The use of laser cutting technology on leather is becoming increasingly popular amongst artisans and fashion designers. It allows for fast, intricate and precise cutting of leather, making it an ideal choice for a range of projects. By understanding the basics of laser cutting leather, you can unlock a whole world of creative possibilities in leather crafting. From delicate details to intricate patterns, explore the possibilities of laser cutting leather and discover new levels of creativity.

Preparing for the Cutting Process

The type of laser cutter to use

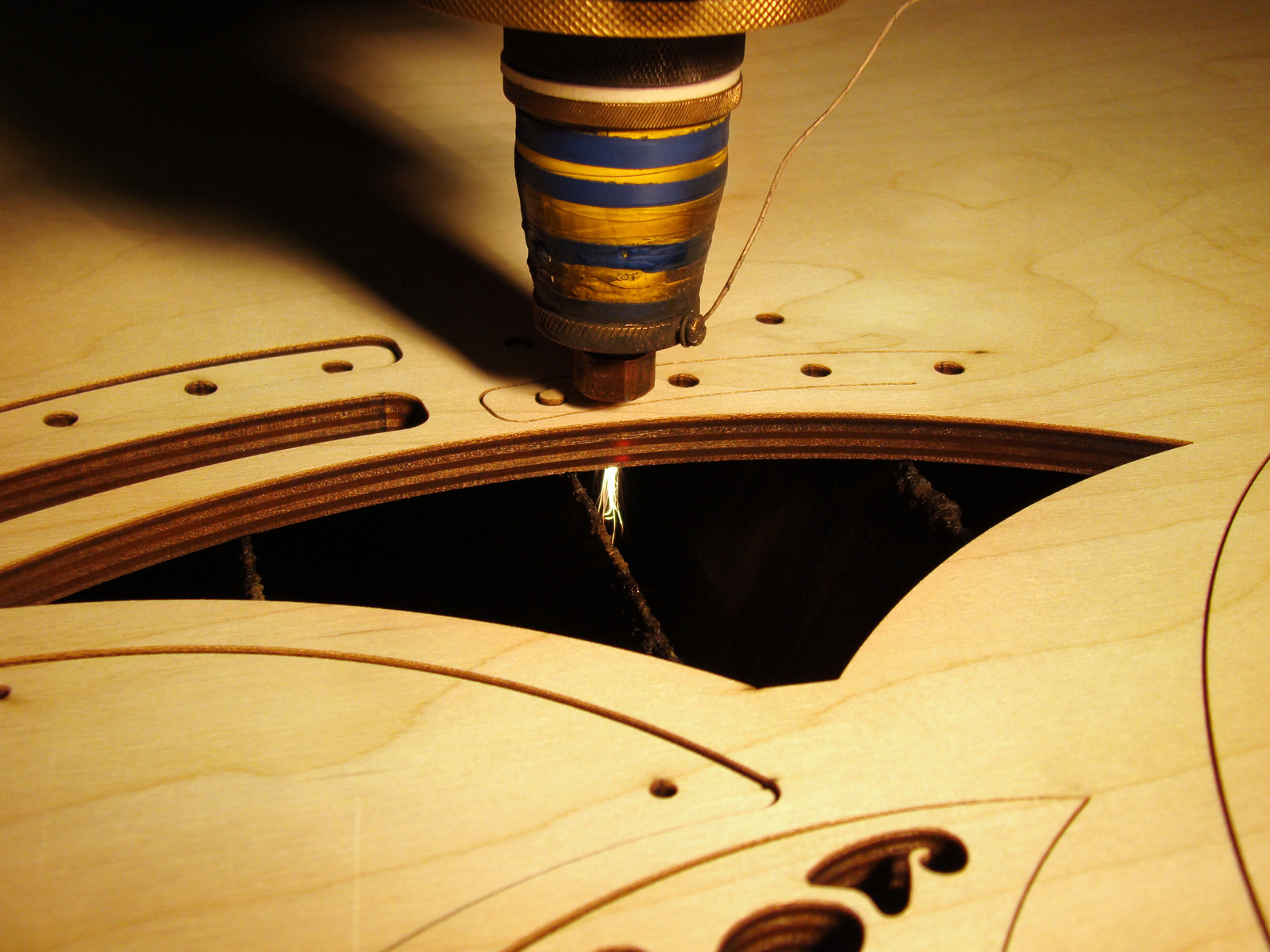

leather When it comes to exploring the possibilities of laser cutting leather, the type of laser cutter you use is a key factor in the cutting process. While laser cutters have been traditionally used for engraving and marking on fabrics, they are now being used to cut leather as well. A laser cutter works by emitting a light beam that is focused and directed onto a specific material.

The beam is then adjusted to suit the material being cut and the thickness of the leather.

Selecting the right type of leather

leather When it comes to exploring the possibilities of laser cutting leather, selecting the right type of leather is key to achieving successful results. It’s important for leather makers to explore the advantages and limitations of laser cutting in order to make effective use of their tools, and ultimately produce the best possible results. The type of leather selected for a laser cutter must be compatible with the specific power settings and speed of the cutting process.

Different types of leather can be cut with a laser cutter, but the qualities and composition of these materials determine the machine settings that are needed for efficient cutting.

Gather the materials

leather Gathering the materials for a leather laser cutting or engraving project can seem like a daunting task. To make things easier, it’s best to take an organized approach so that you can start your laser cutting project quickly and efficiently. The first step is to gather the right materials.

When it comes to laser cutting leather, there are several important items to consider. First of all, you’ll need a laser cutting machine. This device uses a beam of high-intensity light to cut and engrave certain types of materials, including leather.

The Laser Cutting Process

Safety considerations

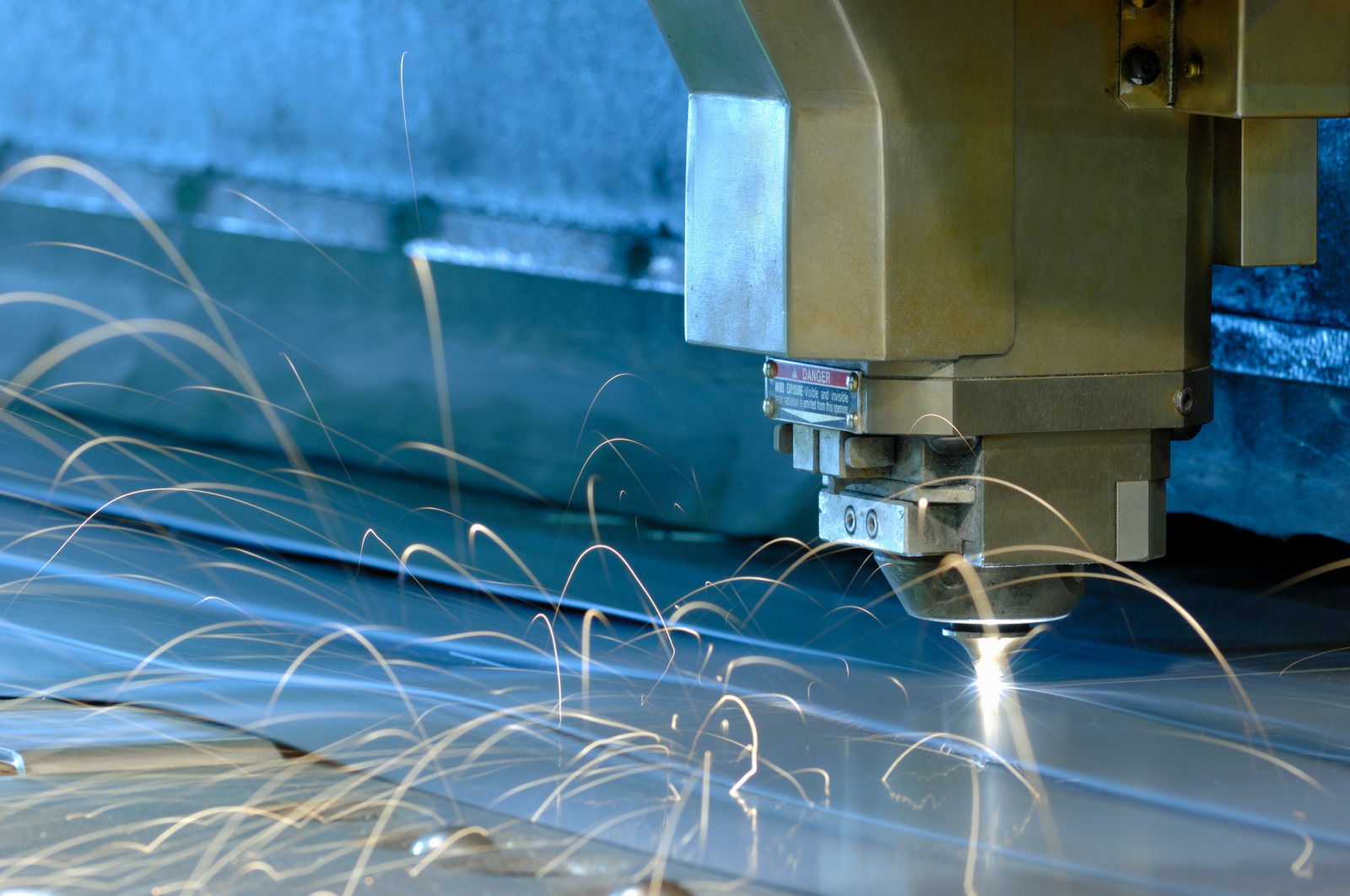

leather Safety considerations are especially important when exploring the possibility of laser cutting and engraving leather. Laser cutters are powerful tools and the presence of flammable and volatile materials, such as leather, presents a higher risk of danger. As such, special care should be taken when using laser cutters in these circumstances.

When using a laser cutter to cut or engrave leather, precautions must always be taken to ensure safety. The most important safety consideration to keep in mind is to always wear the appropriate safety gear, including goggles, protective clothing and gloves, when working with the machinery. In addition, materials and machines must be properly arranged and set up before use.

Basic cutting functions

leather Exploring the possibilities of laser cutting leather is a great way to add unique and intricate details to your leather projects. There are many different kinds of laser cutters available that can be used to cut leather, ranging from basic models to advanced commercial grade machines. While the laser cutting process is relatively simple, there are some important steps that need to be taken to ensure the best quality results.

Detailed cutting designs

leather When it comes to leather working, exploring the possibilities of laser cutting can open up all kinds of creative new opportunities. With the help of a laser cutter, you can make detailed and delicate cuts that accurately replicate intricate designs to create stunning, finished leather pieces. The laser cutting process for leather starts with a CAD drawing, or computer-aided design, of the desired design.

Post-Cutting Process

Treating and finishing the Leather

When exploring the possibilities of laser cutting leather, it is important not to overlook the post-cutting process. Treating and finishing the leather correctly after being cut with a laser cutter will ensure that the end product looks great and remains robust. There are several things to take into consideration when treating and finishing the leather.

The first step is to clean away any residue or dust leftover from the cutting process. Make sure to use a soft cloth, as abrasive materials can damage the leather. The second step is to add protectants to the leather.

This can be done with a mild leather conditioner to keep the leather supple and prevent drying out.

Creative applications of laser cutting

leather Laser cutting is a process that uses focused light beams to cut and etch intricate patterns and designs onto materials. Laser-cut leather is made by melting and cutting through the hide with a laser cutter. This technology is used in a variety of industries, from furniture-making to jewelry-working.

But it has also found its way into the world of fashion, where laser cutting leather can be used to create elaborate, unique looks.

What type of leather can be laser cut?

leather When it comes to exploring the possibilities of laser cutting leather, it is important to know what type of leather can be used. Generally speaking, laser cutting machines are able to work with most types of leather, including full-grain leather, top-grain leather, bonded leather, and suede. While some leathers may be harder to cut, leather laser cutters can easily cut even the most delicate hides.

Can you laser cut into leather?

Laser cutting into leather is one of the most exciting possibilities available to makers, designers, and craftsmen. With the help of a laser cutter, it is possible to create intricate designs, engravings, and patterns into leather for all sorts of projects. The possibilities of laser cutting leather are just about endless – from beautiful leather accessories to laser-engraved logos and more.

The biggest advantage of laser cutting is that it is flexible, precise, and can be used on all sorts of material, including leather.

Conclusion

Recap of the explored possibilities

In this blog, we explored the possibilities of laser cutting leather. We discussed how laser cutters can be used to create intricate, detailed designs on leather, as well as the merits of laser cutting leather compared to traditional methods of cutting. We also explored the steps that are involved in the process of laser cutting leather, the types of laser cutters available, and the costs associated with laser cutting.

In the end, we can conclude that laser cutting leather offers many benefits and possibilities. Not only can laser cutters produce intricate designs quickly and easily, they are also affordable and safe to use.

Summary of key concepts

The use of laser cutters to cut leather has the potential to revolutionize how leather craftspeople and leather workers around the world design and create leather items. Laser cutting can dramatically reduce the amount of time and labor needed to cut into leather fabric, as well as create intricate designs with accuracy and precision. As a result, leather laser engraving and laser cutting leather has been adopted as a popular and trendy way to create leather accessories and other leather products.

Additionally, laser cutting leather can also improve the overall quality of the finished leather item.