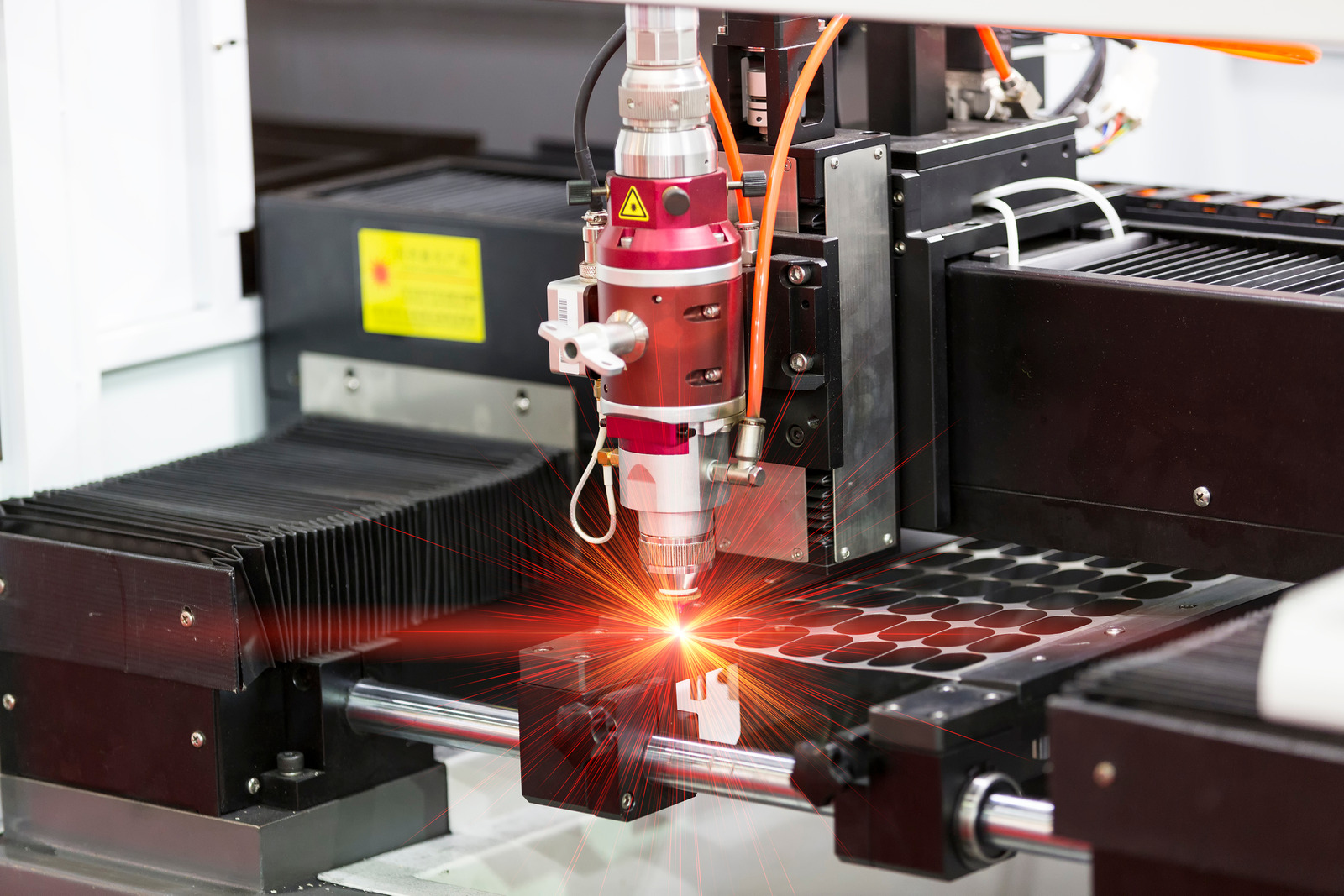

Welcome everyone, to this informative session about the benefits of using laser cutting heads. In this session, we will learn about some of the advantages that laser cutting heads offer over more traditional cutting methods, and what this could mean for your business. We’ll cover topics such as efficiency, accuracy, and cost savings. By the end of this session, you’ll have a better understanding of laser cutting, and the different ways it can be incorporated into your workflow. Let’s get started!

Latest Technologies of Laser Cutting Head

Fiber Laser

laser When it comes to the business of creating and cutting materials, laser technology is often our first choice. We have been using laser cutting head for years at factories, labels, and other professional facilities to craft any shape of material. The latest technology in laser cutting head are fiber laser cutting machines, which come with a handful of advantages when compared to traditional laser cutting systems.

CO2 Laser

laser One of the key advantages of using a CO2 laser cutting head is its precision. Laser cutting is an extremely accurate process which leaves a precise, finished edge to the material being cut. The laser beam can be precisely adjusted to achieve intricate shapes, making it ideal for intricate designs and projects that traditional cutting methods simply cannot achieve.

In addition, laser cutting can produce complex shapes in a much quicker time-frame than other traditional cutting methods such as sawing and drilling. The heat generated by a CO2 laser cutting head is also much lower than other cutting methods.

Nd:YAG Laser

laser When it comes to the latest technology of laser cutting, the Nd:YAG laser is an excellent choice. This type of laser cutting head is one of the most powerful and efficient laser cutting solutions available. Not only does it offer precise and accurate cutting, but it can also be used to cut a wide variety of materials.

The advantages of using a laser cutting head with a Nd:YAG laser are numerous.

How to Select the Right Laser Cutting Head

Analyze application and requirements

lasers Analyzing application and requirements is a crucial step in selecting the right laser cutting head. For example, when choosing a laser cutting head, you should consider the type of material you’ll be cutting, the speed and power the material requires, and the total number of cuts that need to be made. Next, you should consider how precise the cuts must be, and if the maximum efficiency of a single head is necessary for your application.

Choose the right laser technology

laser Laser cutting technology offers a lot of advantages in the manufacturing process, allowing for higher accuracy and speed than other cutting methods. It can be used to precisely cut a variety of materials with very high accuracy, including metals, plastics, composites, and ceramics. The process works by focusing a high-powered laser beam onto the material to be cut and precisely heats and melts the material so that it can be cut to the exact dimensions required.

Select appropriate laser power

laser Exploring the benefits of using a laser cutting head can be hugely advantageous for any manufacturing process. Laser cutting offers a number of advantages, including accuracy, speed, and precision which can improve production time, reduce material costs, and create aesthetically pleasing parts. As such, it is important to select the appropriate laser power when considering a laser cutting head.

The power of a laser beam is important for cutting through thick materials and is generally measured in watts (W).

Summary

Conclusion

laser In conclusion, the advantages of using a laser cutting head are many. Thanks to its precision, speed, accuracy, and versatility, laser cutting is an invaluable asset for any company, organization, or individual looking to cut objects quickly and accurately. From cutting acrylic and metal to engraving wood or metal, the benefits of using a laser cutting head for all your cutting and engraving needs are truly extraordinary.

Laser cutting requires minimal effort, minimal material waste, and can be done quickly and accurately, saving time and money in the process. Laser cut items also have a high-quality finish, ideal for a wide range of businesses and applications.

How does a laser cutter head work?

a laser When it comes to precision and accuracy, it’s hard to beat a laser cutter head. Laser cutting is a tool used to precisely cut out components and materials using a thin, focused beam of laser light. The head is the device used to move the laser beam in a designated path, allowing it to cut shapes and patterns, engrave, weld, mark, and carry out other tasks that require precision.

The advantages of using a laser cutter head are numerous. For one, it is highly accurate. The laser beam can be adjusted to get much finer detail than traditional tools and materials can achieve.

What are the benefits of using a laser cutter?

laser One of the major advantages of using a laser cutter is its precision. A laser cutting head is incredibly precise, able to achieve results that traditional cutting methods can’t match. If you need precise cuts that require minimal manual intervention, a laser head can provide them.

Additionally, laser cutters don’t incorporate any mechanical components, making them quieter than traditional cutting methods. The fact that there are no contact points also means less wear and tear, longer lifespan, and lower operating costs.

Conclusion

laser Conclusion To summarize, there are many advantages to using a laser cutting head. Laser cutting is extremely precise, allowing you to cut with exactness and consistency; it is also faster than traditional cutting methods, so you can complete jobs faster. Additionally, laser cutting is more cost-effective because of its precision, meaning the material used is less, and the parts you get are better quality.

It is also more flexible and can be used to cut different materials including plastics, metals, and even fabrics.