The use of automation in any industry has the potential to create cost savings, improved outcomes and increased safety for both the workers and the machines. Laser cutting technology has become an integral part of many industries, and the utilization of automation to optimize the precision of laser cutting tolerances can have a huge impact on the finished product. This article will provide an in-depth look at the benefits associated with utilizing automation to fine-tune laser cutting tolerances.

Benefits of Utilizing Automation

Improved Process Consistency

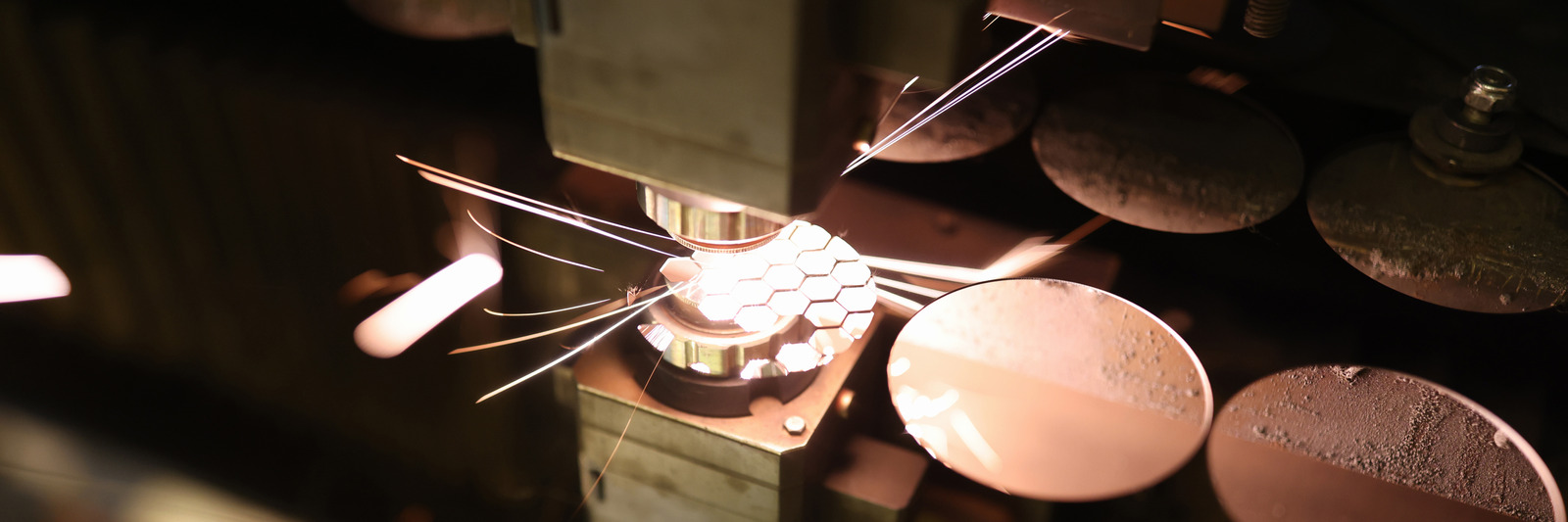

Using automation in laser cutting can greatly improve process consistency and accuracy. Automation in laser cutting refers to the use of automated systems such as CNC controllers and software which are used to automate the process of cutting metal parts. The automation systems can be programmed to quickly and accurately cut metal parts according to the desired design, and can also be used to fine-tune the cutting tolerances to achieve higher accuracy and repeatability.

One of the biggest advantages of using an automated laser cutting system is the improved consistency in the cutting process.

Increased Product Quality

tolerance Automation can be used to dramatically increase the quality of products created with laser cutters. By automating the laser cutting process, it allows for a greater degree of accuracy and precision with each cut–measured in terms of how closely the final product adheres to the specified shape and tolerances. The process of fine-tuning the laser cutting tolerance with automation involves a few steps.

Streamlined Business Cycles

Automation is becoming an increasingly popular tool for streamlining businesses, and laser cutting is no exception. Automation can help to both improve and speed up the process of laser cutting, allowing businesses to reduce their costs and increase the quality and accuracy of the end product. When it comes to laser cutting, automation can be used to fine-tune the cutting tolerances of a given piece.

By utilizing automated processes, businesses can quickly and accurately adjust the tolerances of any given item with extreme precision.

Challenges of Automation

Expensive System Implementation

tin When utilizing automation systems to fine-tune laser cutting tolerances, it’s important to consider the costly implementation process. Automated laser cutting systems are more expensive than manual systems and may not be viable for some budgets. While the cost of automated cutting systems can vary, the installation and implementation processes can be significant.

Depending on the complexity of the system, there may be a need for additional equipment, software, and personnel in order to establish the system and keep it operational. Because of this, organizations may find it challenging to properly budget for such a system, especially if it is an expensive one.

Barriers to In-House Training

When it comes to laser cutting, it is essential to have an effective training program in place to effectively implement automation. Automating laser cutting processes can allow for tighter tolerances, faster turnaround times, and more consistent results. However, there are several barriers when it comes to in-house training for laser cutting automation.

One of the primary barriers is the cost associated with training programs. Most companies need to hire specialized staff to create, install, and maintain the automated systems associated with laser cutting.

Equipment Upkeep

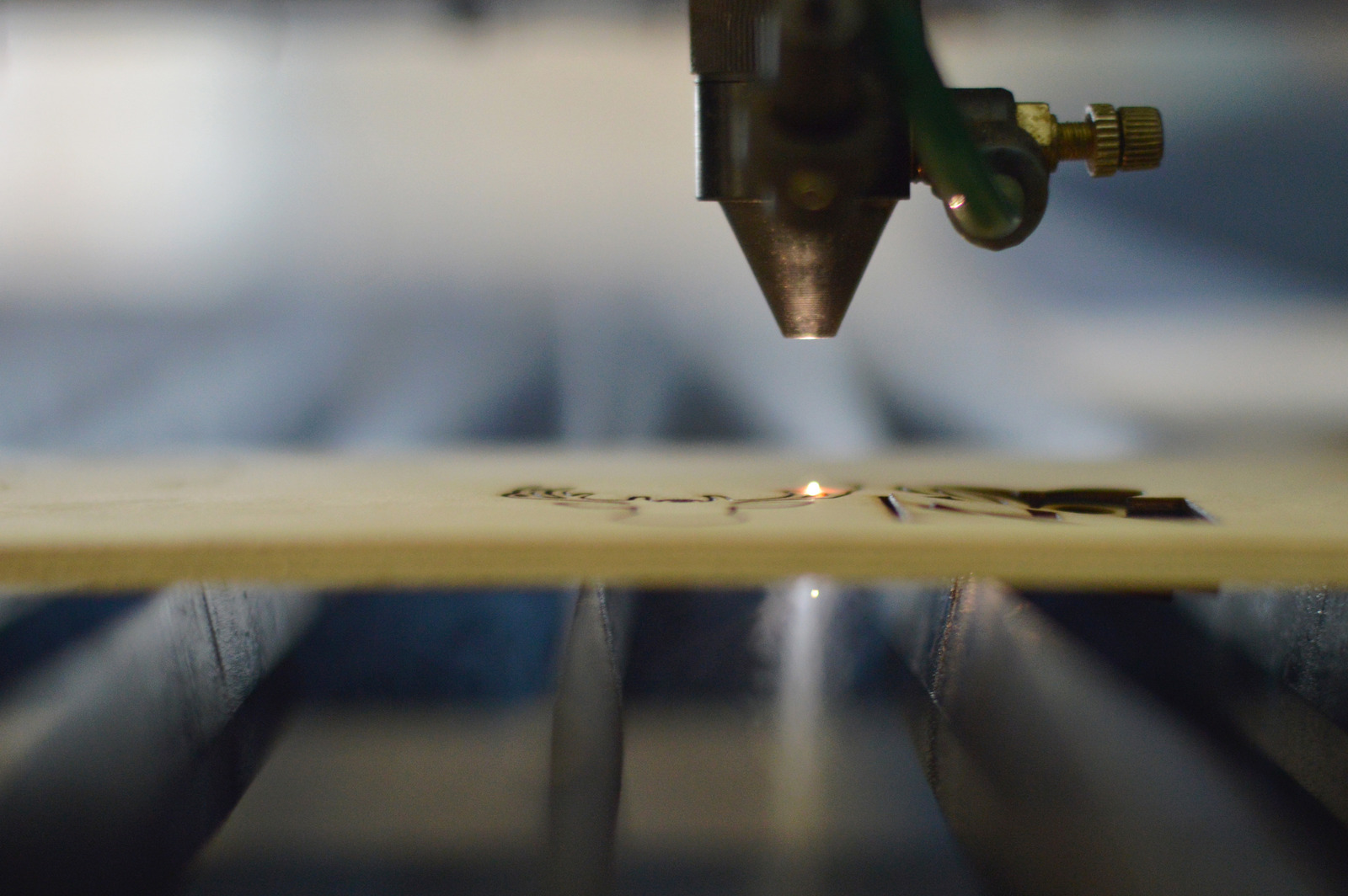

When it comes to utilizing automation to fine-tune laser cutting tolerances, one of the most important considerations is effective equipment upkeep. Laser cutting machines are sophisticated pieces of equipment and must be maintained properly in order to ensure efficient operation. One of the main components of maintaining laser cutters is understanding when to change out laser cutting tools, or nozzles, in order to achieve the highest level of precision and accuracy.

How to Maximize Automation Benefits

Invest in Early Automation

If you’re looking for ways to maximize the benefits of automation when it comes to laser cutting, it’s important to start off on the right foot by investing in early automation. Early automation can provide numerous advantages for those working with laser cutting and other processes in the industrial sector. First and foremost, automation can save you time and reduce labor costs.

Invest in Quality Training

One of the most essential things to consider when trying to maximize the benefits of utilizing automation to fine-tune laser cutting tolerances is investing in the best quality training you can afford. Quality training can not only help you learn how to efficiently use the automation equipment, but it can also provide helpful advice on processes and techniques that can help you reduce your laser cutting costs and time. When investing in quality training, it’s important to choose a provider that has the experience, knowledge, and instruction to help you fine-tune your laser cutting tolerances.

Utilize the Right Software

tting When it comes to laser cutting, one of the most important parts of the process is ensuring that the tolerances are exact. Taking advantage of the various resources available to maximize automation benefits and ensure that the directed energy beam is used in a precise and accurate way is essential. One way to ensure that this happens is to utilize the right software.

The right software can optimize the automation results and make laser cutting easier. By utilizing specialized programs that focus on configuring the direct energy beam and increasing the speed of the system, a machine operator is able to get the most out of their automation setup.

Resources

Books

When it comes to laser cutting, having the right information and resources to make sure that cutting to the right tolerances is critical. One of the best ways of ensuring precision and accuracy in cutting is to utilize automation and this is where books can help. An important aspect of laser cutting is understanding the capabilities of different laser systems and knowing how to get the most out of them.

Books on automated laser cutting basics offer an introduction to the setup, maintenance, and top tips on how to get the most out of your laser. This type of book can also provide detailed explanations of laser cutting techniques and the best techniques for achieving the desired outcome.

Articles

When it comes to high-precision cutting and associated automated processes, laser cutting has become an increasingly popular approach, especially when it comes to manufacturing processes. Laser cutters are specially designed to accurately, quickly, and efficiently cut materials of various sizes, shapes and thickness. The laser cutting process has many advantages, such as the ability to achieve extremely tight tolerances, which means that the cutting of complex shapes is easily achievable.

There are also numerous safety features built into the laser cutters themselves, which adds yet another layer of protection during the production process. One of the biggest advantages of laser cutting is the ability to fine-tune the cutting tolerances to specific requirements.

Online Courses

When it comes to laser cutting, having the right skills and knowledge is key to creating precision parts with exacting tolerances. Many of today’s businesses are taking advantage of the many benefits of automation, including its ability to help fine-tune tolerance levels for laser cutting. To ensure accuracy and excellence, individuals must continue to hone their laser cutting skills with online courses.

Businesses & Services

Laser cutting is a technique that has become increasingly popular in recent years, especially in the manufacturing sector. Using a precision laser beam, it is possible to cut through materials like plastics and metals with high accuracy. Laser cutting is beneficial for companies and services in a range of sectors, allowing businesses to automate, streamline, and modify production processes.

The benefits of utilizing laser cutting in the manufacturing process are numerous. Laser cutting enables manufacturers to accurately control specification requirements and produce parts with tight tolerance levels and an even surface finish.

What is a laser tolerance?

A laser tolerance is the level of exactness or accuracy used to measure the final output of a laser cutting job. This involves measuring the width and depth of the cut in order to ensure the highest amount of precision for the specific project. It is important for the finish of the material to be free from any rough edges, burrs, or different sized cuts.

The higher the laser tolerance, the more exact the laser cut will be.

Conclusion

Summary of Benefits

The conclusion of our analysis of the benefits of utilizing automation to fine-tune laser cutting tolerances is that this automation technique can surely bring unprecedented advantages to laser cutting operations. To summarize, automation offers a variety of advantages that can lead to improved accuracy and efficiency. Automation ensures a consistent, repeatable process for each laser cutting job, meaning that the results can be consistently relied upon for accuracy and precision.

Furthermore, utilizing automation for laser cutting can save time by helping to reduce manual labor needed to program and operate the laser cutter itself.

Importance of Automation for Maximum Efficiency

Automation has become increasingly important in the world of laser cutting, as it allows companies to ensure maximum efficiency when creating fine cuts. Automation can be used to fine-tune the laser cutting tolerances, making it easier to get the exact results desired. This is beneficial because it reduces the time it takes to complete a project, which reduces overhead costs and increases productivity.

Additionally, it can help ensure accuracy and consistency, which can help minimize mistakes and increase customer satisfaction with the finished product. Automation can be used in various ways to fine-tune laser cutting tolerances.

Automated Laser Cutting’s Future

Today, laser cutting technology has enabled a wide variety of industries to develop their operations more efficiently and accurately. Automation has changed the way products – from parts for vehicles to medical devices – are manufactured, and it has also changed the way machines, such as lasers, are used. Automated laser cutting is now being utilized to fine-tune laser cutting tolerances even further, and it has the potential to help further revolutionize the industry.

Though the concept of automated laser cutting is still new, it is being increasingly adopted by manufacturers in order to increase their efficiency, accuracy, and cost-effectiveness.