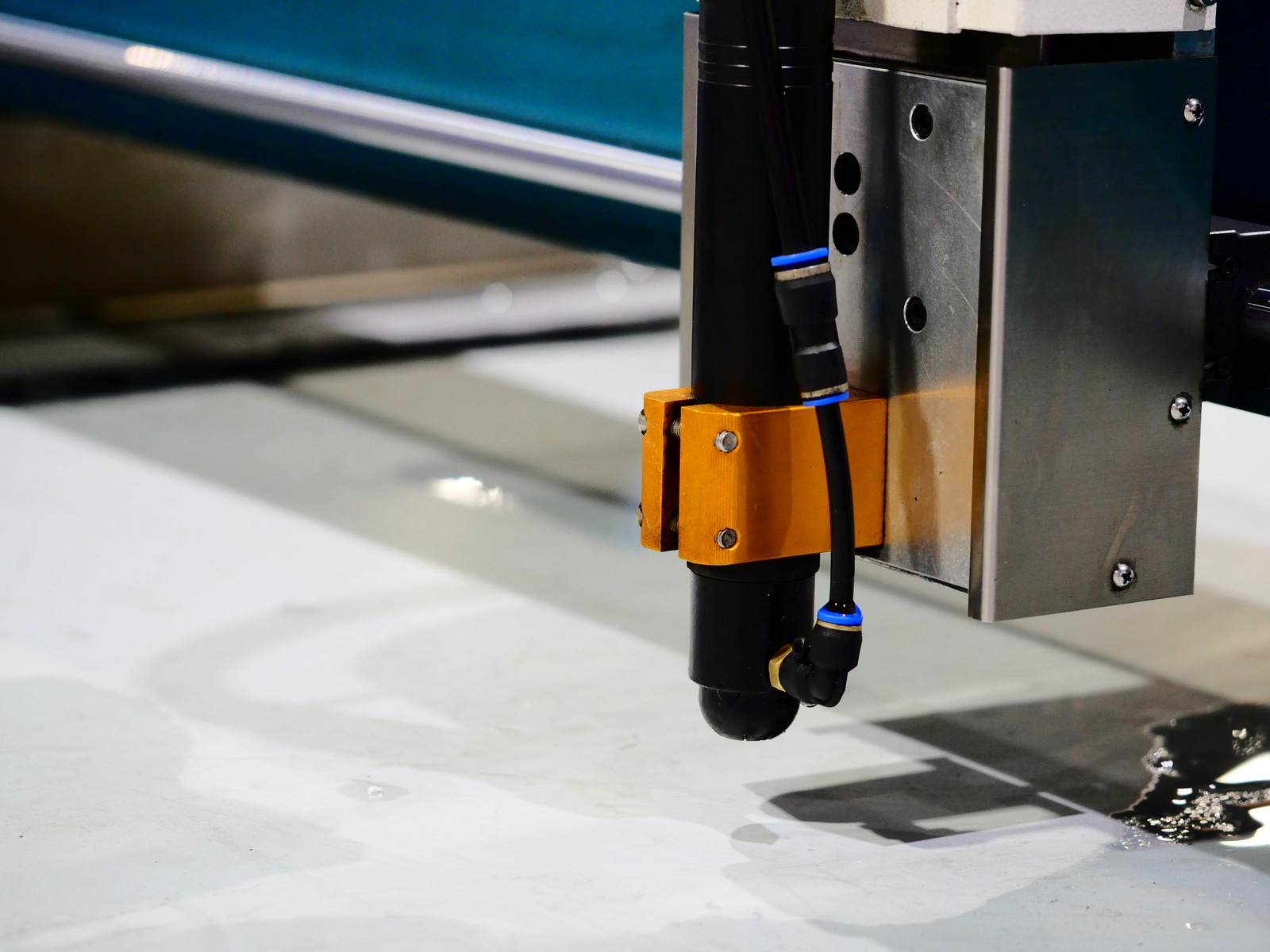

cutting foam When it comes to selecting the best foam for your laser cutting job, the shape and size of the project are essential factors to consider. Depending on the complexity of the design, different cutting techniques may be needed, such as curve or polygon cutting for intricate shapes. Additionally, the need for a specific kind of cutting apparatus, such as a laser or water jet, will determine the type of foam that works best for your project.

The size of the object will, of course, affect the output quality and the amount of time required to complete the job.

Thickness of the Foam

cutter for cutting foam The thickness of the foam you choose for a laser cutting job is an important factor to consider when selecting the best foam for the job. When it comes to laser cutting, the thicker the foam, the harder it is to actually get a clean cut without leaving frayed edges and other imperfections. For that reason, it’s important to choose a foam that is of an appropriate thickness.

When selecting a foam that is ideal for your laser cutting job, there are a few different factors to keep in mind. First and foremost, you need to take into consideration what kind of materials you’re actually cutting.

Quality of the Foam

cutting foam When selecting the best foam for your laser cutting job, an important factor to consider is the quality of the foam. It is important that the foam you choose is suitable for the laser cutter you have, and that it will produce a clean, satisfactory cut. To do this, you will want to look at the foam’s thickness, consistency, and overall stability.

Tips for Selecting the Best Foam for a Laser Cutting Job

Research Different Types of Foam

foam When it comes to selecting the best foam for your laser cutting job, the first step should be to research the different types of foam available. The types of foam typically used for laser cutting include polyethylene foam, polyurethane foam, and expanded polystyrene foam. Each of these materials come in a variety of densities and thicknesses, so it is important to choose a foam that meets the specific requirements of your specific project.

In addition to the type of foam material, you should also consider the best laser cutter for your project.

Find an Experienced Foam Supplier

If you need foam for a laser cutting job, you should select a foam that has been specifically designed to be resistant to laser cutting temperatures. Tips for selecting the best foam include looking for a product with the right density of the material in the right thickness range. You should also consider the type of cutting being done and what the maximum cutting temperature is.

- Look for a foam supplier who has a lot of experience with laser cutting. Ask for examples of previous work and make sure they understand the different materials, how they will look after being cut, and the necessary safety precautions that should be taken.

- Ask what kind of laser cutting techniques they use and if they’ve used any techniques that you’re interested in before. It helps to make sure they have the right equipment and techniques to meet your specific needs.

- Research the different types of foam available to find the right one for the job. Ask the supplier what number of materials they have and their recommended foam for laser cutting.

- Make sure the foam supplier has an understanding of your application, specific design needs, and time frame. They should have a comprehensive overview of the materials being used, the process of fabrication, and the complexity of the design.

- Read customer reviews online and check out the supplier’s website to get a better understanding of their quality of service, on-time delivery, and overall customer satisfaction.

Consider Durability of the Foam

cutting foam When selecting the best foam for your laser cutting job, one of the most important factors to consider is its durability. Depending on what you’re cutting and the amount of time you’re going to be spending cutting it, you will want to make sure the foam is going to be able to handle the job and stand up to repeated use. For example, if you’re cutting intricate and detailed artwork or shapes, you may want to consider a foam that can hold up to continuous use without becoming distorted or damaged.

What materials are best for laser cutting?

cutting When it comes to selecting the best foam for your laser cutting job, you want to make sure you’re using the most appropriate material for the job. There are several types of foam that are suitable for laser cutting, such as polyethylene, polyurethane, PVC, and foam board. Before making a selection, you need to consider the size and thickness of your material, the type of laser cutter you’re using, and the desired level of precision.

Polyethylene foam is one of the most commonly used foams for laser cutting.

Is it safe to laser cut polyurethane foam?

cutting When it comes to laser cutting, choosing the right foam is essential in order to achieve the desired results. The question is often asked, is it safe to laser cut polyurethane foam? The answer is yes, laser cutting is safe for polyurethane foam when it is done correctly.

Can Eva foam be laser cut?

cutting foam When it comes to selecting the best foam for your laser cutting job, a common material to consider is EVA foam. EVA foam is an extremely versatile material that can be used for all sorts of applications, including laser cutting. But before you choose EVA foam for your project, it’s important to understand the nuances and challenges of laser cutting the material.

Conclusion

Summary of Important Tips

cutting In this blog post, we’ve discussed how to select the best foam for your laser cutting job. There are several important considerations that you should keep in mind when selecting a foam for your project, such as the thickness, density and shape of the material, as well as the type of laser cutter you’re using. The most important factor to consider is the type of laser cutter you’re using.

Foam is most effectively cut with a high-power laser, such as a CO2.

Final Thoughts

cutter In conclusion, selecting the best foam for your laser cutting job is essential to get optimal results. The key is to consider the type of job you’re cutting, the budget you have, and the best laser cutter for the job. The best foam will depend on the size of the job and the complexity of the laser cut pattern.