Investing in a quality laser cutter comes with many advantages. Laser cutting is one of the most efficient and cost-effective ways to produce parts and products for a variety of commercial and industrial applications. With the wide range of lasers available to choose from, the benefits of Laser cutting go beyond just cutting accuracy and speed. Benefits of investing in a quality laser cutter include consistently high-quality cuts, increased cutting speed, as well as cost and time savings. It also requires less labor and has a range of applications, making it an excellent long-term investment. In this article, we will discuss the many advantages of investing in a quality laser cutter.

Advantages of Using a Quality Laser Cutter

Ability to Customize Designs

cutters Investing in a quality laser cutter opens up a world of possibilities in terms of customizing designs. Many laser cutting machines allow for intricate detailing and multiple cut layers, creating highly unique pieces. With the precision of laser cutting, you can create just about anything from custom jewelry to intricate technical pieces.

Having a quality laser cutter can also save you time, money, and material. You can make exact and consistent cuts with one cut – no additional trimming or elimination is required.

Increased Precision and Accuracy

cutter If you’re considering where to invest in production equipment, a quality laser cutter deserves your attention. A high-quality laser cutting machine is capable of providing precise, accurate cuts and engravings on a variety of materials. The improved precision and accuracy offered by a quality laser cutter can help to ensure that your projects are completed quickly and correctly the first time and without having to invest in costly reworking or raw material replacements.

Time and Cost Savings

cutter If you’re looking to save time and money in your business, investing in a quality laser cutter is the way to do it. Laser cutters are incredibly precise and efficient pieces of equipment that can cut and engrave a wide variety of materials, from plastics and metals to paper and leather. Even fine detailing can be achieved with a laser cutting machine, allowing for intricate designs to be accurately replicated and quickly cut.

With a laser cutter, you can quickly and accurately produce items in a fraction of the time it would take to use traditional manual cutting methods.

Material Versatility

cutter Investing in a quality laser cutter can provide a wide range of benefits, including material versatility. Traditional cutting technologies, such as sawing, tend to be limited in the materials they can work with. Laser cutters offer a unique advantage in that they can cut a broad range of materials at a high quality.

Wood, polycarbonate, acrylic, and metals are just a few of the materials that laser cutting machines can work with.

Common Materials Used in Laser Cutters

Plywood

cutter When investing in a quality laser cutter, it’s important to understand the various materials that can be used. One of the most common and versatile materials used in laser cutters is plywood. Plywood is a composite wood product that is made up of multiple layers of wood, with each layer glued in alternating directions.

This crisscrossing pattern gives the wood extra strength and stability.

Cardstock

cutter When it comes to investing in a quality laser cutter, cardstock is one of the most common materials used in laser cutting machines. Cardstock is paper that is thicker than ordinary paper but still much thinner and lighter than cardboard. It is ideal for laser cutting because of its versatility, since it can be used in various shapes, angles, and sizes.

Also, it is less likely to get damaged due to the heat generated during the laser cutting process. Cardstock is used in many different industries, including art, jewelry making, apparel design, scrapbooking, and more.

Leather

cutter Laser cutting has become a great option for those looking to create intricate designs out of materials such as leather. With a quality laser cutter, you can make precise cuts to create detailed designs that you won’t easily find with other methods. Leather is a great material to work with in a laser cutter because it’s easy to work with and doesn’t require too much expertise.

When cut correctly, the leather pieces will have a smooth and clean finish. With a good machine, you can create excellent products easily, quickly, and accurately.

Acrylic

cutter When it comes to investing in a quality laser cutter, knowing which materials to cut can help you maximize the benefits of a machine purchase. One common material that works great with laser cutters is acrylic. Acrylic is a thermoplastic material that can be easily cut by a laser cutting machine.

It is also durable and long-lasting, making it a great choice for many projects. Acrylic can be cut into thin sheets of varying thicknesses and sizes, making it great for a variety of laser cutter projects.

Glass

cutter When it comes to investing in a quality laser cutter, it’s important to consider the materials you’d like to be able to cut with it. Glass is one of the more common materials used in laser cutters, though it can be more challenging than other materials due to its ability to absorb and reflect light from the laser. However, if you’re looking for a material that can produce fine details and intricate shapes, glass is the material to use.

Metal

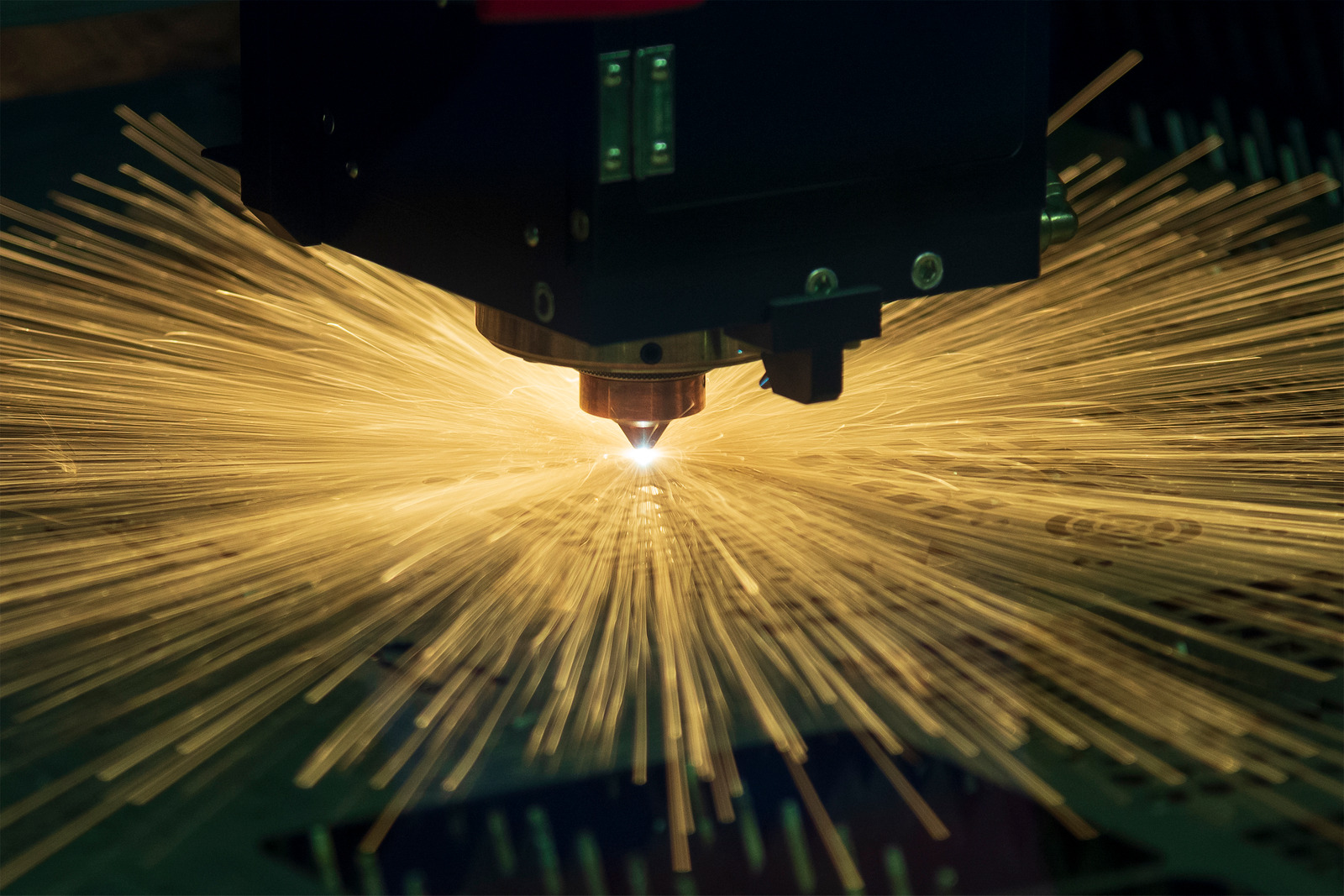

cutters When it comes to investing in a quality laser cutter, one of the most popular materials used with this type of technology is metal. Laser cutting machines are used to cut and shape metal into almost any desired shape and design. With its precision and accuracy, this type of machine allows for unparalleled precision when cutting and fabricating metal.

Some of the common materials used in laser cutters are aluminum, steel, and copper.

Popular Applications for Laser Cutters

Crafting

cutter One of the many benefits of investing in a quality laser cutting machine is the array of creative and crafty possibilities it opens up. Having a laser cutter in your arsenal can help you make items from home to the highest quality specifications. This makes crafting with laser cutters a great way to make gifts for friends and family, or to earn extra income by designing and selling custom items.

Engraving

cutter Engraving Engraving is one of the most popular applications for a laser cutter. Engraving allows you to create intricate designs and patterns onto various materials with a single pass. With the help of a quality laser cutter, you can create etched designs on metals, plastics, glass and other materials with incredible detail and accuracy.

Laser engraving also offers a quick and versatile form of production as compared to traditional engraving methods.

Modeling

cutter When it comes to investing in a quality laser cutter, modeling capabilities should be one of the primary features you consider. Laser cutters are great for producing intricate models and shapes that would be difficult, time-consuming, or cost-prohibitive to achieve through traditional modeling methods. The laser cutting machine works by using a focused laser beam to cut, mold, or shape the materials you are working with.

This allows you to achieve precise cuts, shapes, and patterns with ease. Depending on the material you are working with, you can get a very high level of accuracy and detail with your final product.

Etching

cutter Investing in a high quality laser cutter opens up a multitude of possibilities, from material cutting to etching to browning and marking. Etching is a popular use for more advanced laser cutters, as it allows you to imprint very intricate designs onto surfaces like wood, plastic and metal. This results in incredibly unique and beautiful pieces that you simply cannot achieve through other means.

Using a laser cutter to etch is an extremely precise and fine process that yields superior detailed results compared to other methods.

Cutting

cutters When it comes to investing in a quality laser cutter, one of the main benefits is cutting. Laser cutting is a powerful and accurate manufacturing technology that is used to precisely cut a wide range of materials, regardless of size and shape. Laser cutters use high-powered, focused light and high-pressure air to precisely cut a wide range of materials, which can include plastic, wood, paper, metal, and more.

The benefits of using laser cutting technology are increased production speed, accuracy, and materials that are easier to work with.

Important Considerations When Investing in a Laser Cutter

Power Output

cutter When you’re considering investing in a quality laser cutter, one of the most important things to consider is the power output of the device. This is generally defined in watts, and it is a crucial element that will determine the size and kind of material you’re able to cut with the machine. A higher wattage output machine, for example, would be capable of cutting thicker materials or processing more detailed or intricate cuts.

Work Area Size

cutter The size of the work area is a critical factor when investing in a quality laser cutter. Depending on the type of materials you plan to cut and the shapes you need to create, the size of the work area will be a deciding factor for many businesses. It’s important to measure the work surface first and consider the largest piece that you need to cut and shape.

Laser cutters typically have a fixed work area, so it’s important to make sure that the size is compatible with the size of materials that you plan to cut.

Safety Features

When investing in a quality laser cutter, one of the most important considerations is the safety features that it offers. Laser cutters operate at very high temperatures, and lasers themselves are highly concentrated beams of light that if not used properly, can cause serious injury both to the operator and to anyone in close proximity to the machine. Therefore, when investing in a quality laser cutter, it is important to look for one with a robust suite of safety features to ensure your safety and the safety of those around you.

Maintenance

cutter Keyword: maintenance When it comes to investing in a quality laser cutter, maintenance is an important consideration. Generally, laser cutters require regular maintenance to ensure that they keep running smoothly and efficiently. This means that you should plan for regularly scheduled maintenance for your laser cutter, such as cleaning the optics and mirror, lubricating moving parts, calibrating, and checking safety systems.

Maintenance can help extend the life of your laser cutter and reduce the risk of costly repairs. Regular maintenance will also help you maintain the quality capabilities of your laser cutter as well as its precision.

Computer Connectivity

cutters When it comes to investing in a quality laser cutter, computer connectivity is an important consideration. Having a laser cutter connected to your computer and compatible with many different software packages such as Corel Draw makes it a much more versatile tool. This kind of connection allows you to quickly transfer images, vector files, and CAD drawings to the laser cutter, speeding up the production process.

Many laser cutters can be connected to the internet, allowing you to remotely monitor and control your laser cutting machine from anywhere.

Conclusion

Recap of Benefits of Investing in a Quality Laser Cutter

cutter To recap the benefits of investing in a quality laser cutter, laser cutting machines offer incredible precision, accuracy, and speed that traditional methods of cutting simply cannot match. With the right materials, laser cutters are able to deliver high-quality, detailed cutouts and engravings on a range of materials, from wood and cloth to metal and stone. Laser cutters also create much less waste in comparison to traditional methods since they don’t require any additional materials beyond the materials used for cutting.