The laser cutting and engraving machine is an incredibly powerful tool which can be used to produce high-quality and precise results. With the right knowledge and understanding, getting the best possible results out of laser cutting and engraving machines is easier than you think. In this article, we will discuss some tips and tricks on how to get the most out of a laser cutting and engraving machine.

Select a Laser Machine

Discuss types of laser machines

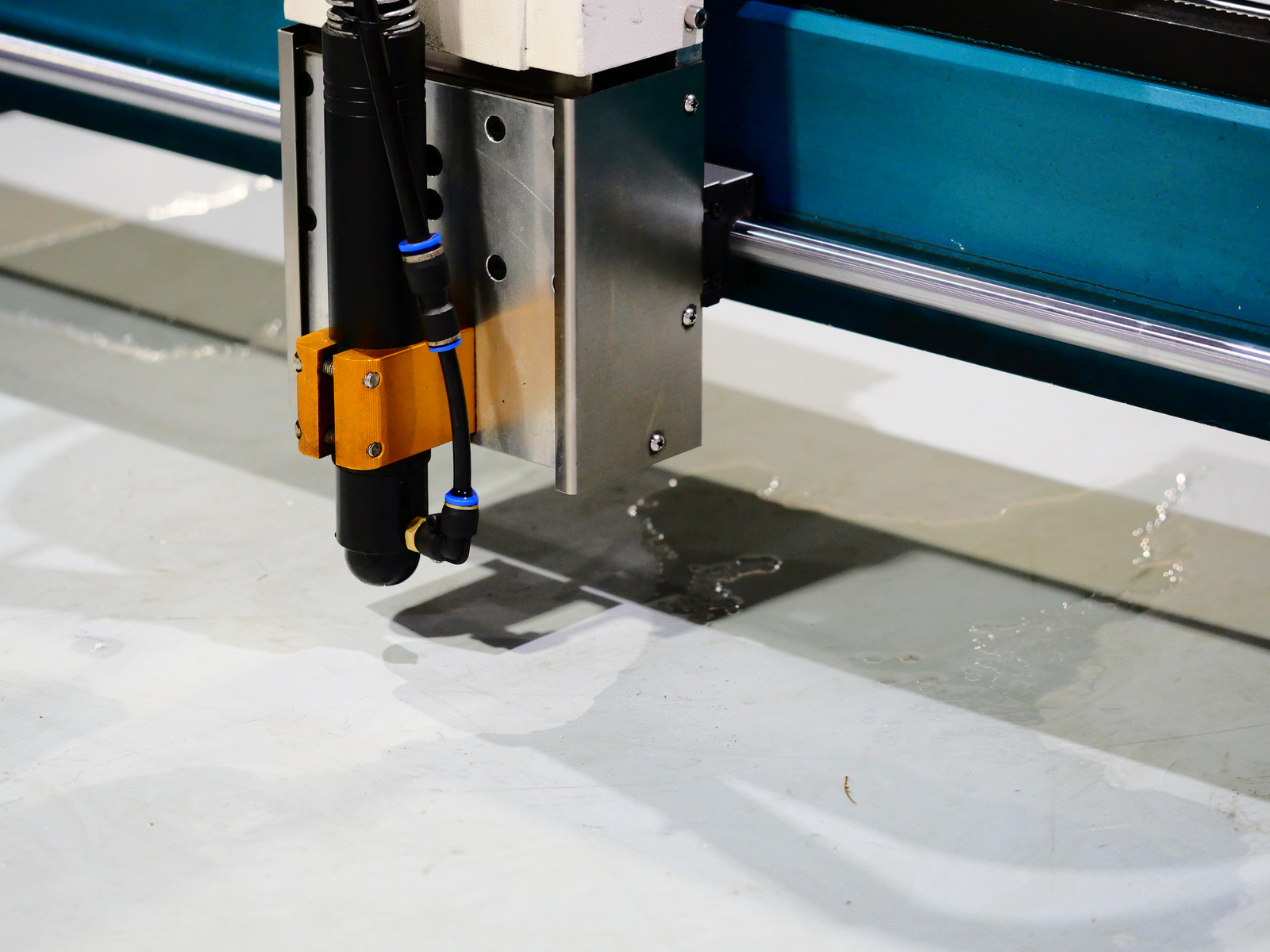

When it comes to laser cutting and engraving, one of the most important parts of the process is selecting the correct laser machine for the job. There are several different types of laser machines available, and each type has its own advantages and disadvantages that need to be considered when selecting the right machine for the job. The two most popular types of laser machines are CO2 laser cutters and Fiber Laser Markers.

CO2 laser cutters use a laser beam to cut through a range of materials, but are most often used for cutting wood, plastic, glass, and acrylic.

Consider budget, power, size, and capabilities

When it comes to getting the best out of a laser cutting and engraving machine, budget, power, size, and capabilities have to be considered. The right set of features will ensure that your laser works effectively and efficiently. Here are some key points to consider when selecting a perfect laser cutting machine.

Budget: When looking at laser cutting and engraving machines, it’s important to think about your budget.

Advise on where to find the best deals

Finding the perfect laser cutting and engraving machine to suit your cutting needs can be a daunting task. Fortunately, there are many resources out there that can help you find the best deals on laser cutting machines. One of the first places to look is online.

There are many online vendors that offer discounts on all kinds of laser cutters and engraving machines, so it pays to shop around and compare prices. Be sure to look at the specifications of each machine carefully and ask any questions you may have before making a purchase – this can help to ensure you are getting the best out of the product for your money. Another great option is to look for used or refurbished laser cutting machines.

Preparing for Use

Setting up the machine

When it comes to setting up a laser cutter and engraver for use, there are several steps you should take to ensure that you get the best results possible. The first step is to make sure that the machine is properly installed and grounded before use. This will help to minimize the risk of any electrical shocks to you or the machine.

Next, it is important to check the power supply to ensure that it is properly connected. When power is properly applied, it should not cause any sparks, smoke, or other unusual activity.

Preparing software for use

To get the best results out of your laser cutting and engraving machine, the first step is preparing the software and materials you’ll be using. This includes buying, downloading, and/or creating the material you’ll be using with the machine. If you’ll be using a computer-aided design (CAD) program–such as CorelDraw, Inkscape, CAMotics, Plycom or Illustrator–make sure your computer is up-to-date and you’re running the latest operating systems and graphic drivers to ensure a smooth, slick workflow when producing your designs.

Cleaning and routine maintenance

If you are looking to get the most out of your laser cutting and engraving machine, there are a few basic steps to follow in order to ensure that your machine is in top operating condition. Before using your machine, it is important to ensure that it is properly prepared with the necessary safety equipment and that the area is properly ventilated.

- Regularly wipe down surface of the machine to remove dust and debris that can impact how the laser cuts.

- Clean the window and mirror of the laser cutting/engraving machine to eliminate any residue build up that can obstruct light from travelling smoothly.

- Check tightness of screws and bolts on the machine to make sure that components are held properly together.

- Ensure that air passages of the machine are clear from any blockages, such as dust or lint, which can lead to smoke release.

- Clean laser beam lens or swap it out for a new one if any noticeable spots or discoloration appear.

Training and Tips

Operational safety considerations

If you plan to use a laser cutting and engraving machine for your project, you will need to pay extra attention to some key operational safety considerations. Laser machines are powerful tools that need to be used properly to ensure perfect laser cutting and engraving results. This will help you get the best out of your machine and protect yourself and those who may be working with you.

The first key safety consideration is to always wear the appropriate protective gear when working with your laser. This should include protective gloves, eye goggles, and a face mask. This will protect your skin and eyes from potentially dangerous flashes of light and laser beams.

Working with the software

When it comes to getting the best results out of a laser cutting and engraving machine, the software is key. As they say, garbage in, garbage out – so selecting the right software and working with the software to use it properly is essential. Prior to starting any project with a laser cutting and engraving machine, it is necessary to first understand the components and software involved.

Sample projects to get started

Sample projects to get started with a laser cutting and engraving machine can be a great way to get comfortable with how the machine works, and how to get the best out of it. There are a wide variety of materials you can use on your laser cutter, so it can be helpful to start with different sample projects to get a feel for how each material reacts when it’s being cut or engraved. Starting with smaller, simpler projects can let you get comfortable with the basics of how the laser cutter works before progressing onto projects that require more detailed forms and intricate designs.

A common practice is to start with basic shape cutting, before progressing onto engraving or cutting out images or text.

Helpful tips to achieve the best results

In order to get the best results out of a laser cutting and engraving machine, the most important tips to consider is the proper training and understanding of the machine’s capabilities. Training should involve learning the safety protocols as well as understanding how to properly calibrate the machine and adjust settings. In addition, use proper materials that are suitable for laser cutting, such as acrylic.

- Invest in quality materials – The quality of your finished product starts with the materials you use, so make sure you’re using top-notch materials when you’re laser cutting and engraving.

- Ensure proper machine setup – Good machine setup is necessary for optimal results. Make sure your devices are properly calibrated and functioning correctly.

- Prepare your artwork – Experience with working with vector files like Adobe Illustrator and Corel Draw will come in handy when creating your artwork, as they are tailored for laser machines.

- Experiment with contrast – Delicate contrast between your artwork and background will make your finished product stand out more. This can easily be achieved by the power settings and speed on your laser cutter.

- Follow safety protocols – Safety is of utmost importance when dealing with powerful machines like laser cutters and engravers. Make sure you are fully aware of the safety protocols and use all the necessary protection when operating the equipment.

Summarize the topics covered

This blog post covers the steps needed to get the best results with a laser cutting and engraving machine. The first step is to choose the right machine for the job. Length and power of the machine, speed of the motors, the rail system, and the power supply are all factors to consider when choosing the right machine.

Next, you’ll want to determine the type of material and thickness you will be cutting or engraving.

Provide helpful resources

Having the right resources is essential for ensuring you get the best results out of your laser cutting or engraving machine. Here are a few helpful resources to get you started: Laser Cutting Tutorials: Most laser cutting machines come with a set of instructions but tutorials online can provide detailed step-by-step instructions to help get you acquainted with the different settings and functions of the machine.

What should you not laser engrave?

When it comes to laser cutting and engraving, one of the most important things to consider is what should not be laser engraved or cut. This is due to the fact that some materials respond differently to the laser cutting process, and can create undesirable results. Examples of materials not to laser engrave or cut include: -Polycarbonate: This is a type of clear plastic that is not suitable for laser cutting.

It will melt when cut with a laser due to its high melting point. -Metals: Metal is usually not a good candidate for laser cutting due to the fact that the high heat of the laser beam can cause warping or other types of damage to the metal.

Conclusion

Conclusion Congratulations! Now you are armed with the necessary knowledge to get the best results when using a laser cutting and engraving machine. Keep in mind that perfect results can be difficult to achieve, so it’s important to think carefully about the material, settings and preparation of the material you are going to cut beforehand.

Before every job, consider investing a little extra time to double check your settings and your design to ensure that you get the perfect laser cutting results.