Laser cutting and engraving technology has been around for a few decades, and its development has unlocked a myriad of possibilities for various manufacturing and engineering processes. This article will explore the different benefits of laser cutting and engraving and why it has become an increasingly popular technique for many industries. From its high speed production capabilities to its accuracy and precision, laser cutting and engraving can be instrumental in the development of a wide range of products. We will also look at the other uses for this technology and its potential for the future.

History of Laser Cutting and Engraving

Origin and Development

The Origin and Development of Laser Cutting and Engraving: The concept of using a laser to cut and engrave materials has been around since the 1950s, though the technology didn’t become available until the late 1960s. Since the introduction of laser cutting and engraving, there has been a steady evolution of the technology which has resulted in a wide range of versatile, efficient and precise machines. Laser cutting and engraving are now common in most industries and are becoming increasingly popular due to their versatility and variety of applications.

Different Applications

Different Applications The uses for laser cutting and engraving are truly endless. Laser cutters and engravers can be used to create and decorate almost any type of material, such as wood, plastic, metal, paper, leather, and glass. Common applications include developing product prototypes, making artwork and signage, engraving awards and memorial plaques, decorations and ornaments, and creating jewelry and fashion pieces.

How it Works

Process of Laser Cutting and Engraving

process The process of laser cutting and engraving is extremely precise and complex, but the end results are well worth the effort. Here, we’ll explore the advantages of laser cutting and engraving, as well as how it works. When it comes to precise cutting and engraving with accuracy, few tools compare to laser cutters and laser engravers.

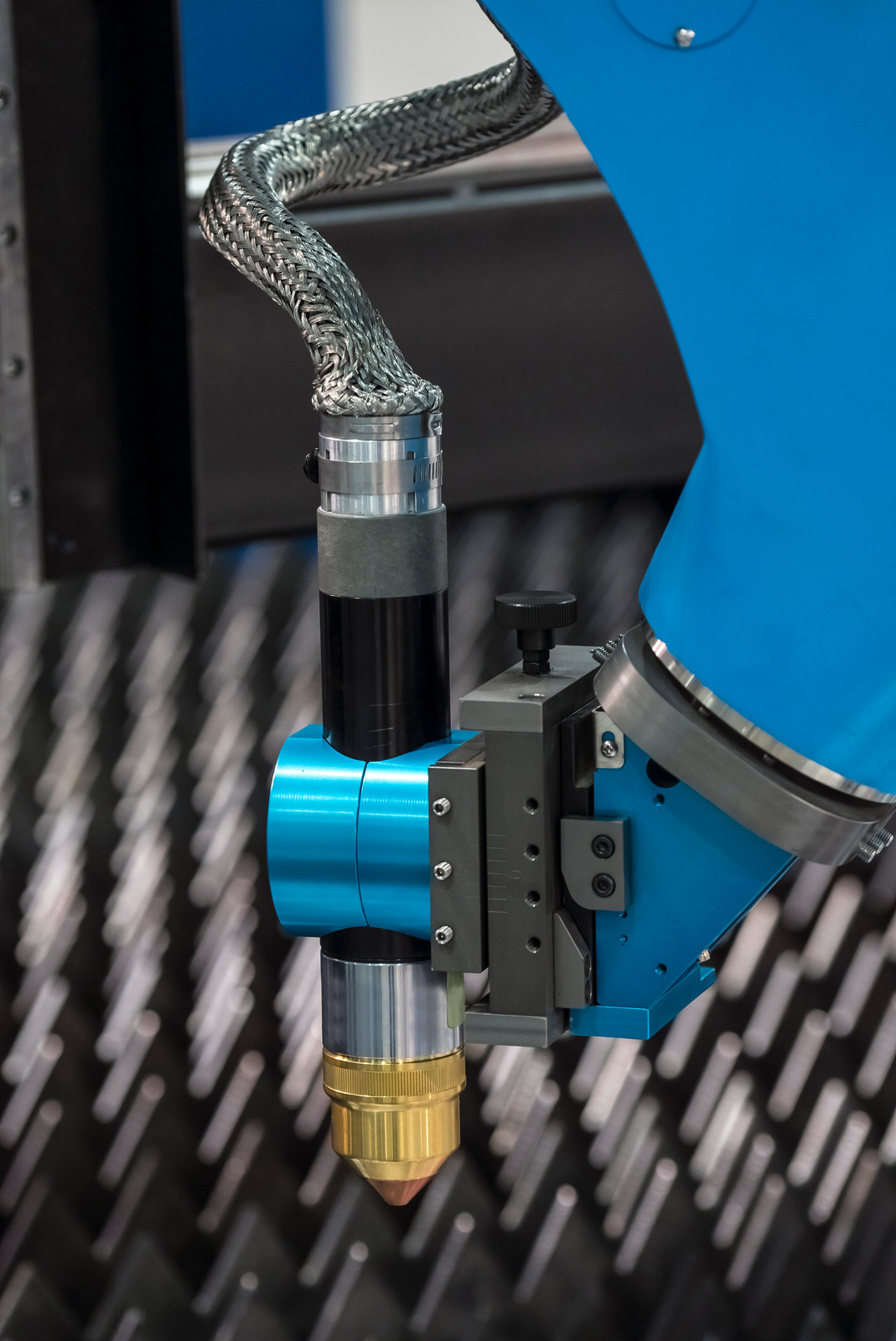

By focusing a beam of light onto an object, laser cutters and engravers are able to create precise designs, shapes, and patterns on almost any material.

Different Types of Lasers

and engraving Laser cutting and engraving is a form of manufacturing that uses a laser to cut and engrave materials like wood, metal, glass, leather, and various plastics. Laser cutting and engraving can be used for a variety of applications including product prototyping, creating custom signs or decorations, and producing precision parts for larger projects.

Advantages of Laser Cutting and Engraving

Quality

One of the biggest advantages of laser cutting and engraving is that it produces parts of exceptionally high quality. The laser beam is able to precisely cut and engrave intricate shapes, leaving a smooth and clean finish. There are no burrs or rough edges, making it ideal for creating parts that require a high level of accuracy and precision.

Compared to other cutting methods, laser cutting and engraving is incredibly precise, leaving little to no wastage.

Efficiency

Efficiency is one of the major benefits of laser cutting and engraving over traditional cutting techniques. Lasers can cut through materials quickly and efficiently, with no mechanical force required. This results in a faster production time, as well as less wear and tear on machinery.

The same laser can be used to make hundreds of cuts in a short span of time, making these machines a great choice for any project that requires accuracy and speed.

Cost

One of the main advantages of laser cutting and engraving is cost. Laser cutting and engraving machines typically require little overhead to operate, making the pricing for their services relatively affordable. The cost effectiveness of laser cutters and engravers occurs because there is very little material waste.

With conventional cutting methods, typically large amounts of material is wasted because of the inefficient cutting process. With laser cutting and engraving, the exact needed material can be cut precisely with a single operation, allowing for lower material costs.

Disadvantages of Laser Cutting and Engraving

Cost

One of the biggest advantages of laser cutting and engraving is cost. Laser cutters and engravers usually require a much lower upfront cost than other types of cutting or engraving tools, such as CNC machines. Laser cutters and engravers are also easier to operate and require less skill and training than other machines.

Hazards

When it comes to laser cutting and engraving, there are many benefits that this technology provides. Laser cutters and engravers offer high speed and accuracy, making them a popular choice for manufacturers and professionals. They can produce intricate designs and cut through various materials.

While they can be incredibly useful, they also come with certain hazards that need to be taken into consideration.

Examples of Laser Cutting and Engraving

Automotive

When it comes to automotive manufacturing, laser cutting and engraving are becoming more popular than ever due to their various benefits. Laser cutting and engraving is a technology that uses a focused beam of light to cut, engrave, or mark materials such as plastic, wood, steel, and more. The process is much less time consuming than other machining processes, and the quality of the finish is much better.

The advantages of laser cutting and engraving in the automotive industry are numerous. Laser cutters and engravers require less setup time, reduce material waste, and offer greater design flexibility than other methods.

Packaging and Labeling

and engraving examples When it comes to packaging and labeling, laser cutting and engraving offer many advantages, including a clean, precise cut or engraving, speed and efficiency, and cost-effectiveness. Laser cutters can be used to cut a variety of materials, from simple cardboard and paper to more complex plastics and metals. Laser cutting allows for fine detail when producing intricate designs and logos, specifically for packaging and labeling.

Signage

and engraving examples Signage is one of the most popular examples of how laser cutting and engraving can be beneficial. Laser cut or engraved signage can create eye-catching displays that are extremely durable and resistant to weather. This can range from large outdoor signs to intricate 3D sculptures.

Laser cutting and engraving both offer precision that results in a very clean and high-quality look that can be seen from distances. The advantages of laser cutting and engraving are numerous as they are very quick, easy to use, and cost-effective.

Conclusion

Summary

and engraving Conclusion Laser cutting and engraving is an incredibly precise and efficient way to cut, engrave, and mark a wide range of materials. Laser cutting and engraving offers superior accuracy and speed that can drastically reduce lead times for production – making it ideal for many industrial applications. The features and capabilities of laser cutting and engraving make it an exceptional alternative to traditional cutting and etching methods.

Final Thoughts

When it comes to laser cutting and engraving, the advantages are clear: it’s fast and precise, easy to learn and use, cost efficient, and requires minimal manual labor. It also offers design flexibility, meaning you can quickly and easily create intricate designs that are otherwise impossible with traditional methods. Additionally, laser cutting and engraving can be used with a variety of materials.

One of the main disadvantages of laser cutting is that it poses a health risk to the user.