Welcome to a day in the life of a laser cutting operator! Laser cutting is an exciting, highly precise technology used in various industries such as automotive, aerospace, electronics, and metalworking. In this article, you’ll get an in-depth look at the typical daily tasks of a laser cutting operator, from setting up the machining process to inspecting the production. You’ll also learn about the safety measures taken, the technology used, and the operator skills necessary for the job. By the end of this article, you’ll have a better understanding of what it takes to be successful in a laser cutting operation.

A Typical Day

Arriving at the job and preparation

When arriving at the job, a typical day as a laser cutting operator often begins with putting on several hats. Not only are they responsible for the daily setup and operation of a CNC laser cutting machine, but they are also often responsible for maintenance and troubleshooting as well. This means that they must possess a wide range of skills and knowledge in order to properly perform daily operations with minimal supervision.

Operating the machinery

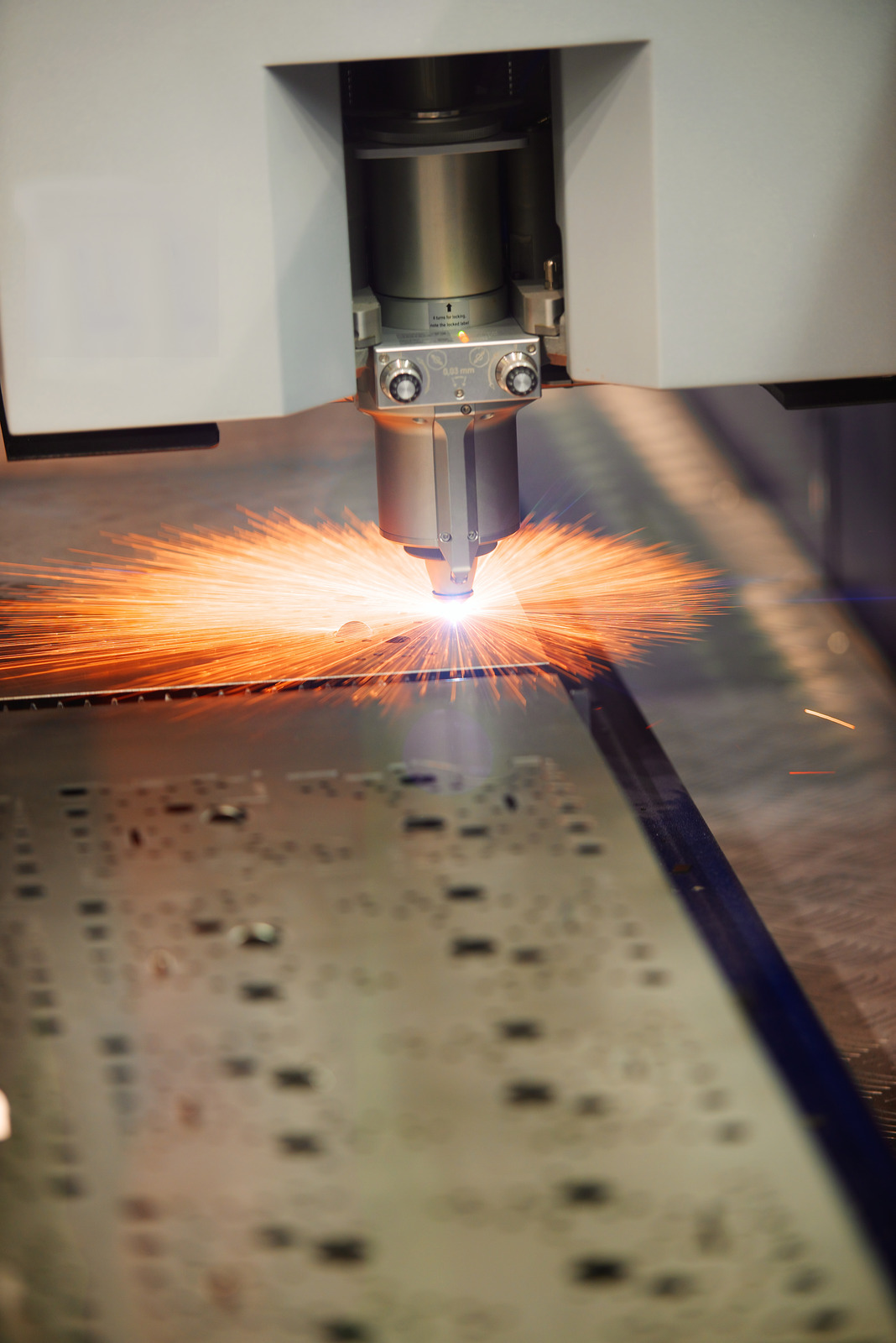

A typical day for a laser cutting operator would involve making sure the machine is powered and in good working order, loading designs into the software, and then operating the machinery itself. This includes operating the laser to cut through the material, such as metal and plastics, according to the design in the software.

- Prepare the materials for the job carefully, ensuring everything is cut to specification before the cutting process begins.

- Familiarize yourself with the machine settings, ensuring the settings are appropriate for the job.

- Inspect the machine before each cutting job, checking for any signs of damage or malfunction.

- Monitor the cutting process throughout to ensure the job is done correctly.

- Regularly clean the work area and check the laser beam to ensure it is working properly.

Maintenance and troubleshooting

As an experienced laser cutting operator, you’re accustomed to wearing several hats and taking on several responsibilities throughout the course of a single day. You’re responsible for the daily setup and operation of a CNC laser cutting machine, and for recognizing any potential problems before they arise. Maintenance and troubleshooting are two of the most important tasks in this role.

You must be able to properly perform daily operations with minimal supervision, and complete machine checks and maintenance in accordance with safety and quality standards. This includes repairing, replacing and calibrating equipment, as well as inspecting cutting beds and checking air flow.

Important Skills and Experience

Education and training

When it comes to being a successful laser cutting operator, education and training are key. As a laser operator, you wear several hats. You must be able to properly perform daily operations with minimal supervision, be responsible for the daily setup and operation of a CNC laser cutting machine and be aware of safety regulations and procedures.

Isaac Levverdick, a machine operator from Wisconsin, explains the importance of having proper laser operating education and training.

Technical knowledge

As a laser cutting operator, you must wear several hats during the course of your day. You are responsible for the daily setup and operation of a CNC laser cutting machine. It is essential that you possess a strong technical knowledge of the machine, its operations, and the materials it is used to cut.

Isaac Levverdick, a laser cutting operator, provides a high-level overview of his typical day: “My job begins with programming the CNC laser machine. This involves inputting the correct cutting parameters and making sure everything is working properly.

Working Conditions

Safety concerns

As a laser cutting operator, it’s essential that safety is a top priority. While the job is physically demanding, as Isaac Levverdick, a laser operator for over 40 years, has said, “it is also important to take safety precautions especially when working with machines that use high powered lasers”. The laser cutting operator is responsible for the daily setup and operation of a CNC laser cutting machine.

A typical day requires several hats to be worn, as the operator will have to ensure that the machine is properly set up and monitored while running.

Physical requirements

As a laser cutting operator, you are expected to wear several hats during your daily operations. You must be responsible for the daily setup and operation of a CNC laser cutting machine, with minimal supervision from a supervisor or manager. You are expected to ensure that the machine is properly setup and working correctly so that it can correctly produce the desired product.

In order to do this, you need to be familiar with the various settings and programing options on the CNC laser cutting machine. The operator must also be knowledgeable about safety procedures when working with these types of powerful machines, as well as being able to properly utilize the additional tools and materials used in the process.

What is a CNC laser operator?

If you’re looking for a unique, multifaceted job in the world of fabrication and industrial manufacturing, you should consider a career as a CNC laser operator. As the name implies, this person is responsible for the daily setup and operation of a CNC laser cutting machine. The laser operator must be able to properly perform daily operations with minimal supervision as they wear several hats to ensure their tasks are performed correctly and safely.

Conclusion

Summary of the job

In concluding our day in the life of a Laser Cutting Operator, let’s take a look back at the job of a laser operator. As a laser operator, your role is to be responsible for the daily setup and operation of a CNC laser cutting machine with minimal supervision. The job requires you to wear several hats; you are a machine operator, technician, and fabricator all in one.

Final thoughts on the advantages of being a laser cutting operator

In conclusion, being a laser cutting operator carries with it several advantages. As a laser operator, you are able to wear several hats and take full responsibility for the daily setup and operation of a CNC laser cutting machine. The work is often versatile and often requires creative problem solving on the fly.

On top of that, laser cutting technology is advancing quickly and staying proficient in the trade requires constant study, emphasizing the need for curious and enthusiastic workers.