The use of laser cutting has become increasingly popular in the world of textiles, offering an array of unique opportunities to create unique and intricate designs that would not be possible through traditional methods of cutting. By exploring the possibilities of laser cutting for textiles, one can gain an understanding of the varied techniques and techniques that can be used to create beautiful, intricate designs with a variety of fabrics. In this article, we will explore the possibilities of laser cutting for textiles, and the advantages, limitations and techniques that accompany this emerging technology.

Types of Laser Cutting

Carbon dioxide lasers

Laser cutting is one of the more interesting and versatile tools that can be used for a number of applications, such as fabric cutting. It has been shown to be intimately helpful in more precise and accurate works in all sorts of industries, and is becoming a much more commonplace tool. When it comes to laser cutting for textiles, there are several different types, but the most popular is the carbon dioxide laser.

Carbon dioxide lasers use a gas medium that is usually a mixture of carbon dioxide, nitrogen, and other gases.

Fibre lasers

Fibre lasers have opened up new possibilities for laser cutting of textiles. Unlike traditional CO2 lasers, fibre lasers use an infra-red beam and are often much more accurate and powerful. The downside is that there is less choice of wattages available and the laser head has to be positioned closer to the cutting material for it to be effective.

Fibre lasers are not limited to just fabric cutting, it can also be used for other materials such as wood, plastic, and even metal.

Excimer lasers

When it comes to laser cutting for textiles, excimer lasers are one of the most powerful options available. Also known as exciplex lasers, these machines use wavelengths of light that fall within the UV region of the spectrum, which makes them particularly effective at cutting textiles. The most common type of excimer lasers used in laser cutting are excimer laser systems, which include a laser beam generator and a pulse controller.

These systems enable the laser cutter to produce extremely precise cuts, allowing it to create intricate designs with ease. Additionally, because excimer lasers are typically more powerful than other types of lasers, they are able to make cuts at high speeds, which makes them particularly useful in mass production applications.

Techniques for Laser Cutting Textiles

Cut and fuse

The use of laser cutting for textiles is a relatively new process. It is an innovative way to create intricate patterns and shapes in fabric that traditional methods of cutting cannot achieve. The “cut and fuse” technique is one of the most popular methods for laser cutting textiles.

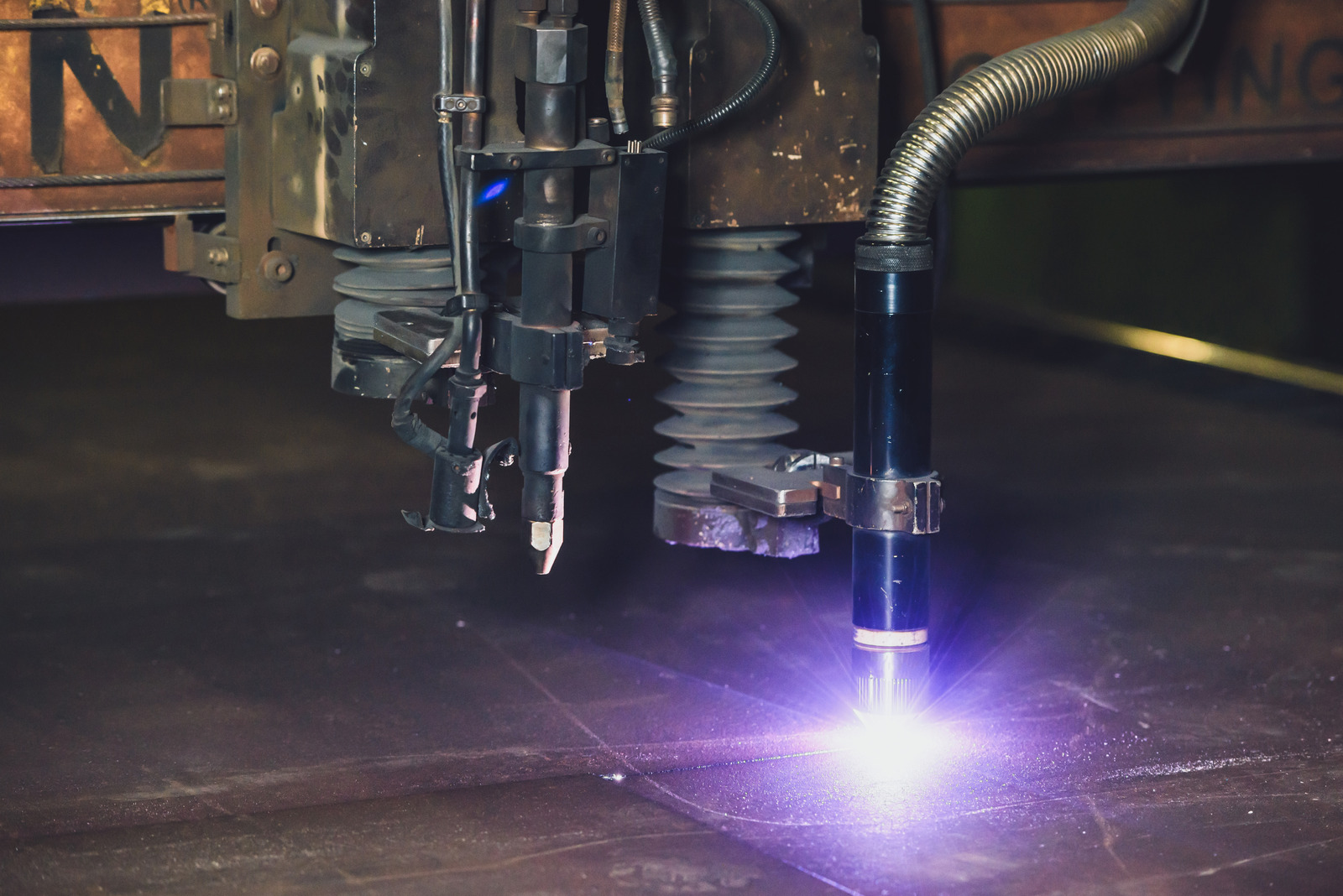

This method uses a laser cutter to cut through fabric and then use a medium such as heat or ultrasonic waves to fuse the cut fabrics together. The process begins with the use of a laser cutter. It is important when selecting a laser cutter to make sure you choose one that is capable of creating accurate and precise cuts.

Applique

Applique is a great technique for making laser cut textiles. It is a decorative technique in which a piece of fabric, often with a design or pattern, is attached to a larger piece of fabric by stitching or bonding with adhesives. With a laser cutting machine, this process can be taken to the next level.

You can easily cut intricate shapes in fabric and get a precise, clean edge that you can’t achieve with traditional scissors and cutting tools. Using laser cutting for applique will create beautiful, intricate shapes and designs for garments or home decor.

Engrave

Engraving with a laser cutter is one of the most versatile techniques available when it comes to laser cutting textiles. Engraving involves etching a design or pattern onto the fabric, and it’s an incredibly effective way to add unique details, patterns, or shapes onto your fabric. It’s much more intricate than a regular cutting job, as it requires the laser cutter to focus its beam in a very precise way in order to create the desired design.

Depending on your fabric, the design will be engraved differently.

Benefits of Laser Cutting for Textiles

Design flexibility

Design flexibility is probably one of the main advantages of using laser cutting for textiles. Not only is this technology precise and accurate, it also allows considerable design flexibility. With a laser cutter, designs can be customised and adjusted until they perfectly fit the fabric of choice.

And the amazing thing about laser cutters is that once the design process is done, you can quickly and easily transfer the design onto the fabric for cutting.

Variety of textures

for textiles When it comes to laser cutting for textiles, the possibilities are virtually limitless. Laser cutting offers a variety of advantages when it comes to working with textiles, but one of the most noteworthy is the versatility of textures it offers. Laser cutting allows for detailed patterns and cuts in a variety of materials – from delicate silks to heavy-duty fabrics, and anything in between – giving designers the ability to create intricate designs and in turn, offer their customers a variety of textures.

Cost effective

For those in the textile industry, laser cutting is an incredibly cost-effective solution for producing intricate patterns and shapes from fabrics. Laser cutters have made it easier and more affordable than ever before to produce intricate designs for textiles. With laser cutting, the pattern is quickly and precisely cut out with lasers using a computer-controlled system.

Unlike hand-cutting, which is labor-intensive and can often be wasteful due to the use of straight edges and X-Acto knives, laser cutting offers precise and repeatable results.

Challenges of Laser Cutting for Textiles

Risk of melting or burning

When it comes to laser cutting for textiles, one of the main potential risks is that of melting or burning the material. This happens when the laser is used at too high a power setting, or when its beam focuses on one spot for too long. The laser can produce extremely high temperatures within a very small area, and if the textile material is not strong enough to withstand the heat, it can quickly melt or burn.

Difficult to cut certain fabrics

When it comes to laser cutting for textiles, one of the most common challenges is cutting certain fabrics. Fabrics such as leather and synthetic materials can be more difficult to cut, due to their reflective surfaces, which interfere with the laser’s precision. Additionally, the melting temperature of some fabrics can be difficult to regulate, which can cause excessive burning or melting of the cloth.

While some fabrics and textiles can be cut using a laser cutter, others may need to go through a pre-treatment process in order to be cut effectively. For example, some materials require a layer of adhesive or a coating applied before laser cutting in order to better absorb the energy of the laser and prevent scorching.

Need for specialized knowledge

When it comes to laser cutting for textiles, having specialized knowledge is essential for achieving the best results. Laser cutters, which use a focused beam of light to precisely cut or shape a desired material, have become increasingly popular in the textiles industry. The beauty of laser cutters lies in their ability to precisely cut materials that would otherwise be damaged or unable to be cut by other more traditional methods.

However, to get the best results with a laser cutter, it’s important to have the right expertise in setting up the machine and the material being cut.

What fabrics can you laser cut?

for textiles When it comes to laser cutting for textiles, there are numerous possibilities. With the right laser cutter and a range of fabrics, all sorts of designs and pieces can be created. But, what exactly can you laser cut?

Generally speaking, most fabrics are compatible with laser cutting. Most natural fabrics containing cellulose, such as cotton and linen, and synthetic fabrics such as polyester, can be lasered without trouble.

Conclusion

Summary of advantages of laser cutting for textiles

The use of laser cutting for textiles has a variety of advantages that make it a great choice for many projects. To begin, laser cutters are incredibly precise and accurate, meaning that fabric can be cut with perfect consistency and accuracy. Laser cutting also eliminates the need for blades and fabric scissors, reducing the risk of painful cuts for sewers.

Additionally, laser cutters create smooth, clean edges in fabrics, reducing the need for hand-finishing. Sewers can even create intricate, detailed patterns with laser cutters.

Final thoughts on exploring the possibilities of laser cutting for textiles

As we reach the conclusion of our exploration of the possibilities of laser cutting for textiles, it’s worth taking a look back at what we’ve learned. With the help of laser cutting technology, textile manufacturing has become easier, more efficient, and more precise. Thanks to the precision of laser cutters, it’s now possible to cut out intricate designs and shapes with great accuracy, enabling the production of beautiful textiles.