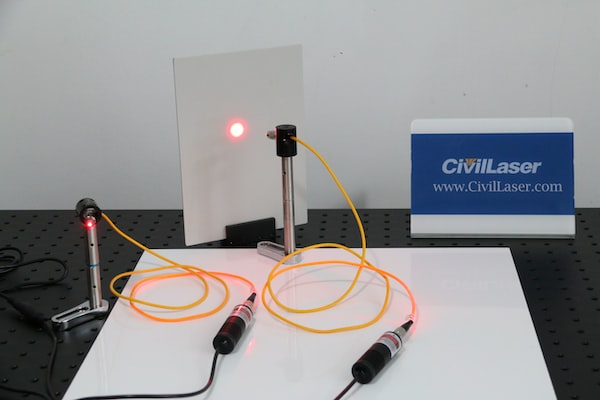

Over the years, the development of new technologies has enabled immense leaps in the manufacturing industry. The invention of lasers and laser cutting systems has opened up exciting possibilities and alternatives to traditional cutting techniques. In the nylon industry specifically, laser cutting can cut, shape and weld materials with precision, making it an invaluable tool to have in any production process. This article will provide an overview of laser cutting in the nylon industry, its advantages and its place in modern manufacturing.

Benefits of Laser Cutting in the Nylon Industry

Accuracy

Accuracy is one of the main benefits of laser cutting in the nylon industry. Laser cutting uses a high-precision laser that is used to cut the fabric into the desired pattern shapes, with a high degree of accuracy and repeatability. Laser cutting is able to cut many different materials including nylon with accuracy, detail and at a much higher speed than traditional methods.

In particular, laser cutting has revolutionized the way nylon products are cut and sealed. Fusion cutting uses a high-pressure jet of an inert gas like argon or nitrogen to blow out the molten material from the cut created by the laser beam. Cutting and sealing edges simultaneously saves time and creates perfect cuts.

Cleaner Cuts

When it comes to cutting nylon in the manufacturing industry, laser cutting is a highly versatile, clean and efficient method. Laser cutting is used to cut thinner materials that require intricate detail with a minimal amount of heat or melting of the fabric. This often includes components such as textiles, plastics, paper and metal.

The process works by using a high-pressure jet of an inert gas like argon or nitrogen to blow out the molten material from the cut created by the laser beam, while focusing the laser onto the material to be cut.

Faster Production

The use of laser cutting in the nylon industry is an increasingly popular and reliable way to achieve faster production. With laser cutting, it is possible to cut a variety of materials into desired patterns and shapes, without manually cutting and sealing edges. The laser is used to cut the fabric, and then the edges are sealed, thus avoiding the manual process.

One particular type of laser cutting, known as fusion cutting, works by using a high-pressure jet of an inert gas like argon or nitrogen to blow out the molten material from the cut created by the laser beam.

Challenges of Laser Cutting in the Nylon Industry

High Costs

One of the challenges of laser cutting in the nylon industry is the high costs associated with it. Laser cutting is an effective and precise method of cutting and sealing edges simultaneously, but the cost of the equipment, power requirements, and the maintenance of the laser cutting machines can add up quickly. Laser cutting is done using a laser beam, either a CO2 laser, which produces an infrared light, or a gas laser.

This light is used to cut the fabric into desired patterns and shapes.

Material Preparation

When it comes to laser cutting nylon materials, the process of material preparation is very important. To ensure the best cutting results with minimal damage to the fabric, several steps need to be taken before the actual cutting process. First of all, the fabric must be very flatly laid and bent little as possible.

This helps ensure that the laser beam is able to focus on a precise spot and keeps the fabric aligned, as even the slightest movements could skew the cutting patterns or cause damage to the material.

Case Studies

Successful Examples of Laser Cutting in the Nylon Industry

Successful Examples of Laser Cutting in the Nylon Industry The nylon industry has been taking advantage of laser-based cutting technologies for many years, specifically when it comes to fabric-related applications. Laser cutting is used to cut and shape fabric with very precise results and minimal wastage. This makes it a popular choice for the manufacture of clothing, upholstery, and other fabric-based products.

One of the most common applications of laser cutting technology within the nylon industry is the cutting and sealing of edges simultaneously.

Can you laser cut nylon?

Yes, you can laser cut nylon! Laser cutting is a process whereby a focused beam of light is used to cut and shape a material, such as nylon. This focused beam of light is usually generated by a laser source, most commonly a CO2 laser.

It works by using a high-pressure jet of an inert gas, such as argon or nitrogen, to blow out the molten material from the cut created by the laser beam. The laser beam is generated by a gas laser that creates infrared light. Using the laser to cut nylon results in a clean edge with minimal melting along the cut path.

Conclusion

Advantages of Laser Cutting

Laser cutting is one of the most preferred methods for cutting nylon and other materials in the nylon industry. It enables the fast and accurate cutting of fabric into desired patterns and shapes. Laser cutting is also capable of cutting and sealing edges simultaneously.

This means that there is no need to add additional finishing touches like serging, a process which can be done by machine but is very time consuming. The two most commonly used lasers for cutting nylon are CO2 and gas lasers.

Disadvantages of Laser Cutting

Despite the benefits of laser cutting in the nylon industry, there are some drawbacks. One of the most significant disadvantages is that it can only be used to cut certain types of materials. Although a laser is employed to cut the fabric into the desired pattern shapes with a CO2 laser, the materials cannot be of too high or too low of a density.

The edges of the cuts may also need additional sealing to prevent fraying. Furthermore, laser cutting isn’t always capable of cutting and sealing edges simultaneously.

Overall Review of Laser Cutting in the Nylon Industry

Overall Review of Laser Cutting in the Nylon Industry Laser cutting is an important process for the nylon industry, as it enables the cutting and sealing of edges simultaneously and with precision. The process of laser cutting utilizes a laser, typically a CO2 laser, which produces a very precise infrared beam, to cut the fabric into the desired pattern shapes. CO2 lasers are especially advantageous, as they create a clean cut edge with minimal melting along the cut path.

This means that the edge is finished with minimal to zero overburning or fraying.