Are you curious about leveraging laser cutting machines in woodworking to produce professional finishings? If so, you’ve come to the right spot. In this article, we will explore the basics of how to create professional finishings with laser cutting machines. Specifically, we will discuss topics such as the benefits of laser cutting, as well as the various types of laser cutting machines available. Additionally, we’ll discuss some tips on how to get the best results while using laser cutting machines in woodworking. So, if you’re ready to enhance your woodworking projects with professional finishing, let’s get started!

Laser Cutting in Woodworking

What is laser cutting?

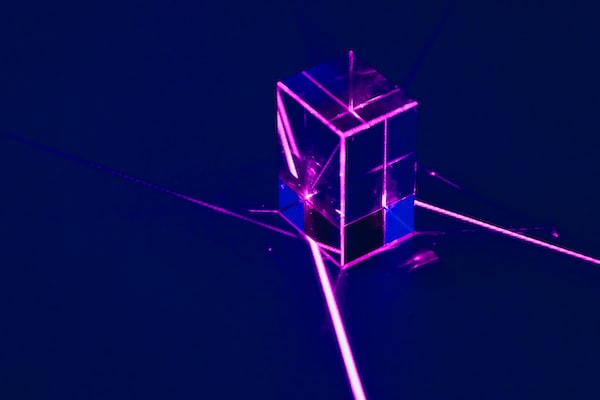

Laser cutting is a type of manufacturing process in which a laser is used to cut and shape materials, such as wood. This type of technology is often used in woodworking projects, as it is a precise and efficient way to produce a quality result. Laser cutters use a high power laser, usually a CO2 laser, to cut through materials with a high level of accuracy.

The laser beam is focused on the material, melting, burning, vaporizing, or cutting it away as it is moved along the cutting path. In addition to cutting, laser cutters can also be used for engraving intricate patterns into wood and other materials.

Types of laser cutting in woodworking

engraver When it comes to woodworking and creating professional finishings, laser cutting machines have revolutionized the industry. Laser cutters are advanced tools used to develop a quality result for projects. A laser cutter uses a beam of laser (hence the name) to cut through material with high precision and accuracy.

Depending on the strength of the laser and the type of material you’re working with, you can produce a variety of shapes and sizes.

Laser cutting safety

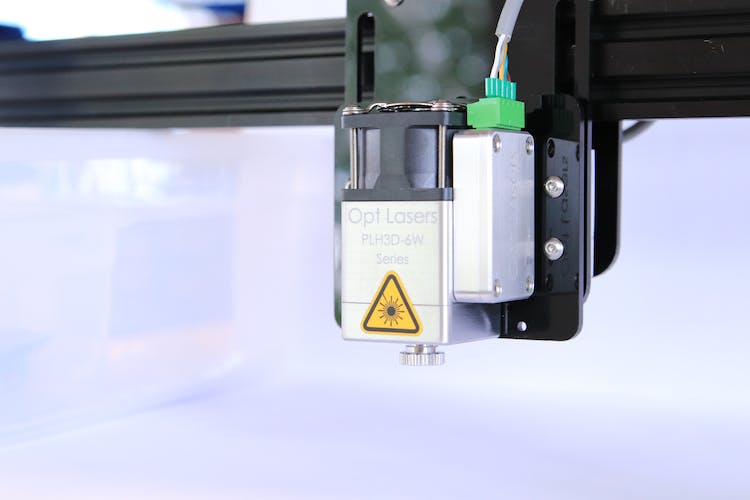

cutter When working with laser cutters, safety should always be your top priority. There are a few basic guidelines to keep in mind when using a laser cutter. First, make sure the machine is properly ventilated to reduce the exposure to fumes.

Also ensure that all operators are wearing protective gear, including eye protection and a face shield. Secondly, check to make sure the laser cutter is properly aligned before use. Finally, always check for loose wires or other potential hazards that could cause the laser to malfunction.

Getting Started with Laser Cutting

How to choose the right type of laser cutting machine

Choosing the right type of laser cutting machine for your woodworking projects will require a bit of research and understanding of the various types of laser cutters. A laser cutter is a type of machine that uses a beam of light to cut or engrave materials, and is ideal for precision machining and intricate details for projects like woodworking. Depending on the type of project, there are different types of laser cutting machines available that can help create a professional finish.

Setting up a laser cutting machine

engraver If you’re exploring the field of woodworking and have been curious about the possibilities of producing a professional-level finish with a laser cutting machine, you’re in the right place! Laser cutters and engravers provide a unique solution to turn your projects into a work of art, adding precision and intricate detailing that may have previously been unattainable with traditional woodworking methods.

Tips on using a laser cutting machine

cutting Using a laser cutter to create professional finishings with woodworking doesn’t have to be intimidating. Developing a fine finish using a laser cutter has a lot of potential to create items of very high quality that can be difficult to achieve using traditional methods. The first thing to do is to gather the resources for creating items with a laser cutter.

Most machines are capable of either laser cutting or laser engraving (or both). Different materials and settings are required for each task, so it’s important to consult the manufacturer’s guide or any available documentation. Laser cutting usually requires thicker materials than engraving.

Enhancing the Look of Woodworking Projects with Laser Cutting

Popular laser cutting techniques in woodworking

technology Laser cutting is a popular technique used in woodworking to create professional finishings and enhance the look of woodworking projects. Laser cutters are used to develop a precise finish, allowing woodworkers to produce a desired result in a shorter amount of time. A laser cutter uses a laser technology to provide a highly-accurate cut to the wood without sacrificing detail or precision.

Tips for achieving professional results with laser cutting

Laser cutting machines can add amazing professional finishing results to your woodworking projects and can instantly enhance their visuals. For best results with laser cutting, be sure to use high quality wood, as low quality wood may cause the laser to cause burns, discoloration, or other unwanted effects. You should also set the laser parameters according to the thickness of your wood, as incorrect settings can cause smoky edges or uneven cutting.

- Use a high-quality laser cutting machine that applies a precise cut for enhanced accuracy and consistency in your project.

- Design your laser cutting paths in advance so that you can control the speed and accuracy of the laser.

- Consider the material you are cutting before you start and make sure it is suitable for the laser cutting process.

- Invest in laser cutting software that can give you accurate cutting paths while also giving you detailed output.

- Always use protective gear and equipment when using a laser cutting machine to ensure safety.

Different types of materials for laser cutting

When working on woodworking projects, one of the most common techniques used to create professional finishings is laser cutting. Laser cutters are versatile tools that can work with a wide variety of materials, so you can use them to develop a diverse array of projects. Whether you’re a professional woodworker or a hobbyist, a laser cutter can help you create precise and intricate designs that will really make your projects stand out.

When choosing a laser cutter, you should consider what types of materials you plan on working with.

Maintenance and Care for Laser Cutting Machines

Tips for maintaining and caring for your laser cutting machine

Creating professional fininshings with laser cutting machines in woodworking requires immense attention to detail and accuracy. The first step is to be aware of the operating manual for the laser cutting machine and to know how to use it effectively and efficiently. Once you are comfortable operating the machine, the next step is to select the materials and settings that will help you create the desired finishings.

- Regularly clean and inspect the laser optics: To ensure proper functioning of your laser cutting machine, as well as accuracy and quality of your cuts, check and clean the machine optics frequently. Clean them using compressed air and cleaning fluid if necessary.

- Manage the air and exhaust system: Keep all air and exhaust vents clear and replace air filters regularly. This will not only help to maintain the power and performance of your laser cutter but will reduce noise levels as well.

- Maintain the beam source: Make sure to regularly check the beam source for any gas leaks or dirt, and ensure that the correct tinted glass and mirrors are installed.

- Take preventive maintenance measures: Caring for your laser cutting machine starts with preventive measures. The backing shims, electrodes, and timing must be inspected and adjusted as necessary.

- Store the machine in a dry environment: High humidity can cause condensation to accumulate inside the machine, damaging components. Storing it in a dry, dust-free environment will reduce the chances of this happening.

Cleaning and lubricating a laser cutting machine

Cleaning and lubricating a laser cutting machine is an important step in creating professional finishings with laser cutting machines. Keeping the machine clean will ensure that it runs efficiently and produces top-quality cuts. When using a laser cutter, it is important to always follow the manufacturer’s instructions for cleaning and lubricating your machine.

The first step in the process is to vacuum the interior and exterior of the laser machine. This will remove loose dirt and dust particles that can accumulate on the lenses and mirrors, as well as in the mechanics of the machine. It is also important to make sure that you clean the cutting bed of any residual materials that may be left behind.

Troubleshooting common laser cutting machine issues

machine Troubleshooting common laser cutting machine issues is an important part of achieving a professional finish with laser cutters. It can be tricky to develop a comprehensive maintenance and repair strategy for your laser cutter, but with a bit of research and experience you can get the results you’re looking for. The first step to troubleshooting any issue with a laser cutter is proper diagnosis.

By understanding the source of the issue, you can more easily determine what the best solution will be. If the issue turns out to be a material problem, different strategies can be used to mitigate the issue.

How do you prepare wood for laser cutting?

cutting If you want to create professional finishings with a laser cutter in woodworking, then it’s essential to start with good preparation. The right tools, materials and techniques can go a long way towards achieving a professional-looking end result. But before you get to the decorating and dressing stages of your project, you’ll need to know how to prepare the wood for laser cutting.

For the best results when preparing your project, you’ll need the right tools and materials.

How detailed can laser cutting be?

Laser cutters are powerful tools used in woodworking to develop a high-quality, professional finish. With a laser cutter, a variety of materials can be cut to create intricate shapes and patterns with a high degree of accuracy. Laser cutting also eliminates the need for manual cutting, making the process faster and more efficient.

One of the most impressive features of a laser cutter is its ability to produce a high level of detail. A laser can cut wood up to 0.001-inch thick with incredibly sharpness, often leaving a near-polished cut edge.

Conclusion

Summary of the different aspects of laser cutting in woodworking

cutter In conclusion, laser cutters are a great tool for any woodworker looking to develop a professional finish for their products. With a laser cutter, one can easily produce a precise and accurate cut and achieve a smooth edge. Additionally, laser engraving machines can be used to etch various patterns onto woods, increasing the outcome of the work.

Through a laser cutting machine, one can easily produce complex shapes, intricate designs, and elegant curves.

Benefits of using laser cutting machines in woodworking

engraving The benefits of using laser cutting machines in woodworking are clear. Laser cutters are perfect for many types of projects, from detailed architectural and design work to simple 2D item production. In addition to quickly and accurately producing parts, laser cutters can give a professional finish that can be hard to achieve with manual tools.

You can also develop a better understanding of the material you are working with and adjust your projects accordingly. When used in combination with a laser engraver, you can take the process a step further and produce a detailed, professional finish.