Identifying the right laser cutter for zinc plated steel is essential to achieving optimal cutting results with any project. There are various factors to consider when it comes to selecting a laser cutter to ensure the best performance. This article will provide guidance on how to identify the best laser cutter for cutting zinc plated steel, highlighting the different types of laser cutters, how to choose the right cutter, and how to get the best performance from a given laser cutter.

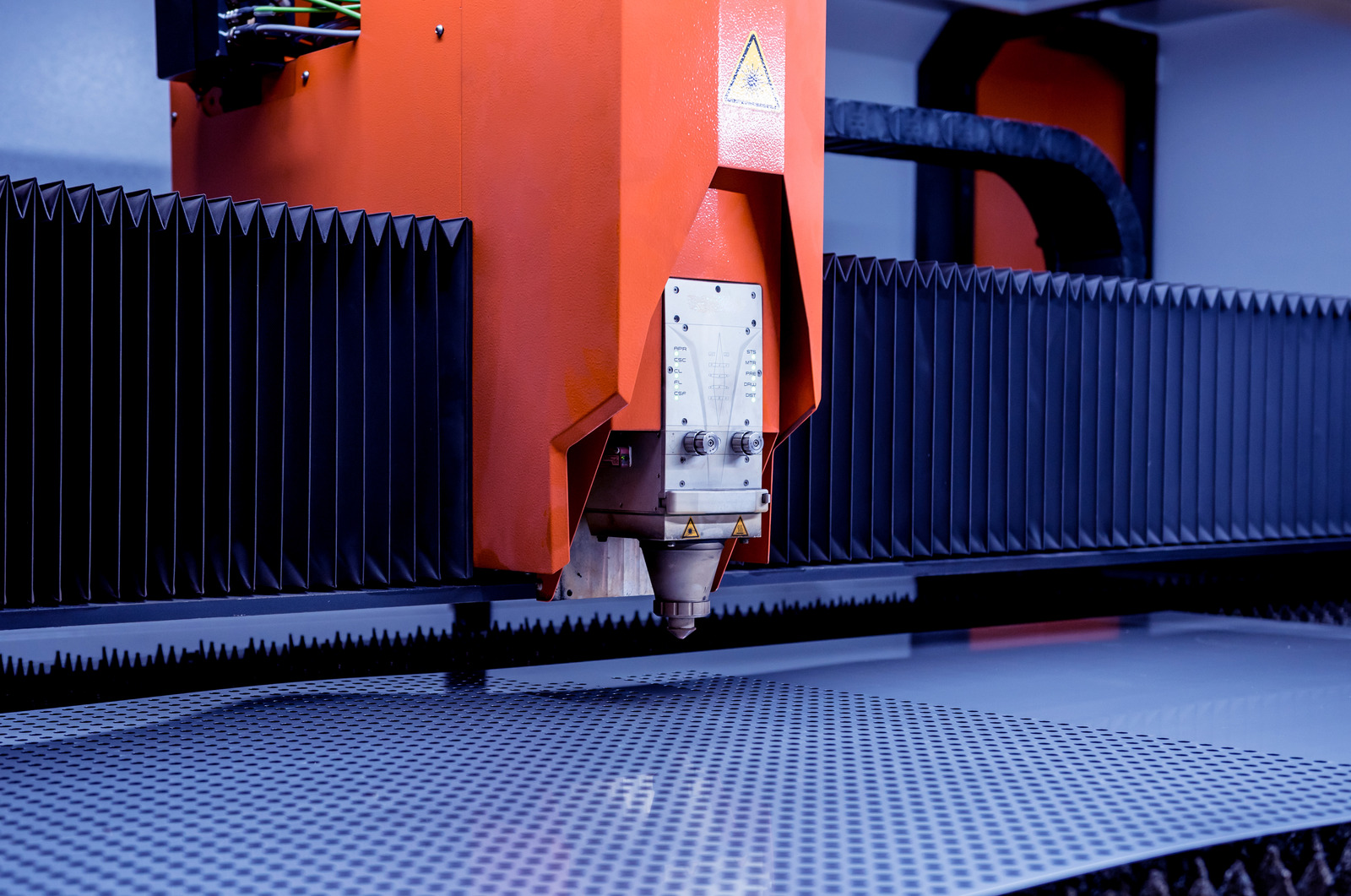

Identifying the Right Laser Cutter

Consider Power Level

When it comes to identifying the right laser cutter for zinc plated steel, the first thing you need to consider is the power level of the machine. The power level is what will determine the accuracy and speed of the cuts made on the steel. You need to ensure that the laser cutter you choose provides an adequate amount of power to ensure clean, precise cuts.

For laser cutting zinc plated steel, the power level of the machine should be at least 50 watts. The higher the power level, the better, as this will allow for quicker and more detailed cuts. Higher powered machines also tend to be more expensive, but may be necessary, depending on the complexity and detail of the project.

Consider Beam Dynamics

When it comes to properly identifying the right laser cutter for cutting zinc plated steel, it is important to consider the beam dynamics. The beam dynamics refer to the interactions of the laser beam, the workpiece, and the environment.

Consider Materials Handled

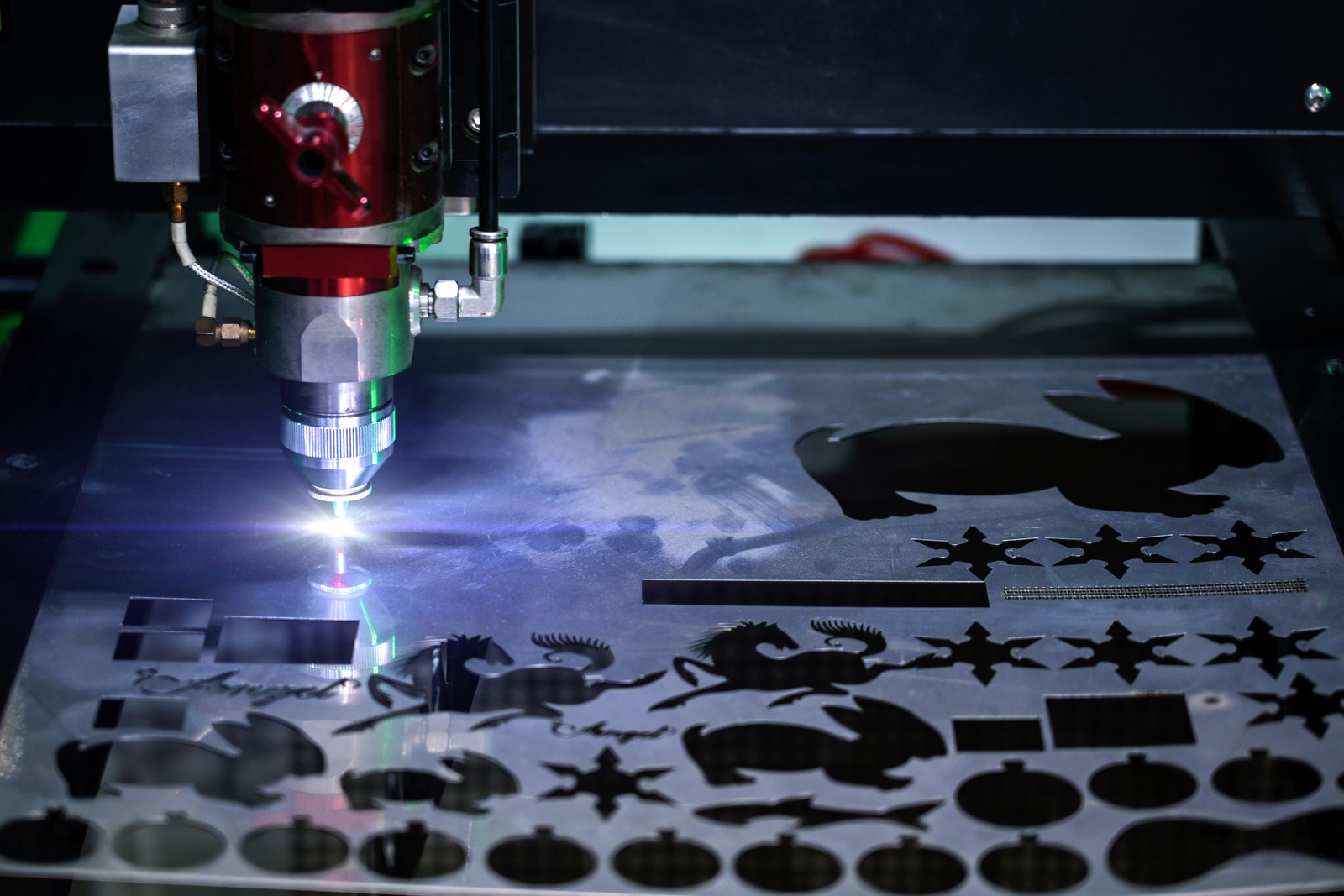

When it comes to identifying the right laser cutter for zinc plated steel, deciding on the materials that need to be handled is an important factor. Depending on the type of laser cutter you choose, different materials can be cut, engraved, or etched – whether that be wood, stone, plastic, or metal such as stainless steel, aluminum, and zinc plated steel. It’s important to determine which materials you want your laser cutter to handle, in order to make sure you get the right machine for the job.

Key Considerations for Laser Cutting Zinc Plated Steel

Safety

Safety is a major consideration when it comes to laser cutting zinc plated steel. Zinc plated steel is highly reflective and can significantly increase the chances of burn and fire hazards occurring during the process. As a result, the right laser cutting machine needs to be chosen carefully, and all potential safety risks must be addressed.

It’s important to select a laser cutting machine that is specifically designed to cut zinc plated steel without risking the safety of the operator or the machinery.

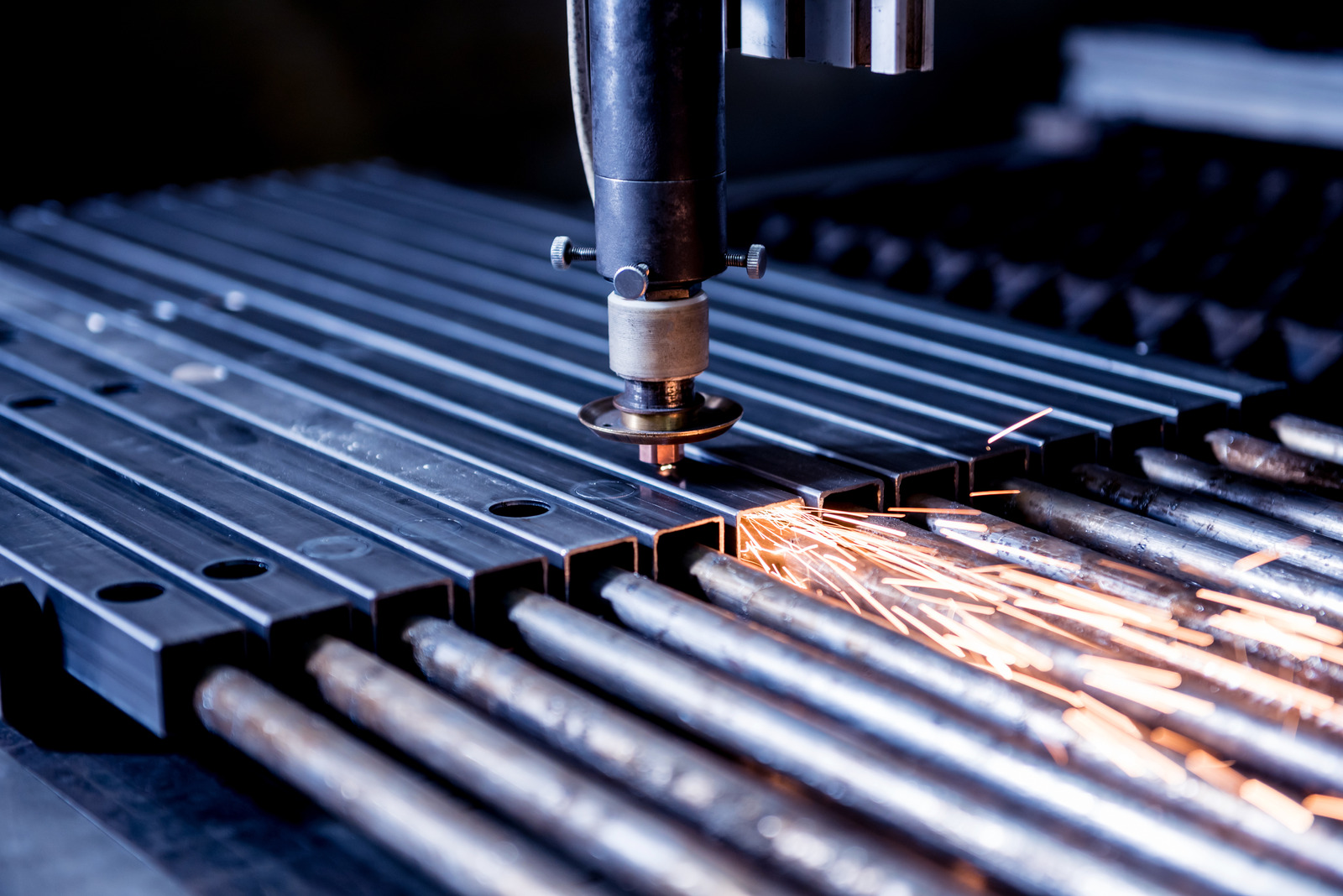

Cutting Performance

Cutting Performance is an important factor to consider when choosing the right laser cutter for zinc plated steel. Here are a few key aspects to consider: Power: The material that the laser cutter will be cutting, such as zinc plated steel, will usually require a higher wattage laser to cut through. Generally speaking, the harder the material, the higher the wattage.

Therefore, a higher wattage laser will be needed to effectively cut zinc plated steel. Speed: Zinc plated steel is a thicker material and will likely require a faster cutting speed than other, less dense metals.

Workpiece Capacity

When it comes to selecting the right laser cutter for zinc-plated steel, one of the most important considerations is the workpiece capacity of the machine. It is important to choose a machine that will be able to process both the size and thickness of the workpiece. Size: When considering the size of your work piece, the maximum sheet size of the laser cutters capacity should match or exceed the size of the material to be cut.

This will ensure that the laser engraver can effectively process all of the material that needs to be cut.

Can you laser engrave on galvanized steel?

It is possible to laser engrave on galvanized steel, but it needs to be done with the right laser cutting machine. When selecting a laser cutting machine for zinc plated steel, it is important to take into consideration the material properties, desired cut quality, and type of engraving. Different types of laser systems such as CO2, Fiber, and YAG can be used to engrave on zinc-coated steel.

What laser will engrave steel?

When it comes to identifying the right laser cutter for zinc plated steel, the answer isn’t an easy one. This is because each laser cutter is designed to laser engrave or cut different types of metals. Zinc plated steel can be tricky to laser cut as the zinc coating can cause a reaction when exposed to high power laser beams.

The right laser cutter, however, can make a huge difference in getting the desired results. When choosing the right laser cutter for zinc plated steel, one needs to consider the power, peak power, and wavelength of the laser, as well as the material thickness, quality of cut, and the maximum cutting speed.

Can you laser cut zinc?

Yes, you can laser cut zinc plated steel, but it is important to use the right laser cutting machine to do so. Laser cutting is a fast and precise way to cut, engrave, and mark a variety of materials, including metal. Before choosing a laser machine for your zinc project, first research the laser engraver you are looking at to ensure it can be used for cutting zinc.

Conclusion

Summary of Key Points

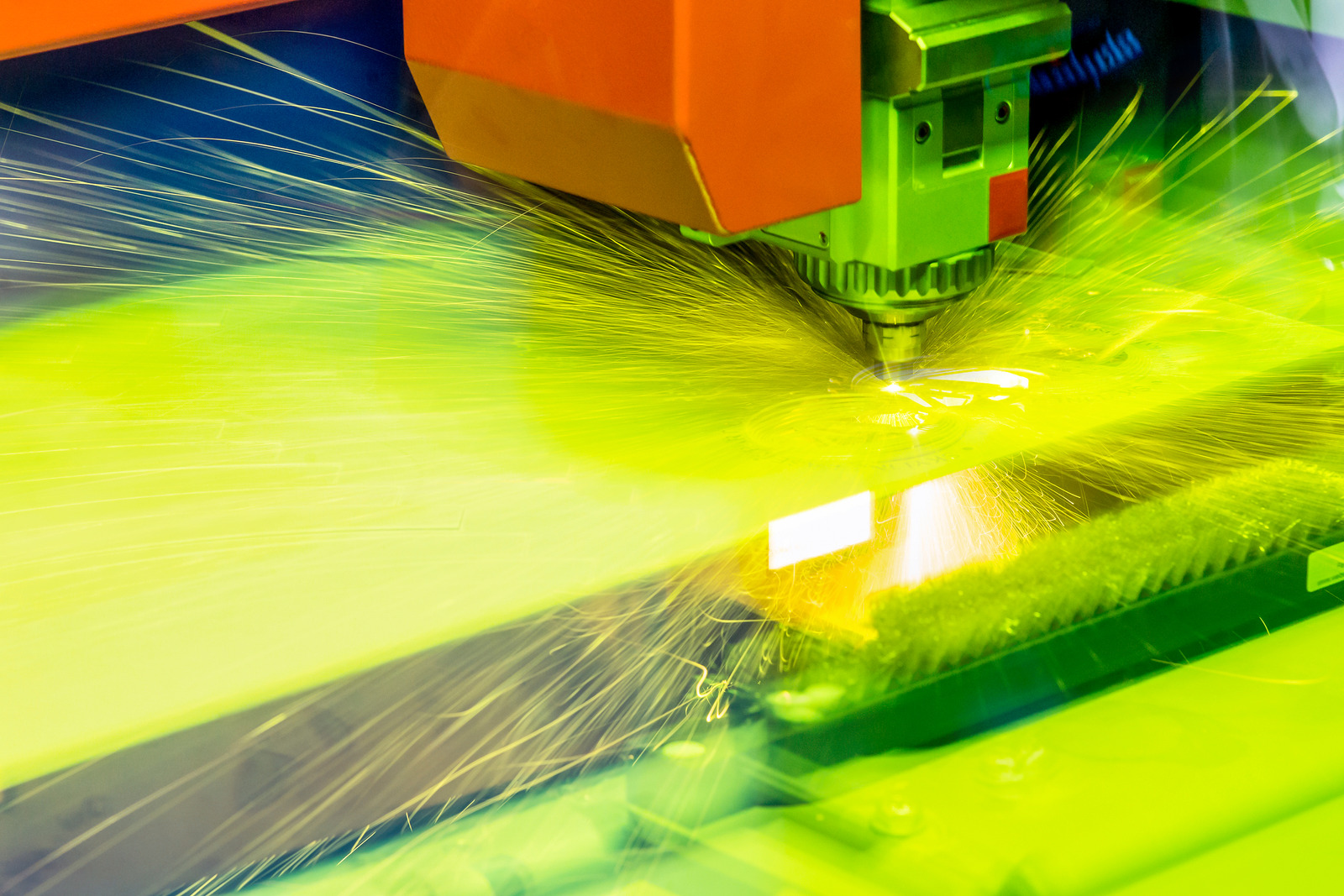

Conclusion: Identifying the right laser cutter for zinc plated steel can be a complicated task and one that requires considerable research. In order to get the best results, it’s important to weigh a variety of factors and determine which qualities are a priority for your project. Metal lasers are essential for efficient cutting of zinc-coated steel, and laser engravers can produce intricate designs and patterns in the material as well.

It is also important to consider the size of the material and the speed at which the laser is able to cut it. Each of these factors is essential when selecting the right laser cutter for zinc plated steel.

Final Thoughts on Choosing the Right Laser Cutter

In our conclusion for finding the right laser cutter for zinc plated steel, we can now confidently recommend the most suitable laser cutter for the application. Choosing the best fit involves a combination of weighing the benefits and researching the laser cutter’s specifications. If you need a laser cutter that can cut zinc plated steel precisely, then metal laser cutter can help you finish the job with ease.

In order to ensure the best results, always look for a laser cutter designed with a metal power source and an adjustable laser head. It’s also important to choose the right kind of settings that will provide an adequate amount of power and speed.