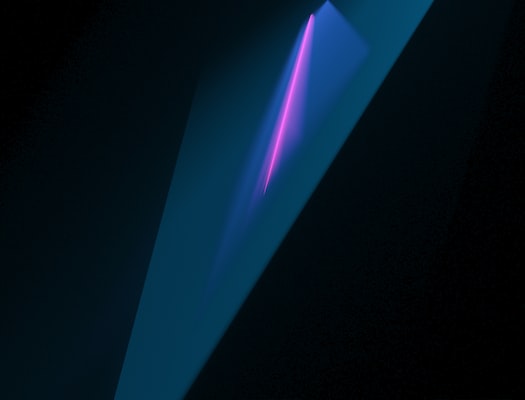

Laser cutting technology has been available for decades, but recently it’s become more common for use in precision woodworking, such as cutting plywood. If you’re not familiar with laser cutting, it is a process where a computer-controlled beam of light is used to cut materials. Unlike traditional woodworking methods such as saws, lasers produce very accurate, detailed shapes in a variety of materials with a high degree of accuracy. In this article, we’ll explore the advantages of laser cutting plywood compared to traditional woodworking methods.

Benefits of Laser Cutting Plywood

Precision Cuts

The precision that laser cutting offers when cutting plywood is unparalleled compared to traditional woodworking. This high-powered laser can offer ultra-fine cuts and curves, easily burning through wood and producing very crisp edges. CNC laser cutting can offer even more complex designs with intricate angles and curves.

The higher the power of the laser, the more easily it can cut through wood or other materials. Laser cutting requires significant power to be able to perform clean cuts with minimal burns along the edges of the cut. This makes laser cutting incredibly useful for mass production of parts that can be cut from sheets of materials which have any complexity of design.

Cost Savings

One of the most significant benefits of laser cutting plywood is the cost savings it provides compared to traditional woodworking methods. With laser cutting, you can create much more complex and intricate designs than with traditional methods, which makes it great for mass production of parts that can be cut from sheets of material. Laser cutting uses a high-power laser that can cut through wood and other materials with extreme precision.

Speed of Production

When it comes to production speed, laser-cutting plywood has significant advantages over traditional woodworking. Compared to other cutting and carving methods, laser cutting is much faster and can produce intricate designs quickly and accurately. The high-powered laser creates exact cuts with minimal burns along the edge of the cut.

As the laser power increases, cuts can be made quicker and more intricate.

Lower Power Consumption

can easily be achieved One of the biggest advantages of laser cutting plywood compared to traditional woodworking is lower power consumption. Laser cutters burn through wood with a techonology called CNC (Computerized Numerical Control) laser cutting. These laser cutters use a high-power laser to create very crisp edges with minimal burns along the edge of the cut.

This process is great for mass production of parts that can be cut from sheets of material and is exceptionally precise, which allows you to draw extremely fine curves and complexity of designs that can easily be achieved.

Downsides to Laser Cutting Plywood

Initial Investment Costs

When discussing the initial investment costs when comparing laser cutting plywood to traditional woodworking, it is important to consider the power of the laser that will be used. Higher powered lasers are able to easily cut through materials like wood, creating crisp edges with minimal burning along the edges of the cut. This means that the complexity of the design is not a factor when creating parts with a laser, which makes it great for mass production of parts that require intricate designs quickly and easily.

While the initial investment for a laser cutter is usually more expensive than traditional woodworking tools, the quality and accuracy of the cuts makes up for the higher cost.

Requires Proper Maintenance

Laser cutting is a great way to increase productivity and work more precisely than traditional woodworking methods, but it does require proper maintenance to ensure maximum performance. The higher the power of the laser cutter, the more easily it can cut wood or other materials. However, laser cutters must be regularly prepared before use and only used with the correct materials.

This is because laser cutters produce very crisp edges, but they can also burn through wood and other materials easily if the correct power levels are not set. In addition, CNC laser cutting is a different skill set compared to traditional woodworking.

Advantages of Traditional Woodworking

More Economically Accessible

and shapes are no longer a barrier When it comes to cutting plywood and other woods, laser cutting is quickly becoming the go-to method. It is more precise and allows you to draw extremely fine curves that you simply can’t do with traditional woodworking tools. The higher the power of the laser cutter, the more easily it can cut wood or other materials, and the cleaner the cuts will be.

Stronger Connections

When compared to traditional woodworking techniques, laser cutting plywood offers many advantages, including stronger connections and greater precision. With laser cutting, a high energy beam is emitted from a CNC laser cutter and is used to precisely cut complex shapes into a material with great speed and accuracy. The higher the power of the laser beam, the more easily it can cut through materials such as wood, allowing for extremely precise and intricate shapes that would otherwise not be feasible with other methods.

Laser cutters also burn through wood much faster than other methods, allowing for efficient and reliable mass production of parts that can be cut from sheets of material.

Possibilities for Repurposing

When it comes to repurposing timber, the possibilities become endless when it comes to laser cutting plywood. Laser cutting allows you to draw extremely fine and complex curves with precision, allowing for more creative and daring designs. As the laser cutters are so powerful, wood or other materials can be easily cut, leaving very crisp edges without any burn marks.

CNC laser cutting uses a high-powered laser beam to cut sheets of material into precise shapes.

Conclusion

Summary of Laser Cutting Plywood Benefits

In summary, laser cutting plywood offers many benefits over traditional woodworking due to its precision, speed and efficiency. Laser cutters are able to burn through wood, producing very crisp edges. Additionally, they can cut complex patterns quickly and accurately.

They also allow for mass production of parts, with minimal burns along the edges of the cuts. CNC laser cutting is a different skill set, and requires high laser power to achieve clean cuts. The higher the power and complexity of the design, the more easily it can cut wood or other materials.

Laser cutting is a great solution for those looking to unlock their creativity and produce intricate, detailed designs quickly and cost-effectively.

Summary of Traditional Woodworking Benefits

Traditional woodworking is an age-old craft that has been passed down from generation to generation. Unlike laser cutting, it does not require the use of high-powered lasers, but instead uses physical tools such as saws, chisels, and planes. Traditional woodworking allows for a greater level of creativity and customization in the end product, as it is usually tailored to the buyer’s specifications.

With traditional woodworking, each piece of the furniture or cabinetry will be unique and one-of-a-kind, making it a more memorable item.

Final Thoughts

can be made easily with laser cutting In conclusion, laser cutting plywood offers many benefits when contrasted with traditional woodworking methods. Laser cutters are precise, customizable, and can produce very crisp edges with minimal burning along the edge of the cut. They can also be used for mass production, since high laser power allows for complex designs that can be cut from sheets of material.

CNC laser cutting is also getting easier to accomplish and requires a different skill set with a high-power laser, making it increasingly accessible.