The use of laser cutting on nylon materials has become increasingly popular in recent years, offering a highly precise, time- and cost-efficient way of producing a wide range of items. From complex shapes to delicate fabrics, laser cutting nylon can be used to create intricate designs with speed and accuracy. In this article, we’ll explore the various benefits associated with laser cutting nylon to help you decide if this approach is right for your project.

Main Body

Safety benefits of laser cutting nylon

Nylon One of the major benefits of using laser cutters for cutting nylon is the improved safety that it provides. Laser cutting is a non-contact process that requires minimal manual intervention. This reduces the risk of cuts, burns and hazardous materials being released into the atmosphere, reducing the risk of workplace injuries.

Furthermore, the lasers used in laser cutters are low-power, reducing the risk of fire or explosions. Laser cutters also reduce the need for manual labor, meaning less energy is needed for the operation and fewer people need to be involved in the process. This leads to lower overall costs, since fewer workers are required and only a low-power laser needs to be utilized.

Efficiency benefits of laser cutting nylon

nylon When it comes to efficiency, laser cutting nylon has some major benefits. Laser cutters use focused laser beams to precisely cut material, resulting in faster, more accurate cuts than traditional cutting methods. With laser cutting, manufacturers can reduce lead times, improve quality, and reduce production costs.

One of the key advantages of laser cutting is the consistency of the cuts produced. Cut components are produced quickly and accurately using laser technology, which means that components are cut to the same quality each time, leading to reduced waste. Laser cutting also produces more precise cuts than other cutting methods.

Accuracy benefits of laser cutting nylon

nylon One of the major benefits of using laser cutters for cutting nylon is accuracy. Laser cutters create a much higher degree of precision than traditional methods, making it easier and more accurate to produce parts with intricate designs and high accuracy. Nylon is very hard to cut using traditional methods, as it is a very tough material, but laser cutting can easily slice through it.

The laser cutter’s higher level of accuracy ensures that edges are smooth, parts fit together perfectly and the overall design meets the necessary specifications. In addition, laser cutters are capable of cutting through components of variable thicknesses, which helps to maintain the accuracy of the cut no matter how thick the material is.

Advantages of laser cutting nylon compared to other methods

Laser cutters have become the go-to method of cutting and shaping nylon fabrics, as they are incredibly precise and offer a few major benefits to the user. Lasers cut relatively fast due to the high speed and accuracy of the beam, making it a great option when fast and precise cuts are needed. The accuracy of laser cutters also allows more intricate and detailed shapes to be created out of nylon than with other methods, making it the perfect choice for complex patterns, designs, and parts.

Environmental benefits of laser cutting nylon

nylon Using laser cutters to cut nylon has some major environmental benefits to consider that make it a great choice when it comes to fabricating or machining. By using laser cutters to cut nylon, you can achieve precise, consistent cuts that provide a better finish than conventional cutting methods. Compared to saws, lasers cause significantly less waste and debris, which helps reduce harmful emissions–especially when sawing materials like laminated plastics or fiberglass.

Why lasers are used in cutting materials?

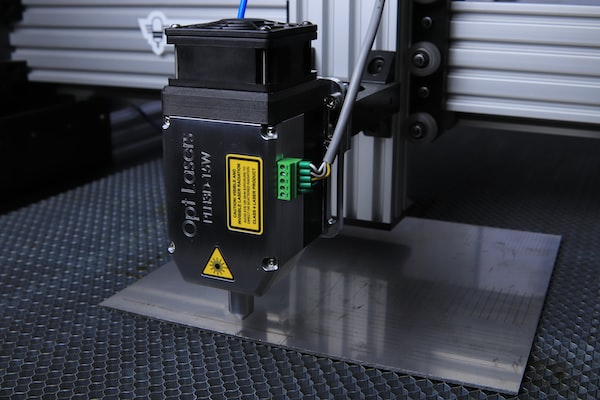

nylon Laser cutters are a type of tool used to accurately and precisely cut through strong materials like metal and nylon. Lasers are becoming increasingly popular in industrial environments due to their ability to make quick, precise cuts that produce very little waste material. The laser technology used in these machines makes them capable of cutting through thicker or tougher materials that other methods simply can’t handle.

Laser cutters use a highly focused beam of light to create heat at the point of contact to cut through the material. Laser cutting offers many advantages over traditional cutting methods. It is much faster, particularly for higher volume projects and can be used to produce complex shapes.

Can you laser cut nylon fabric?

When it comes to laser cutting nylon fabric, the answer is yes! This is because laser cutters are incredibly precise and can easily cut the tough material with its high intensity focused beam of light. Not only is it an accurate way of cutting, but laser cutting can also help reduce your costs and turnaround times when it comes to any project involving nylon fabric.

The advantages of using a laser for cutting nylon fabric are numerous. First, the cutting accuracy that laser cutters offer is unrivaled. Lasers are able to easily cut through the tough material without leaving a jagged edge, resulting in crisp and clean edges that will look perfect.

Conclusion

Summary of key points

nylon When it comes to cutting nylon, laser cutters offer a variety of advantages over other methods. Laser cutting nylon is a much faster process, with smoother, cleaner cuts that are free from burrs and imperfections. This high-precision method also yields better-quality cuts in one pass, with little to no secondary finishing required.

Laser cutting is also a much more energy-efficient option, as it uses a fraction of the energy required to produce the same cuts with other methods.

Outline of practical applications of laser cutting nylon

nylon When it comes to cutting nylon with a laser cutter, there are a number of advantages over other cutting methods. Laser cutters are precise and efficient, making them ideal for applications where accuracy and precision are key. For example, laser cutters can create intricately detailed parts that may not be possible with other cutting methods.

Another advantage of laser cutting is that it does not require additional project support, enabling faster production with fewer steps.