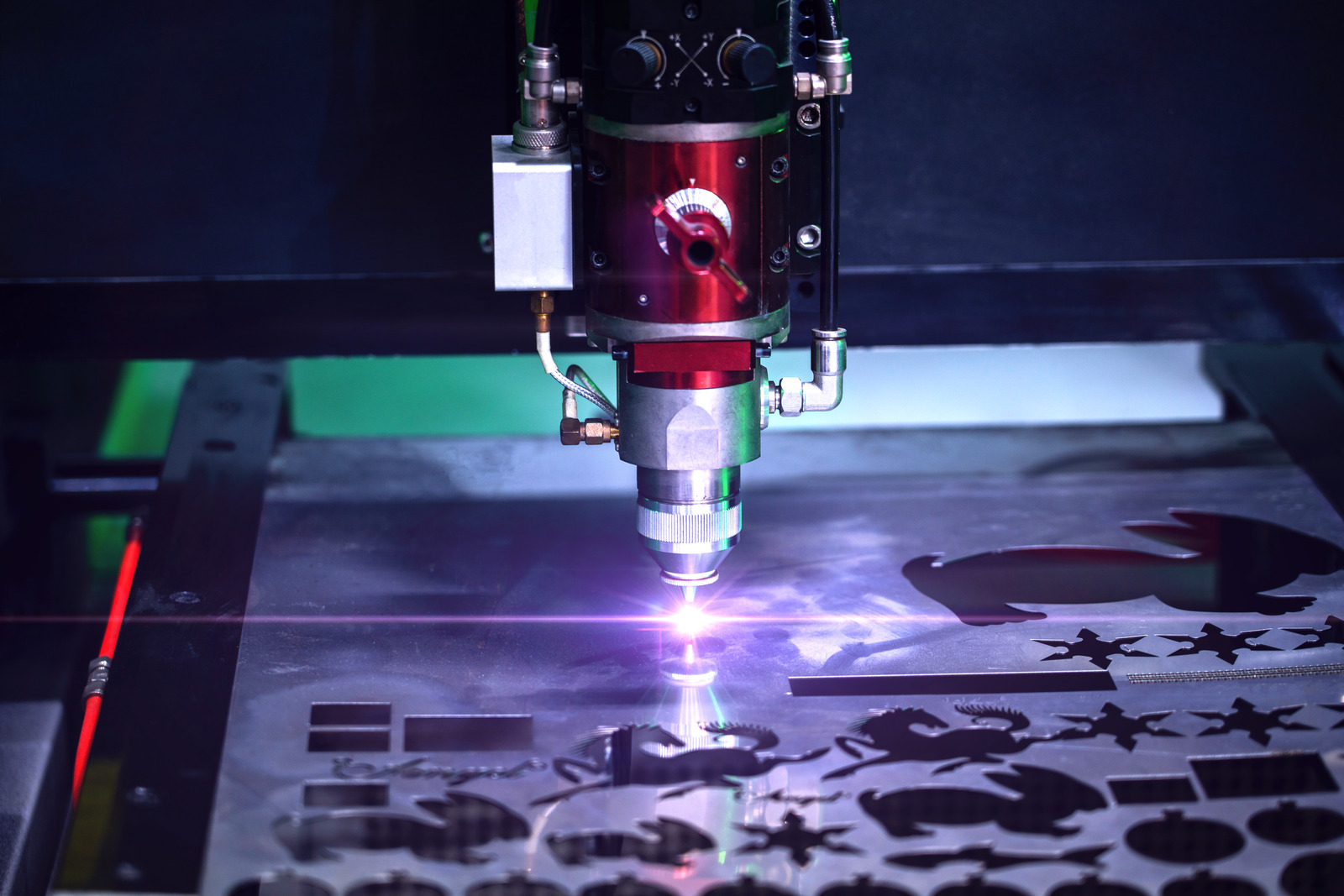

The process of laser cutting nylon is an incredible way to produce intricate parts and components with precision and accuracy. With its high-tech accuracy, laser cutting is becoming increasingly popular as a way to produce complex parts with complex features. In this discussion, we will explore the laser cutting process from the user’s perspective, and discuss the advantages and limitations of the process. We will look at the different laser cutting options available and the best ways to use them. Furthermore, we will see how to maximize the technical benefits of laser cutting and minimize any potential problems. Let’s start the discussion by exploring the basics of laser cutting and its advantages for the user.

Types of Nylon

Nylon 6 and Nylon 6.6

Nylon is an excellent material for laser cutting due to its density and heat resistance. It is easily cut using laser cutters and can be used for a range of applications, from laser-cut shapes to intricate detailing of thicker materials. Nylon also produces a clean edge with minimal melting along the cut path.

When laser cutting nylon, it’s important to identify the optimal power for the job, as too much power can damage the material. It is also important to distinguish between the two main types of nylon – Nylon 6 and Nylon 6.6.

Different Weave Designs

When it comes to laser cutting nylon from the user’s perspective, there are a variety of different weave designs that can be used. Some of the main ones are: plain weave, circular knit, tubular knit, and true knit warp. It’s important to identify the optimal power required for each weave pattern as choosing the wrong one can lead to poor quality cuts, and a variety of issues.

When laser cutting, the type of material used will determine the intensity of the power required to cut through it.

Setting Up Laser Cutters

Considerations for Laser Cutter Specifications

When it comes to setting up laser cutters for nylon, it is important to consider the specifications of the machine. Generally, laser cutting for nylon requires the precise identification of the optimal power so that it can both cut through the material, and to prevent overburning the edges. Knowing how to use the laser cutter correctly can make a major difference when it comes to producing a clean edge with minimal melting along the cut path.

Bed Dimensions and Masks

When it comes to laser cutting nylon from the user’s perspective, setting up the laser cutters can be one of the more challenging steps. One of the most important steps is correctly determining the dimensions of the laser cutter’s bed. If the dimensions are not correctly set up, the part may not fit or could be cut outside of the vector boundaries, leading to incorrect machining.

Additionally, masks can be used to cover the regions of the bed not being used to help keep the interior components clean. Once the areas of the bed have been established, the operator must identify the optimal laser cutting power.

Advantages of Cutting Nylon with a Laser

Smooth Edge Finish

One of the great benefits of laser cutting nylon is the smooth edge finish that it produces. This is especially beneficial for materials which are intended for decorative purposes, such as wall hangings or clothing. Laser cutting allows for minimal melting along the cut path and a clean edge every time.

As compared to other cutting methods, laser cutting provides more precise, accurate results with very little primary processing. When cutting nylon with a laser, it is important to identify the optimal power settings. Typically, settings will depend on the thickness of the material.

For instance, if you’re cutting thicker materials, these require more power. Likewise, thinner materials require less.

Clean, Accurate Cut

The benefit of using a laser cutter to cut nylon is that it can provide a clean and accurate cut. Laser cutting uses laser technology to identify the optimal power to cut through the material and produce a clean edge with minimal melting along the cut path. With laser cutters, you can cut thick materials like nylon with greater precision and accuracy than with traditional cutting tools.

However, one of the difficulties in laser cutting nylon with a laser cutter is distinguishing between visually similar materials.

Versatility of Different Materials

When it comes to cutting different materials or fabricating parts, laser cutters are becoming increasingly popular in the manufacturing industry. They provide an economical and efficient way to produce parts quickly and accurately. Nylon is a versatile material and is often used in manufacturing and other applications, making it an ideal choice for laser cutting.

The main advantage to laser cutting nylon is that it can accurately identify and cut thick materials with a minimum of melting along the cut path.

Preparation Tips

Techniques for Prepping the Material

When prepping nylon for laser cutting, there are some key steps and techniques you’ll need to employ in order to get a clean edge with minimal melt along the cut path. Whether cutting thin or thick nylon, the two most important things to consider are how to identify the optimal power for the laser and how to identify which type/style of laser cutter is best for your particular job. When choosing a laser cutter, it is important to understand that all laser cutters are not created equal.

Applying Heat and Pressure

Applying heat and pressure when laser cutting nylon is an important step in achieving a successful end product. Laser cutting nylon relies on the combination of focused laser light, heat, and pressure to create the desired cut. Heat dissipates in concentric circles while the laser is cutting, causing the surface fibers to heat up at the point of contact.

This heat softens the material, making it easier to cut and less prone to producing rough edges. Pressure is then applied, forcing the softened material against the cutting edges of the laser cutter for a clean cut. Users should identify the optimal power to apply when cutting in order to achieve a precise and exact cut that produces minimal melting along the cut path.

Post Processing

Cutting Tips for Nylon

When it comes to laser cutting nylon, the user needs to take some important factors into consideration. It’s important to identify the optimal power settings that can ensure a clean edge with minimal melting along the cut path. This requires some trial and error to see what works best, as it will vary depending on the type of material and the power of the laser cutter.

To make sure the laser cutter is up to the task, it’s also essential to make sure it has the power and capability to cut through thick materials.

Treating Nylon Cut Edges

When laser cutting nylon, the post-processing treatment of the edges is one of the most important factors to ensure that the final product will be of the highest quality. The optimal laser power when cutting nylon can be identified based on a number of different factors, including, but not limited to, the material thickness, material type and density, and the photosensitivity of your particular laser cutter.

Conclusion

Benefits of Laser Cutting Nylon

One of the key benefits of laser cutting nylon is that it can provide a consistent and precise cut with a very high degree of accuracy. By selecting the optimal power settings for a specific material, laser cutting nylon can even cut thick materials that would be impossible to do with other methods. Laser cutting can easily produce a clean edge with minimal melting along the cut path for a much better finished product.

Not only is laser cutting nylon effective and reliable, it is also very safe. Laser cutters only emit a tiny, invisible beam that does no harm to the user or the material being cut.

Cost Savings of Laser Cutting Technology

Using laser cutting technology to cut nylon has numerous advantages over traditional methods, including lower cost and faster operation, as well as a cleaner edge with minimal melting along the cut path. Many users have realized cost savings by using a laser cutter, as the machine is able to precisely identify the optimal power and cutting speed that a material needs and can then cut thick materials with accuracy and speed. The main challenge associated with laser cutting is the difficulty users may have distinguishing between materials that are visually similar.

For example, users may mistake a heat-resistant material for regular nylon, or a material that is reflective for one that is not.