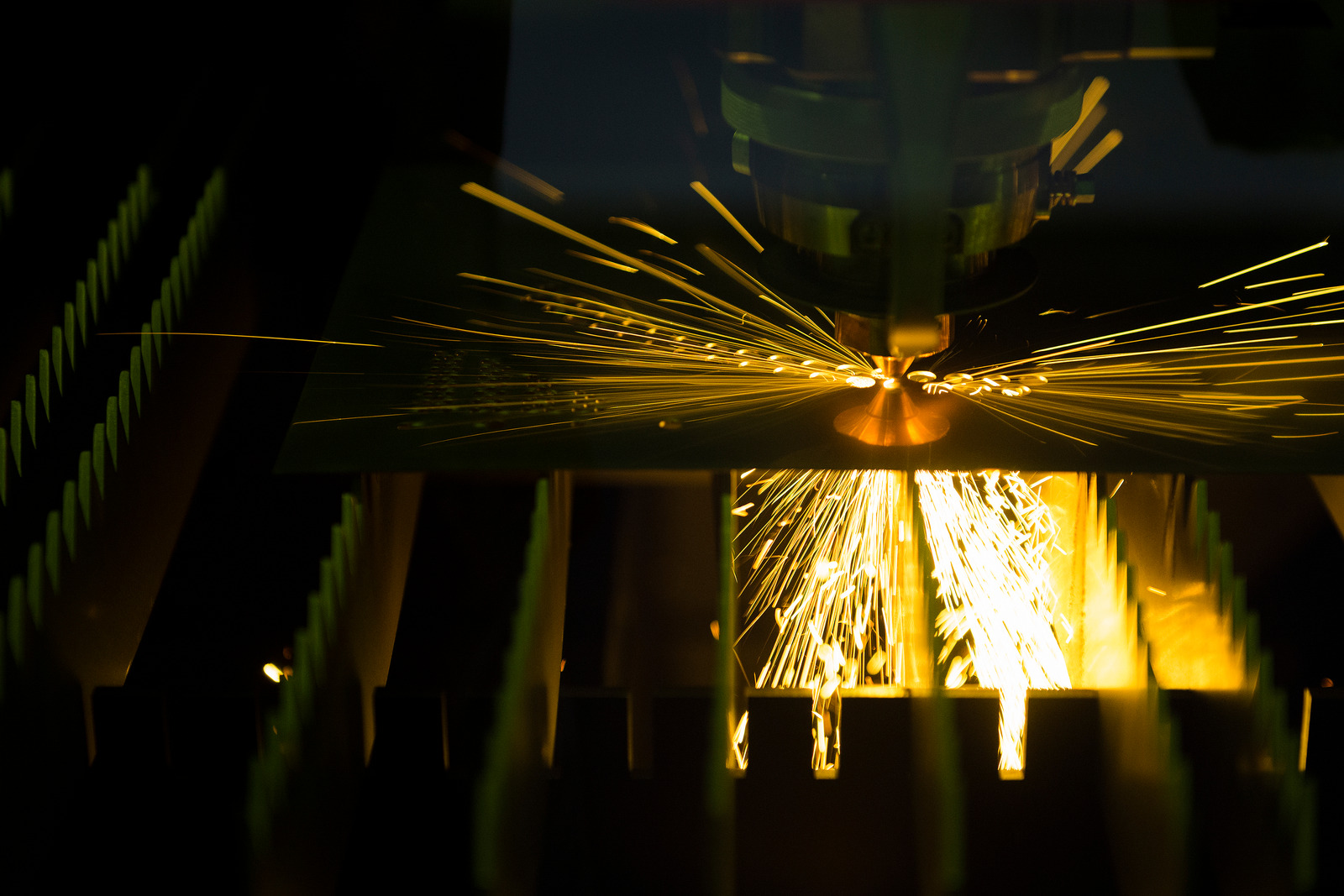

Laser cutting is a relatively new and advanced technique that has revolutionized the way materials like metal and plastic are cut. This method makes complex shapes much easier to achieve, with a greater level of accuracy and precision. The use of laser cutting with CNC technology has made it possible for even small businesses to have access to the same level of technological sophistication as larger manufacturers. In this article, we will be exploring the many benefits of laser cutting CNC, from increased productivity to cost-effectiveness.

Benefits of Laser Cutting CNC

Accuracy and precision

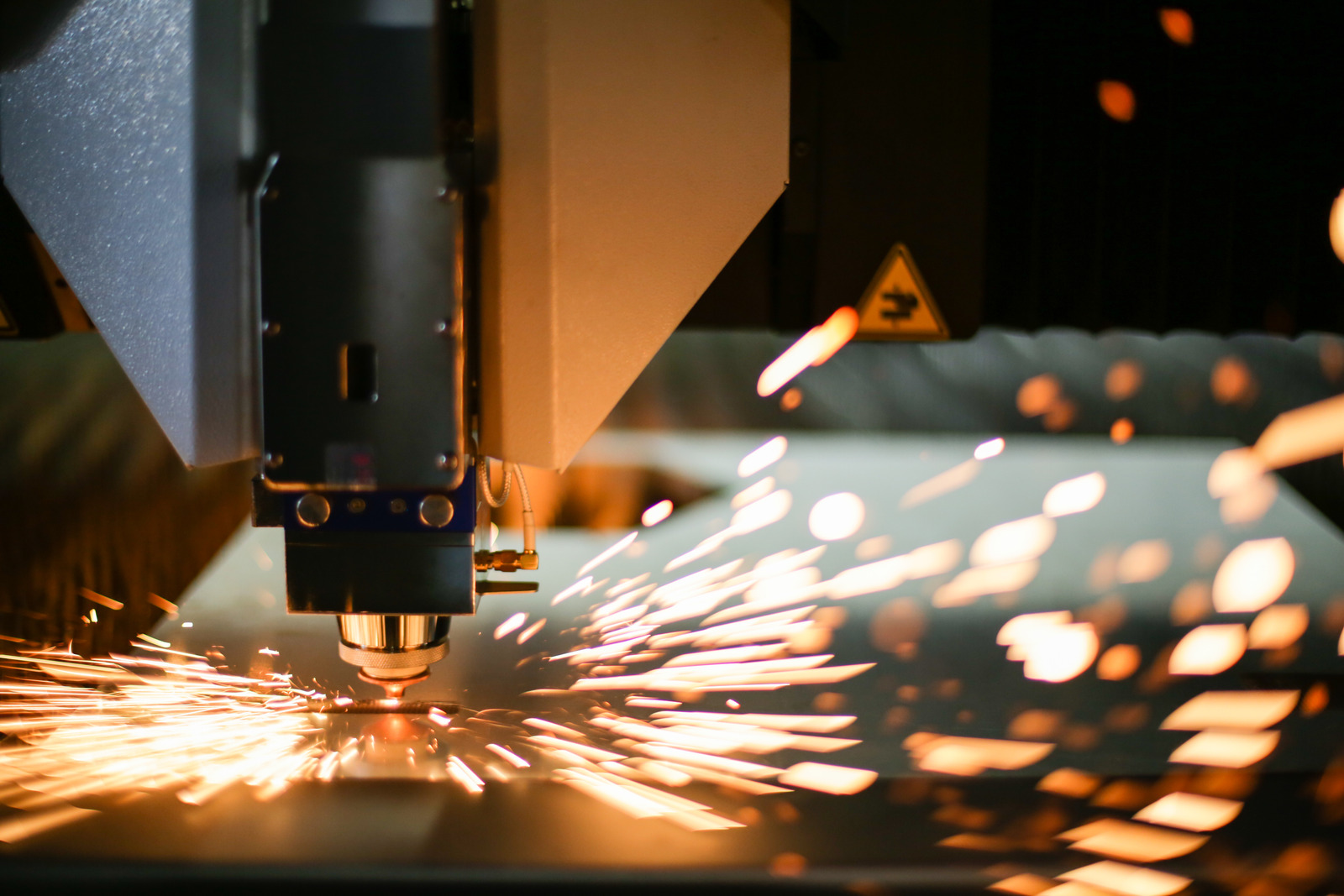

When it comes to accuracy and precision, CNC laser cutting has no equal. This precision cutting technology utilizes a focused laser beam that can cut through even the most intricate designs with extreme accuracy. The process is incredibly exact and takes the guesswork out of creating perfect shapes, patterns, and designs.

Unlike traditional cutting methods that use a spinning blade or saw, the laser beam heats and melts the material rather than cutting it with physical contact.

Speed and efficiency

One of the major advantages of laser cutting CNC is its speed and efficiency. Laser cutters produce faster cuts than many traditional methods, as the laser is able to cut or engrave much faster. This can be beneficial for large production runs, where a high rate of finished product can be achieved.

The laser’s ability to cut quickly and accurately minimizes associated waste when cutting materials, allowing the user to produce precise, tailored parts with little to no scrap material. Additionally, CNC-controlled laser cutting machines are programmed and managed with a computer, giving the user a significant amount of control over the cutting process. This enables precise cuts and tight tolerances, leading to higher production quality and consistent results.

Cost-savings

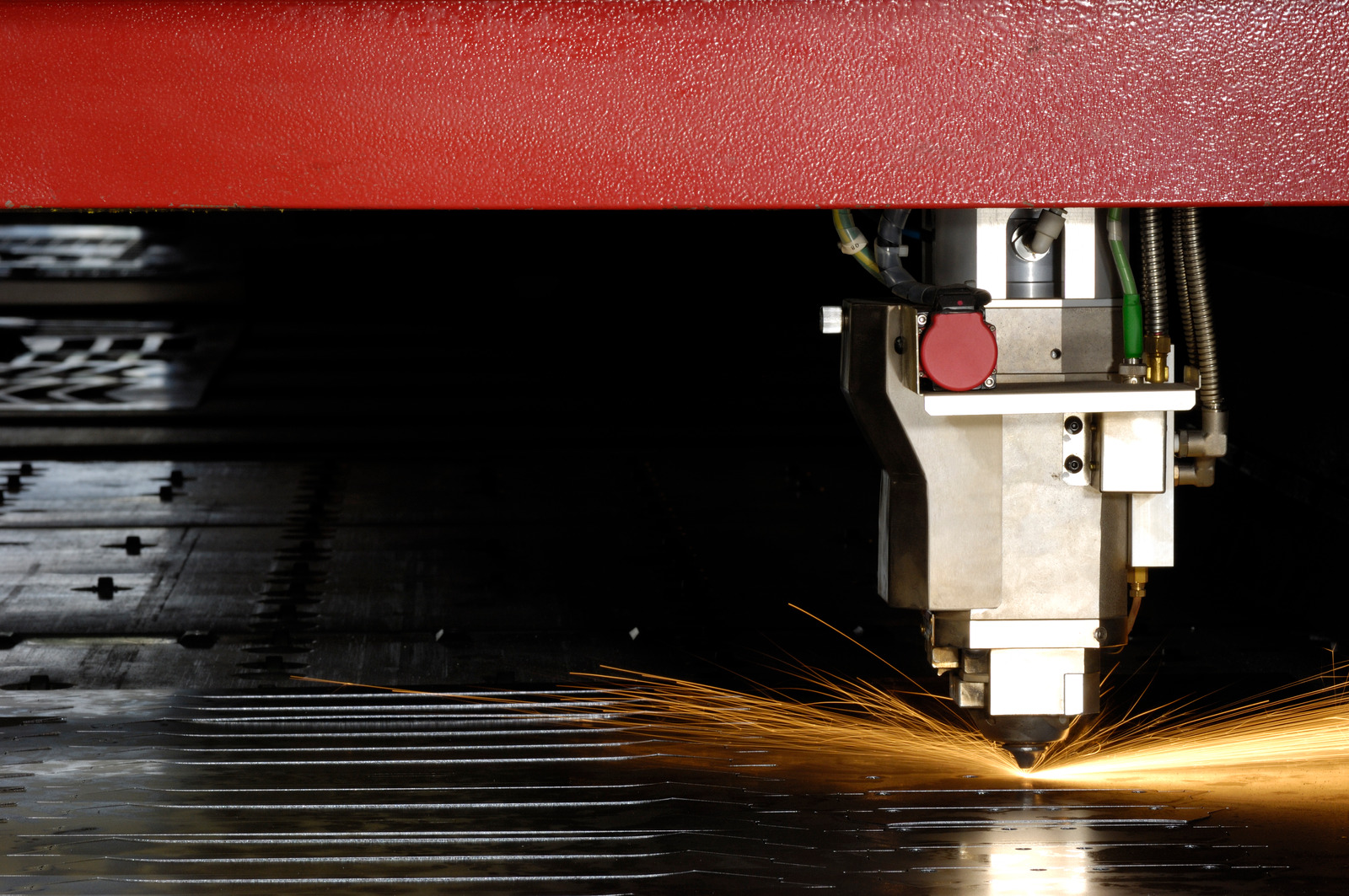

When it comes to CNC machining, one of the biggest benefits is the cost-savings that can be achieved with laser cutting technology. Traditional cutting and engraving processes can be costly and time consuming, but laser cutting has the potential to drastically reduce the number of man-hours required to complete a job. By utilizing laser cutting CNC machines, you’re able to drastically reduce the cost of materials, labor, and overhead associated with completing projects.

Versatility

When it comes to CNC Laser Cutting, versatility is one of its biggest advantages. A CNC Laser Cutter takes a machine, computer, and laser to create precise shapes and sizes that would be impossible with traditional cutting tools. Laser cutters can cut through a wide range of materials, such as wood, plastic, and metals, with extreme precision and accuracy.

Plus, with a laser, you can achieve intricate and 3D designs in a matter of minutes, which can save time and money in the long run.

Applications of Laser Cutting CNC

Automotive and aerospace

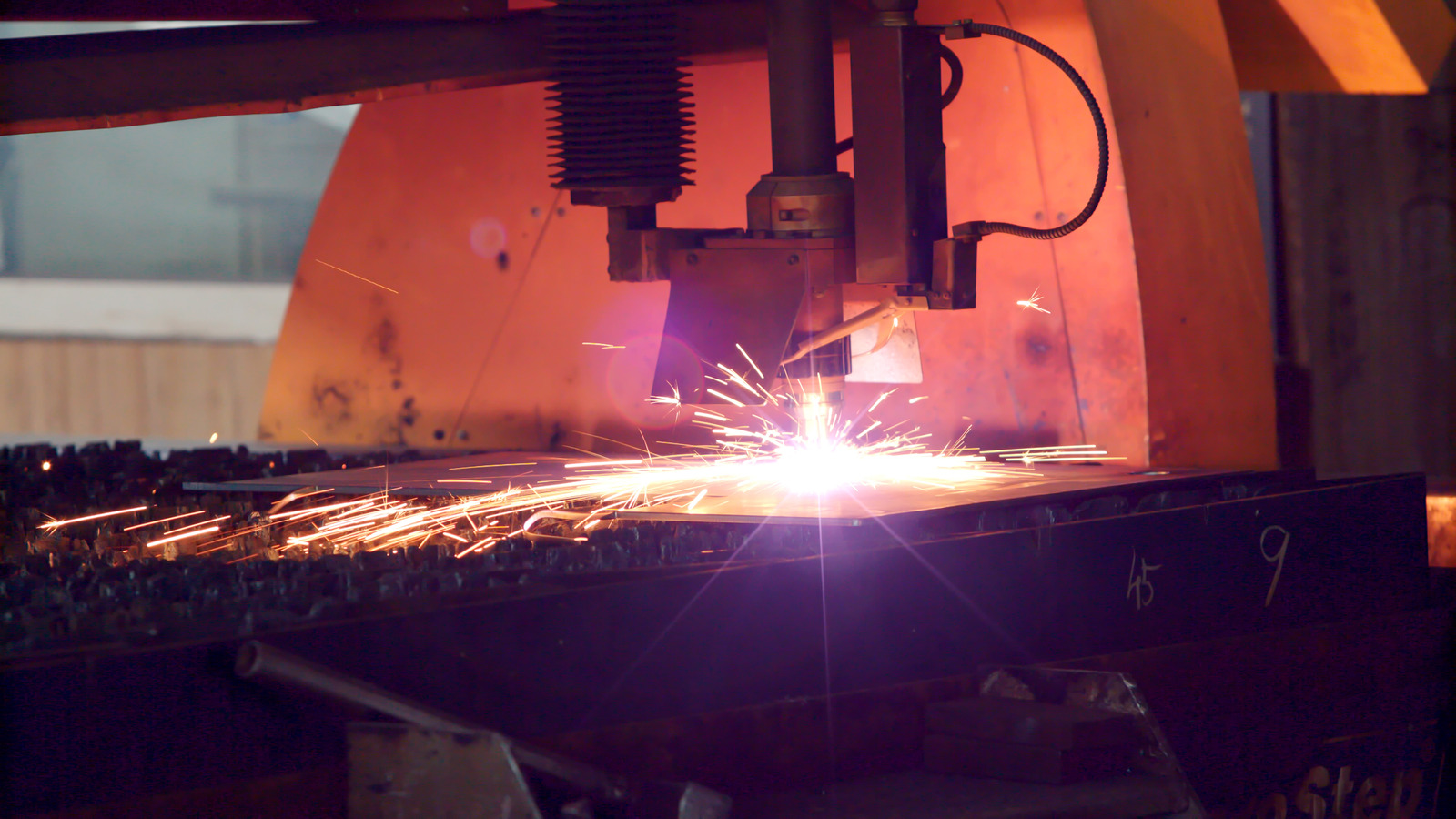

The automotive and aerospace industries have long been heavy users of CNC laser cutting technology for its many advantages. CNC laser cutters are powerful and precise, making them the perfect choice for these industries. Laser cutters can be used to cut and shape metal, create intricate engravings, drill holes, and trim or shape sheet metal with laser precision.

Laser cutters produce clean and precise cuts and surfaces, with minimal distortions and no need for rework or finishing. The high power and small size of CNC laser cutters make it easy to maintain tight tolerances and produce complex components quickly and efficiently.

Electrical and electronics

Electrical and electronics industries have long embraced the versatile and powerful capabilities of CNC laser cutters. CNC stands for computer numerical control, and laser cutting is a form of machining that utilizes precision laser cutters. CNC laser cutting is an ultra-precise and highly accurate form of machining with numerous distinct advantages.

The laser cutting process heats up a surface before the laser beam passes through the desired material, which controls the accuracy and the range of materials that can be cut. It works by directing a high-powered laser beam at the material and vaporizing any material along the edge of the beam in one precise, clean cut.

Medical

The medical field has seen great advances in laser cutting CNC technology. Laser cutters enable precise and accurate cutting of materials, and they can be used to cut everything from tissue to bone. They can also be used to cut components and parts with complex shapes and geometries.

CNC laser cutting machines are a great way to create custom products with maximum precision and accuracy. The benefits of laser cutting CNC in the medical field are many. It enables faster, more accurate cutting of materials, and it’s very precise.

In addition, because the laser can be programmed to cut precise patterns, it allows for a higher level of accuracy and consistency.

Manufacturing

When it comes to manufacturing, laser cutting CNC is one of the most efficient and precise techniques available. A CNC (Computer Numerical Control) laser cutting machine uses a computer-controlled laser to cut shapes and materials with incredible precision. Laser cutting can be used to cut and engrave acrylics, woods, metals, and many other materials, with no contact with the material, creating a highly precise, high-quality product.

Advancing Technology

Development of new laser materials

Continuing the exploration of the benefits of laser cutting CNC technology, a closer look at the development of new laser materials is important. The advancement of laser cutting materials has been crucial in its widespread acceptance as an effective means of machining, creating intricate designs and patterns with precision and accuracy. In the past, laser cutting machines were limited in the types of materials it could be used on.

However, decades of research to develop new laser cutting materials has opened up a world of new possibilities for CNC machining.

Improvements in CNC technology

CNC (Computer Numerical Control) is the use of computerized systems to control and automate the production of a product. It involves the use of computers and digital instructions to move a drill, router, or machine tool along a specified path to cut and shape a product. Although CNC has been used for a number of decades, the technology has grown leaps and bounds over the last few years, particularly in terms of laser cutting.

What is CNC laser cutting used for?

CNC laser cutting is a highly precise machining process that uses focused laser light to cut materials into intricate shapes and designs. It is primarily used in a range of industries, including aerospace, furniture design, automotive, and electronics. The benefits associated with laser cutting CNC are numerous, some of which include high accuracy, fast cutting speeds, low heat input, and versatile material support.

When it comes to accuracy, CNC laser cutting machines can make cuts with precision down to .

What is one advantage of a laser cutter over a CNC router?

When it comes to precision machining, laser cutters and CNC routers are powerful tools that serve a variety of purposes across industries. But what’s the difference between the two and which one is best? One of the biggest advantages a laser cutter has over a CNC router centers around the power and detail at which it can cut materials.

Laser cutting is more precise and offers more control than a CNC router and can be used for more intricate and detailed patterns with no hassle.

Conclusion

Summary of exploration of the benefits of laser cutting CNC

In conclusion, laser cutting CNC is an invaluable modern machining technology that offers a range of tangible and significant benefits. CNC laser cutters are capable of incredible accuracy – far greater than manual cutting – while also being able to cut complex curves, intricate patterns, and contours which would take man-hours to produce. Moreover, because the laser cutting process is largely automated, it reduces the need for bench labor, allowing companies to save on labor costs and become more competitive.

Laser cutting also facilitates faster production turnaround times and increased throughput, allowing for faster product delivery and customer satisfaction.

Discussion of future possibilities and advancements in the technology

The conclusion of our discussion of the benefits of laser cutting and CNC machining is that this technology continues to show promise and will positively impact many types of industries. When laser cutting machines are used, they can provide faster speeds, higher accuracy, and help to reduce production costs for various types of parts and components. They can also be used to cut a variety of materials, such as metal, plastic, wood, glass, and textiles.