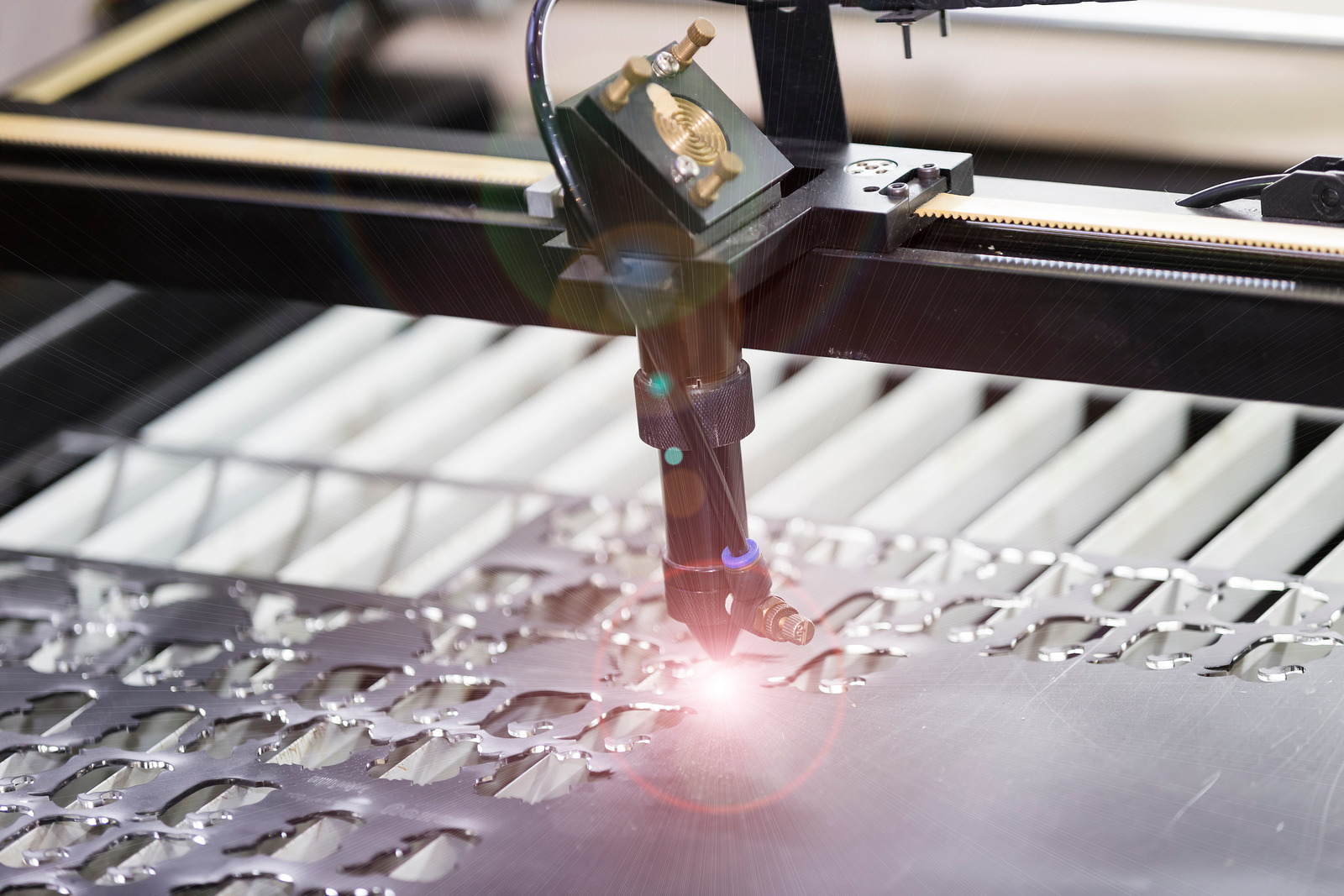

Welcome to our guide to laser cutting aluminium. In this article, you will learn about the tips and tricks for making the most out of laser cutting aluminium and gaining optimal results. Laser cutting aluminium is becoming an increasingly popular and cost-effective method for producing a wide range of precisely crafted and decorative parts from aluminium sheet stock. With its ease of use, versatility, and accuracy, laser cutting aluminum is becoming the go-to choice for industries from advertising to aerospace. With this guide, you’ll be able to navigate the ups and downs of laser cutting aluminium and get the very best results for your next project.

Advantages and Limitations for Laser Cutting Aluminium

Benefits of Laser Cutting Aluminium

Laser cutting aluminium is a widely used industrial process for cutting various metal materials. It has various advantages such as efficiency and accuracy, however, there are also some limitations and techniques that can be used to maximize its benefits.

- Laser cutting aluminium is a precise and cost-effective way to cut complex shapes and designs. It also produces a clean, sharp edge that is free from burrs and other surface imperfections.

- Laser cutting aluminium produces a cleaner, more consistent finish that is free from the inconsistencies found with manual cutting. This is ideal for producing intricate shapes on precise parts.

- Laser cutting aluminium is fast, precise and efficient, making it suitable for production runs of any size without sacrificing quality.

- Laser cutting aluminium can reduce costs by providing precise tolerances and repeatability. It also minimizes wasted material, as there is no cutting force required to produce a finished product.

- Laser cutting aluminium also provides a high degree of accuracy, as the laser beam is controlled by a computer that can accurately adjust the size and shape of the cut parts with a high degree of precision.

Common Limitations of Laser Cutting Aluminium

Laser cutting aluminium is a popular fabrication technique due to its superior accuracy, flexibility and cost-effectiveness. Aluminium is a great material to laser cut because it is a relatively soft but durable metal that is easy to design for.

- High Reflective Properties: Laser cutting aluminium is difficult due to the material’s high reflectivity. When the beam reflects off the shiny surface of the aluminium, it can lead to it being redirected or scattered. This can damage the optics of the machine, or simply reduce the effectiveness of cutting.

- Heat Effect: Due to the high heat generated during laser cutting aluminium, thermal distortion is common. The heat generated by the laser, combined with the heat created by the workpiece, can result in a different finished product than intended.

- Fast Cooling: Once the cutting process is complete, the aluminium cools quickly. This creates internal stresses that can cause distortion.

- Limited Cutting Depth: Laser cutting aluminium has a limited cutting depth. The maximum cutting depth for most sheet metal materials is 25 inches / 6 millimeters.

- Thickness Limitations: The thickness of aluminium that can be laser cut is limited to 04 – 25 inches / 1 – 6 millimeters. Anything thicker than this will require other cutting methods.

Preparing Aluminium for Laser Cutting

Safety Tips and Protective Tools

Safety Tips and Protective Tools When it comes to laser cutting aluminum, safety is always of utmost importance. As with any other kind of machining or engineering process, there is always the potential for hazards and it’s important to take the necessary precautions. Here are some safety tips and protective tools to keep in mind when handling laser cutting aluminum.

Eye protection: Eyes are one of the most important parts of the body to protect while operating a laser cutting machine.

Prepping Methods Based on Thickness

Prepping Methods Based on Thickness Cutting aluminum with a laser can be tricky, as the metal is highly reflective and can easily warp when exposed to the heat of the laser. As such, it’s important to prepare your material based on thickness so that your job runs smoothly.

Laser Cutting Aluminium – Tips and Tricks

Settings for Laser Cutting Aluminium

Laser cutting aluminium is a precise and cost-effective way to produce precise shapes from this material. Starting from choosing the correct type and thickness of aluminium to setting up the laser cutter, there are many settings and tips to keep in mind. Some of the most important points are to work with a low focus lens, increase the kerf width to compensate for the material’s thermal conductivity, and to select a proper speed and power settings.

- Choose Your Focus – Before attempting laser cutting aluminum, make sure to select the right focus setting for your project. Use a higher focal point when cutting thicker materials and lower focal points on thinner metals.

- Adjust Your Power Levels – Always use the correct power levels when cutting aluminum, as the material is sensitive to heat. Set the power levels lower to avoid overheating and damaging the material.

- Use Two Passes – For thicker aluminum, use two passes when cutting to ensure a clean edge and reduce the risk of deforming the material.

- Adjust Your Speed – Adjust the cutting speed for thicker aluminum to reduce the risk of burning and avoid creating too much heat.

- Cut With Abrasives – Use abrasive materials, such as sandpaper or a sanding wheel, to prep the edges for a clean finish. This step will ensure a professional-looking result and prevent any aluminum from sticking to the machine.

Post-Cutting Automations

Post-Cutting Automations Once you’ve finished laser-cutting your aluminium parts, there are a few things you can do to automate the rest of the process. This post outlines a few of these automations and tips to save time. One of the most common automations used with laser-cutting aluminium is edge-deburring.

This is the process of removing any burrs, sharp corners or edges created by the laser-cutting process. This can be done manually with a deburring tool or automated with a machine that uses abrasive blades or a polishing wheel. Automating this process can help save time by eliminating the need for manual deburring.

How fast can a laser cut aluminum?

How fast can a laser cut aluminum? The answer depends on a few variables, such as the type of laser being used as well as the type of aluminum being cut. Generally, most carbon dioxide-based lasers with a power between 200 to 500 watts can cut aluminum at a rate of between 20 to 25 inches per minute.

However, lasers with a higher wattage can cut even faster. For instance, fiber lasers with 2,000-5,000 watts can cut aluminum sheets at a rate of up to 100 inches per minute, while a 6,000-watt fiber laser can cut nearly twice as fast.

Conclusion

The conclusion to our guide of laser cutting aluminium comes with some great takeaway tips. Laser cutting aluminium has many advantages when compared to other metal cutting methods. It is quick, cost-effective, and offers a much greater degree of precision than traditional methods.

Plus, because of its extreme accuracy, you can produce nearly any shape with ease.