When it comes to laser cutting, it is important to understand the different power requirements that have to be met in order for successful cuts to be achieved. This article will explore the various power requirements for laser cutting to ensure the process runs smoothly and efficiently.

What are the Different Types of Laser Cutting?

Discussion of their Power Requirements

Levels There are many different types of laser cutting processes, each with its own unique power requirements. The power required for laser cutting depends on a combination of the cutting material, the source of the laser and the size of the laser cutter. Generally speaking, higher power lasers are capable of cutting through heavier and thicker materials.

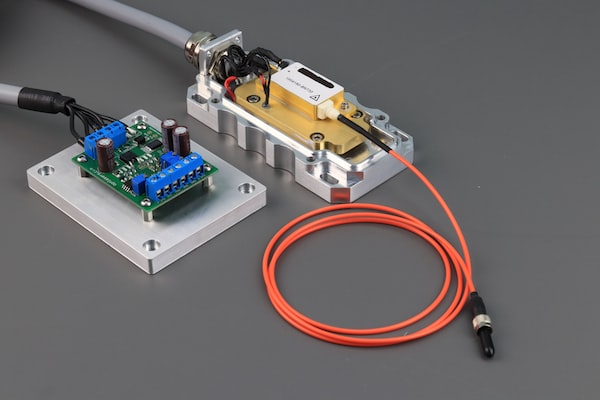

CO2 lasers are among the most popular type of laser used in laser cutting and they require high levels of energy in the range of 500 to 5000 watts. This type of laser is capable of cutting through a wide variety of materials such as metals, plastics, glass, and paper.

How Does Laser Power Affect Cutting Quality?

Exploring the Different Power Levels and their Cutting Efficiency

Levels When it comes to laser cutting, power levels play a critical role in determining the cutting quality of the material being cut. The most common type of laser cutting is done using a CO2 laser cutter. These types of laser cutters require different levels of energy to be successful.

Generally, the higher the power requirements of the laser, the more efficient it is at cutting the material. Different materials require different power levels to be effectively cut. For example, thick materials such as steel require more power than thin materials such as wood.

Softer materials such as paper require less power than harder materials such as ceramics.

Ways to Enhance Laser Cutting Performance

Benefits of Higher Power Lasers

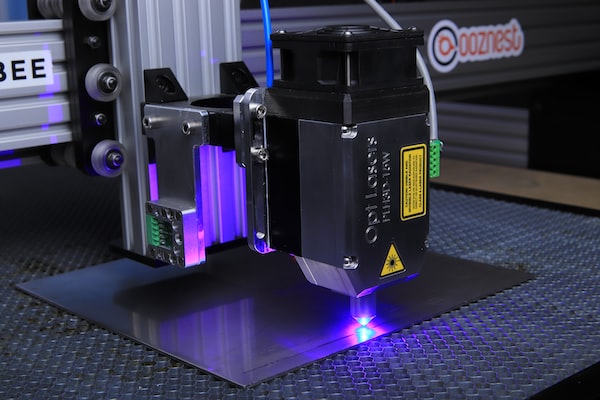

Requirements The increased power of higher powered laser cutters has many advantages over standard laser cutters. Higher power lasers allow for faster, more precise cutting and engraving of materials such as wood, plastic, leather, and metal. They can also be used to cut thicker materials, as well as thinning or blending edges on a variety of materials.

With higher powered lasers, there is less heat generated, meaning the cuts are less likely to distort or create bulging around the cut area.

Summary of Power Requirements for Laser Cutting

What to Consider When Choosing the Right Laser Power for a Specific Project

When selecting the right power for a laser cutter for a specific project, there are a few factors to consider. The type of material that needs to be cut, the speed at which you want to complete the job, and the intended use of the laser cutter for that particular project. Different materials require varying amounts of laser energy to cut.

Materials like wood, fabric, leather, and PVC require less energy than metal or hard plastics. When choosing the right power for a laser cutter, it’s important to consider the type of material that you’ll be cutting.

What can a 100W Watt co2 laser cut?

requirements The power requirements for laser cutting can range, depending on the particular laser cutter being used. A 100 watt CO2 laser can cut through most materials under 1/4 inch such as wood, leather, plastic and some metals like brass and aluminum. The great thing about these lasers is that they are accurate and the pieces they cut tend to have clean edges, but they struggle more when cutting through thicker materials.

Besides a CO2 laser, there are other types of laser cutters with varying power requirements. For example, pulsed fiber lasers are typically more powerful than CO2 lasers, and can easily cut through thicker materials.

What can a 40 watt laser cut?

Requirements When it comes to laser cutting, the wattage requirements vary significantly depending on the type of laser cutter you are using. A 40 watt laser, for instance, is typically used for etching and engraving on objects like wood, glass, and plastics. With this type of power laser, you can achieve detailed workmanship and intricate patterns, as well as cut through materials that are around 5mm thick.

How much power does a laser cutter need?

Powering a laser for cutting can be a complicated affair, depending on the type of laser being used and the thickness and composition of the material being cut. Generally speaking, for laser cutting, laser cutters need anywhere from 600 to 2000 watts of power, but different laser types require different power requirements.

Conclusion

Consumption In conclusion, laser cutting is an efficient, versatile, and accurate tool for industrial and consumer applications. Laser cutters can offer different power requirements depending on the type of laser used, with varying levels of energy consumption. Fiber lasers consume the most energy but can enable fast, precise cutting of a variety of materials.

CO2 lasers and Nd:YAG lasers demand less power and may have a higher scoring angle, but they can process metal materials at slower speeds. UV lasers use the least amount of power, but they can only process non-metallic materials. Thus, the type of laser system used in the laser cutting process has an impact on the energy requirements and cutting performance.