Laser cutting glass is a precise and efficient way of cutting precise shapes and sizes of glass with the aid of a laser beam. However, like any other form of cutting, there may be some common issues and problems that you may encounter. In this article, we will discuss some of the most common problems and issues with laser cutting glass, so you can be prepared if you decide to use this type of cutting method.

Common Issues with Laser Cutting Glass

Warping and Hygroscopy

of warping and hygroscopy When it comes to laser cutting glass, warping and hygroscopy are two common problems that need to be dealt with. Warping is the distortion of the glass caused by uneven temperature distribution. As the laser cuts through the glass, the heat generated by the laser causes instability in the glass, resulting in a warped shape.

Hygroscopy is the absorption of moisture by the glass. It occurs when the glass absorbs too much moisture from the air, leading to an uneven surface when cut. In order to prevent warping, the surface of the glass must be precisely sealed.

Corrosion Resistance

of corrosion One problem that can arise from laser cutting glass is that the cut edges of the glass can become corroded. This is due to the fact that the laser beam creates a high temperature during the cutting process, which can cause certain materials, like certain metals, to react with the glass and cause it to corrode. The process of laser cutting also creates a vapor, which can contain particles of the reaction product and can, in turn, lead to corrosion of the cut edges of the glass.

The corrosive reaction can also cause stress fractures and discoloration in the glass, which can further weaken the material and increase the chance of breakage during use.

Trapping and Cracking

When laser cutting glass, one of the most common issues is trapping and cracking. Trapping is when a piece of material becomes wedged between the laser and the material being cut. This can cause a number of issues, such as uneven cutting, melting of the materials, over-shooting the cut, or cracking the material.

The cracking can be especially problematic since it can cause the piece that you were attempting to cut out to become compromised. This can create a huge headache and can complicate projects that you are working on. The main cause of trapping and cracking is due to the force with which the laser cutting takes place.

Image Bleeding

with image bleeding When using a laser cutter for glass, image bleeding can be a common problem. Image bleeding occurs when a design element, like a logo or text, is distorted from its original shape as light from the laser passes through the glass cutting process. This is especially common with intricate designs that have a thin outline around their shape, as the thin outline will be especially affected.

The causes of image bleeding vary, but can mostly be attributed to the poorly focused laser beam.

Problem-Solving Strategies

Choosing the Proper Laser Parameters

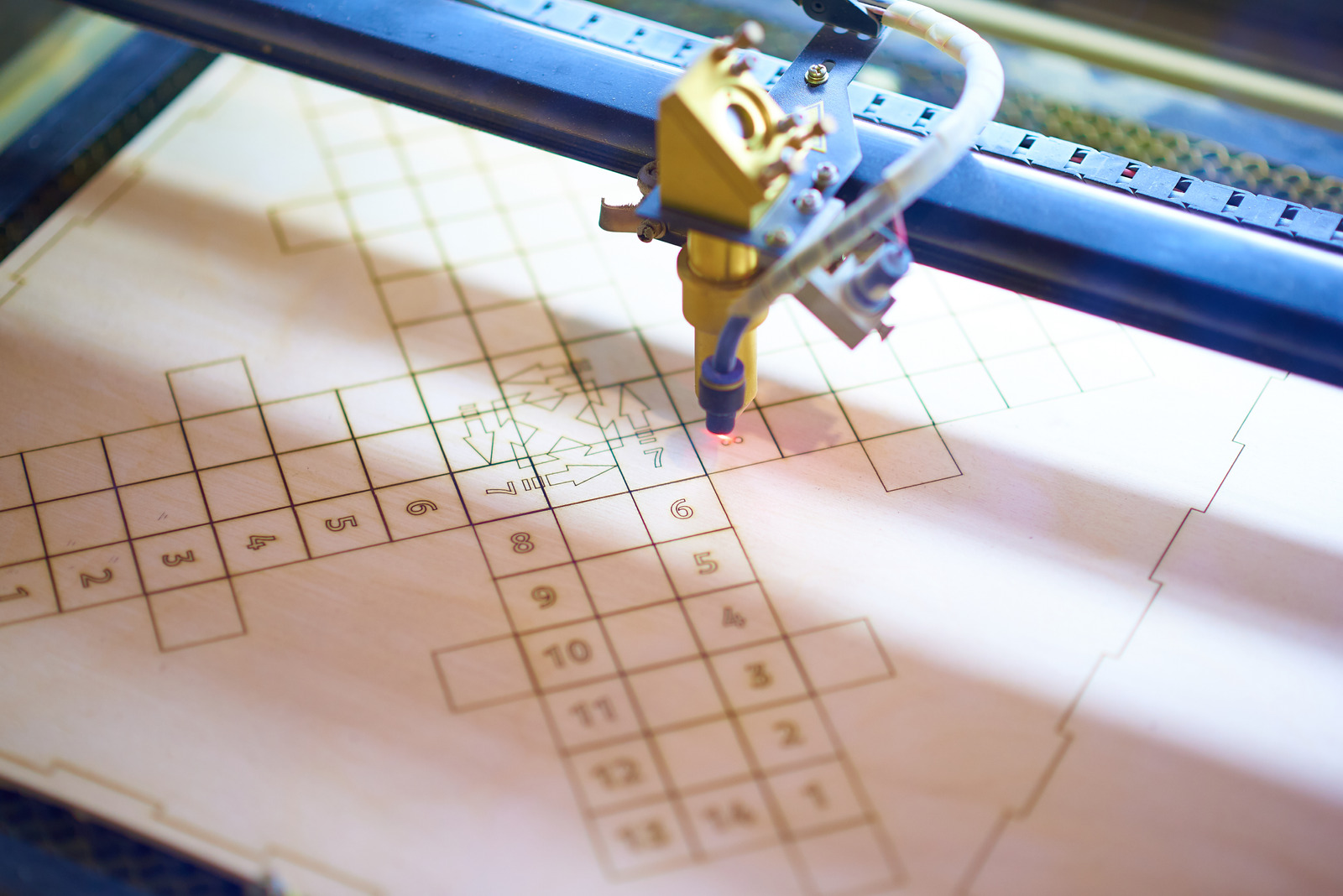

with laser cutting glass When laser cutting glass, it is essential to consider the type, thickness, and strength of the material being cut. Each of these factors can affect the laser parameters used, including the speed and power of the laser. Choosing the proper laser parameters can be problematic, especially with glass which can be especially sensitive to the heat of the laser.

Too much power in the laser and the glass could become damaged due to overheating.

Choosing the Appropriate Lens Diameter

of Choosing the Appropriate Lens Diameter is one of the most common problems encountered when laser cutting glass. The lens diameter is the distance between the laser and the focal points of the laser, and is determined based on the thickness of the material being cut.

Using Adequate Safety Protection

Using adequate safety protection when laser cutting glass is a very important step that must never be overlooked or forgotten. When laser cutting glass, the high-energy beam used to break down the material produces a large amount of heat. This heat, paired with the particles created by the cutting process, can create a hazardous environment that can cause serious injury if proper safety procedures are not followed.

The first step to ensure safety while laser cutting glass is to wear protective gear.

Common Causes of Laser Cutting Problems

Poor Design

of poor design Poor design is one of the most common issues when it comes to laser cutting glass. Poor design and a lack of knowledge can lead to many problems during the laser cutting process. In glass laser cutting, it is important to understand the material and its properties in order to determine the best design practices to ensure an accurate cut.

Poorly designed pieces often require more time to cut, which can lead to additional costs for the project. In addition, poorly designed parts or pieces can have a risk of breakage due to improper cutting paths or techniques.

Poor Choice of Materials

When it comes to laser cutting glass, one of the biggest problems is selecting the wrong materials. Different types of glass react differently when paired with laser cutters, so it’s important to find the type of glass that will work best for your project. Using the wrong material can lead to numerous problems, including distorted shapes, cracking, and a more general lack of precision in the finished product.

There are two main types of glass that can be used in laser cutting: soda-lime glass and borosilicate glass.

Machine Alignment Issues

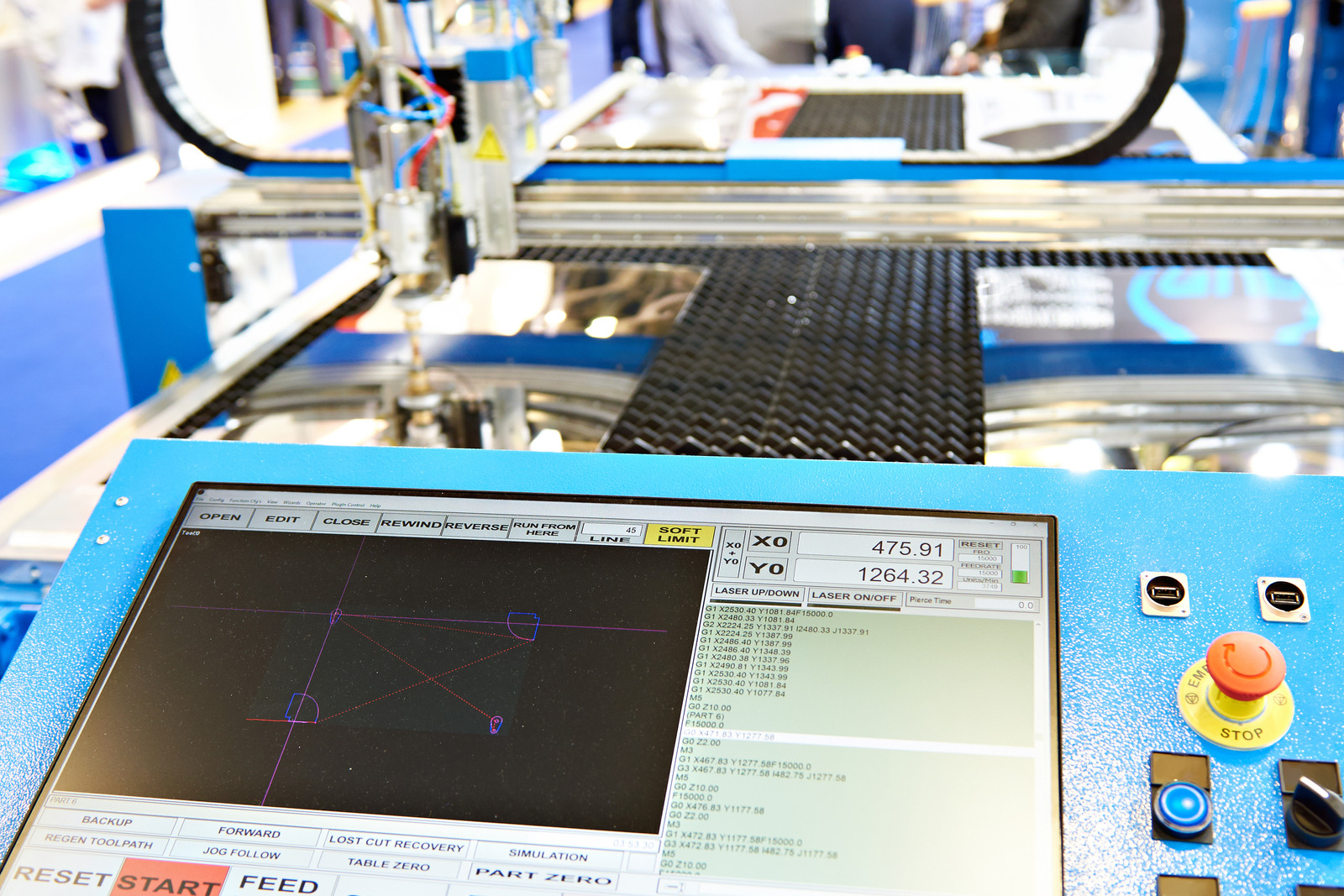

for laser glass cutting One of the most common problems with laser cutting glass is incorrect machine alignment. This issue can cause the laser beam to be out of alignment with the workpiece and create inaccurate cuts, or even cause the material to suffer serious damage during the cutting process. Other problems resulting from incorrect machine alignment can include incorrect speeds and focal lengths being used while cutting, which can cause glass breakage or poor quality cuts.

When it comes to laser cutting, it’s important to check the machine alignment regularly and make sure that it’s properly adjusted before the start of each job.

Can a laser cutter cut through glass?

One of the most common problems with laser cutting glass is that most lasers aren’t powerful enough to completely cut through the material. Laser cutting requires very high levels of heat and pressure that may not be possible with standard machines or settings. This can cause the laser to only partially cut into the glass, resulting in warped edges or other defects.

In addition, some glass types may be too brittle to withstand the laser heat and pressure, leaving the glass cracked or otherwise damaged. It is therefore important to choose the right type of glass and laser settings to ensure a successful cut.

What causes a laser lens to crack?

with laser cutting glass One of the most common problems and issues with laser cutting glass is the risk of cracking a laser lens. When laser cutting, the laser’s beam is focused through a lens, and it is this lens that translates the beam into a sharp and precise cut. If the lens takes too much of a beating, it can crack, rendering the laser unusable until the lens is changed.

There are a few different things that can cause a lens to crack. The most common culprit is using a lens that is not adequately suited to the job.

Conclusion

Summing up the key points of the discussion

In summary, common problems and issues with laser cutting glass can be divided into three categories: shifting/page misalignment, burning/engraving errors, and power settings. Shifting/page misalignment can be caused by poor setup or settings; burning/engraving errors can caused by incorrect power setting or too much power; and power settings can be adjusted depending on the material to be cut. Of course, the best way to avoid most of these issues is to use a machine with high quality components and to take the time to properly calibrate it.

Additionally, proper care of the cutting tool and proper cooling techniques can help minimize the risk of damaging the glass.