Understanding the pros and cons of laser cutting zinc coated steel is essential for making an informed decision as to which material to use for your project. Zinc coated steel is increasingly being used for applications in the automotive and aerospace industries due to its excellent corrosion resistance and ability to form complex shapes. Therefore, it is important to explore the benefits and drawbacks of using laser cutting technologies to create zinc coated steel components. In this article, we will discuss the advantages and disadvantages of laser cutting zinc coated steel, offering insight into the best way to utilize this material for your project.

Main Body

Advantages of Laser Cutting Zinc Coated Steel

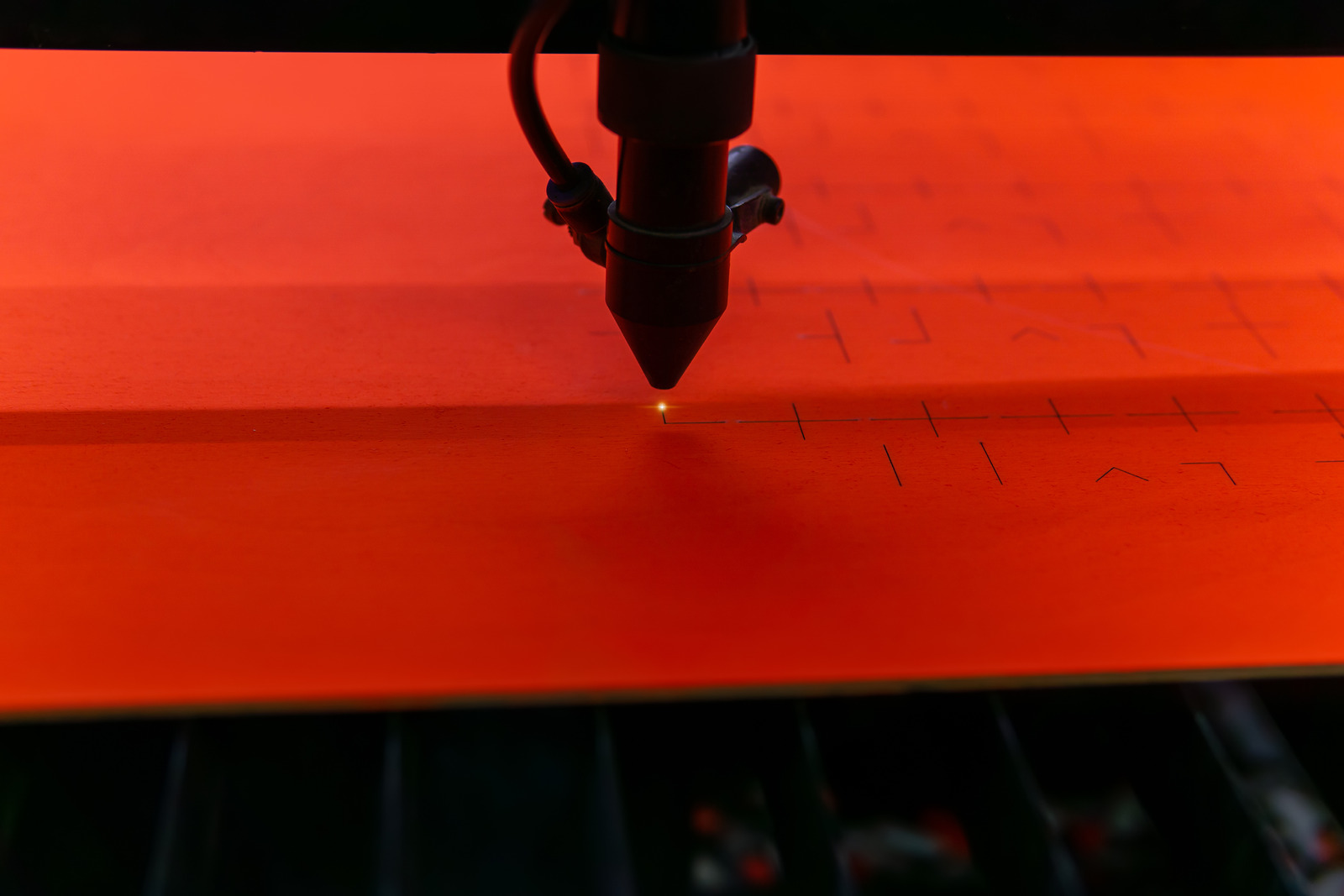

Laser cutting zinc coated steel has some distinct advantages that make it an attractive option for many projects. By using lasers to cut the steel, manufacturers can achieve greater accuracy, produce parts with fewer burrs and finish edges, and cut steel with greater consistency than other methods. The laser beam produces a very precise cut, making it ideal for fine detailing or complex shapes.

Improved Accuracy

Laser cutting zinc coated steel provides improved accuracy when compared to other cutting methods. Its accuracy is due to the fact that lasers are able to produce very precise cuts, eliminating the possibility of material waste. This is especially important for complex cuts that require intricate designs.

The thinness of the coating also does not affect the cutting process, allowing for better accuracy when cutting even thick layers of steel. In addition to the improved accuracy, laser cutting zinc coated steel also enables faster production and allows for smoother edge finishes. This means that production lines can produce more products faster, while still ensuring they are of the highest standard of quality.

Cost Effectiveness

When it comes to understanding the cost effectiveness of laser cutting with zinc coated steel, it depends on the specific application. Laser cutting of zinc coated steel is generally more expensive than cutting untreated steel or aluminum because of the extra step of chemical etching required to achieve an accurate and clean cut. But laser cutting may be the most cost effective method when used for certain parts with complex geometry, as the laser can cut intricate details that may be too costly to machine.

In terms of the preparedness of the zinc coating, laser cutting is not affected by the thickness of the zinc coating.

Less Heat Affected Cut Edge

When it comes to laser cutting zinc coated steel, one of the biggest advantages is the less heat affected cut edge. With cut edges that have less heat affected, the edges are smooth and have a significantly cleaner cut than when using other methods. Since these edges are smooth, there is no need to do any other kind of finish on these edges, saving time and money.

Additionally, since these edges are clean, they look much better than finished edges created with other methods, which makes them an ideal choice for projects where aesthetics are important.

Disadvantages of Laser Cutting Zinc Coated Steel

Quality of Surface Finish

When it comes to laser cutting zinc coated steel, there is an important consideration regarding the quality of the surface finish. Laser cutting can leave the surface of zinc coated steel looking pitted and dull, which can result in a decrease in the quality of the steel. While this aspect of laser cutting zinc coated steel does not directly affect the strength of the steel, it does affect the steel’s aesthetic appeal.

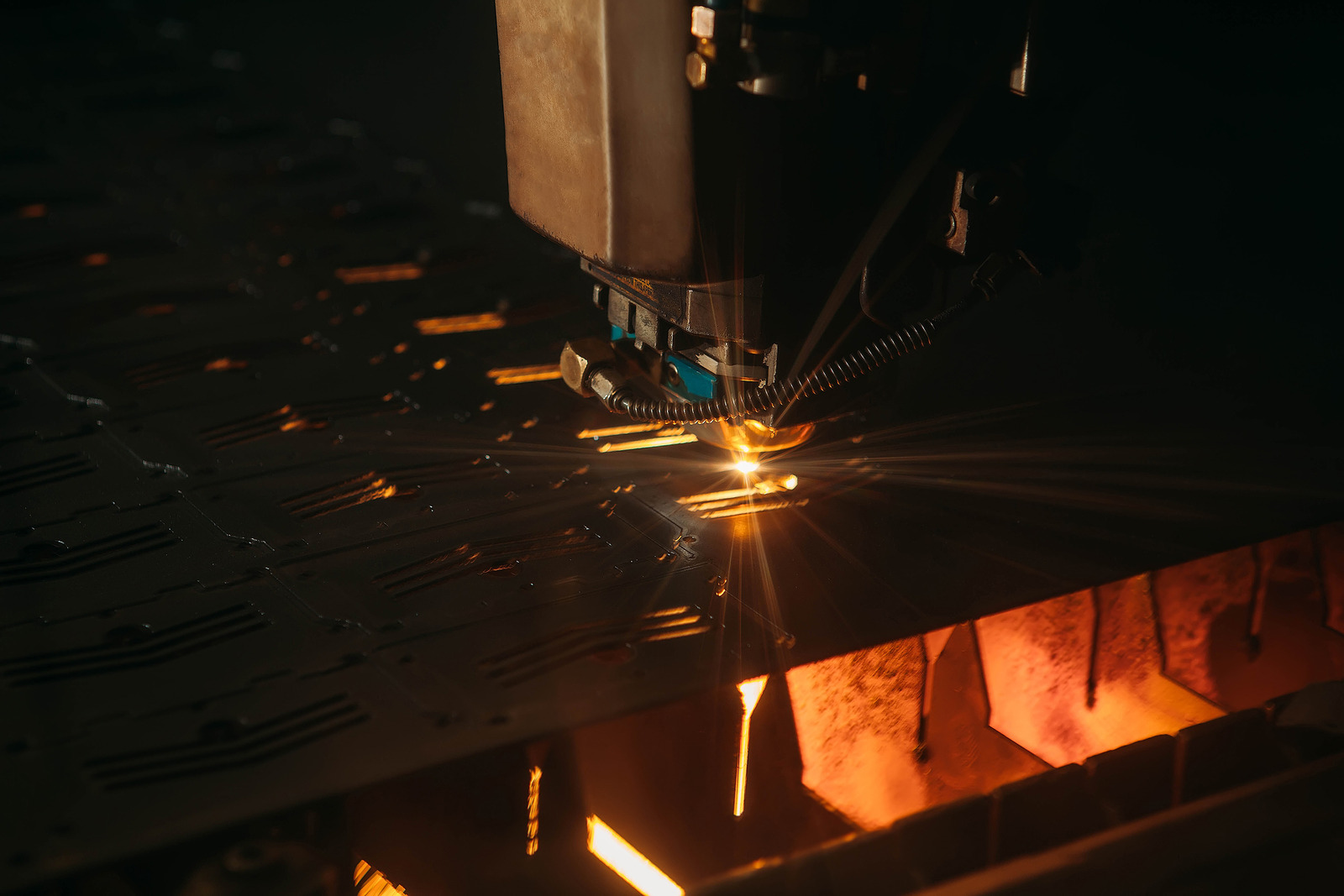

Another important consideration when it comes to the quality of the surface finish is the heat generated by laser cutting. High temperatures generated during the laser cutting can cause the zinc coating to discolor. As a result, the zinc coating can get burned and dull looking.

Toxic Fumes

When it comes to laser cutting zinc coated steel, it’s important to understand the potential dangers of this process. One of the major dangers comes from the toxic fumes that can be created during laser cutting. As the beam of a laser cuts through the metal, the high heat can vaporize the zinc coating, releasing fumes that are hazardous to human health.

High Potential for Thermal Stress

When discussing the disadvantages of laser cutting zinc coated steel, one of the main issues to consider is the high potential for thermal stress. When using laser cutting on any sheet metal, the process involves a high temperature heat beam that is used to pierce through the metal, creating the desired shape. However, because zinc coated steel is already under high amounts of thermal stress, the additional heat caused by the laser cutting process can cause the steel to become brittle and weak.

Can you cut galvanized steel with a laser?

When it comes to laser cutting zinc coated steel, it’s important to understand both the advantages and disadvantages of using this particular process. Laser cutting is often the preferred choice for quick and accurate cutting of a variety of metals, including zinc coated steel. But before you make your decision, it’s important to understand the pros and cons of doing so.

The biggest advantage of laser cutting zinc coated steel is that it requires minimal effort and produces extremely accurate cuts. Laser cutting machines can accurately measure and create very intricate cuts that would not be possible with other methods.

Can you laser cut zinc plated steel?

Yes, you can laser cut zinc coated steel. Laser cutting is an ideal method for cutting many materials, including zinc coated steel. The laser cutter uses a high-powered laser to cut through material, which means it can easily penetrate zinc coated steel.

This makes laser cutting one of the fastest and most precise cutting methods available. When laser cutting zinc coated steel, it is important to keep in mind the pros and cons of the process.

Conclusion

Summary of benefits and drawbacks of laser cutting zinc coated steel

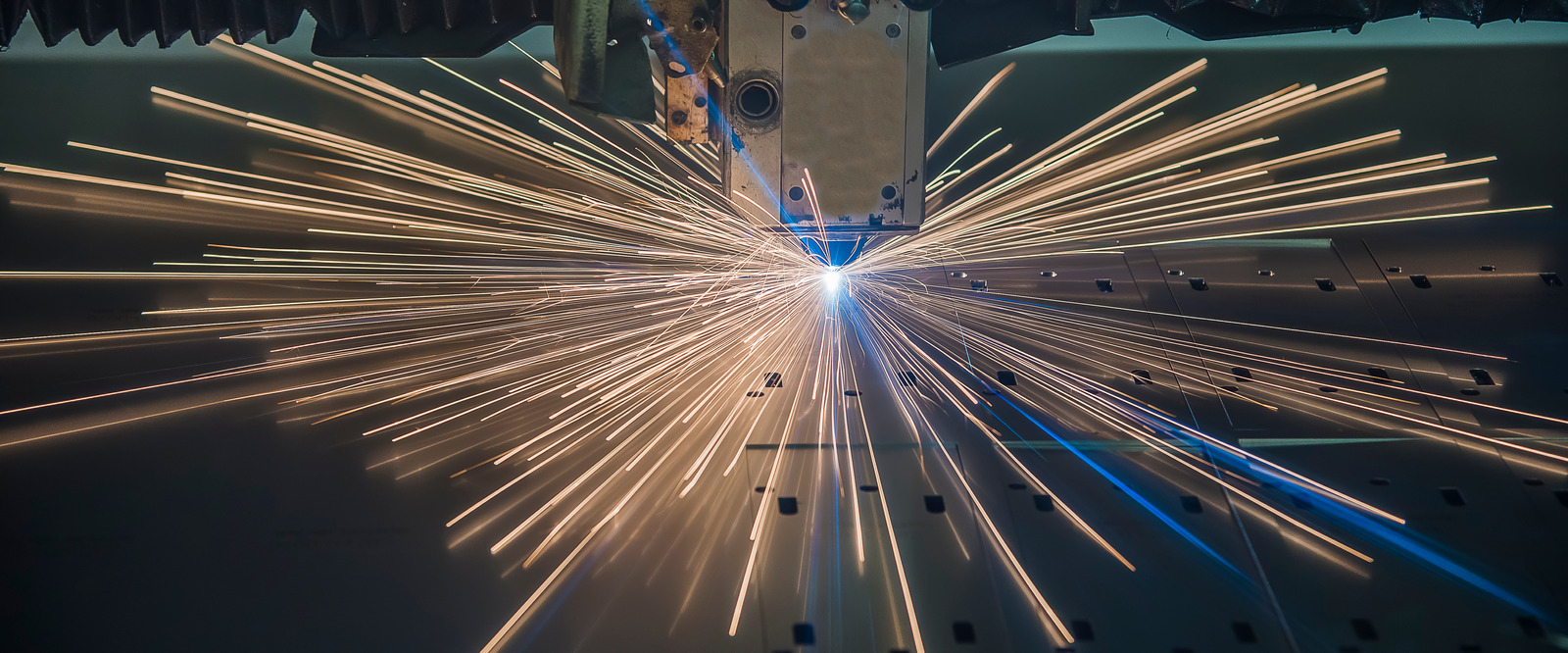

Laser cutting zinc coated steel can be a great tool in many fabrication processes. It provides a fast, efficient, and safe option for cutting this material. The process results in a high-quality, precise cut, and is capable of cutting both thick and thin sheets.

The main benefit to laser cutting this material is that it produces clean edges and has a small kerf width, meaning very little material is lost, resulting in lower costs and increased precision. Additionally, because the laser is not in contact with the material, it is less liable to be scratched, dented, or otherwise damaged, resulting in a high-quality finished product.

Recommendation for achieving best results when laser cutting zinc coated steel

When laser cutting zinc coated steel, there are certain recommendations that should be followed in order to achieve the best results. The first and most important thing to keep in mind is the choice of laser. You should use a higher power machine to cut zinc coated steel, as lower powered machines can make the cut more difficult.

Additionally, it is essential to use the correct settings for your laser type as well as to adjust the cutting speeds and beam diameters to accommodate the type of coating you are using. Using an oxygen assist gas during the cutting process can help to speed up the process and reduce the risk of scorching the material.

Questions and Answers about laser cutting zinc coated steel

Questions and Answers about laser cutting zinc coated steel Q: What are the advantages and disadvantages of laser cutting zinc coated steel? A: The advantages of laser cutting zinc coated steel include its ability to cut complex shapes and angles with precision, as well as its low risk of thermal damage and minimal burring. Additionally, laser cutting can work with a variety of metal thicknesses and coatings.

However, there are some disadvantages to consider. Laser cutting can cause an increase in zinc oxide dust, which requires extra ventilation during processing to reduce the risk of inhalation.