When it comes to laser cutting of metals for production and engineering, precision and quality of services are of utmost importance. Evaluating the various laser cutting services for metals requires a thorough understanding of the processes, materials and costing involved. In this article, we will discuss the factors and criteria to consider for assessing and selecting a laser cutting service for metals.

What to Consider When Evaluating Laser Cutting Services

Durability

When evaluating laser cutting services for metal, durability is an important factor to consider. Laser cutters use various materials to cut metal, such as oxygen, nitrogen, and carbon dioxide, and you want to make sure that the metal will be durable enough to withstand the laser cutting process. When choosing a laser cutting service, look for a company that has a long history of reliable and consistent cutting techniques, as well as the latest technology and processes that guarantee top-notch performance.

Make sure the laser cutter is reliable, with a low failure rate, good laser beam quality, and an accurate cut pattern. It is also important to consider the lifespan of the equipment.

Precision

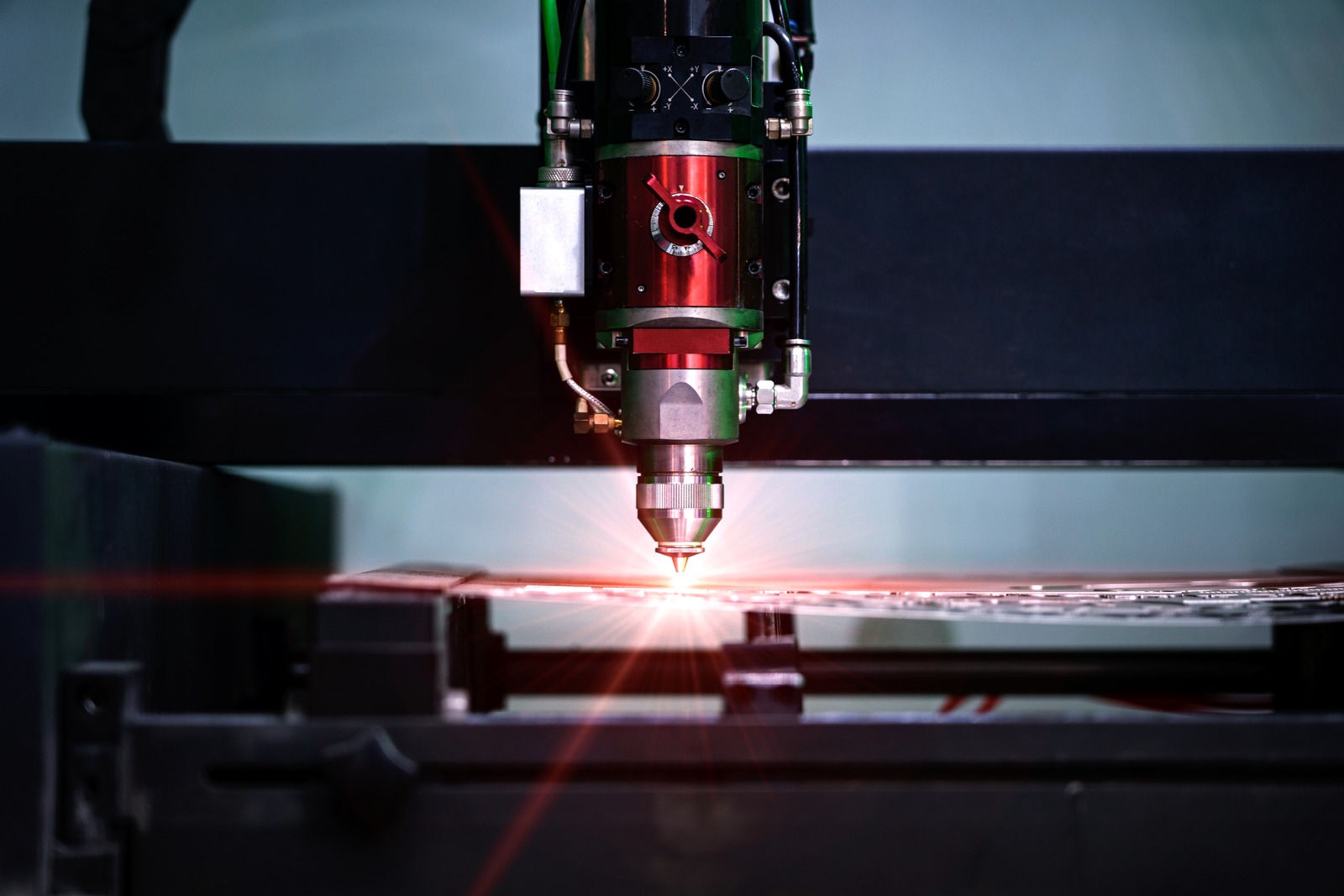

Precision is a key consideration when evaluating laser cutting services for metal. Laser cutters use a high-powered laser to cut through metal with accuracy and efficiency. The lasers used in laser cutting are precise and the beam of light is focused, so the cut is precise and the edges are smooth without any jagged edges.

The operator needs to set the cutting parameters precisely to ensure that the job is completed accurately and with less waste.

Quality

Quality is an important factor to consider when evaluating laser cutting services for metal. The quality of the laser cutter that is going to be used to cut your metal parts, as well as the quality of the material that is going to be cut, will directly affect the quality of the end product. In order to ensure the highest quality of metal parts, look for laser cutters that are capable of cutting precise, precise edges and have the power to cut through the thickness of the metal you will be working with.

Cost vs. Quality

Investing in Quality Services

When it comes to evaluating laser cutting services for metal, cost vs. quality can be a tricky balance. As a business owner or organization, investing in high quality laser cutters and services can make a substantial long-term difference in the results you achieve. Generally, the more money you invest in quality laser cutting services, the better results you will achieve in terms of accuracy, repeatability, and overall performance.

Finding the Right Balance

When it comes to evaluating laser cutting services for metal, such as those offered by laser cutters, it is important to understand the balance between cost and quality before choosing the best solution. Cost is always an important consideration because projects often must remain within a specific budget. However, it is also important to make sure that the quality of the product is not compromised by seeking out too low a price.

When shopping for a laser cutting services, it is a good idea to focus on the company’s quality standards and turnaround times.

Things to Look for in a Laser Cutting Service

Experience

When you’re evaluating laser cutting services for metal, it’s important to pay attention to experience. Laser cutting has been around since the 1960s, and since then, it has become one of the most popular ways of cutting metal. The best laser cutting services have been in business for many years, so they know what they’re doing and will have the expertise and knowledge to get the job done right.

You want to look for a company that has a good reputation, and one that can offer references or a portfolio of previous work.

Reputation

When you’re evaluating laser cutting services for metal, one of the most important factors to consider is the service’s reputation. A laser cutting service with a good reputation will not only be more reliable, but it can also provide a better customer experience. Before signing a contract with a laser cutting service, it’s a good idea to do your research.

Start by reading reviews from customers who have already used the service. You’ll get an idea of the customer service level, reliability, and quality of the service.

Professionalism

When evaluating laser cutting services for metal, one of the most important criteria should be the professional conduct of the company. Professionalism means that the company is organized and ensures that their work is of the highest possible standard. Make sure they have customer service representatives ready and willing to assist you with any questions you may have, and that any problems you may encounter get addressed quickly and thoroughly.

Good laser cutting services will also have a solid understanding of their field, with experience working with different types of metals and machines.

What to Ask Prospective Laser Cutting Services

How Long Have They Been in Business?

When evaluating laser cutting services for metal, it’s important to ask the prospective laser cutter how long they have been in business. The length of time that a laser cutting service has been around is a great indicator of the level of expertise that they possess regarding the laser cutting of metal. With over a decade of experience under their belt, laser cutting services are sure to be masters of their craft and are more likely to provide a quality end product.

What Quality Control Processes Do They Have in Place?

When evaluating laser cutting services for metal, it is important to make sure that quality control is a top priority. This means asking the prospective laser cutting service what quality control processes they have in place. Quality control processes help to ensure that all of the parts that are cut are accurate and meet the customer’s expectation.

Some common quality control processes that laser cutting services use include: * Visual inspections: This is when a trained operator visually inspects each part to make sure that they meet the customer’s specifications. The operator looks at the part’s size, shape, and any necessary markings.

What Kinds of Materials Do They Work With?

When evaluating laser cutting services for metal, one of the most important things to ask is what kinds of materials they work with. Laser cutters have the capability to work with a variety of materials, ranging from thin aluminum alloys to thick steel plates. Different laser cutters have different capabilities, so understanding which materials a prospective service works with can be a great way to narrow down your selection.

It’s also important to ask what type of laser cutter they use, since different machines are designed to work with different types of materials.

Final Thoughts

Is Laser Cutting the Right Choice for Your Needs?

When it comes to evaluating laser cutting services for metal, it’s important to consider all of the factors that go into making a decision. While laser cutters may certainly be convenient and efficient tools, there are a number of additional considerations that need to be taken into account before ordering a service. The first step in evaluating a laser cutting service is to ensure that they will be able to cut the desired material and to the correct specifications.

Taking the Time to Find the Right Service

Taking the time to find the right laser cutting service for your metal project can be daunting, but the rewards are worth the effort. It’s important to consider all the factors when evaluating laser cutters. A good laser cutting machine should be reliable, accurate, consistent and produce the desired outcome with minimal materials usage.

Beyond that, there are many other factors to consider. It’s also important to consider turnaround time, cost-effectiveness and lead times for complex projects. The best approach for finding a reliable laser cutting service is to compare several machines and get quotes from multiple services.

What to Do Once You’ve Found the Right Service

Once you’ve done your research and evaluated laser cutting services for metal, you may have found a service that meets your needs and goals. The next step is to take things to the next level – to actually get the service and complete the project. The first thing you’ll want to do is get quotes and estimates.

Ask the different laser cutters for a quote for the project, what materials are included and what the cost will be. You can then compare the quotes and decide which one is the best. Make sure you ask about any additional fees such as shipping or handling.

Conclusion

Conclusion When evaluating laser cutting services for metal, it’s important to consider the quality and accuracy of the cut, the turnaround time of the job, the cost of the service, and the customer service options available. By evaluating these factors and doing research into the company, you can make an informed decision as to which laser cutting service is the best fit for you. You should also take the time to determine which type of laser cutter will be best for your project.