Laser cutting technology has revolutionized the way businesses create products, providing increased accuracy, faster cutting speeds, and stronger cuts. This technology has been widely adopted by many businesses and industries, however, it’s important to understand both the benefits and drawbacks associated with laser cutting technology in order to make the best decisions for the business. Here, we’ll explore the benefits and drawbacks of laser cutting technology, and discuss how it can be used to improve efficiency and productivity.

Benefits of Laser Cutting Technology

Speed

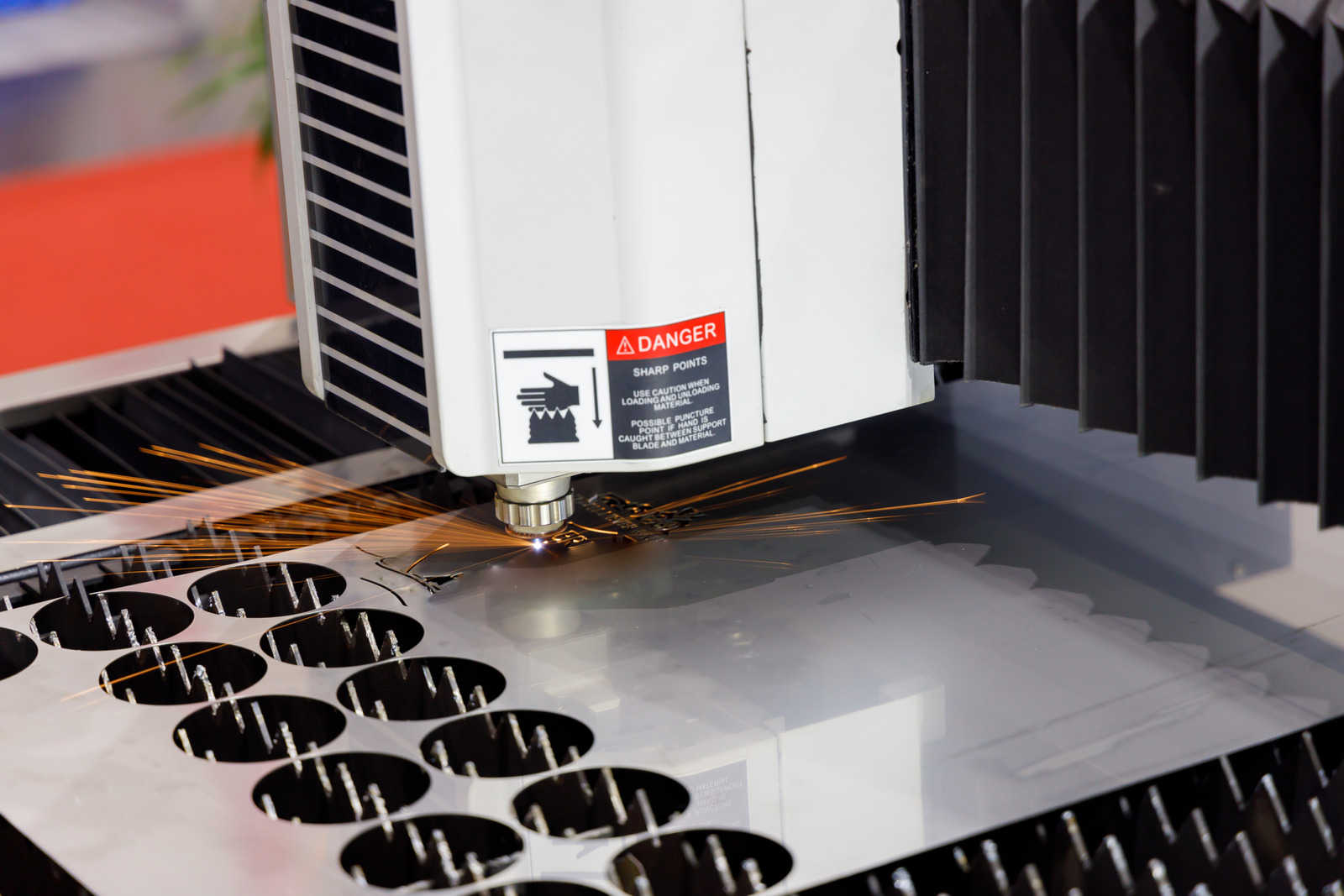

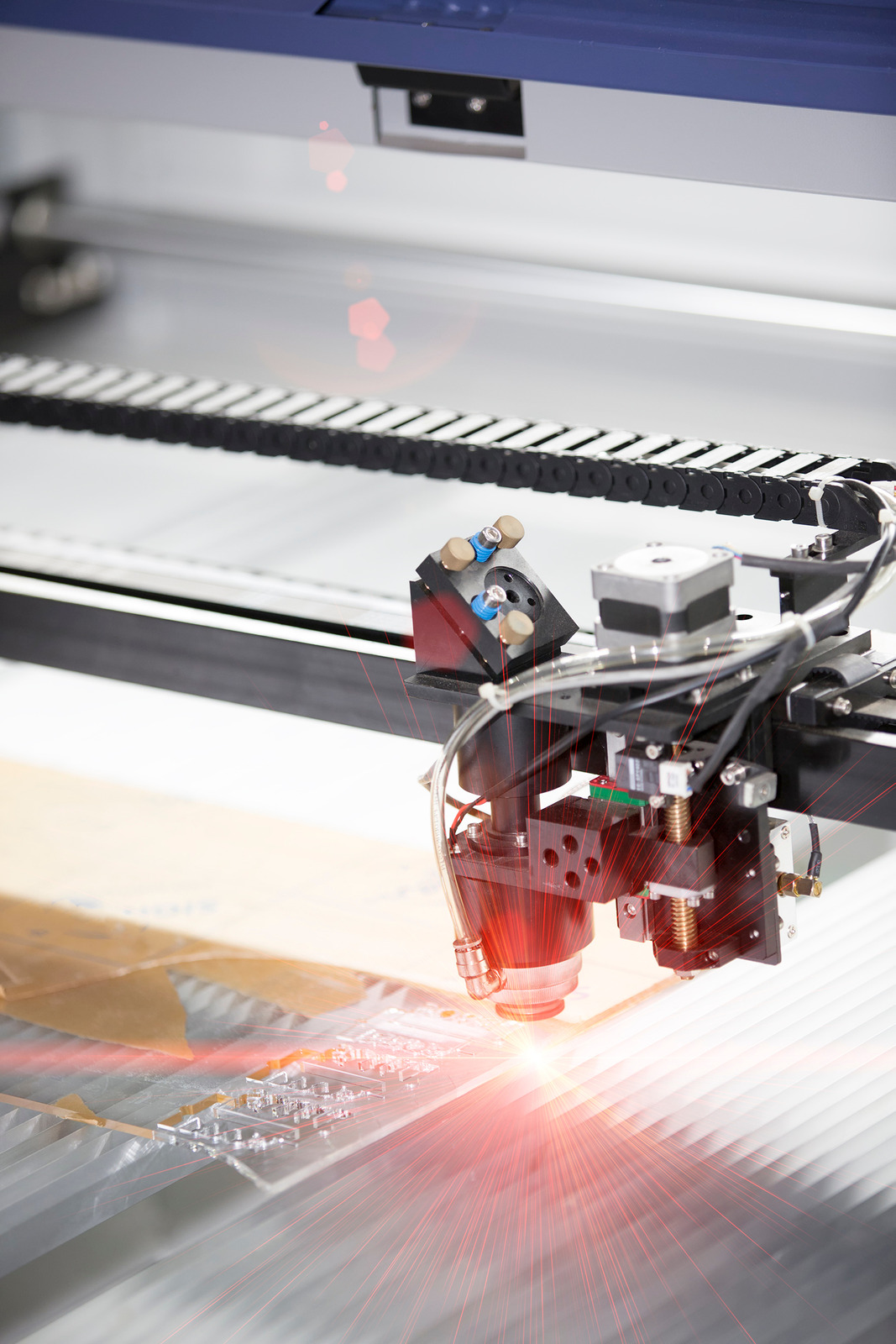

One of the main benefits of laser cutting technology is the speed at which it works. Laser cutters are incredibly fast machines that can cut through almost any material with precision. The laser technology works by focusing a high-energy beam onto the surface of your material, which produces a tiny slit or hole.

This slit or hole then rapidly expands until the material is sufficiently cut. This process happens so quickly that it has been described as “almost instantaneous” by some users.

Accuracy

A key benefit of laser cutting technology is the incredible accuracy it provides. Laser cutting machines precisely follow the instructions of CAD-driven designs and exact patterns are created with the laser’s high resolution capabilities. With a laser cutter, the repetitive accuracy means that cuts can be consistently applied with minimal human input.

This also ensures that once a design has been created, it can easily be reproduced in future projects. The dimensional after-effects are often highly precise in terms of size and shape and the machine can interpret and make cuts with accuracy within fractions of a millimeter.

Cost-effectiveness

One of the major benefits of using laser cutting technology is its cost-effectiveness. Laser cutting machines require minimal upfront investment, but are typically much more efficient than traditional cutting methods. This means that you can save time and money on labor and energy costs, while still producing high-quality results.

Laser cutters can also be used to achieve complex shapes that would otherwise be difficult or time consuming to do with a traditional cutting tool. Additionally, laser cutters produce very little waste, meaning less resources are used, resulting in lower overall costs. Lastly, most laser cutting machines do not require regular maintenance, meaning you can save money on costly repairs.

Drawbacks of Laser Cutting Technology

Heat distortion

One of the main drawbacks of laser cutting technology is the issue of heat distortion. Heat distortion is the result of too much heat being applied to the material you’re cutting. Different materials respond differently to the heat and, if mismanaged, can become deformed or weakened.

Heat distortion is a particularly big issue with thicker, more heat-resistant materials, like wood and metal. When the laser comes in contact with the material during a cut, it melts and vaporizes the material, creating a tiny crater in the material. This process continues along the cutting path until the material is fully cut.

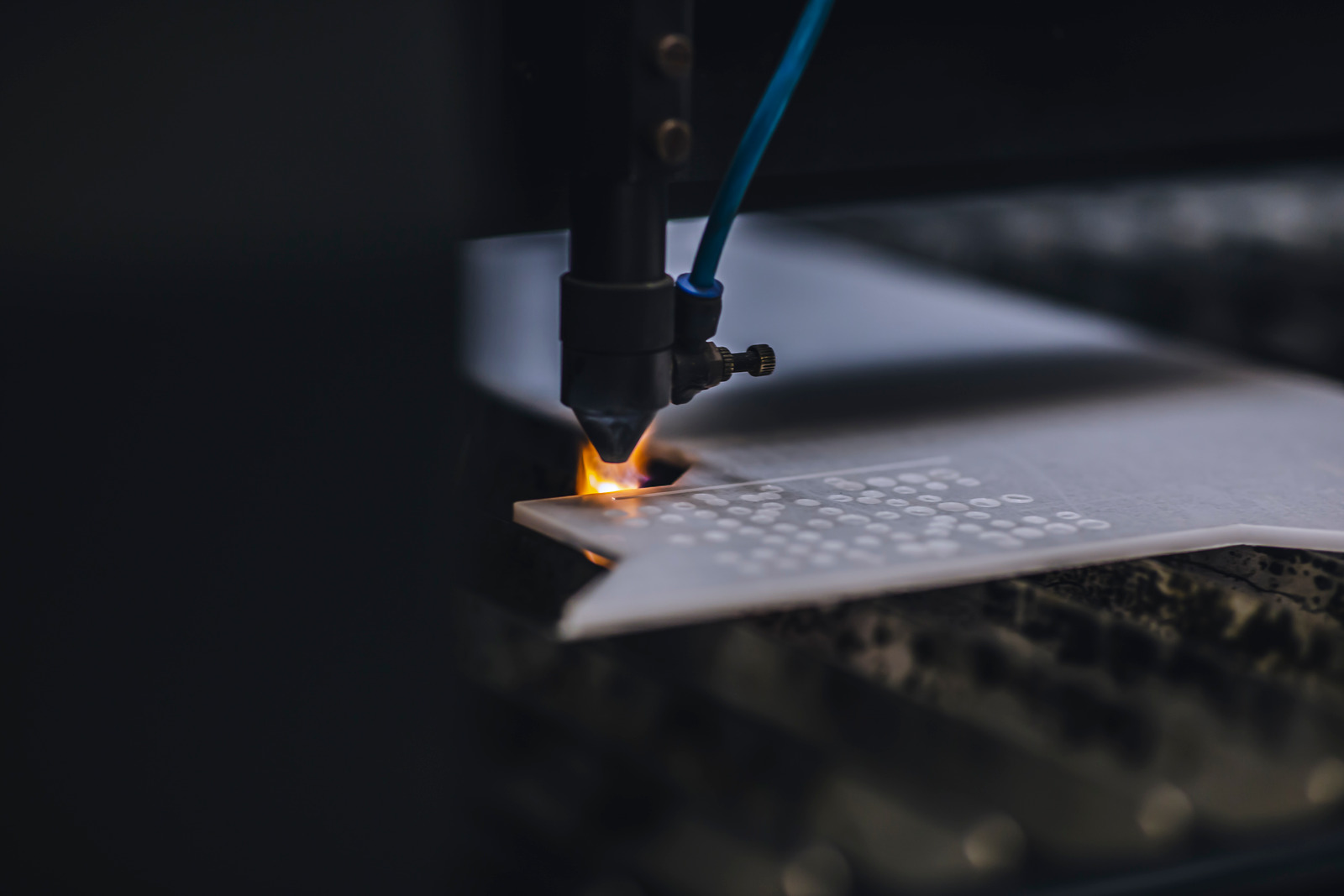

Explosive fumes

Exploring the Drawbacks of Laser Cutting Technology: Explosive Fumes When using a laser cutter or laser cutting machine, there is a risk of explosive fumes emanating from the laser cut. Laser cutting creates a high heat and concentrated beam of light that can create dangerous and explosive fumes in certain type of materials, including plastics and non-metals. These fumes are extremely hazardous, and come from the melting and burning of the plastic.

In fact, many plastics used with laser cutters emit toxic and carcinogenic substances that can harm those in the immediate vicinity.

Limited materials

One of the drawbacks of laser cutting technology is the limited materials that can be used. Laser cutting machines can only work with materials that are capable of conducting electricity, including metals, nylon, and other plastic materials. Because of this, other materials such as paper, formica, stone, and fabrics cannot be used in laser cutters.

Furthermore, the type of metal used in laser cutting should be highly resistant to extreme heat, so that it does not damage the laser cutter’s cutting head.

Closing Thoughts

Advantages of laser cutting over traditional methods

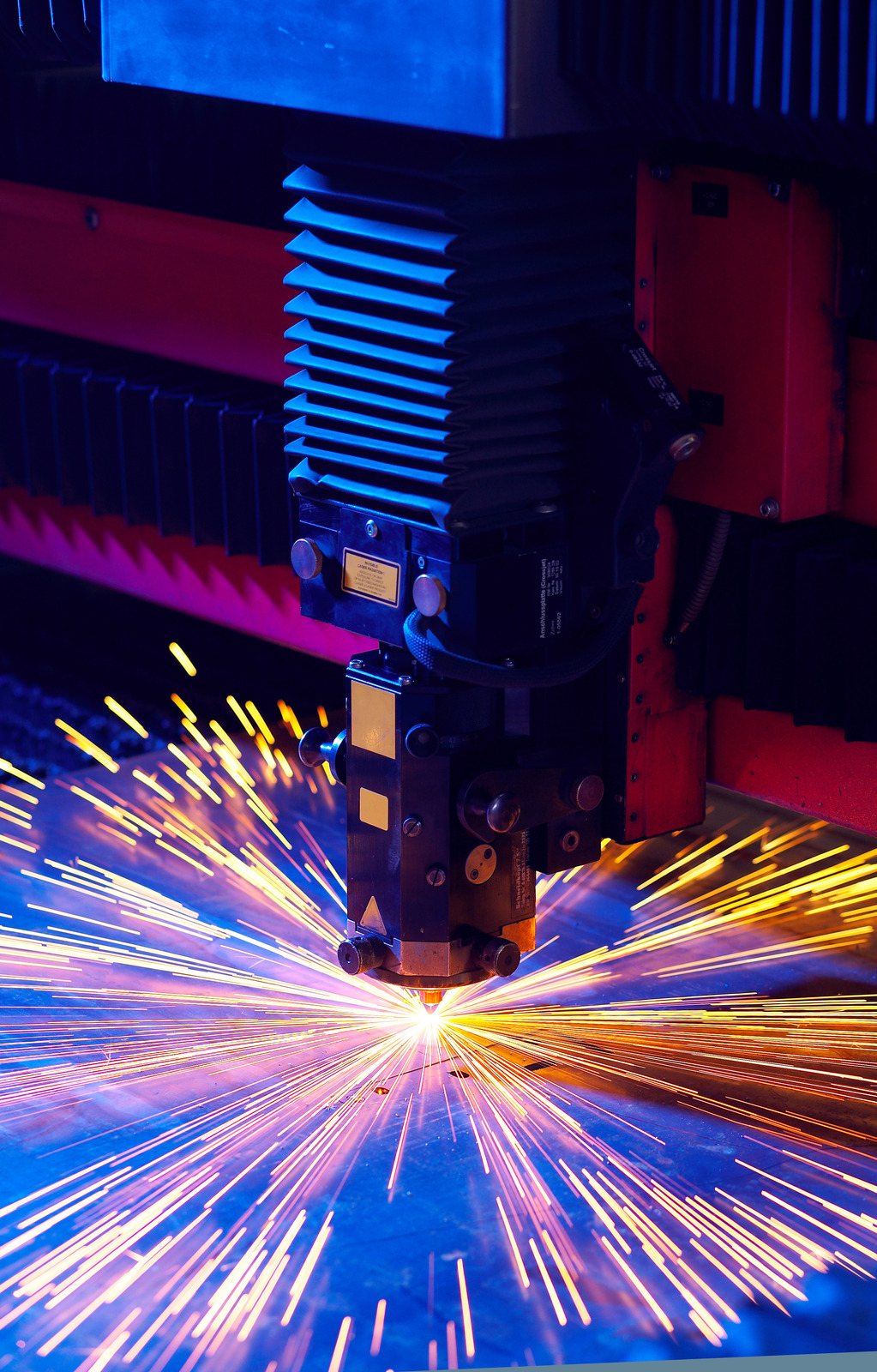

When it comes to creating precision parts, laser cutting has become a reliable and fast technology to utilize, far outstripping the accuracy, speed and repeatability of traditional methods like milling, grinding, or other forms of hand-made fabrication. Laser cutting offers a number of key advantages, such as excellent cut quality, faster processing, low tooling and setup costs, and reduced material waste less material wastage. Firstly, the precision of a laser cutting machine surpasses almost any other cutting method.

Laser cutting can produce intricate curves and shapes that might not be possible with a standard cutting tool, and the cut is much smoother and more precise.

Potential implications of exploring the benefits and drawbacks of laser cutting technology

Exploring the potential implications of laser cutting technology is a complex and often difficult task. While laser cutting technology provides us with the ability to quickly and easily create high-quality, precise cuts, there can be drawbacks to using this technology. These drawbacks include issues such as high power consumption and safety hazards as well as ecological concerns related to the production process and the disposal of waste materials.

The power consumption of laser cutting machines is often quite high, and this can come with significant costs for the environment.

What are four major advantages of cutting wood with lasers?

Laser cutting technology has revolutionized the manufacturing industry, allowing companies to improve safety, accuracy, and cost savings of their operations. One of the most significant advantages of cutting wood with lasers is the precision it provides. Laser-cut parts are of high quality and can be customized to exact requirements. Additionally, laser cutting is both fast and often does not require material rework which can minimizes scrap and overall costs.

- Precise Cuts: Laser cutting technology produces cuts that are incredibly precise, which is ideal for creating intricate and complex patterns in wood.

- Smooth Edges: Laser cutting produces a smooth edge finish on the wood, which eliminates the need for additional sanding and finishing work.

- Versatility: Lasers can cut a wide range of materials including various types of plastic and steel, as well as other materials such as leather or aluminum.

- Efficiency: Lasers are able to produce cuts quickly and without waste, which makes them ideal for high-volume production of wooden parts.

- Automation: Laser cutting machines can be automated, which means that complicated cutting patterns can be completed with a single set-up and minimal human intervention.

What are the drawbacks of laser cutting?

When it comes to laser cutting technology, there are a few drawbacks to be aware of. One main disadvantage of laser cutting machines is cost. Laser cutters are a significant investment, and for this reason, are usually only utilized by larger companies who can afford the upfront and ongoing costs associated with them.

In addition to the cost of purchasing a laser cutter, the materials you plan to cut need to be specifically designed for the laser cutting process, which can lead to higher production costs. Another downside of laser cutting is that the aesthetics of the final pieces can be difficult to predict.

What are the advantages of laser technology?

When it comes to cutting, laser cutting technology has many advantages. Laser cutting machines are able to cut with precision and accuracy, making them ideal for a variety of tasks. In addition, laser cutting technology is relatively fast, as the laser beam can quickly carve through a material as it easily passes through thinner materials.

This makes it ideal for many industrial, medical, and commercial applications. The flexibility of laser cutting technology is another significant benefit. A laser cutter is capable of cutting nearly any type of material, including metals, plastics, paper, wood, and fabrics.

Both thick and thin materials can be worked with, giving it a great deal of versatility.

What are the benefits of laser cutting?

The benefits of laser cutting technology are numerous, especially in industrial settings. For starters, laser cutting machines are incredibly precise and accurate. This means you can create complex shapes and intricate designs with ease.

Additionally, laser cutting technology can achieve extremely high accuracy, even with details as small as 0.01 mm. This means that even intricately designed components and products can be created without worrying about sloppiness. One of the most significant advantages of using a laser cutting machine is speed.

Unlike traditional cutting methods, laser cutting is incredibly fast and efficient. This means you can quickly and easily create parts at a fraction of the cost associated with slower methods.

Conclusion

In conclusion, laser cutting technology has many amazing benefits that cannot be overlooked. From extremely precise and accurate cutting capabilities, to fast and efficient operation, to the reduced need for human labor, it is no surprise that laser cutting machines have become a ubiquitous part of industrial manufacturing in the 21st century. On the downside, laser cutting technology can be costly, and there are some materials, particularly those with high reflectivity, that are difficult to cut with a laser cutter.