Laser cutting technology is growing in popularity as it promises efficient operation and attractive cost-effectiveness. While it is true that laser cutting offers superior precision, increased speed and a variety of benefits, it is important to consider the pros and cons before making a decision about whether to invest in laser cutting technology. In this article, we will examine the advantages and disadvantages of laser cutting for cost-effectiveness.

Pros of Laser Cutting

Improved accuracy and repeatability

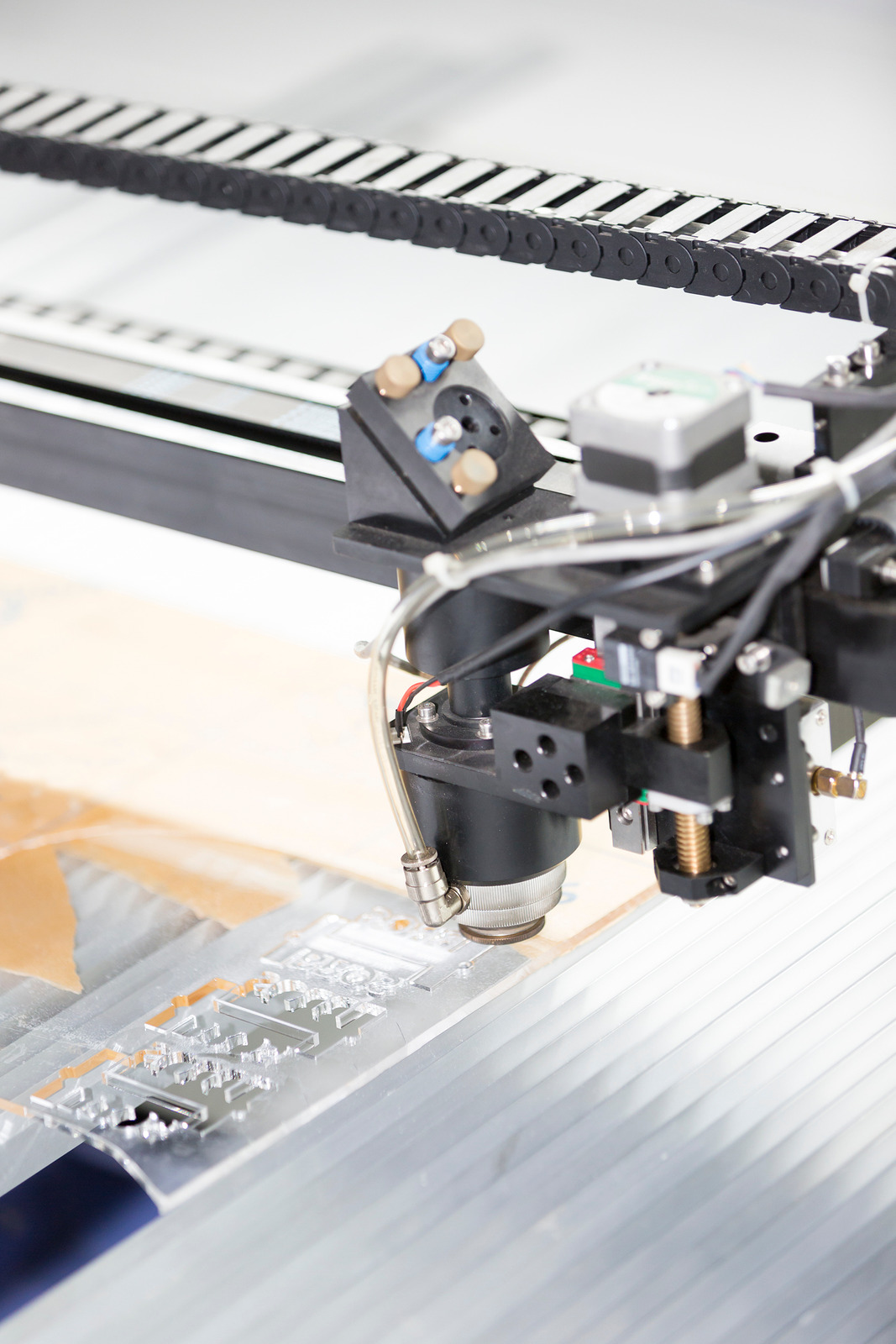

One of the major advantages of laser cutting is improved accuracy and repeatability, which contributes to cost-effectiveness. Since laser cutting is done with a computer-controlled machine, it allows for precise and intricate shapes to be cut without any issue. This precision and repeatability ensures that each cut is the same and always perfect, so there is no need to worry about inconsistencies or having to adjust and refine the product manually.

Increased efficiency

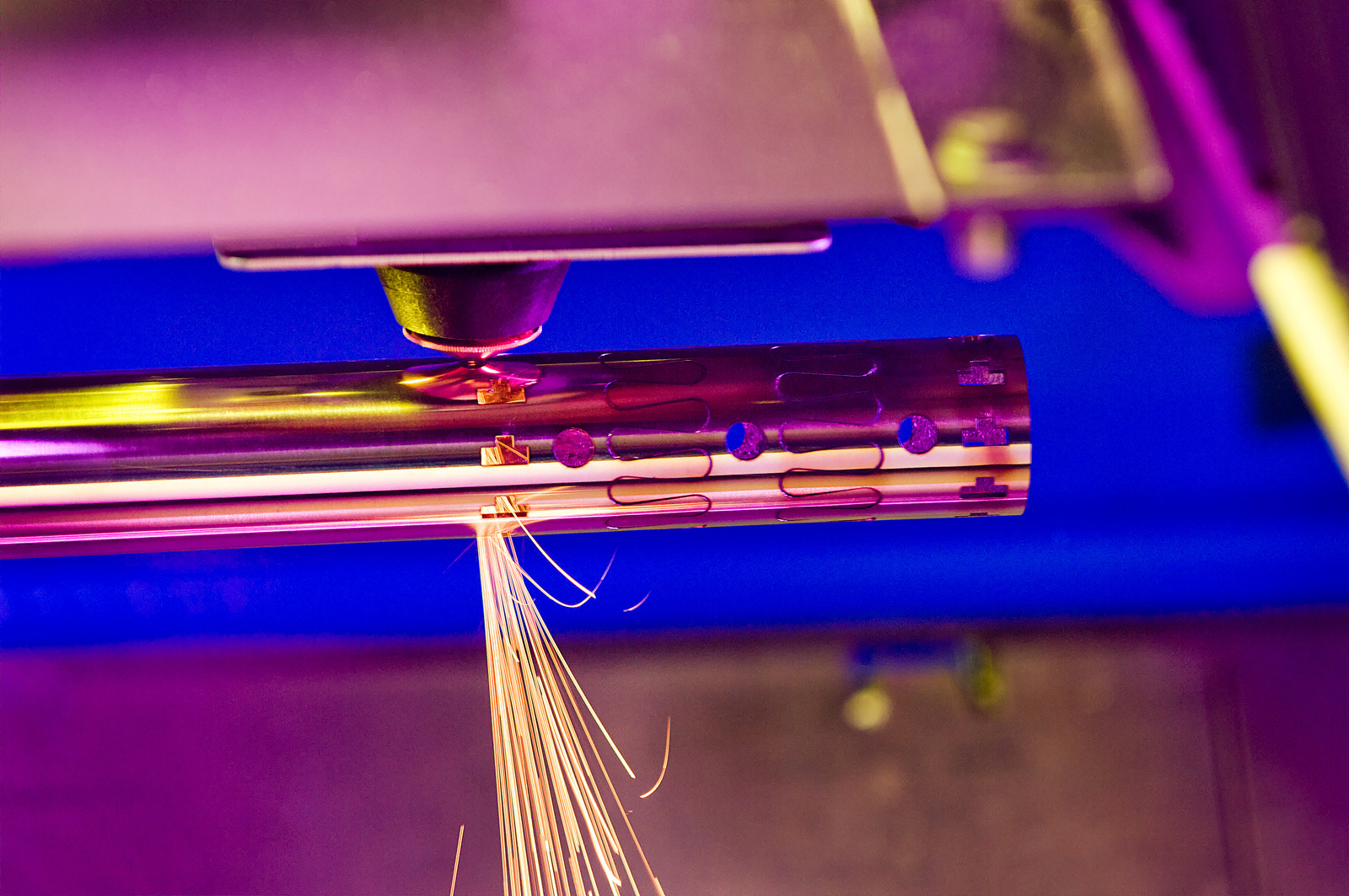

The increased efficiency that comes with laser cutting is one of its biggest advantages – and one of the most cost-effective ways to get the job done. Laser cutting combines the precision of a finely-honed blade with the power of a laser’s cutting and welding capabilities. This means it can easily handle materials of all kinds, including steel and other metals, plastics, wood, and more.

This efficient process leads to a more precise cut, improved accuracy, and a faster production cycle – all of which can result in considerable cost savings.

Reduced Cost

One of the most significant pros of laser cutting is its cost-effectiveness. By contrast to traditional metal cutting methods such as waterjet cutting and other mechanical operations, laser metal cutting requires fewer man-hours and less material compared to other methods. Unlike other metal cutting processes, laser metal cutting does not require tooling costs, which can significantly reduce the overall cost involved in the process.

Additionally, the extreme precision with which laser cutting operates allows the material to be used in its entirety, so there is virtually no wasted material. This process also offers a smaller waste stream, which can help reduce costs associated with waste disposal.

Cons of Laser Cutting

High upfront cost

When it comes to considering laser cutting as a cost-effective option for your business, the most important factor to consider is the high upfront cost of the equipment. Laser cutting is typically the most expensive option available, requiring significant capital investments for the purchase and installation of the cutting system. This high up-front cost can be a major obstacle for many businesses and can be difficult to justify.

Additionally, in order to achieve cost effectiveness through laser cutting, the process must be regularly used near its full capacity to achieve a relatively quick payoff.

Safety and health risks

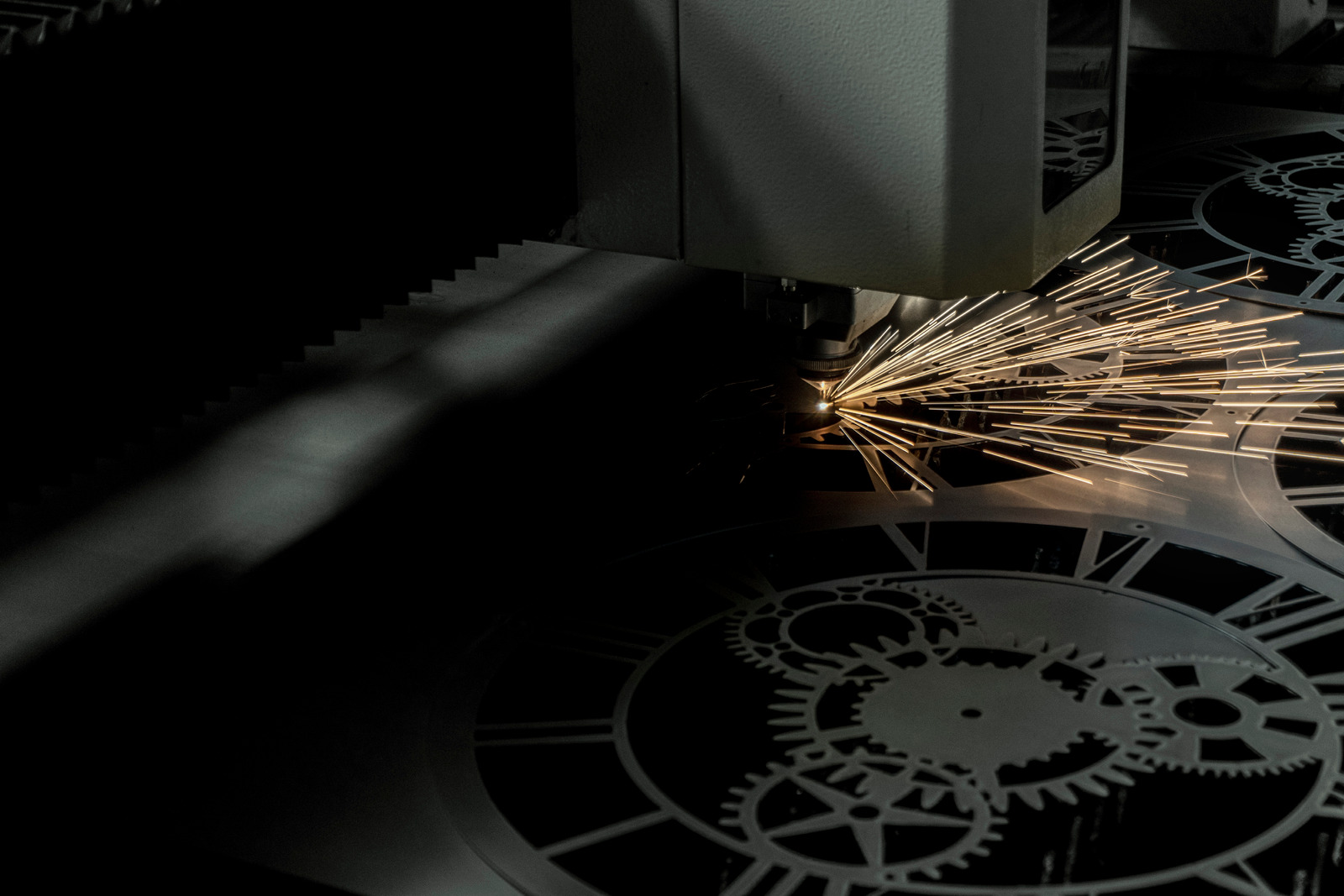

When it comes to cost-effectiveness, laser cutting has a lot to offer. However, there are also some cons associated with this method of cutting. One of the main considerations when it comes to this type of cutting is safety and health risks.

The heat emitted from laser cutting can cause serious safety risks. In order to reduce these risks, it is important that adequate safety equipment is used in order to protect operators from the beam of light and heat.

Waste of scrap material

When it comes to laser cutting, one of the biggest cons is the amount of waste of scrap material that can occur from the process. Laser cutting involves using a powerful laser to cut through metal, plastic, wood, and other materials, making very precise cuts. One of the side effects is that it can cause a lot of scrap material to be produced, leading to more money spent on material.

Evaluating Cost-Effectiveness

Cost-benefit analysis

A cost-benefit analysis is an important tool that can help businesses evaluate the costs and benefits of various decisions related to laser cutting. A comprehensive analysis typically takes both quantitative and qualitative factors into consideration in order to identify the most cost-effective solution. At the forefront of a cost-benefit analysis is an evaluation of the costs associated with laser cutting.

This includes the purchase and maintenance of the equipment, the materials used, and the operating costs associated with labor and energy consumption. It is important to consider any hidden costs as well, such as taxes, insurance, or lease payments.

Answering key questions

Answering key questions: We all have questions when we are considering purchasing a new tool, such as a laser cutter. When it comes to making the decision to invest in a laser cutter, it can be helpful to consider the pros and cons of the technology in order to evaluate its cost-effectiveness. The laser cutter has many advantages that can save time and money in the long run.

First, laser cutting is a much more accurate and precise cutting method than traditional methods like saws, larger milling machines, or even hand cutting. This leads to less wasted material, which lowers costs.

Return on Investment

When it comes to choosing the right cutting technology, whether it’s for a startup business or an established enterprise, evaluating the return on investment of laser cutting is essential. A number of factors come into play when assessing whether laser cutting is cost-effective, including the price of the equipment, labor costs, and the cost of materials. It is important to evaluate the potential savings versus other methods of fabrication and determine whether the additional cost is worth it.

When it comes to laser cutting, it is often thought of as a more expensive technology. However, it can be beneficial for certain job types and has a number of advantages that can help to reduce costs.

What are the pros and cons of using a laser cutter?

When it comes to cost-effectiveness, evaluating the pros and cons of using a laser cutter is important. Laser cutting is a time-efficient, accurate process that can produce highly-detailed products and components. The major pros of laser cutting are its speed, accuracy, and cost-effectiveness.

Laser cutters can be used to process large amounts of material quickly and efficiently, leading to significant cost savings in production time. Additionally, laser cutters are capable of producing extremely precise cuts, which helps to reduce costs associated with scrap waste. The major cons of using laser cutting are the cost of the machinery, the specialized materials needed to operate, and the waste generated by the process.

Conclusion

Summary of Pros and Cons

When it comes to evaluating the pros and cons of laser cutting for cost-effectiveness, it’s important to consider all the factors that may be involved. Laser cutting has many advantages over traditional cutting methods such as lower cost, faster speed, higher accuracy, and is better for precise cutting. In addition, laser cutting can create wide range of shapes and can work with a variety of materials, including metal, plastic, and wood.

It also has minimal downtime for setting up and changing cut pieces, making it a very efficient process. However, there are some downsides to laser cutting as well, such as its reliance on electricity, which can increase costs.

Final Recommendation

When it comes to evaluating the pros and cons of laser cutting for cost-effectiveness, the final recommendation is that laser cutting can be cost effective if its advantages are leveraged. Laser cutting provides high levels of accuracy, repeatability, and speed, which can save time and money. Additionally, laser cut parts require minimal post-processing and internal stress that may cause part warpage is reduced; these two factors can also improve cost effectiveness.

Laser cutting can also make difficult shapes easy to produce and can provide tight tolerance results.

Tips for Maximizing Cost-Effectiveness

When it comes to cutting materials, laser cutting offers a variety of advantages that can help you maximize cost-effectiveness. One key benefit is the ability to easily customize the laser cutter settings and make precise cuts precisely where you need them, which can save you time and money compared to other cutting methods. Additionally, laser cutters are much more reliable and easier to maintain than traditional cutting options, so you don’t have to worry about unexpected breakdowns or downtime.

When it comes to cost, laser cutting is also a great option.