Laser cutting is a rapid and precise method of fabricating different parts and components from various materials, including zinc sheets. In this overview, we will discuss the process of laser cutting zinc sheets, exploring the advantages of using laser cutting for this task. We will also discuss some of the challenges involved in laser cutting thick zinc sheets, and provide examples of when laser cutting can be applied with zinc sheet materials.

Advantages of Laser Cutting Zinc Sheets

Precision and Accuracy

One of the advantages of using laser cutting to cut zinc sheets is its precision and accuracy. Because laser cutters use an incredibly powerful and accurate beam of light, they are able to precisely and accurately cut out flat and thin sheets of metals – including zinc. These objects come out in perfect shapes and size with very little room for error.

In some cases, it is even possible to achieve accuracies of up to 0.1 mm.

Cost and Time Efficiency

When it comes to creating precise shapes and cutting out intricate patterns with sheet metal, laser cutting is a great option. Laser cutters employ a high-powered beam of light (a laser) to cut out flat and thin sheets of metals. The laser can be adjusted to different levels of power and as a result, different materials can be cut with precision.

Zinc sheets, in particular, are a great material for laser cutting as it is relatively easy to cut and cost efficient. Lasers can cut zinc sheets up to 0.

Versatility

Laser cutting zinc sheets is an incredibly versatile process that has become an important part of many metalworking and industrial manufacturing processes. Laser cutting enables fabricators to create intricate parts, precisely cut edges and profiles to extremely tight tolerances. Due to the fact that a laser cutter is essentially a computer-controlled machine, it can be programmed to cut intricate shapes and profiles, allowing for more precise and accurate outcomes than traditional cutting methods.

Laser cutting uses a high-powered beam of light to accurately and quickly cut even the thinnest sheets of metal.

Overview of the Process

Materials

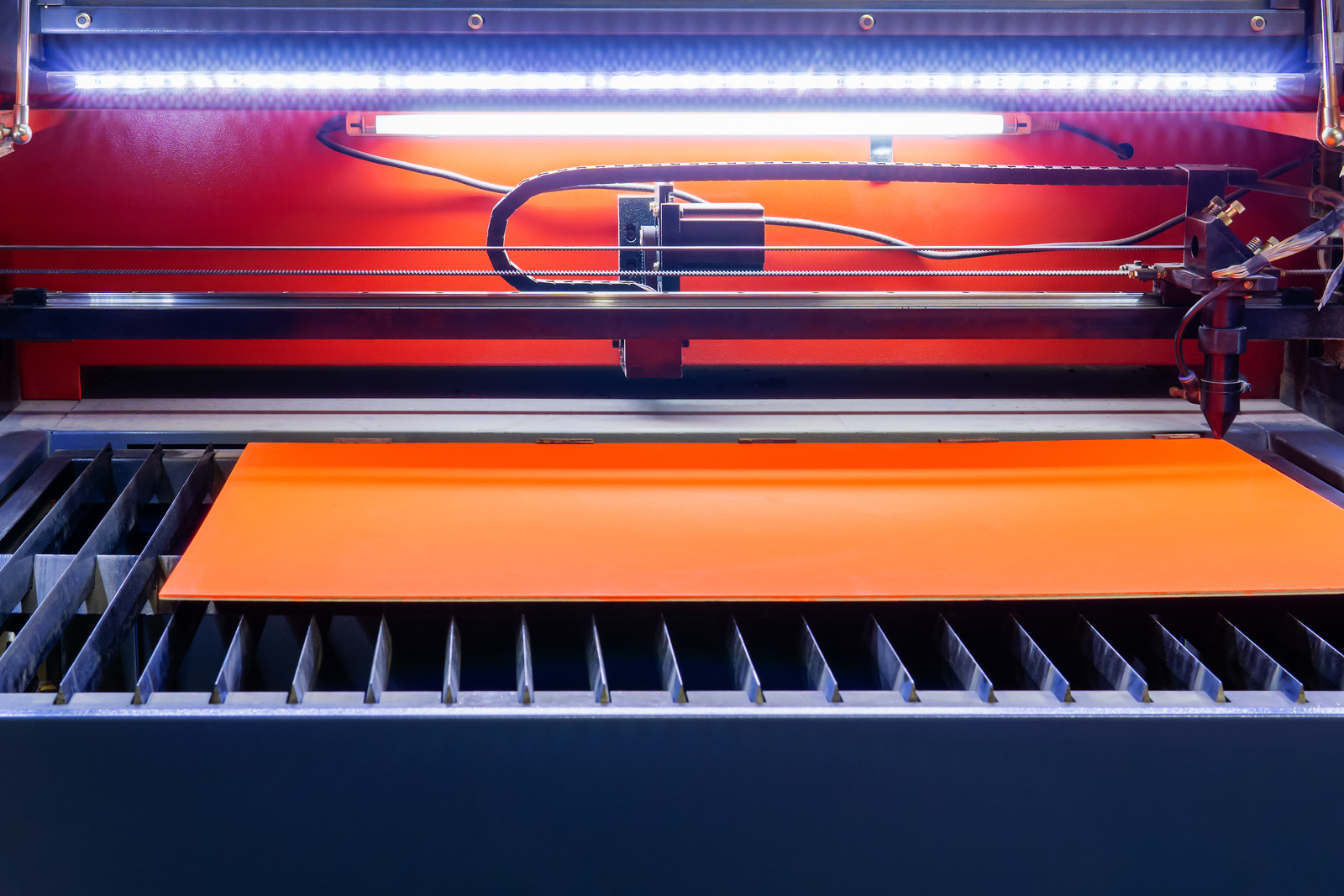

Laser cutting zinc sheets is a precise technique that uses a high-powered laser to cut through materials. The use of laser cutters has revolutionized the manufacturing industry, as it allows for precise cutting of even the most difficult materials. Typically, laser cutters are used to cut out flat and thin sheets of metals like steel, aluminum, brass, and zinc.

Laser Power

Laser power is a key factor when laser cutting metal sheets such as zinc. Laser cutting requires a powerful and focused beam of light (a laser) to cut through the sheet material. The intensity of this focused laser light affects the quality and speed of the cut.

The laser cutting process is controllable and can be adjusted to ensure the highest degree of accuracy and the best results. The power of the laser cutter is measured in watts, and vary in strength depending on the material being cut. Powerful lasers have tens of megawatts of power, while entry-level laser cutters may have a few hundred watts.

Pre- Treatment

When it comes to cutting zinc sheets with a laser cutter, pre-treatment is an essential part of the process to ensure smooth and accurate cuts. Before the laser cutting process even begins, several important steps must be taken to make sure that zinc sheets are ready for laser cutting. First, the zinc sheets must be cleaned thoroughly with a special wire brush to remove any dirt and debris.

After this, a protective layer must be applied to the surface of the zinc sheets.

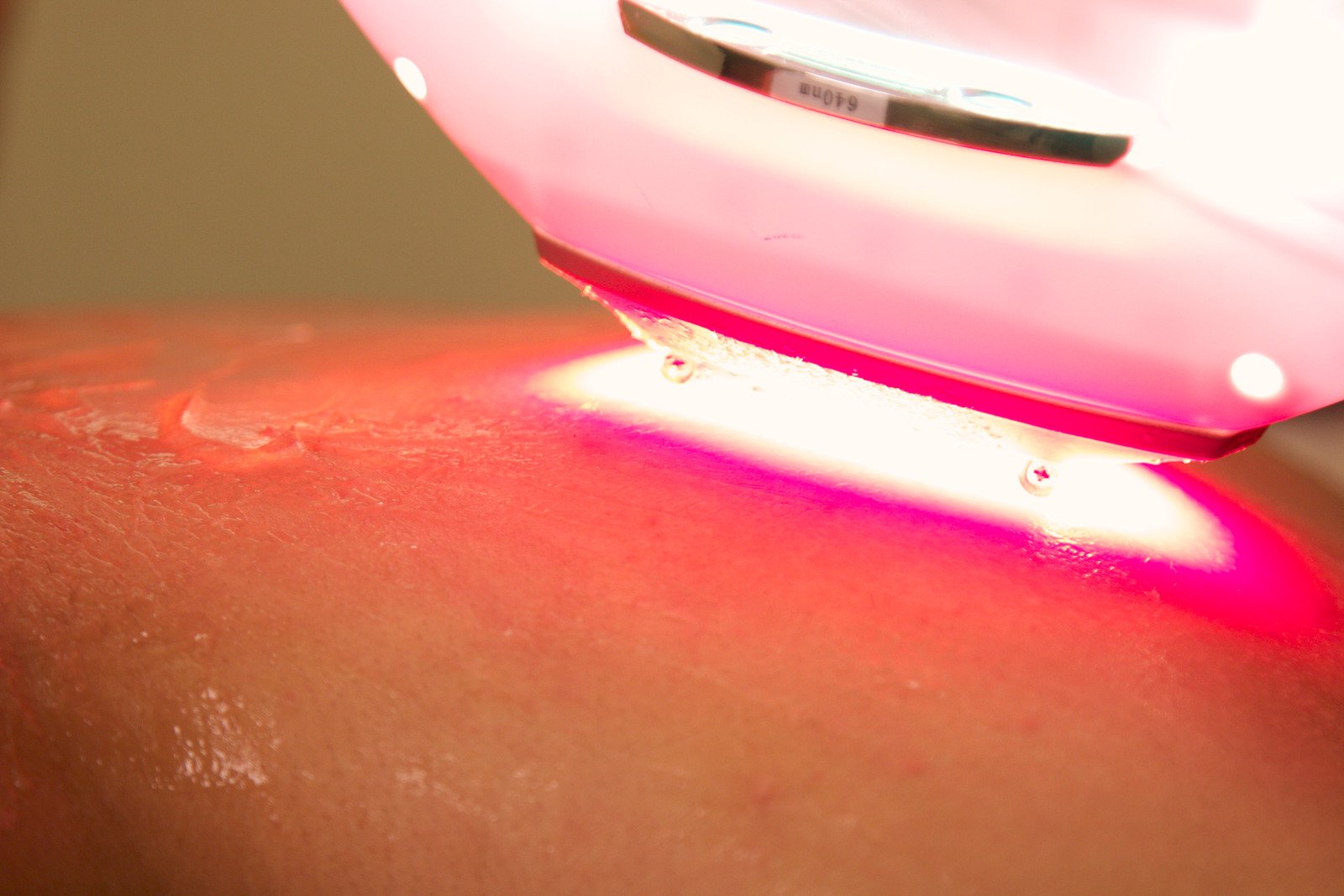

The Laser Cut

Description: Laser cutting is a manufacturing process which uses a high-powered beam of light (a laser) to cut out shapes and designs in thin and flat sheets of metals. Laser cutters are renowned for their precision and accuracy, ensuring a perfect cut every time. This process is ideal for cutting sheet metal into intricate designs and shapes, such as text and images.

The laser cutters are equipped with the latest technology and designed for optimal performance. They use a powerful beam of light to quickly and accurately cut the metal sheet into the desired shape. The laser beam is so thin and precise that it can cut through the sheet without damaging any of the surrounding material.

Considerations

Operational Hazards

Operational hazards are an important consideration when considering laser cutting of zinc sheets. Since zinc is a relatively soft metal, it can be easily cut by a high-powered beam of light (laser). However, operaters should always wear appropriate personal protective equipment when cutting sheets of this metal, as there are many risks involved.

The heat generated during the cutting process can cause thermal burns, while particles created by the cutting process can cause physical injuries. In addition, the highly reflective nature of zinc can lead to reflective hazards, resulting in injuries to unprotected eyes and skin. It is also important to take into account the potential for noise-related hazards when operating laser cutters.

Heat Affected Zones

When laser cutting zinc sheets, there is an important element to consider – the heat affected zone (HAZ). The HAZ is the area that has been irradiated by the laser beam and is affected by heat, changing both its color and mechanical properties. This area has a distinct appearance compared to the untouched metal, and this difference is especially noticeable when using a CO2 laser cutter.

Whenever metal is cut with a high-powered beam, like a laser, heat is generated.

Post Treatment

Post treatment is an important step in the laser cutting process of zinc sheets. After a high-powered laser has cut through the sheets, post treatment is required to help reduce the burrs that may have been created when the laser beam cuts through the sheets. There are several different types of post-treatment processes that can be used.

These include sanding, filing, drilling and cutting. Sanding is typically done to smooth out the edges and to eliminate any burrs.

What is laser cut sheet metal panels?

Laser cut sheet metal panels are flat and thin sheets of metal, usually zinc, that have been cut using a laser cutter. Laser cutters use a high-powered beam of light (laser) to precisely and quickly cut through materials. This process is advantageous for businesses because the laser cutter can be used to cut complex shapes without having to manually cut the material with scissors or with a saw.

What is a laser cut sheet?

Laser cutting zinc sheets is a process of creating intricate designs, shapes, or patterns in a sheet of metal using a precision laser beam technology. It is a type of fabrication method which relies on a high-powered beam of light (laser) to cut out flat and thin sheets of metals like zinc. Laser cutting is a relatively fast, accurate, and efficient way to cut through metals without the need of a knife or saw.

It involves a laser cutter equipped with a cutting head, which emits the laser beam that moves along a computer-controlled path to the exact spot of the metal required to be cut.

Conclusion

Summary of the Benefits of Laser Cutting Zinc Sheets

sheet The use of laser cutting for zinc sheets offers numerous advantages over traditional cutting techniques. Laser cutting zinc sheets with high-powered beams of light is quicker, more accurate, and has less material waste than manual cutting. This is especially true when precision is mandated by a project or design.

Additionally, laser cutting produces a smoother surface finish with the cuts being cleaner and more consistent compared to manual cutting. Laser cutting can also create unique shapes, which are impossible to produce with manual or traditional cutting methods. The use of laser cutting also increases production efficiency and speed.

In addition, laser cutting usually requires less setup and material handling time, allowing for faster cutting of materials and more flexibility in production.

Requirements and Processes for Laser Cutting Zinc Sheets

When it comes to laser cutting zinc sheets, there are several requirements and processes to consider. Firstly, a high-powered laser is used to cut through materials with precision, as it emits a high-intensity beam of light that can easily cut through metals such as zinc. Laser cutters, also known as laser engravers, are the machines that can create laser cuts and engrave text, images, and patterns on various types of materials.

Depending on the desired size and shape of the zinc sheet, the laser cutter operator can adjust the settings on the engraver to alter the width and intensity of the laser beam, allowing them to achieve the desired precision.