In recent years, businesses have become increasingly aware of the importance of going green and making sustainable choices. One way many companies are doing this is by selecting sustainable manufacturing practices. Among these strategies, laser cutting job applications are growing in popularity as a way to reduce the use of traditional paper-based applications. This article will explore the benefits of using laser cutting for job applications, and encourage more companies to take this approach when considering their manufacturing needs.

What is green manufacturing sustainability?

Green manufacturing sustainability is an approach to manufacturing that reduces the environmental impact of production by utilizing sustainable methods and materials. This includes reducing energy consumption, improving air and water quality, and investing in reusable resources. Sustainable manufacturing reduces the amount of pollution generated in order to produce products and create less waste while also conserving resources like water, energy, and natural materials.

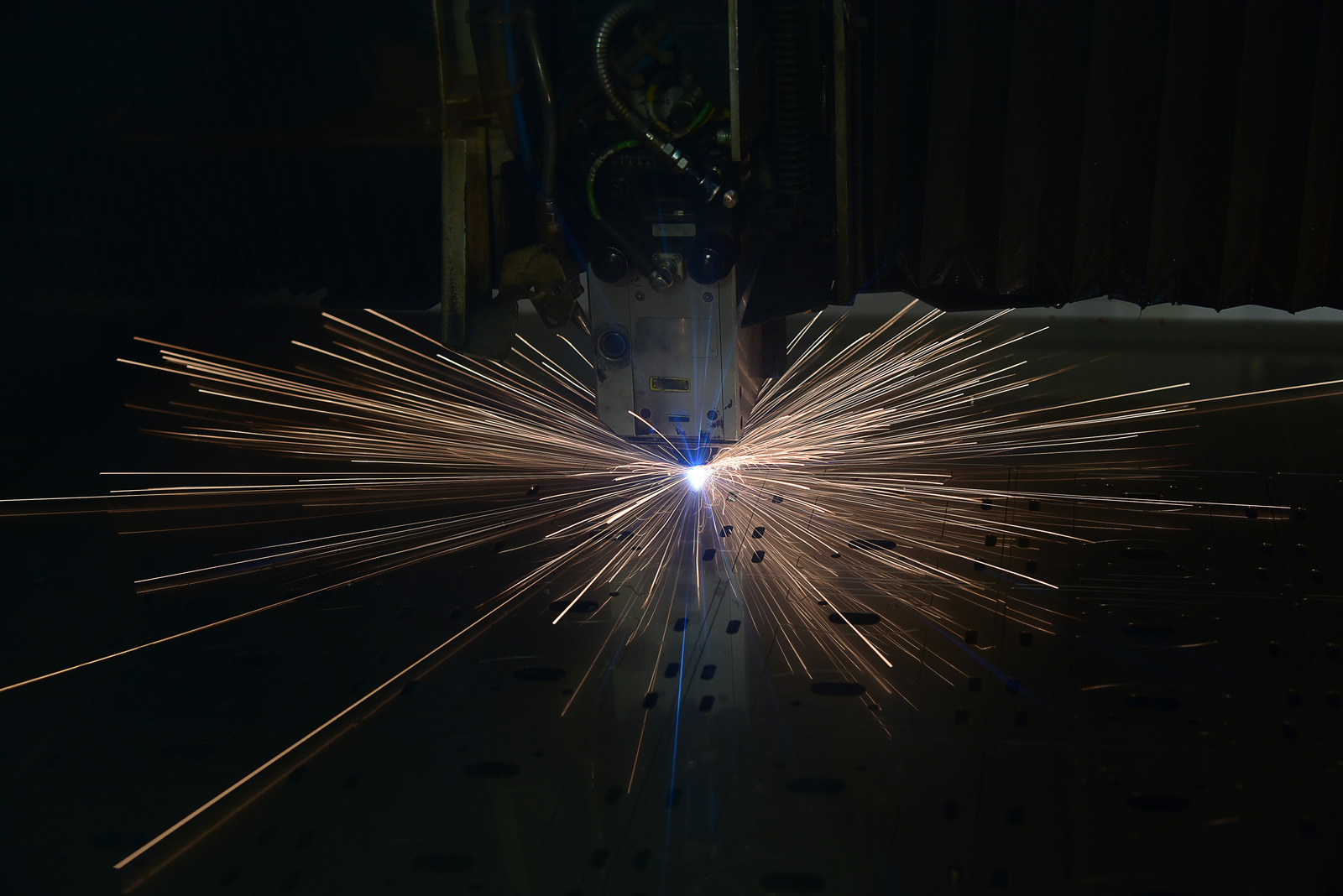

Laser cutting is a process of using a laser beam to precisely cut materials like metal, plastic, or wood.

How do you go green in manufacturing?

Going green in manufacturing requires a shift in mindset to incorporating sustainable and eco-friendly materials and processes. One way to go green in manufacturing is through laser cutting job applications. Laser cutting is a digital fabrication method that uses a laser beam to heat, melt, and vaporize materials, allowing manufacturers to create intricate patterns quickly and accurately while being very resource-efficient.

What are some examples of successful sustainable development projects?

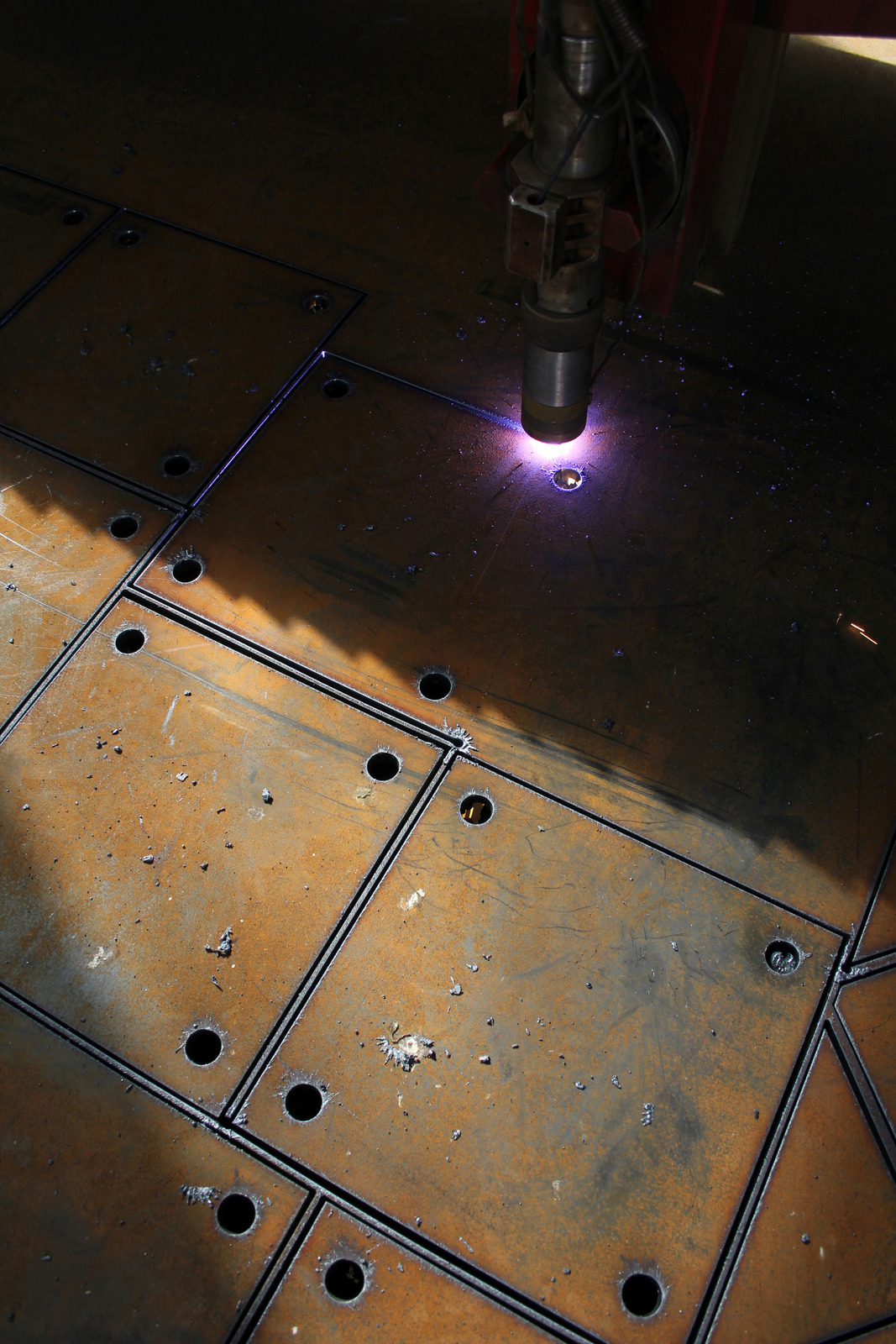

One of the most successful sustainable development projects that is gaining popularity is laser cutting job applications for green manufacturing. This is a process where the manufacturing company utilizes a laser to cut materials and reduce their environmental footprint. This process is one that can significantly reduce the amount of energy and resources used in the production process, as it has the capability to precisely cut materials with superior accuracy and little waste.

For example, manufacturers can use this technology to produce furniture, apparel, and even electronics, with minimal wastage and energy due to laser cutting’s impressive precision and accuracy. This can also allow them to save money, since they are no longer having to use traditional cutting tools and machinery or pay for their disposal.

How sustainable is laser cutting?

When it comes to green, sustainable manufacturing, laser cutting is at the forefront of innovation. Laser cutting is an efficient, precise, and cost-effective tool that reduces our need for traditional manufacturing processes that require immense resources, such as chemicals and energy. The process of laser cutting involves the use of a laser to remove material from the surface of a raw material or pre-manufactured product.

This process leaves little to no scrap material, meaning any waste produced is significantly less than that of traditional material cutting methods. In addition, laser cutting is a non-contact process, meaning it doesn’t create any heat or pressure that could have a negative effect on the environment.

Conclusion

The conclusion of this blog post is that laser cutting technologies offer an opportunity for green and sustainable manufacturing. Laser cutters promise incredible precision while reducing the amount of physical materials used and labor time required to create complex pieces or assemble components, reducing the environmental waste associated with traditional manufacturing techniques. Additionally, laser cutting can be employed to create components for green manufacturing processes that are more efficient overall, such as in buildings, electronics, and transport.

While the technology does come at a cost, the environmental and economic benefits of a sustainable manufacturing process, should it require laser cutting, will certainly outweigh the initial expenses.