When it comes to laser cutting, finding the right balance between cost and quality can be challenging. Understanding the tolerance boundaries of laser cutting and what they mean for the end product is essential in achieving the desired outcome. With knowledge of the limitations of the laser cutting process and related costs, a business can save time and money, as well as ensure that product quality is not compromised. This article will discuss the concept of understanding tolerance boundaries and how to balance cost, quality and efficiency when it comes to laser cutting.

Cost-Effective Quality

Identifying the Right Tolerance

Balancing cost and quality in laser cutting requires that manufacturers understand the importance of tolerance boundaries, identify cost-effective quality, and ascertain the right tolerance for each particular situation. Tolerance boundaries are important to successful laser cutting because it allows manufacturers to control the exact quality of the finished product by specifying the exact specification.

- Determine the required tolerances for the dimensions of the part being produced. Different projects will have different requirements, and understanding the specific tolerances needed will help ensure that both cost and quality are balanced.

- Review the tolerances of the laser cutting system used to produce the parts. If the tolerances are too tight, there will be additional time and cost associated with achieving them.

- Consider alternatives if necessary. Some parts may require higher accuracy than the laser cutting system can provide. In this case, other options such as traditional machining may be more cost-effective.

- Utilize quality assurance tools to ensure the parts meet the desired tolerances. The quality assurance tools should include measuring instruments and other monitoring tools that help identify any deviations in the parts.

- Inspect the parts after production to ensure that the desired tolerances were achieved. This will help ensure that the parts are within the desired specifications and that quality and cost are balanced.

Establishing Acceptable Quality Levels

When it comes to laser cutting, it is important to maintain a balance between cost and quality. Establishing acceptable quality levels ensures that a product meets the standards set by industry, while also not breaking a budget. To do this, it is important to understand tolerance boundaries and how they affect cost-effectiveness when it comes to quality.

Tolerance boundaries are the maximum and minimum allowed sizes of a shape or feature within the product.

Seeking Out Better Quality Materials

When it comes to laser cutting, it is important to consider both cost and quality. Quality should be balanced with cost effectiveness, and understanding the tolerance boundaries for cost-effective quality is key. One great way to ensure you are getting the best balance of cost and quality is to seek out better quality materials.

By using higher quality materials, you can benefit from improved production efficiency, greater accuracy, and longer life span of your laser-cut parts. The higher quality materials tend to be more expensive, but the potential increase in product quality, accuracy, reliability, and durability is worth the extra cost.

Use of Lasers to Maximize Tolerance Boundaries

Understanding the Process

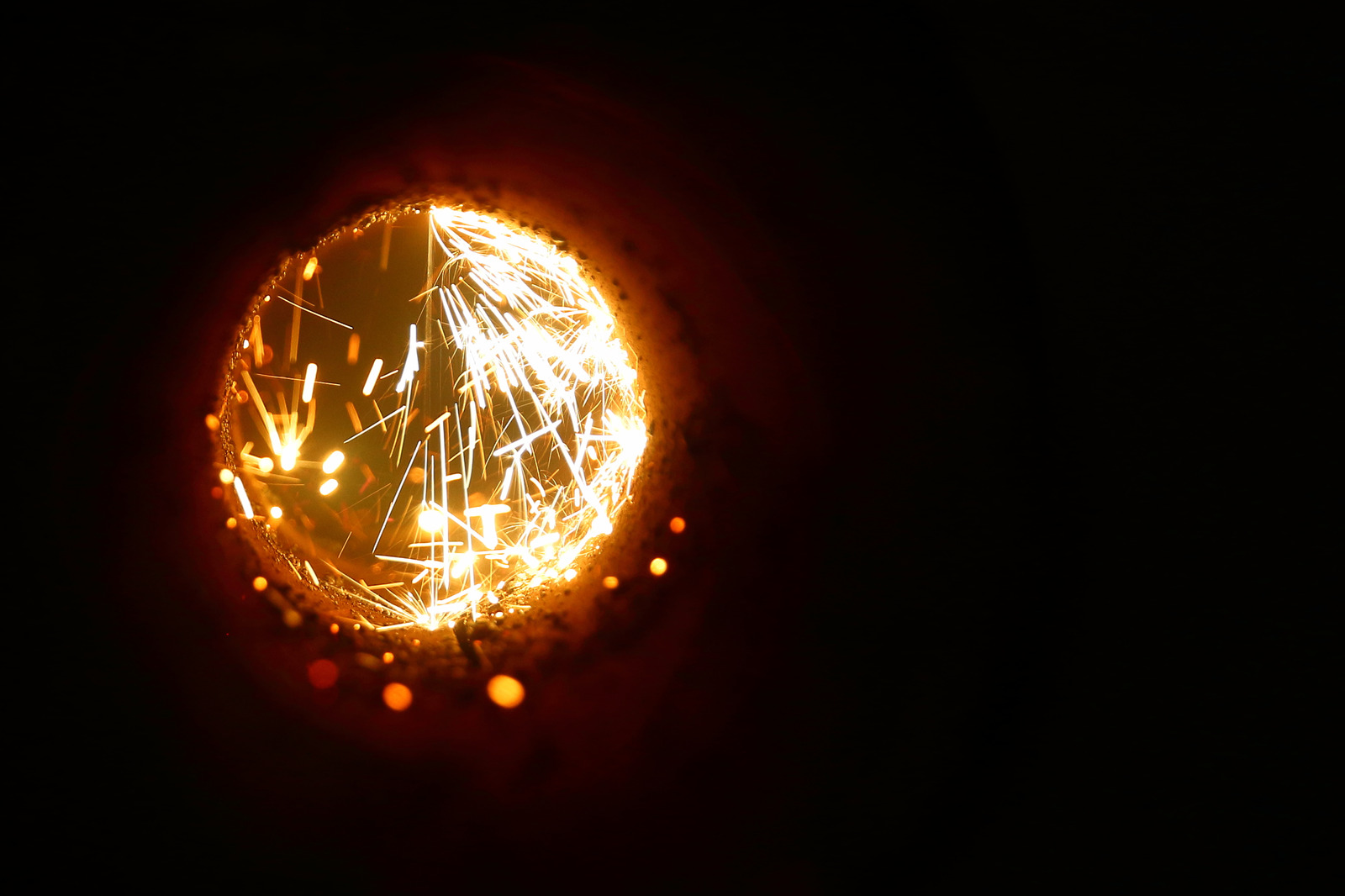

When it comes to creating top-notch products with laser cutting, understanding the process is just as important as finding the right balance between cost and quality. Laser cutting works by using a laser beam to heat, melt, and vaporize the material being cut. This process is extremely precise and cost-effective.

It enables manufacturers to create intricate designs with minimal waste, as well as ensuring that the finished product is of a good quality.

Advantages of Laser Cutting

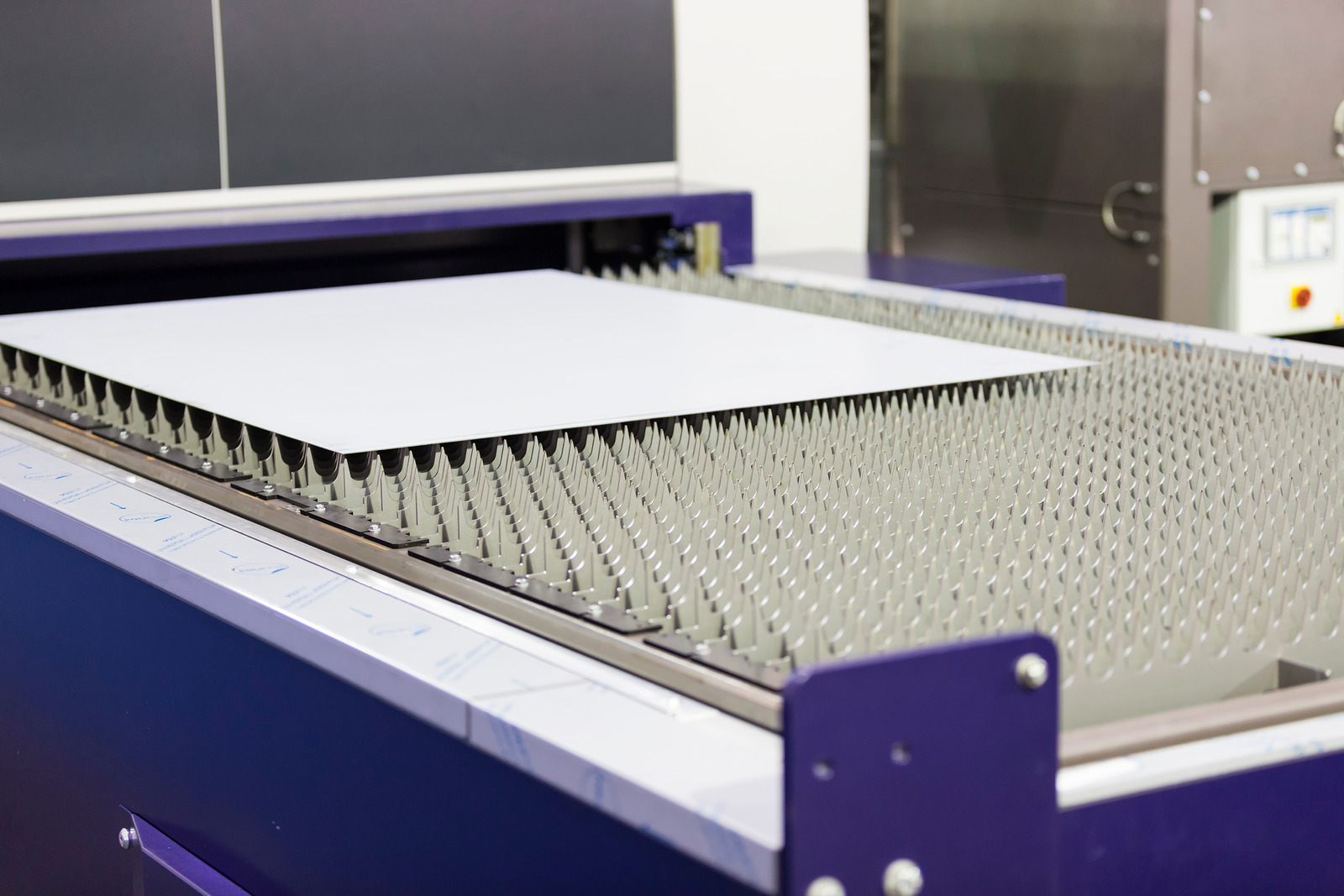

One of the major advantages of laser cutting is that it can balance cost and quality by understanding tolerance boundaries and using lasers to maximize them. Laser cutting has become the go-to choice for many production processes for this reason. One of the best things about laser cutting is the ability to create products with high tolerances, meaning that parts fit together better and last longer for the consumer.

The laser cutting process is highly accurate, meaning that parts can be made to tighter tolerances and even more intricate shapes than more traditional cutting modes. The cutting process itself is also far more precise than other modes of cutting. Not only does this improve quality, it also reduces waste, making it a more cost-effective choice overall.

Exploring Different Cutting Speeds

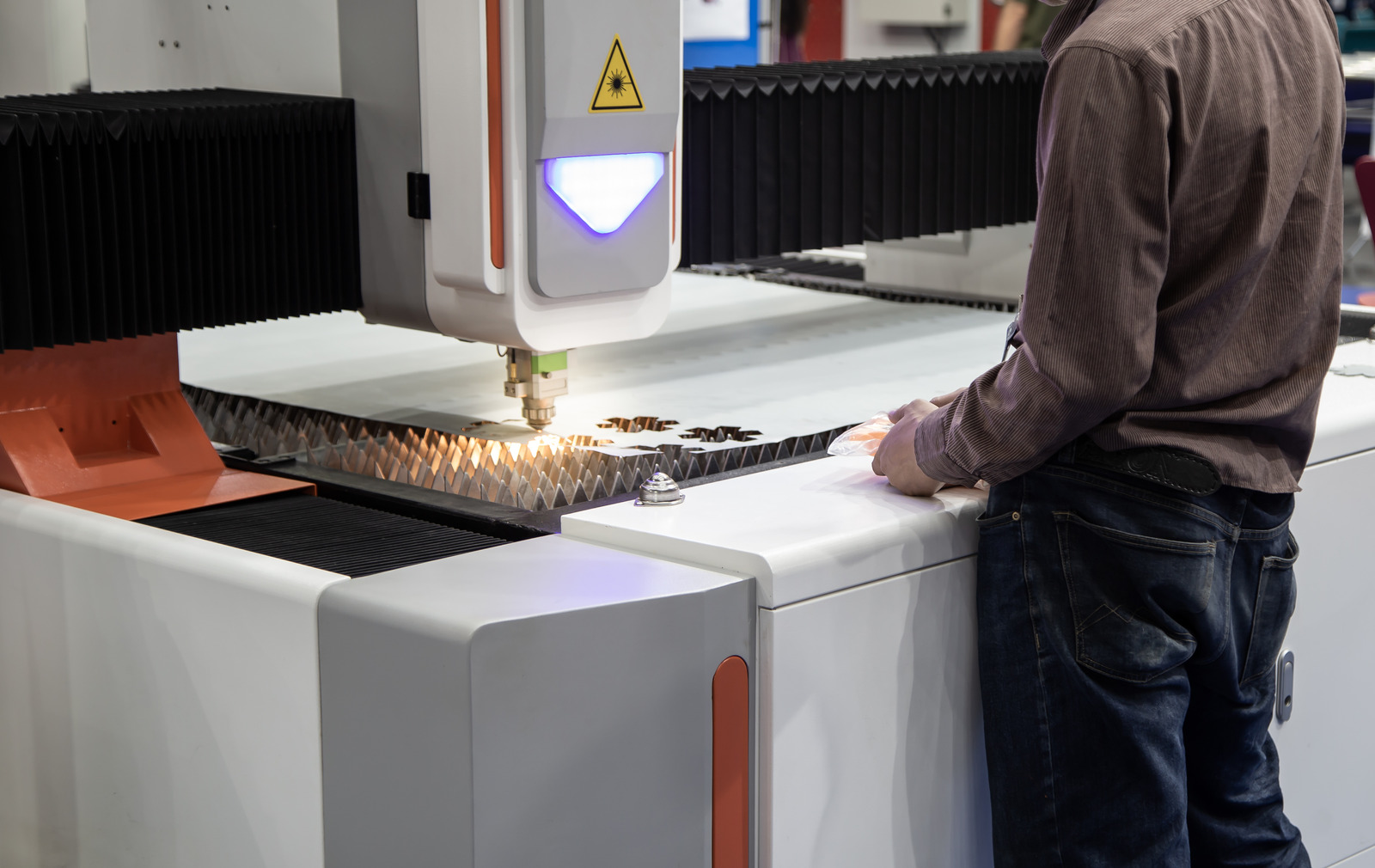

When it comes to balancing cost and quality in laser cutting, understanding tolerance boundaries is key. Tolerance boundaries refer to the accepted variations in size and position of the cut piece that are allowed in order to ensure the desired precision is achieved. It is important to understand that tolerances can be affected by the speed of the laser cutting process.

Exploring different cutting speeds can be done in order to find the optimal speed for cutting given the desired precision and size of the cut piece. It is important for the operator to take into account the material being cut, the type of laser being used, and the power of the laser when exploring different cutting speeds.

Factors to Consider When Deciding Tolerance Boundaries

Geometry of the Part

The geometry of the part in laser cutting is an important factor when balancing cost and quality. Tolerance boundaries, or the dimensions of the final product, determine the quality of the part. Understanding how to properly set these boundaries will help ensure a balance between cost and quality.

When cutting with a laser, the geometry of the part plays a major role in cutting time and accuracy. Depending on the material type and cutting conditions, parts can be cut quickly but with a greater risk of inaccuracy.

Raw Materials Used

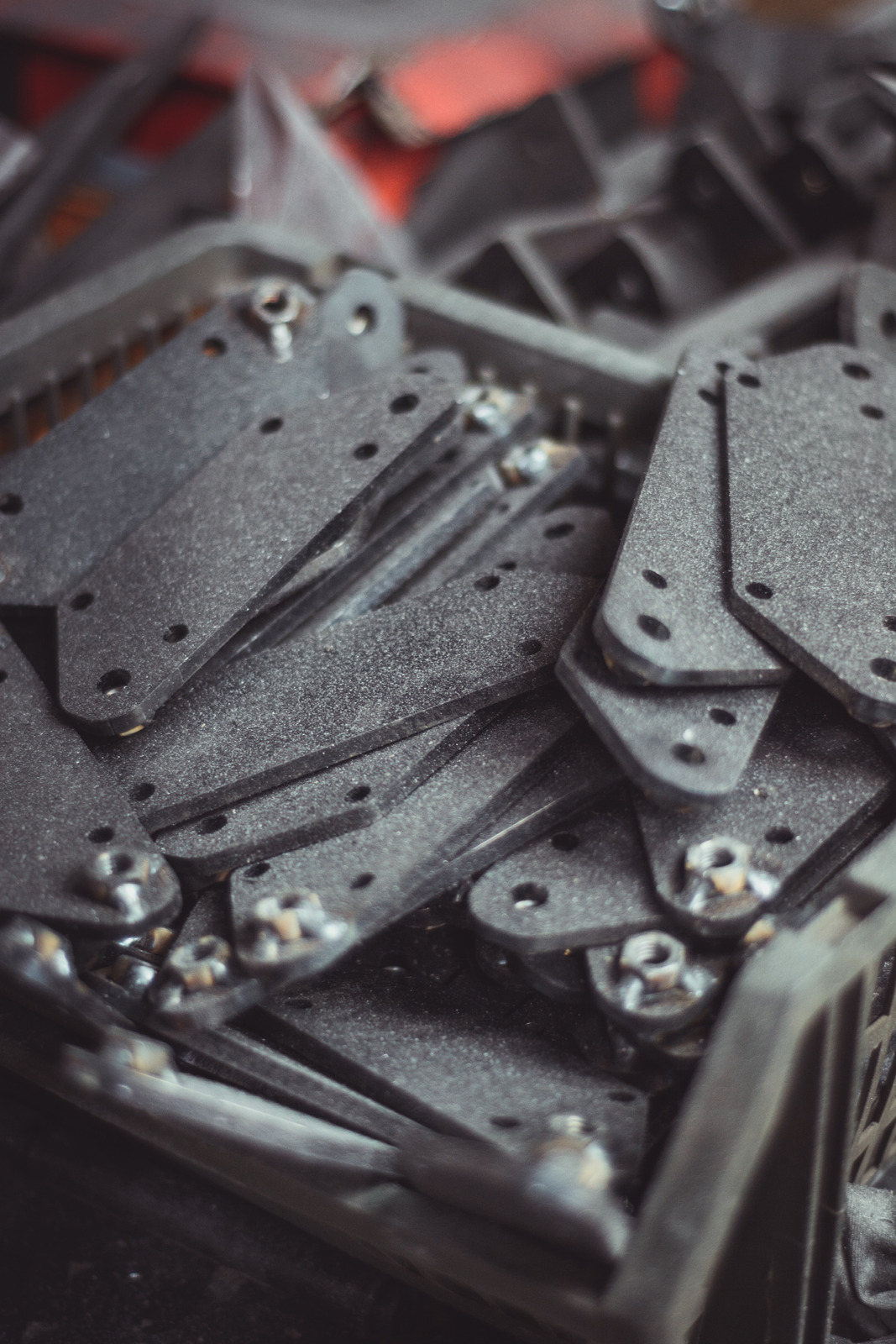

When it comes to balancing cost and quality when it comes to laser cutting, it is important to have a good understanding of tolerance boundaries and the factors to consider when deciding those boundaries. One of the most important factors is the raw materials you are using. Different materials will have different levels of tolerance which need to be considered when determining your tolerance boundaries.

Different materials require different laser cutting speeds and feedrates, different power settings and even different types of lasing itself. The material thickness, complexity of the project, type of laser beam and the quality of the workpiece are all factors to consider when deciding the raw materials you are using.

Heat Affected Zone

When it comes to balancing cost and quality with laser cutting, one of the key factors to consider when deciding on tolerance boundaries is the Heat Affected Zone (HAZ). The Heat Affected Zone affects the quality of the cut and has significant implications on the precision of the material being cut. The Heat Affected Zone is the area of the material that has been exposed to the heat of the laser cutting process.

Due to the rapid heating and cooling of the material, the HAZ may be slightly warped, discolored, or even burned away in some areas. Overall, these effects may decrease the precision of the cut and cause it to be slightly off specification.

How does tolerance affect cost?

When it comes to balancing cost and quality in laser cutting, understanding tolerance boundaries is essential. Tolerance is the amount of deviation or variation in a finished product that is considered acceptable. Tolerance boundaries dictate how precise or accurate a part needs to be, so understanding what the acceptable upper and lower limits are can help you to balance cost and quality.

The higher the tolerance, the less precise the part needs to be, and the lower the cost of production. But it is important to balance cost savings with quality, as too high of a tolerance can impact the optimization of the part.

How much tolerance do you need for laser cutting?

When it comes to laser cutting, understanding tolerance boundaries is essential in achieving the balance between cost and quality. Tolerance is the maximum allowable amount of deviation between two physical points, dimensions, or surfaces. In laser cutting, the amount of tolerance typically depends on the type of material being cut, its thickness, and the complexity of the design.

A good rule of thumb to consider is that the less precise the application, the bigger the tolerance can be. For example, if you are creating sheet metal parts for a prototype or a mockup, then a looser tolerance can be used since the level of precision doesn’t have to be as exact.

Conclusion

Summarizing Key Points

In our concluding blog post, we focused on balancing cost and quality in laser cutting by understanding tolerance boundaries. We discussed how implementing quality tolerance boundaries when laser cutting can help operators to ensure accuracy and repeatability while also saving money and time. We detailed the importance of specific settings such as the thickness of material, the speed of the cut, and whether to use a preheat or not.

Recommending Best Practices

When it comes to laser cutting and finding the right balance between cost and quality, understanding tolerance boundaries is essential. In general, tighter tolerances come with a higher cost, while looser tolerances can reduce costs. The key is to find the right balance that meets your needs.

By taking into account the materials that are being cut, the processes needed, and what the objectives of the project are, you can arrive at a decision that meets the desired outcomes. The best way to ensure you’re achieving the right balance between cost and quality is to practice due diligence in assessing your needs.

Final Advice

When it comes to balacing cost and quality in laser cutting, the most important thing to keep in mind is understanding tolerance boundaries. This is essentially the limit of permissible variation when it comes to cutting an object. Some materials require tighter tolerance boundaries than others, and understanding these can help to ensure the best level of quality while also keeping costs within a reasonable range.

Along with understanding tolerance boundaries, it’s important to consider the size and shape of the object being cut. If it’s too large, cutting costs may be higher as more time may be needed in order to complete the job. If it’s too small, achieving the nicest quality may require more effort than would normally be necessary.