Welcome to the exciting and innovative world of laser cutting carbon fiber. From consumer electronics and automobile parts to aerospace engineering and architectural components, carbon fiber is becoming increasingly prominent in modern applications. With the advent of laser cutting, this powerful material can be molded into shapes and forms with incredible precision. In this article, we’ll explore the art of laser cutting carbon fiber and the myriad of possibilities this technology provides.

History and Development

Origins of laser cutting technology

Since the late 1950s, the industrial world has adopted a variety of laser cutting technologies to manipulate and work with a wide range of materials. Carbon fiber is no exception, and has become increasingly popular due to its superior strength and lightweight properties. Laser cutting carbon fiber opens up a realm of possibilities for manufacturers, as it allows them to create complex shapes and parts with a high degree of precision and accuracy.

The laser cutting technology for carbon fiber originated in the 1970s at the Lawrence Livermore National Laboratory in California. At the time, scientific researchers were using lasers to cut materials like carbon fiber for research purposes.

Development timeline of laser cutting

The timeline of the development of laser cutting carbon fiber starts in the late 1960s with the invention of the very first laser systems. Before this, the only way to cut carbon fiber was with traditional cutting tools such as scissors, knives, saws, and water jets. In 1973, the world’s first industrial-grade carbon fiber laser cutting machine was developed in England.

This unlocked a whole new range of possibilities for the manufacturing industry and set the stage for the growth of carbon fiber laser cutting.

Overview of modern laser cutting technology

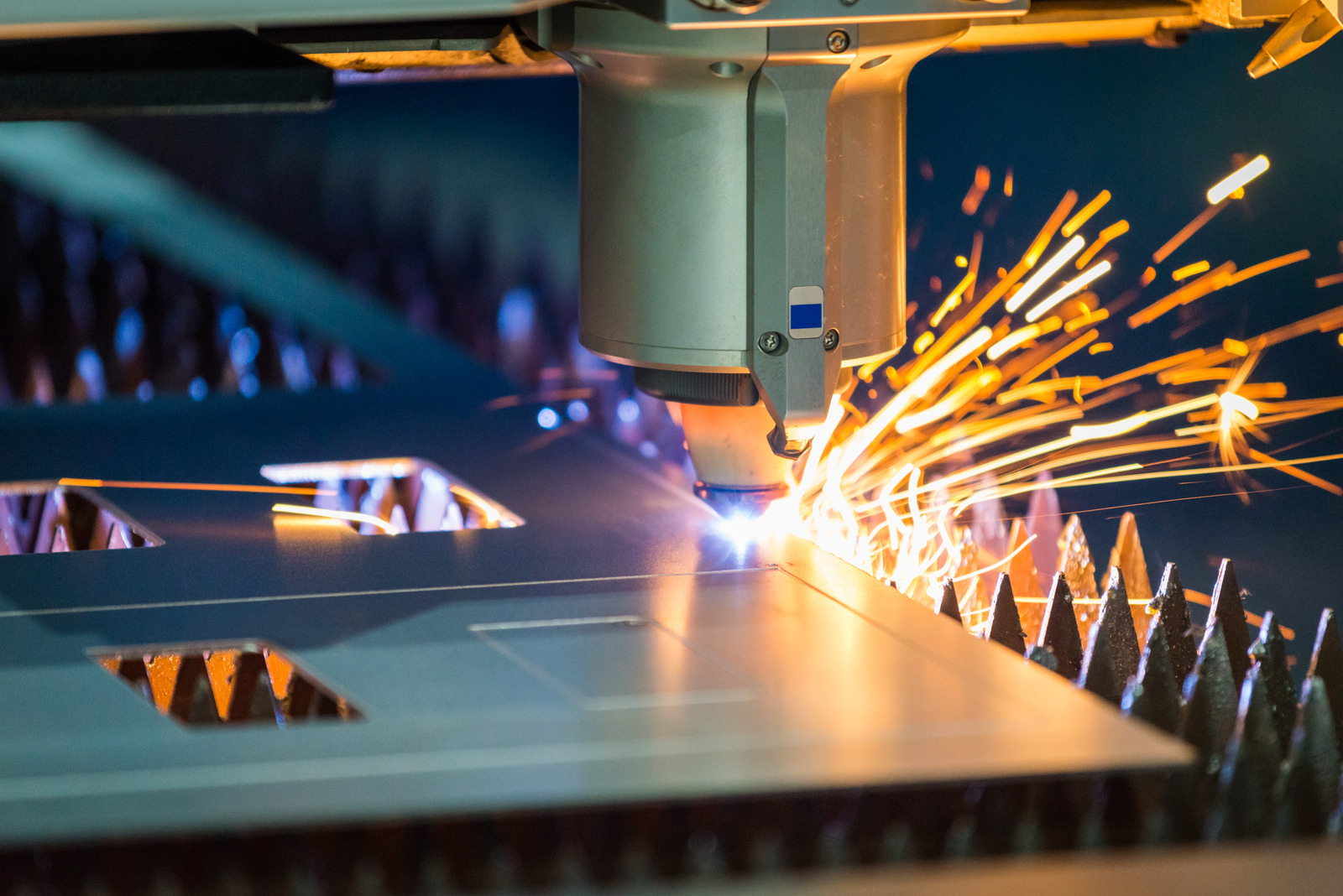

The use of laser cutting for carbon fiber is an increasingly popular manufacturing and production technique. Carbon fiber is one of the most commonly used materials in many industries, including aerospace, automotive, and medical. The tremendous strength and lightness of carbon fiber make it an ideal choice for a wide range of products and components.

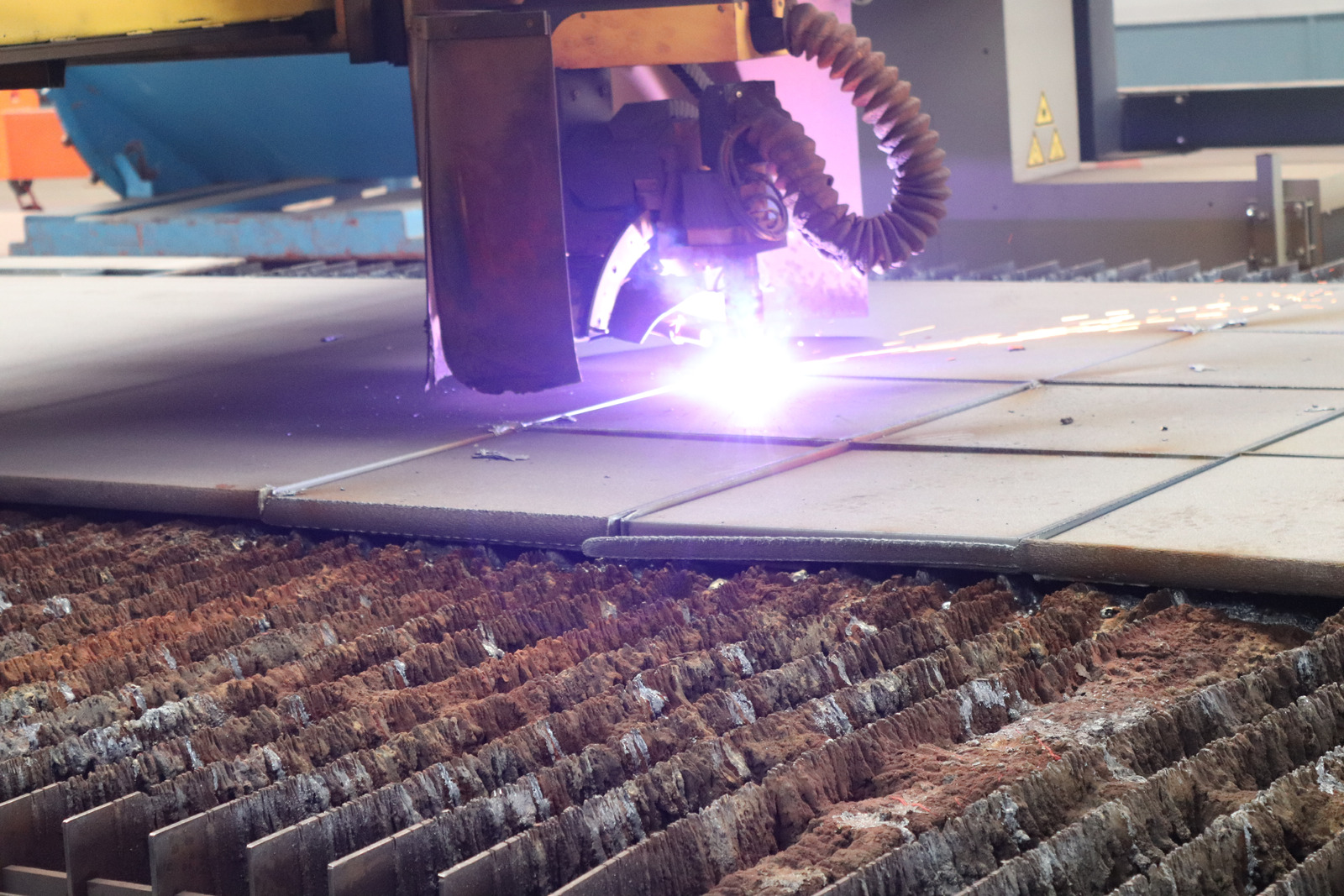

But, due to its unique characteristics, cutting it requires special tools and techniques. Laser cutting, or using a laser beam to precisely and accurately cut through the material, is now the preferred method to cut carbon fiber.

The Manufacturing Process

Description of materials needed

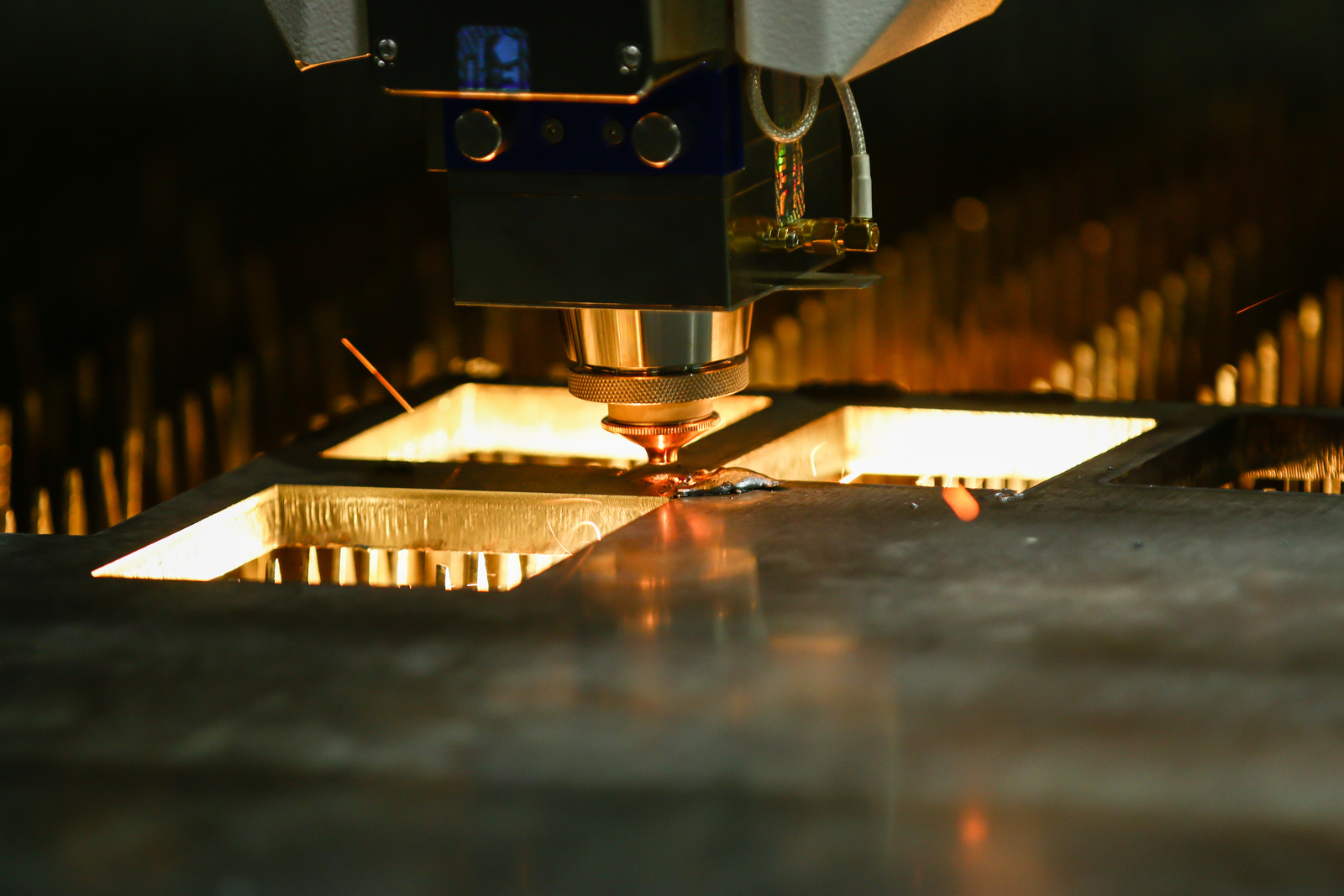

Laser cutting carbon fiber is a commercial manufacturing process used to create a variety of custom shapes and designs. The process typically involves directing a high-energy beam of light, known as a laser, onto a pre-cut piece of carbon fiber to create precise shapes, shapes, and designs. Carbon fiber is a composite material composed of an incredibly strong and lightweight matrix of fibers and resins, commonly used for a variety of mechanical and industrial applications.

Overview of the involved steps

One of the most interesting and creative processes available for manufacturing today is laser cutting carbon fiber. In this process, laser cutting is used to precisely cut and shape thin sheets of carbon fiber material into parts that are often used for aerospace components, medical equipment, and other industrial applications. Before we explore the steps involved in laser cutting carbon fiber, it’s important to understand a bit more about the material itself.

Benefits of laser cutting vs other techniques

When it comes to manufacturing parts out of materials such as carbon fiber, laser cutting is often the preferred technique for many reasons. One of the major advantages of using lasers to cut carbon fiber is that it is fast and highly efficient. Lasers can slice through carbon fiber quickly, resulting in smoother and cleaner cuts, without sacrificing precision and accuracy.

Additionally, lasers are capable of making much tighter and more intricate cuts than other techniques, such as mechanical cutting or abrasive cutting. The use of lasers also helps to minimize waste, as laser cutting produces far less dust and debris than traditional cutting methods.

Applications and Advantages

Various applications of laser cutting carbon fiber

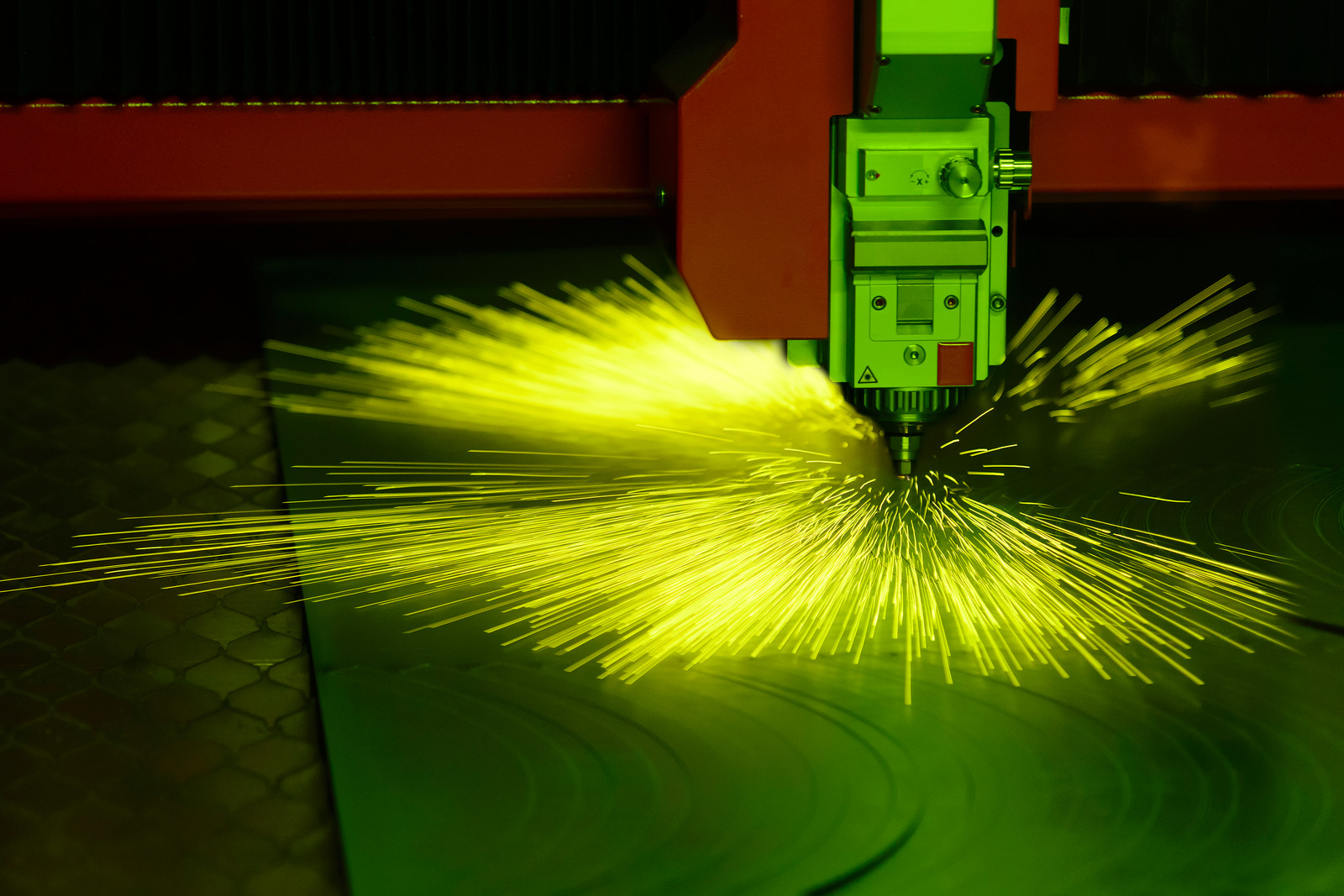

Carbon fiber laser cutting is a process where a laser is used to cut or fabricate carbon fiber sheets, rods, tubes, and other shapes. It has become increasingly popular in the manufacturing industry due to its various advantages such as its efficiency, precision, and cost-effectiveness. Carbon fiber is a strong, lightweight material that is versatile in its range of applications, so it is a great option for laser cutting.

When it comes to laser cutting, carbon fiber is a great material as it provides a high-quality finish and cuts with precision.

Benefits of using laser cutting for carbon fiber

Laser cutting carbon fiber is becoming increasingly popular as a fabrication method mainly because it offers a variety of advantages that other methods of cutting carbon fiber cannot match. For starters, laser cutting is a fast and efficient process that can quickly cut or engrave complicated patterns into carbon fiber with precision and accuracy. Additionally, laser cutting does not generate any heat and thus won’t warp your material, making it particularly suited for cutting thin and delicate materials.

Comparison of laser cutting to traditional cutting methods

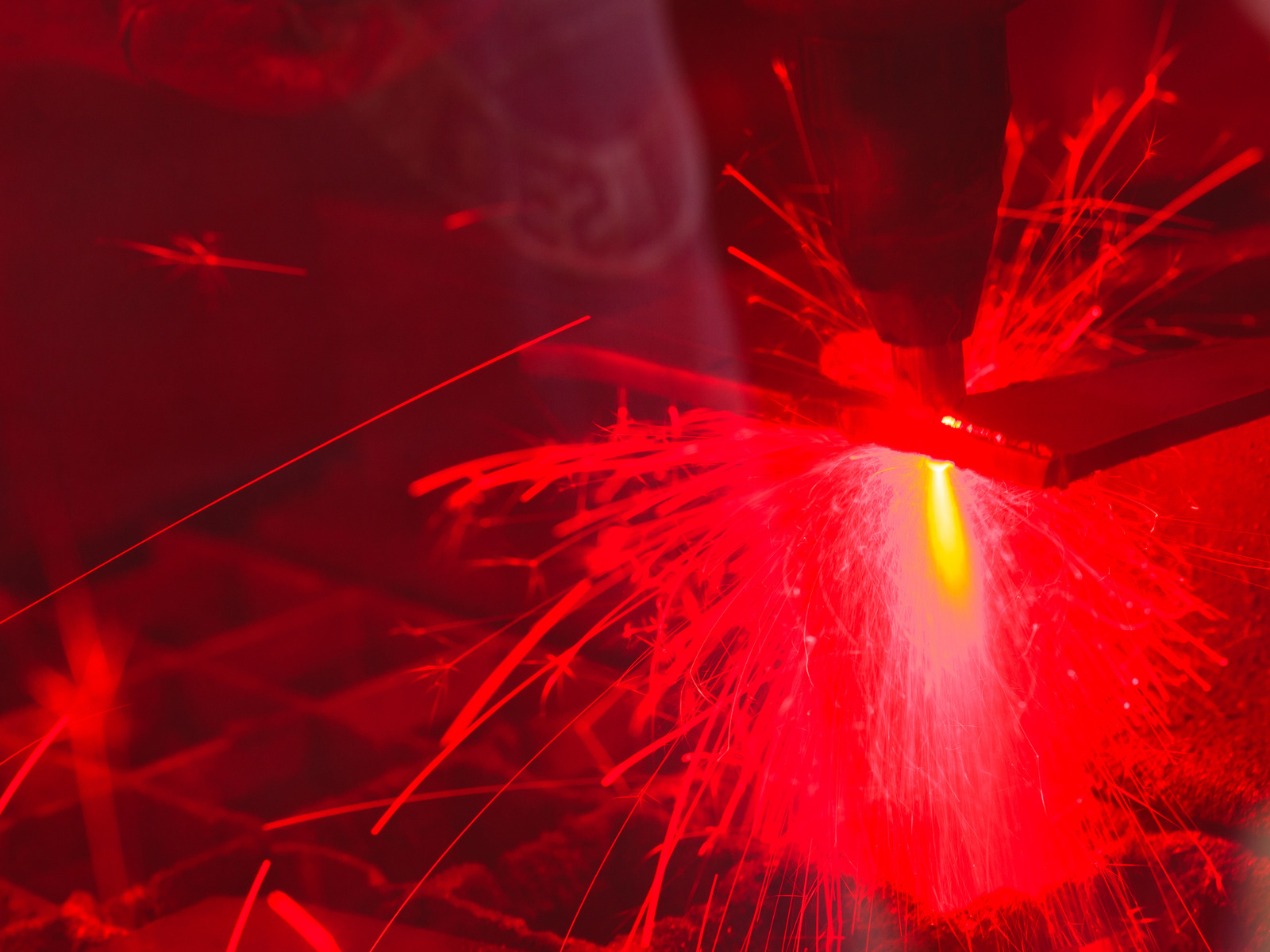

When it comes to working with carbon fiber, traditional methods such as mechanical cutting have their own limitations. Mechanical cutting consists of cutting tools such as a jigsaw or a shear, which can wear or break with prolonged use on carbon fiber or other high-strength materials. Heat-based cutting, like laser cutting, can provide a more precise, consistent, and reliable result with less wear on the machine and less chance of damaging the material.

Can laser cutters cut carbon fiber?

Yes, laser cutters are able to cut carbon fiber, allowing you to create precise pieces of this lightweight but strong material. Laser cutting of carbon fiber is a popular technique for creating everything from drone frames and bike frames to auto body parts and components for aerospace. Carbon fibers are a special type of material because they have impressive physical properties like strength, heat resistance, and light weight.

They are cut using a powerful laser beam that has a very small focal width and can be fine-tuned to produce a wide range of shapes and sizes.

Can you laser mark carbon fiber?

Yes, you can laser mark carbon fiber. Laser marking is the reversible process of permanently etching a mark onto a material, such as carbon fiber, using a laser. It is an ideal method for branding or personalizing your carbon fiber components.

Using a specialized laser machine and an appropriate marking material, you can exquisitely put names, logos, or intricate designs onto carbon fiber.

Conclusion

Summary of reasons to use laser cutting

The use of laser cutting with carbon fiber has become a popular option in many industries due to its many benefits. Carbon fiber is a strong, light, and flexible material that can be used to create complex and intricate parts and components. Laser cutting is a precise and efficient process that requires minimal materials and labor to achieve high-quality results.

When laser cutting carbon fiber, the laser beam does not require a lot of energy to cut through the material, resulting in less heat being generated, making the entire process more efficient, and allowing for thinner cuts with minimal distortion.

Overview of the advantages of the technology

The technology of laser cutting carbon fiber is a revolutionary advance for many industries that rely on the material. Carbon fiber, being an incredibly strong and lightweight material, is often used in applications where low weight and high strength are required. Laser cutting this material allows for complex and intricate shapes to be cut quickly, accurately and with minimal waste – compared with traditionally cut parts.

Laser cutting carbon fiber also has several advantages over other fabrication methods. One of the biggest advantages is that laser cutting carbon fiber requires less energy than other cutting methods.

Ideas for the future of laser cutting

At the conclusion of exploring the art of laser cutting carbon fiber, it is evident that this modern technology has a lot of potential when it comes to the applications of this durable material. Looking to the future, there are a vast array of ideas for the use of laser cutting carbon fiber technology. One use that is becoming increasingly widespread is in the construction of industrial grade parts and components.